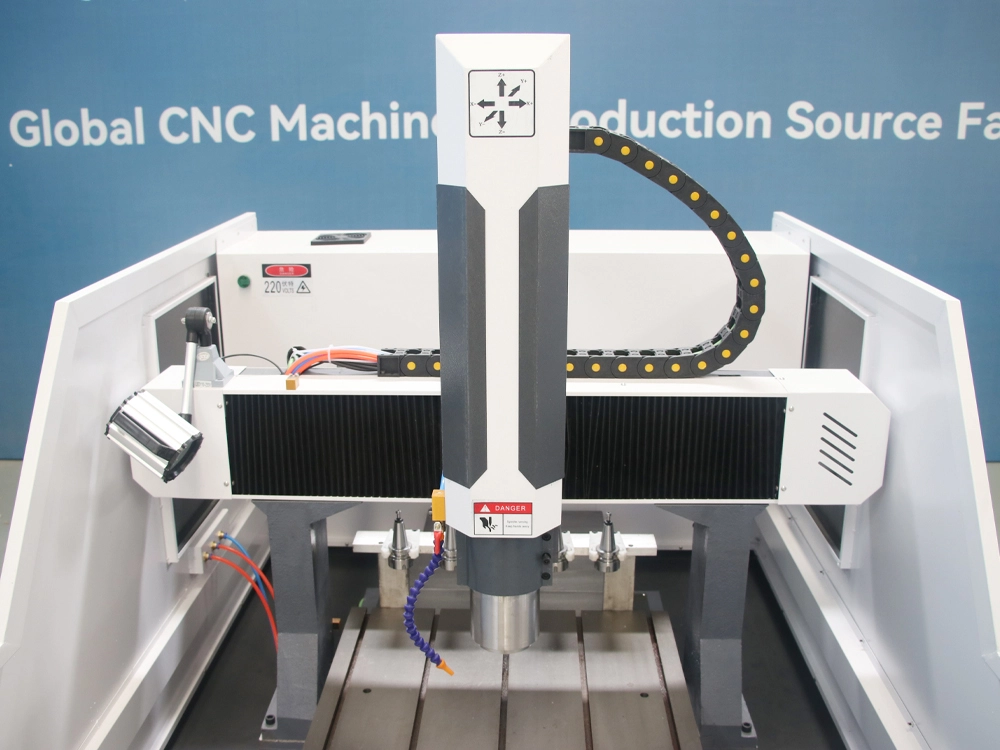

Semi-Enclosed CNC Metal Milling Machine With Linear Tool Changer

Affordable Semi-Enclosed Linear ATC CNC Metal Milling Machine

[Function Description]

The CNC metal milling machine is controlled by a CNC system and has an integrated automatic tool changing system. It is a high-precision CNC metal processing machine. The linear tool magazine can accommodate five tools of different sizes and functions at a time. The tools can be automatically replaced according to the shape of the product and different processes during processing. The tool replacement can be completed within a few seconds without manual intervention. After the tool replacement is completed, the automatic tool setting instrument is used to automatically calibrate the tool. This allows a complex workpiece to be clamped only once on the workbench to complete all processing steps, reducing the time wasted due to manual tool change or changing to different machines. In addition, since the workpiece has been clamped less frequently, the accumulated precision errors caused by multiple clamping of the workpiece are also reduced, which can significantly improve the processing accuracy and achieve efficient and precise processing of high-precision metal molds. It is very suitable for metal mold engraving, milling, drilling, grooving and other process processing.

Automatic tool-changing CNC metal milling machines have become indispensable CNC automation machines in the modern mold manufacturing industry through their four core advantages: improved processing efficiency, guaranteed processing accuracy, support for complex workpieces, and optimized processing costs. Through the cooperation of the CNC system and the automatic tool-changing function, it can effectively reduce more than 40% of the labor input cost. And because the workpiece can be clamped once, it avoids the deviation caused by traditional multiple clamping and reduces processing waste. It is very suitable for various high-precision work scenarios, such as automobile manufacturing, aerospace, watch manufacturing and other industries. Whether it is small-batch production or large-scale production, it can easily handle it and provide support for various high-end manufacturing industries.

How Does the Automatic Tool Changing of the CNC Metal Milling Machine Work

Before processing, when programming, the tool parameters should be set in advance. When programming, the software setting program automatically calls the order of required tools (such as roughing milling cutter → finishing tool → drilling tool), realizing continuous processing from roughing, finishing, drilling and other processes at one time, shortening the production cycle.

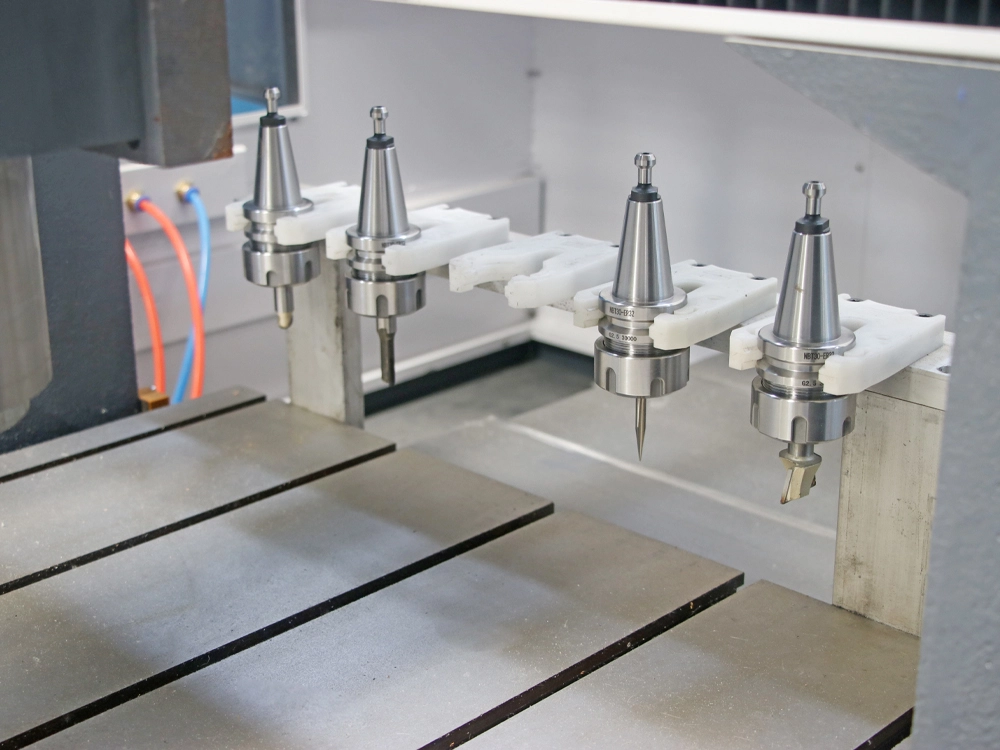

When changing tools, the control system drives the XYZ axes of the machine to coordinate and operate, and the tools are arranged in order on the tool magazine. When the control system executes the code to the tool change command, the tool change action is automatically triggered. At this time, the spindle will automatically move to the tool clamp position of the linear tool magazine, the Y axis slowly retreats, the tool clamp automatically clamps the tool handle, and then the spindle tool release mechanism releases the old tool, the Z axis rises to a safe height, moves to the top of the tool to be used, the Z axis descends, the spindle locking mechanism clamps the tool handle, the Y axis moves forward, and the tool is removed from the tool magazine. The tool change is completed. After the tool change is completed, due to the different lengths of the tools, the machine will automatically move to the position of the automatic tool setting instrument for automatic Z-axis height calibration. No manual calibration is required, saving time and improving efficiency.

Advantages of a Metal Milling Machine With Automatic Tool Changing Kit

- The machine body is made of heavy reinforced cast iron, which can bear more than 300kg. The whole bed is made of high-strength cast iron and undergoes secondary annealing to ensure the rigidity and stability of the structure.

- Taiwan Hiwin 25mm linear guide/linear bearing, 2510TBI ball-ground grade screw, with an accuracy of up to 0.018mm, ensuring the machine processing accuracy.

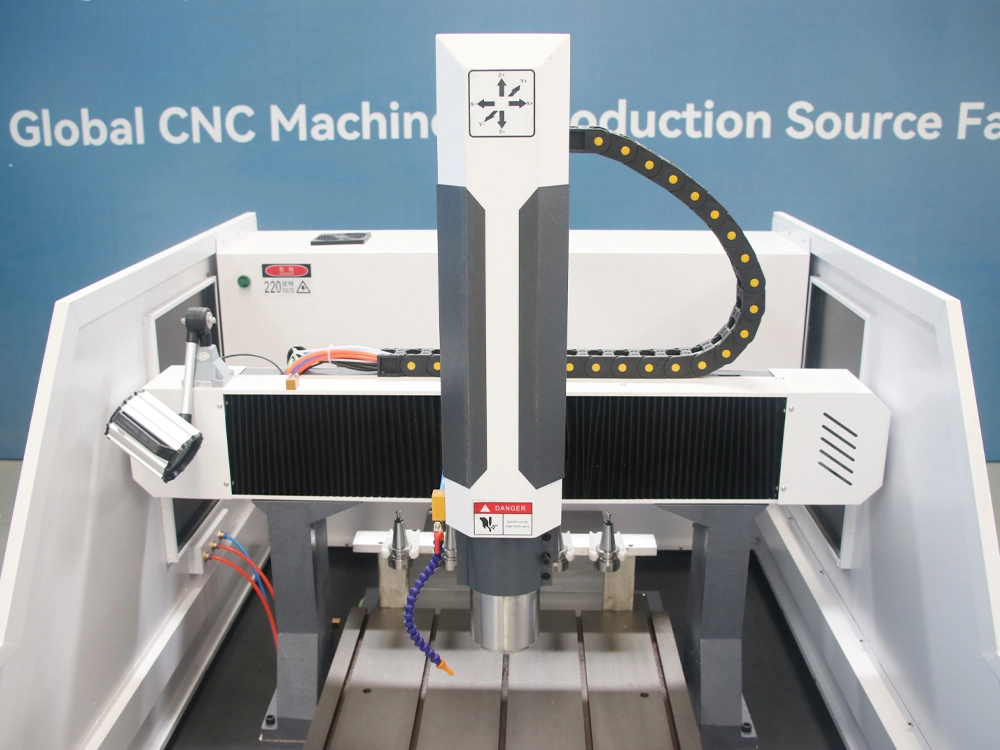

- High torque 3.5KW high-speed water-cooled automatic tool-changing spindle, BT30 tool holder, ER25 tool holder, can clamp tools with 16mm inner tool holder.

- Leadshine 750w servo motor/servo driver has millisecond response speed and rapid acceleration and deceleration capabilities, low operating noise, simple structure, suitable for various high temperature, high pressure, high humidity environments, and requires no maintenance.

- Weihong NK280 CNC system supports English interface, supports multiple tool length settings and error compensation, is compatible with various CAD/CAM software, is simple to operate, and is very easy to use.

- The circulating water cooling system is equipped with a pressure regulating valve, which can be adjusted to an oil mist cooling system. During processing, it is opened and closed by the control system, which can effectively reduce tool wear, improve tool life and processing quality.

- Equipped with an automatic tool setting instrument, it can automatically calibrate tools at different heights after processing is completed, eliminating the need for manual calibration and improving efficiency.

- The electric timed lubrication and maintenance system automatically and regularly lubricates and maintains the transmission parts of the machine according to actual usage, eliminating the need for manual maintenance and saving time.

- The semi-enclosed protective cover wraps the machine processing area to prevent coolant or waste chips from flying out during processing, avoiding injury and pollution.

- The linear tool change magazine can install five different tools at a time and automatically change them according to processing requirements, saving tool change time and improving workpiece processing efficiency.

- The base adopts a double-layer filtration system, which can effectively filter the waste generated during processing, prevent water pipe blockage and increase service life.

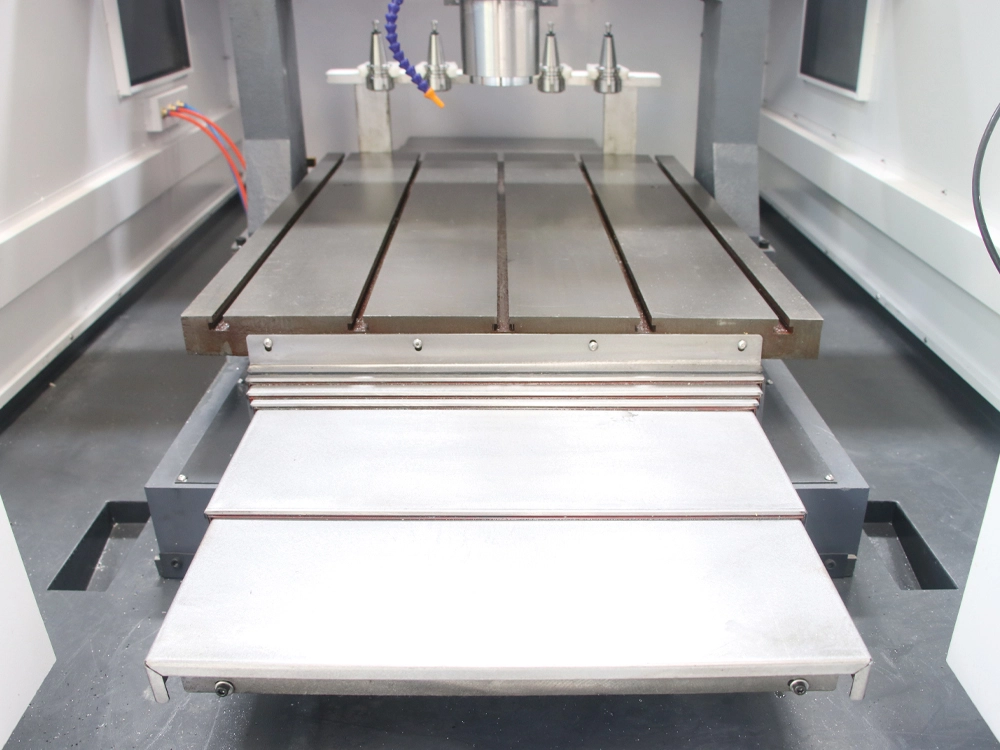

- The Y-axis uses a metal protective cover to prevent dust, and the X-axis is equipped with a telescopic accordion protective cover to ensure the operating accuracy of the machine.

Features of Metal Milling Machine With Automatic Tool Changing Kit

- Improve processing efficiency. Traditional processing requires manual tool change, and each tool change takes several minutes. Using automatic tool changer, tool change can be completed in a few seconds.

- Continuous processing of multiple processes. Through the tool library pre-setting in the tool library, the system automatically calls the tool during processing to achieve one-time continuous processing of multiple processes and shorten the production cycle.

- More suitable for mass production. In the mass production of mold parts, automatic tool change can also significantly improve production capacity and reduce costs.

- Eliminate errors. Manual tool change and repeated clamping of workpieces will cause the error accumulation of workpieces. Using automatic tool changer can complete all processing procedures in one clamping of the workpiece.

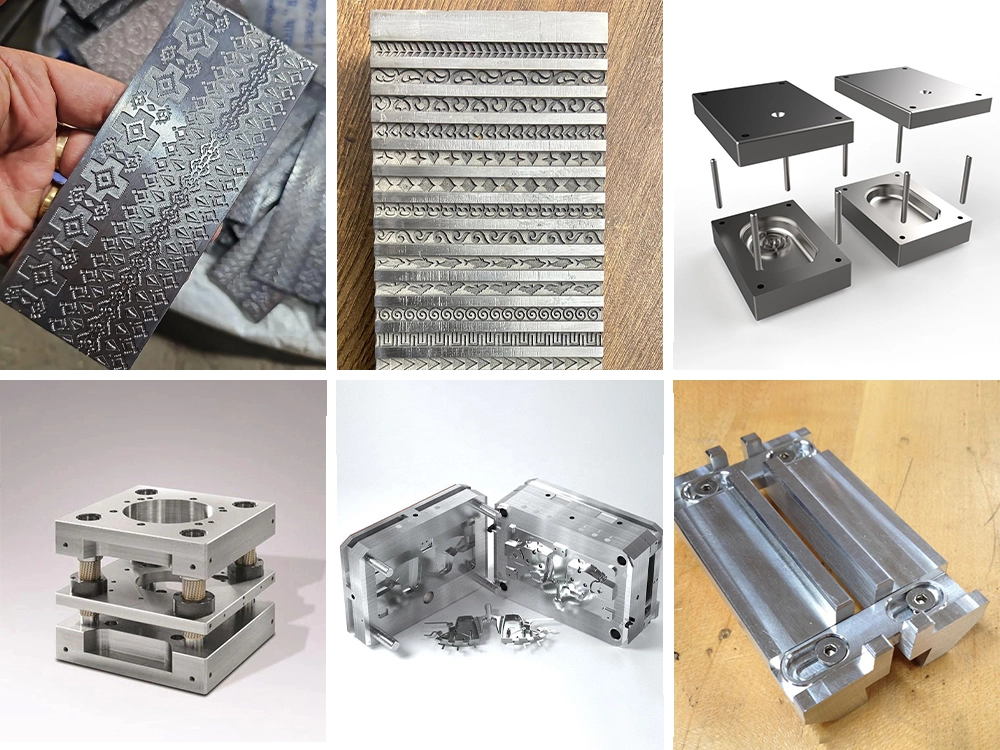

- Adapt to a wide range of materials, can process copper, aluminum, steel, iron and other metal materials, meet the production of various injection molds, die-casting molds, stamping molds and other molds.

- Reduce manual dependence. A single machine can run unattended for a long time, reducing labor costs and human errors.

- Optional fourth or fifth rotation axis to increase the scope of machine use.

Photos of Metal CNC Milling Machine With Automatic Tool Changing Kit

- Semi-enclosed sliding protection door

Prevents cutting fluid and waste slag from flying out during processing, causing harm and polluting the environment.

- High-strength cast T-slot workbench

After multiple treatments, it is strong and durable, can bear more than 400kg, and has good stability.

- Weihong nk80 control system

English interface display, compatible with various cad/cam type software, runs using international universal G code, with intuitive interface and simple operation.

- 3.2KW automatic tool-changing spindle

Water-cooled automatic tool-changing spindle, speed 24000r/min, BT30 tool holder, ER25 tool holder, speed can be adjusted arbitrarily, water circulation cooling, high cooling efficiency, can work continuously for 24 hours.

- Linear tool change magazine

5 tools can be installed at a time, and the tools can be automatically changed according to processing requirements to improve production efficiency. The tool capacity is optional.

- Automatic tool setting instrument

After the tool change is completed, the automatic tool setting instrument is automatically used to calibrate the tool height without manual calibration.

- Automatic lubrication oil pot

Automatically lubricate the entire machine at regular intervals to prevent untimely manual lubrication.

- Protective cover

The x-axis uses a telescopic protective cover, and the z-axis uses a fully enclosed sheet metal shell to prevent waste chips from entering the transmission device during processing and extend the service life of the machine.

- Electrical components

Anti-interference electrical cabinet, built-in Schneider electrical components, Leadshine servo drive, inverter to ensure the normal operation of the machine.

- Industrial Molds: injection molds, shoe molds, drop molds, stamping molds, die-casting molds, food molds, etc.

- Precision Parts: watch parts, auto parts, hardware parts, metal electrodes, eyeglass frames, PCB circuit boards, speaker housings, mobile phone housings, mobile phone middle frames, etc.

- Musical Instrument Manufacturing: piano panels, guitars, violins, cello panels, etc.

- Decorations: personalized seals, jewelry, jade, medals, badges, EDC toys, pen housings, etc.

- Other Products: three-dimensional art sculptures, carbon fiber brackets, turbine blade molds, aluminum alloy structural parts, etc.

Technical Parameters of Metal CNC Milling Machine With Automatic Tool Change Kit

| Model | CK-690D | CK-690 |

|---|---|---|

| Positioning Accuracy | 0.01mm | 0.01mm |

| Repeat Positioning Accuracy | 0.008mm | 0.008mm |

| X, Y Verticality | 0.015mm | 0.015mm |

| Effective Moving Distance | 600x900x250mm | 600x900x250mm |

| Workbench Size | 600x900mm | 600x900mm |

| Working Height | 250mm | 250mm |

| Movement Speed | ≤10000mm/min | ≤10000mm/min |

| Spindle Power | 3.2KW automatic tool change spindle | 3.5KW high speed water-cooled spindle |

| Frequency Converter | Fu Ling inverter | Fu Ling inverter |

| Spindle Speed | 0-24000rpm(Infinitely variable speed) | 0-24000rpm(Infinitely variable speed) |

| Knife Handle Specifications | BT30-ER25 | ER25/ER20 |

| Tool Magazine | Linear tool magazine | / |

| Tool Holder Capacity | 4/5/6 | / |

| Air Pressure | ≥0.8MPa | / |

| Drive System | 750W Leadshine servo motor | 750W Leadshine servo motor |

| Control System | Weihong NK280 | Weihong NK280 |

| Guideway | Taiwan Hiwin Guide Rail/Linear Bearing | Taiwan Hiwin Guide Rail/Linear Bearing |

| Ball Screw | Taiwan TBI grinding ball screw | Taiwan TBI grinding ball screw |

| Supply Voltage | AC380V | AC380V |

| Electrical Devices | Omron/Schneider | Omron/Schneider |

| Body Material | HT250 aging treatment | HT250 aging treatment |

| Dimensions | 1500x1800x1750mm | 1500x1700x1700mm |

| Weight | 1450kg | 1400kg |

What Products Can the Metal CNC Milling Machine With Automatic Tool Change Kit Be Used to Process

Applicable Materials:

copper, aluminum, steel, iron, stainless steel, aluminum alloy, light alloy, wood, plywood, mdf, pvc board, acrylic, engineering plastics, epoxy resin, ABS, PP, PE, jade, crystal, graphite, bakelite, carbon fiber, stone, foam and other metal and non-metal materials.

Application Industries:

| Model | CK-690D | CK-690 |

|---|---|---|

| Positioning Accuracy | 0.01mm | 0.01mm |

| Repeat Positioning Accuracy | 0.008mm | 0.008mm |

| X, Y Verticality | 0.015mm | 0.015mm |

| Effective Moving Distance | 600x900x250mm | 600x900x250mm |

| Workbench Size | 600x900mm | 600x900mm |

| Working Height | 250mm | 250mm |

| Movement Speed | ≤10000mm/min | ≤10000mm/min |

| Spindle Power | 3.2KW automatic tool change spindle | 3.5KW high speed water-cooled spindle |

| Frequency Converter | Fu Ling inverter | Fu Ling inverter |

| Spindle Speed | 0-24000rpm(Infinitely variable speed) | 0-24000rpm(Infinitely variable speed) |

| Knife Handle Specifications | BT30-ER25 | ER25/ER20 |

| Tool Magazine | Linear tool magazine | / |

| Tool Holder Capacity | 4/5/6 | / |

| Air Pressure | ≥0.8MPa | / |

| Drive System | 750W Leadshine servo motor | 750W Leadshine servo motor |

| Control System | Weihong NK280 | Weihong NK280 |

| Guideway | Taiwan Hiwin Guide Rail/Linear Bearing | Taiwan Hiwin Guide Rail/Linear Bearing |

| Ball Screw | Taiwan TBI grinding ball screw | Taiwan TBI grinding ball screw |

| Supply Voltage | AC380V | AC380V |

| Electrical Devices | Omron/Schneider | Omron/Schneider |

| Body Material | HT250 aging treatment | HT250 aging treatment |

| Dimensions | 1500x1800x1750mm | 1500x1700x1700mm |

| Weight | 1450kg | 1400kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.