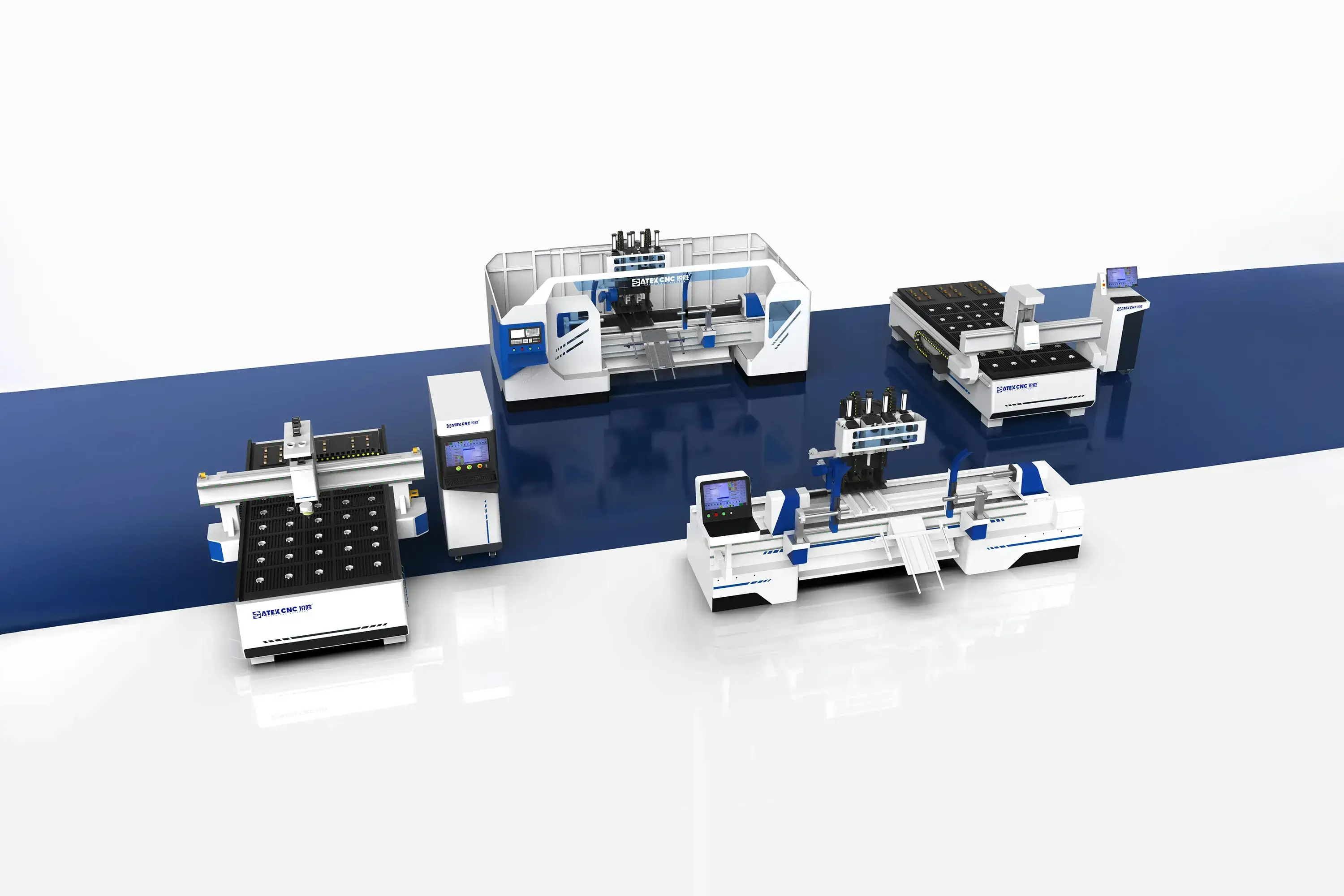

FIND THE CNC MACHINE THAT SUITS YOU BEST HERE

GET A FREE QUOTEOUR PRODUCT CATEGORIES FOR YOU TO CHOOSE

Find the CNC machine that's right for you here, whether you're a novice or an expert, we've got you covered.

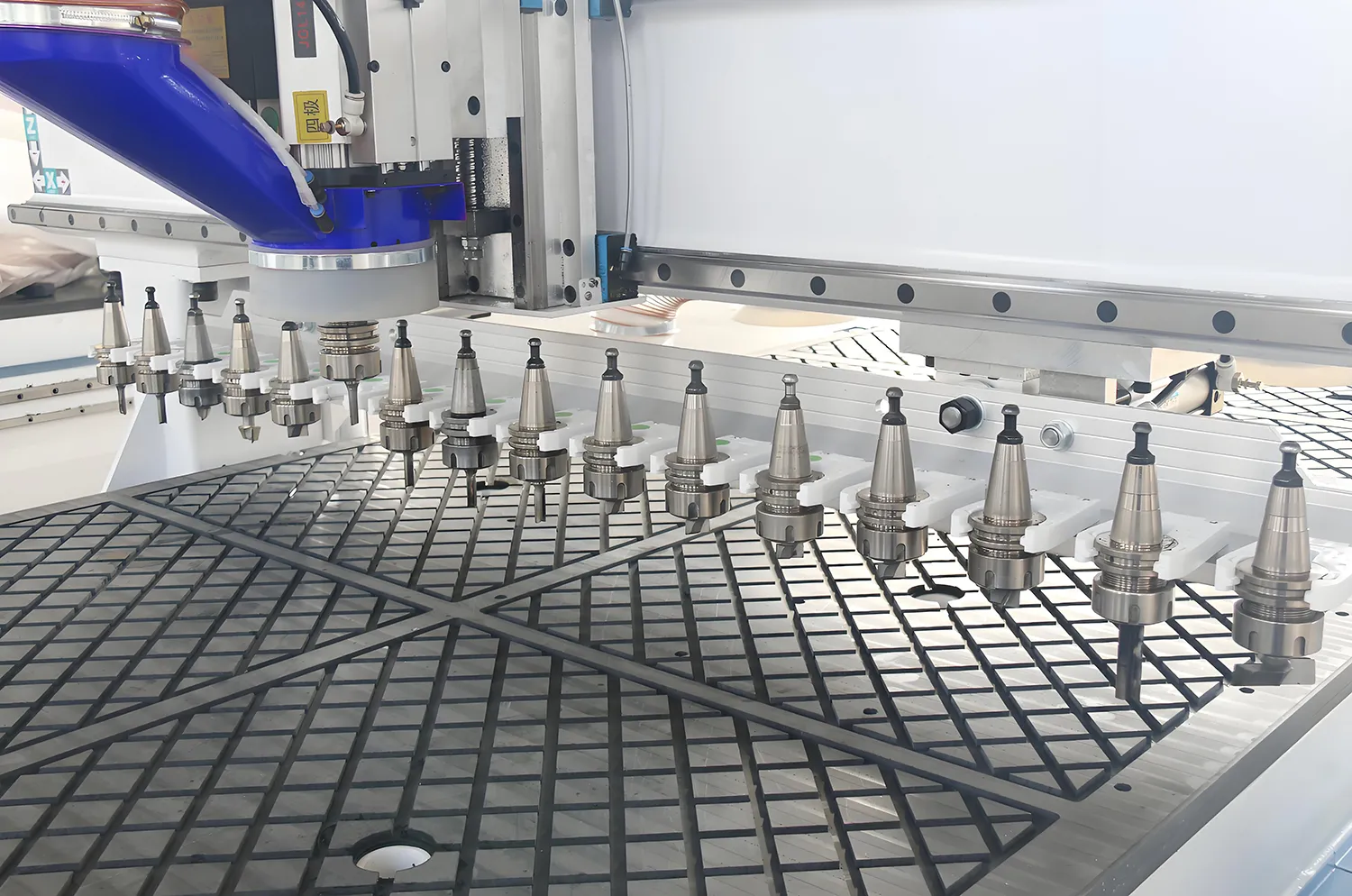

CNC Router

CNC routers use a variety of engraving tools to perform flat engraving, 2.5D and 3D engraving on wood, plastic, stone, and metal.

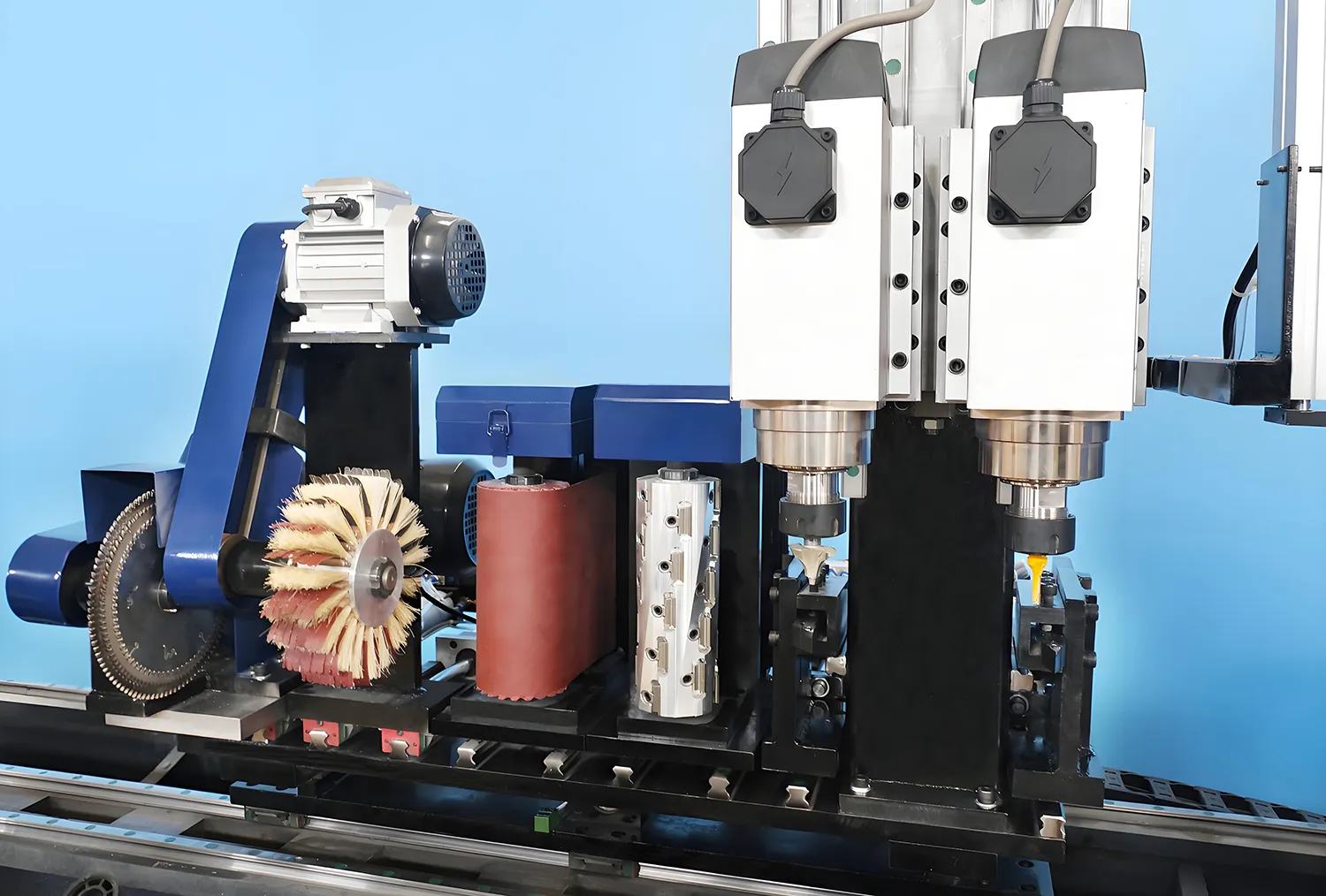

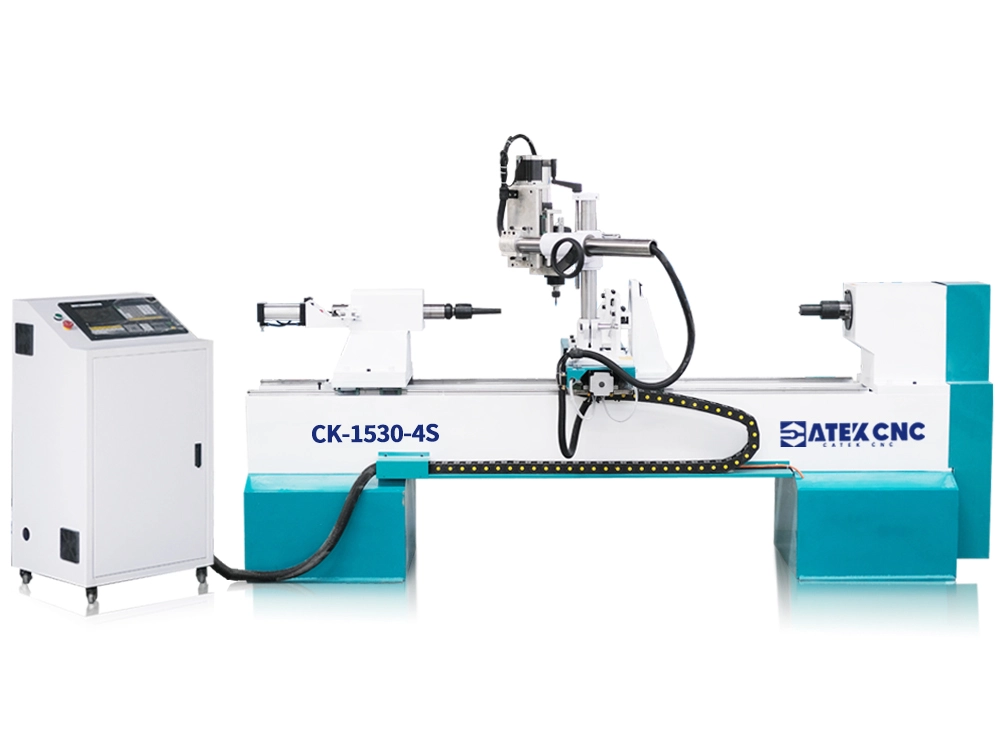

CNC Wood Lathe

CNC wood lathe is an automated lathe that uses cutting tools to turn, sand, plan, drill, and groove wood strips.

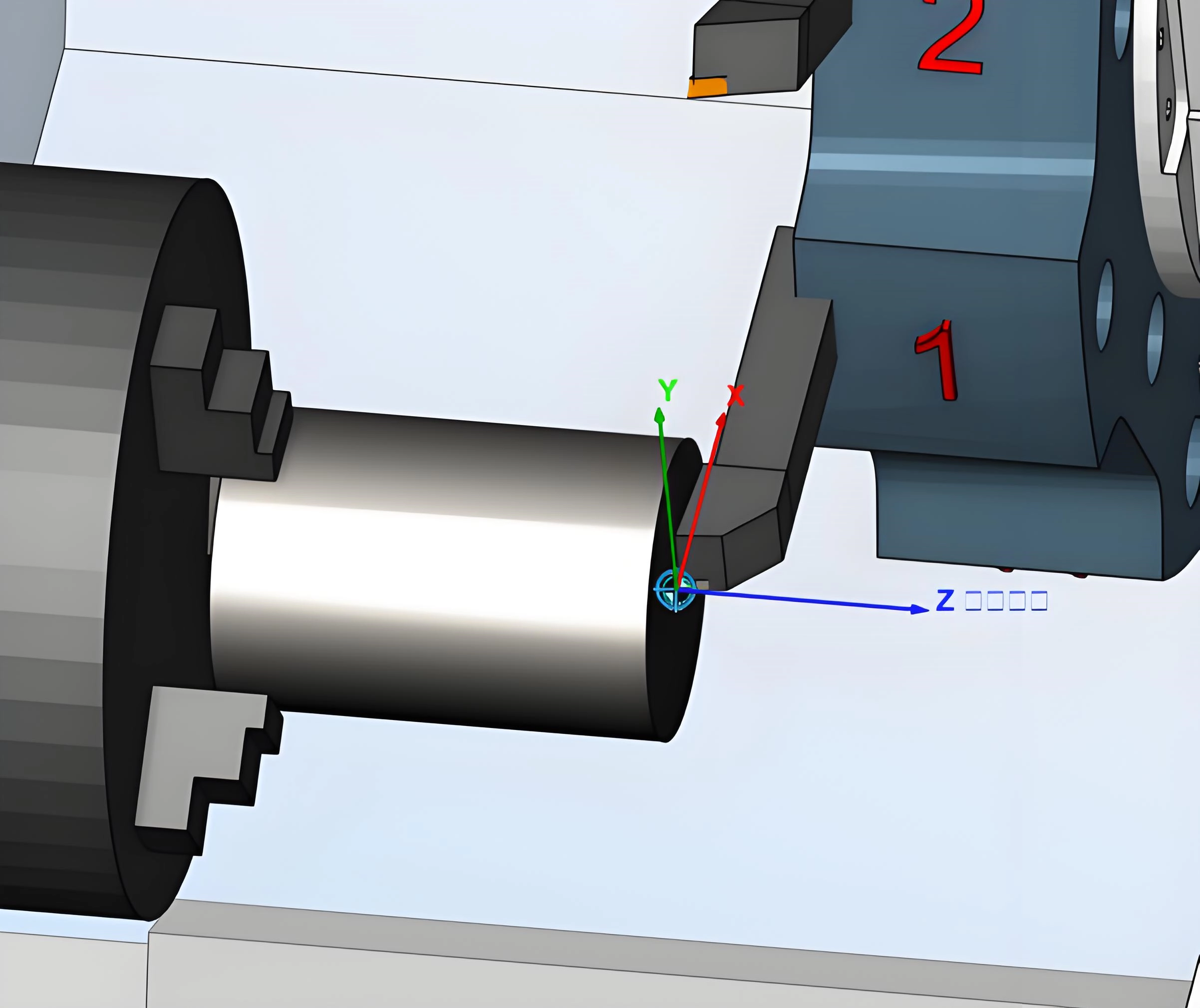

CNC Metal Machine

CNC metal milling machine is a high-precision CNC machine used for machining metal molds and metal parts.

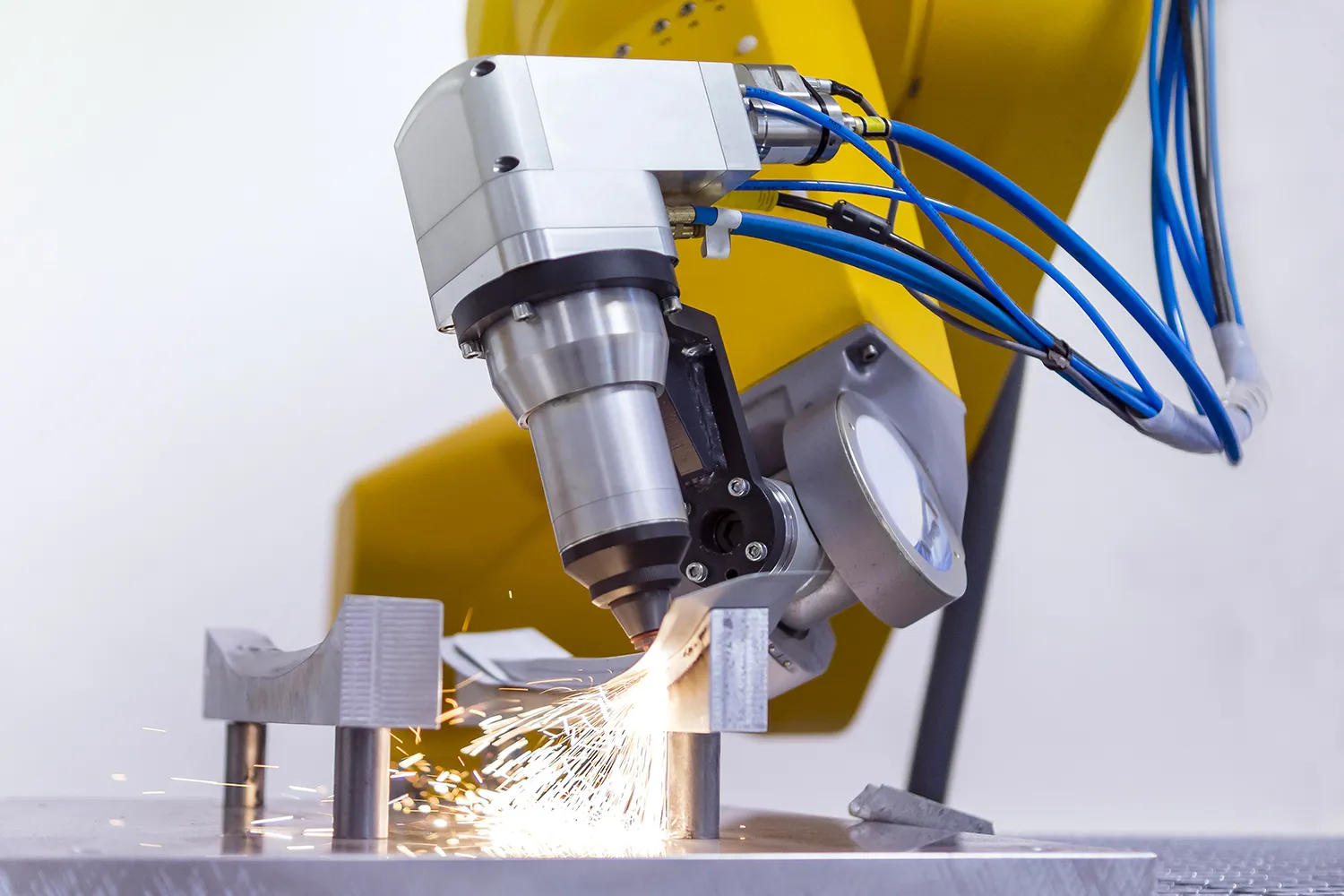

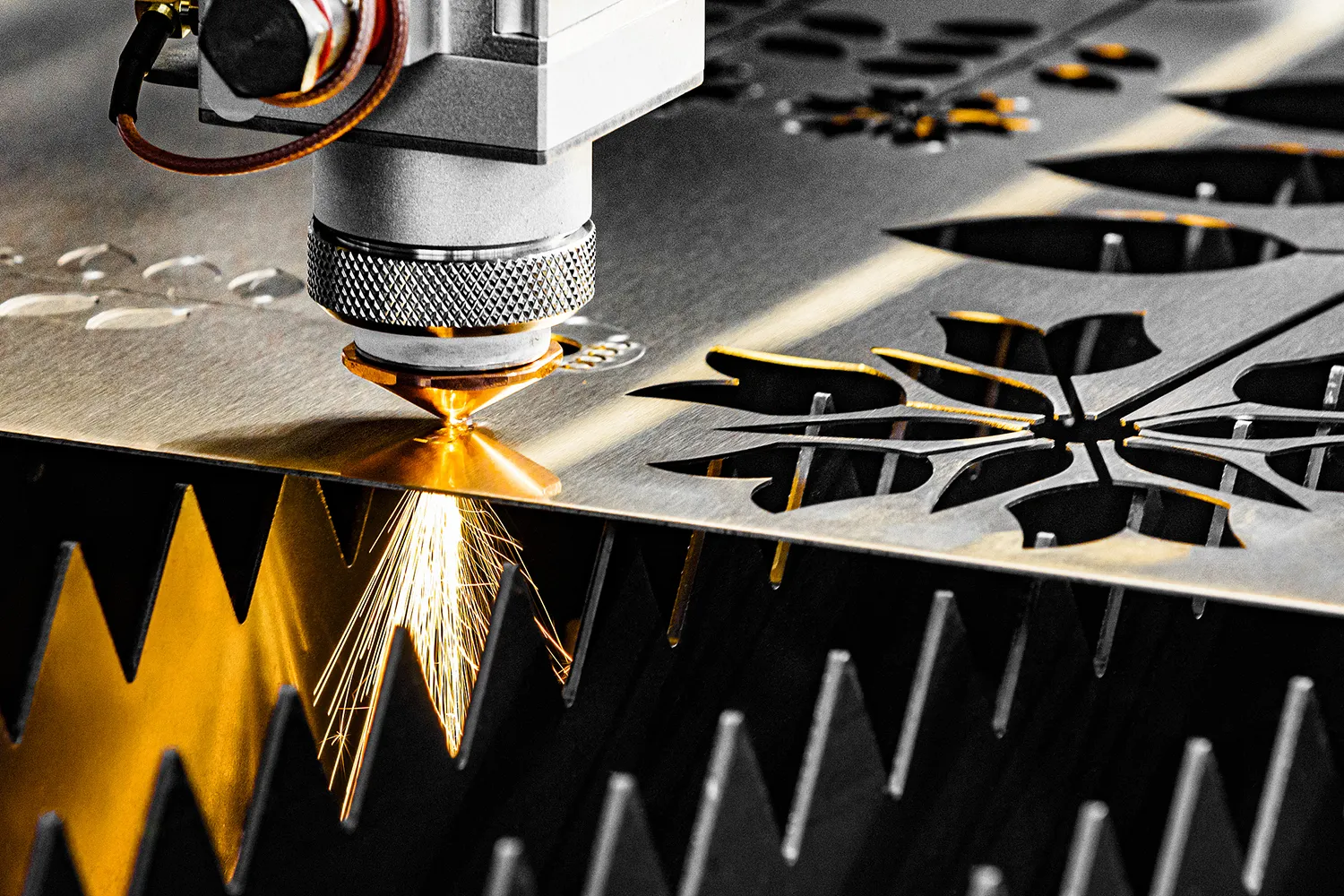

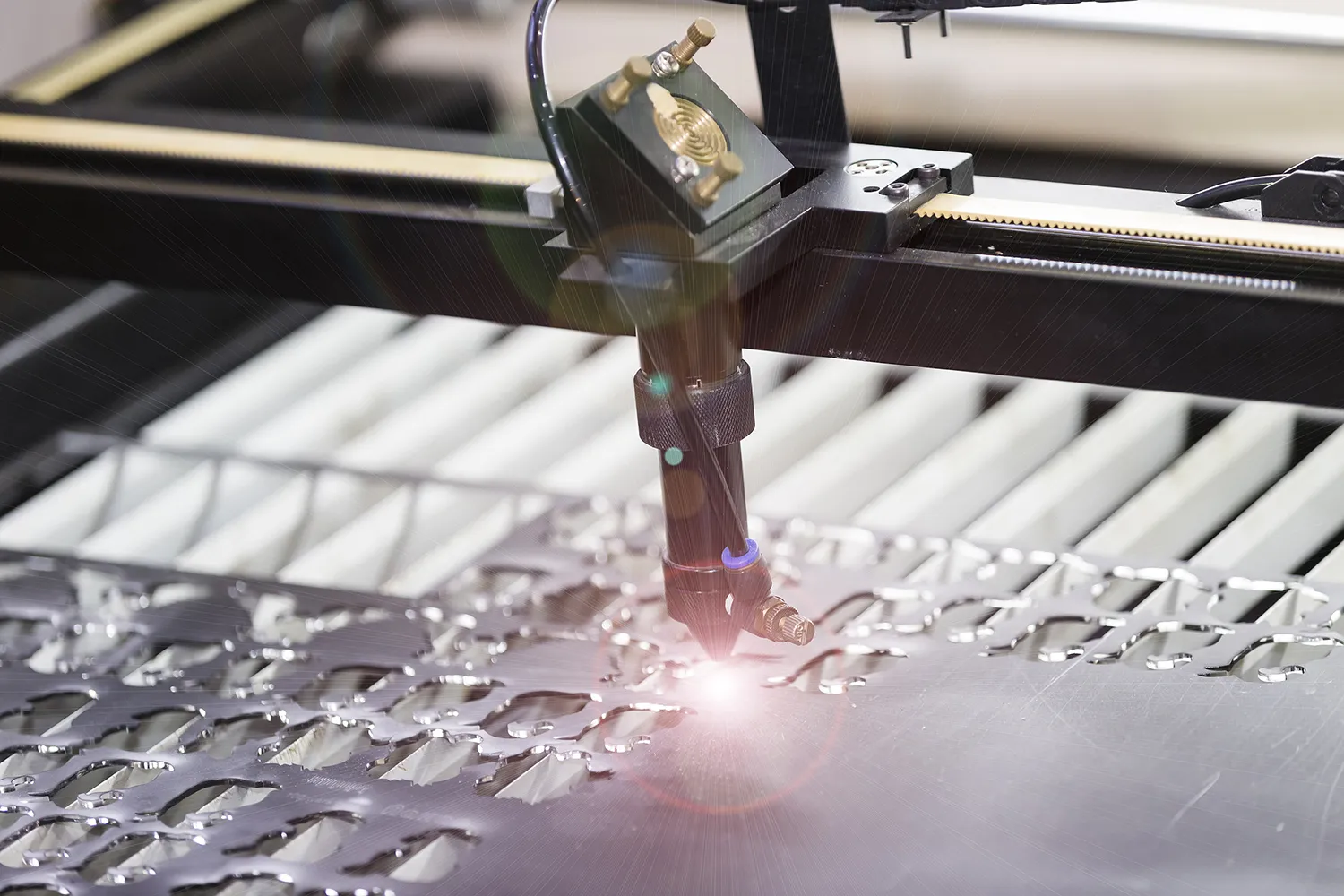

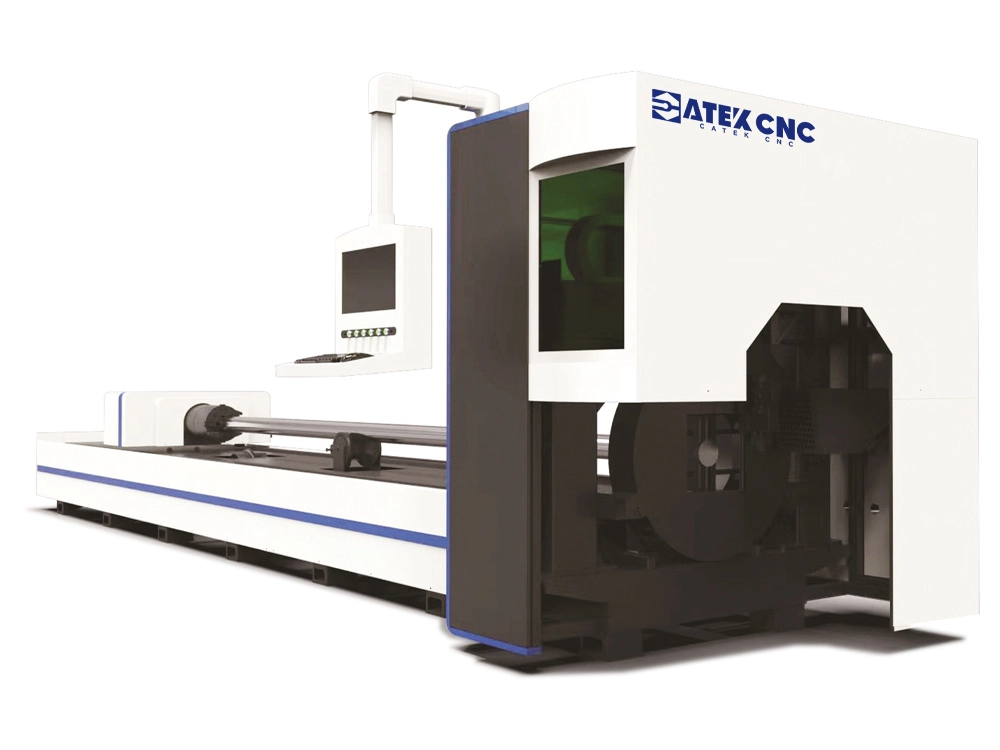

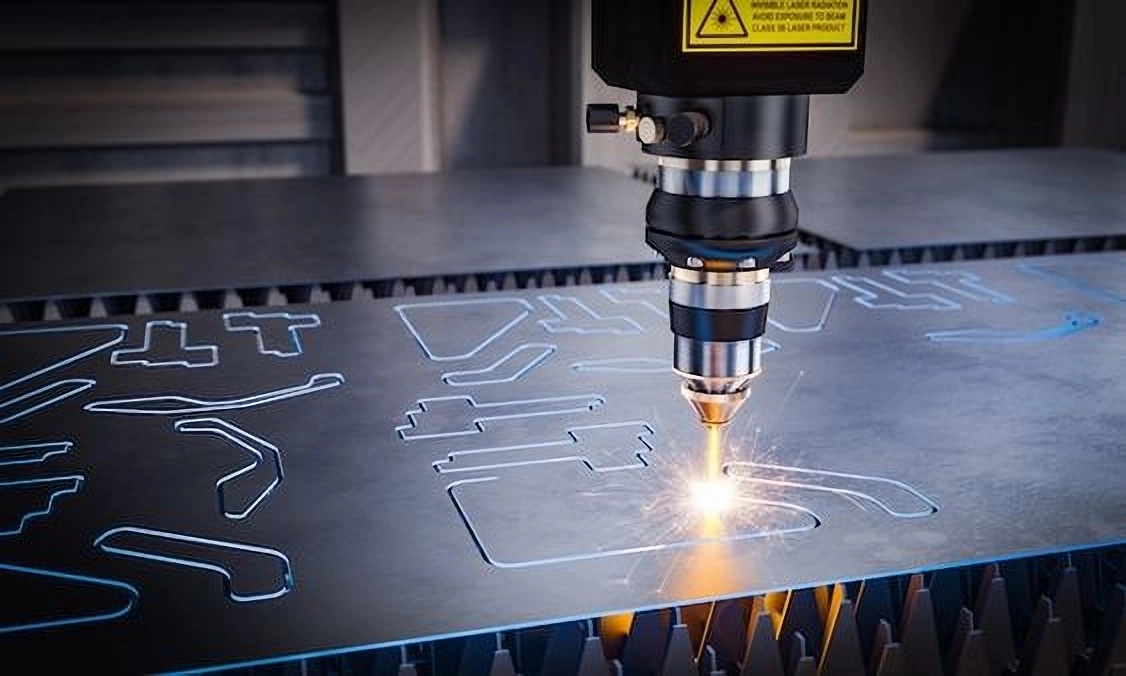

Laser Cutting Machine

Laser cutting machine is a new type of machine that uses various lasers as laser sources to cut metal or non-metal materials.

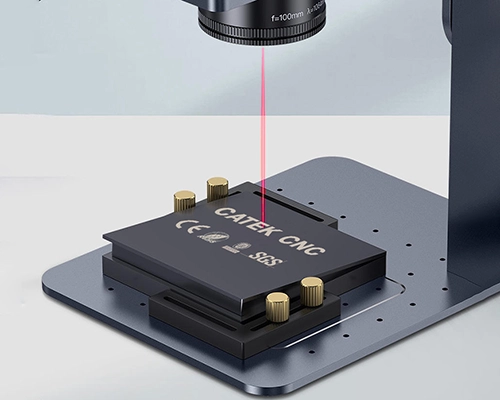

Laser Marking Machine

Laser marking machines use laser beams to permanently mark the surfaces of various materials.

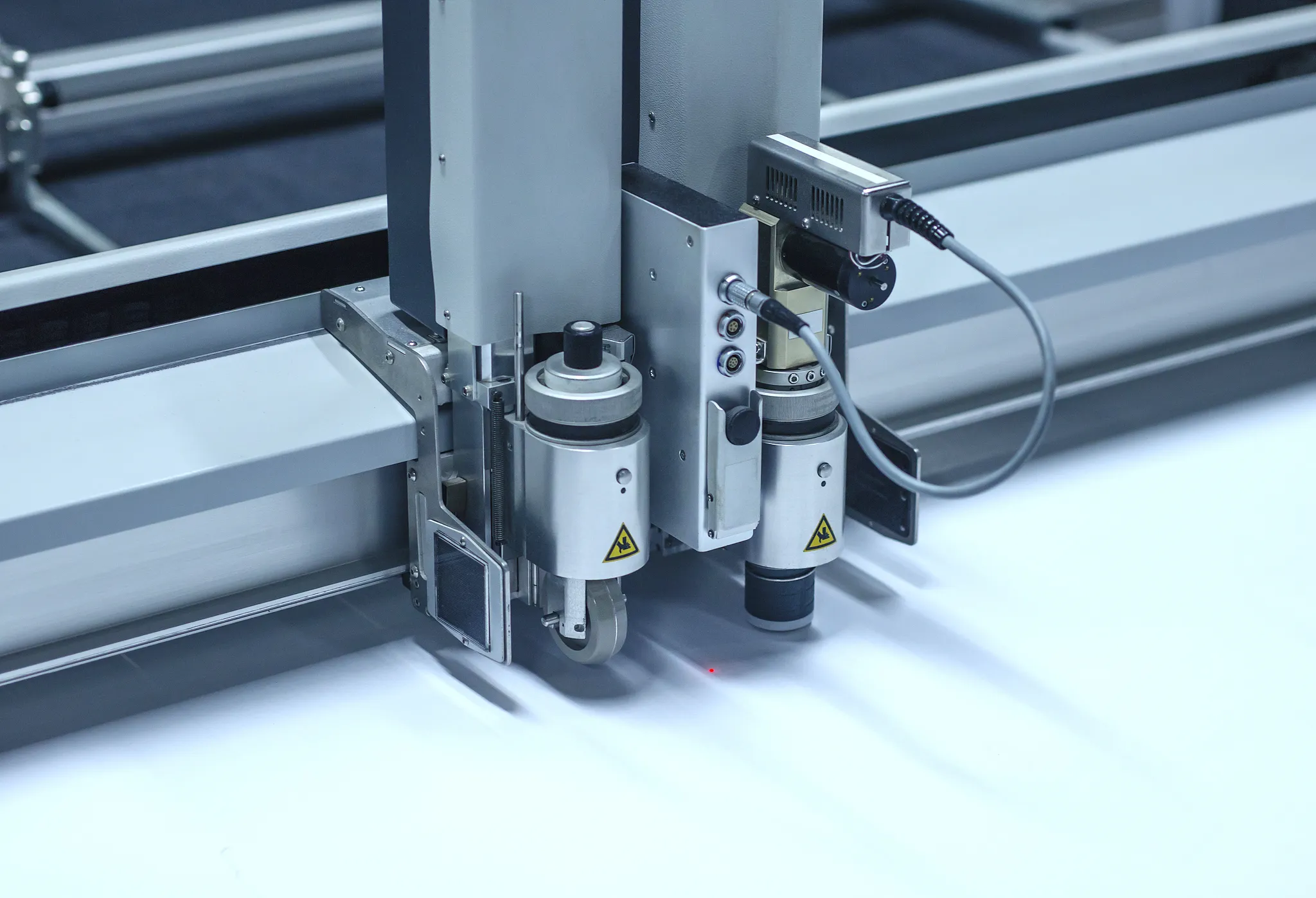

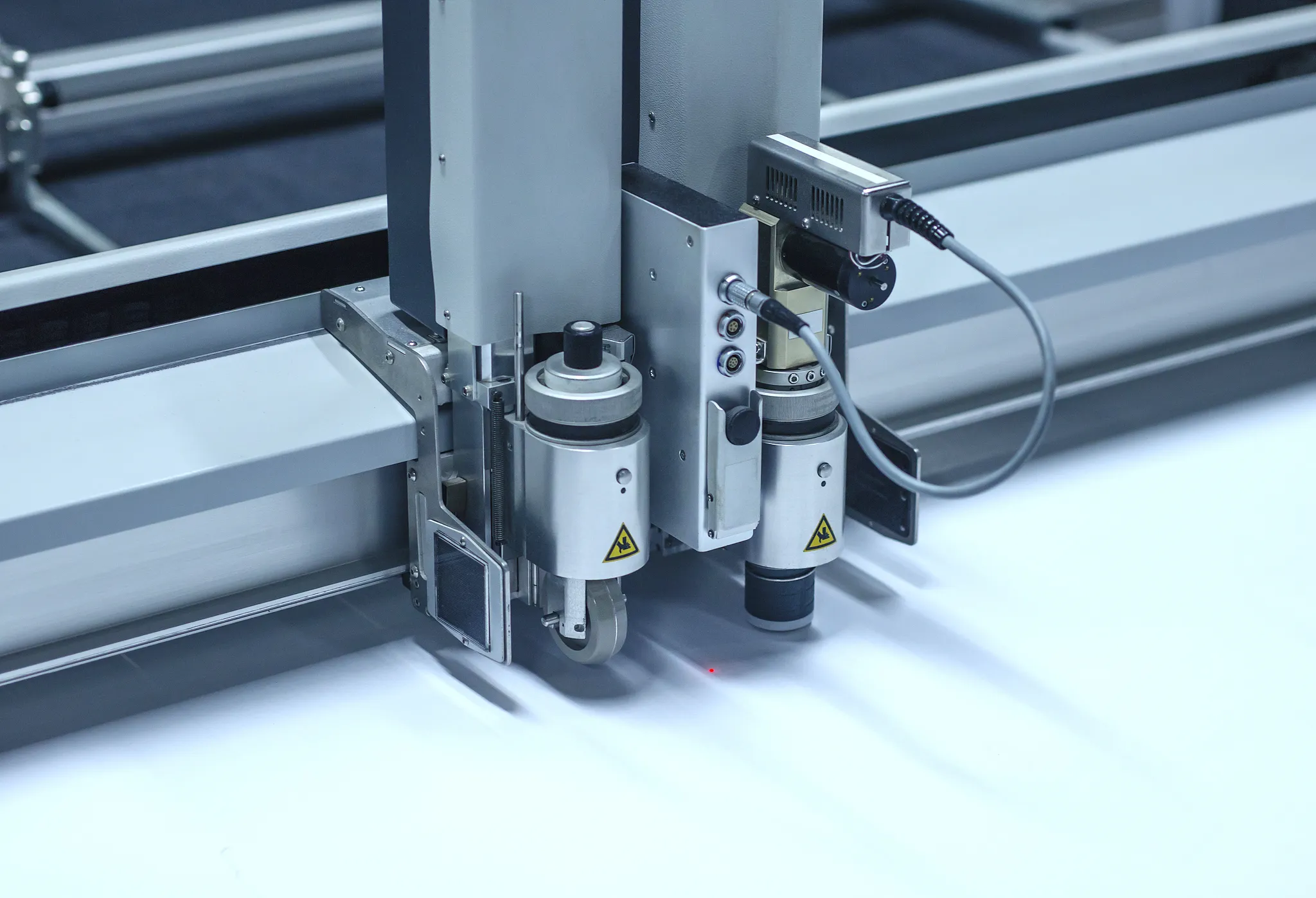

Oscillating Knife Cutting Machine

Oscillating knife cutters use a high frequency oscillating knife that oscillates up and down to physically cut flexible materials.

HOT PRODUCTS

Find the most popular CNC machines here.

- CNC Router

- CNC Lathe

- Laser Cutter

- Laser Marker

-

-

![1325 Linear ATC CNC Router Machine 1325 Linear ATC CNC Router Machine]() This model is the 4*8ft linear ATC CNC wood router from the Spire Series. Its appearance and mechanical structure have been fully redesigned, and it is equipped with Yaskawa servo motors and HSD spindles, along with exclusive VIP services.$15,800.00~$29,800.00

This model is the 4*8ft linear ATC CNC wood router from the Spire Series. Its appearance and mechanical structure have been fully redesigned, and it is equipped with Yaskawa servo motors and HSD spindles, along with exclusive VIP services.$15,800.00~$29,800.00 -

![Entry-Level 4x8 feet 1325 CNC Wood Router Machine for Hobby Entry-Level 4x8 feet 1325 CNC Wood Router Machine for Hobby]() The standard basic 4x8 feet CNC wood router comes with a T-slot aluminum alloy workbench as standard and can be equipped with various functional kits for processing wooden boards.$2,570.00~$5,370.00

The standard basic 4x8 feet CNC wood router comes with a T-slot aluminum alloy workbench as standard and can be equipped with various functional kits for processing wooden boards.$2,570.00~$5,370.00 -

![Best-Selling Linear ATC CNC Router with Automatic Loading and Unloading Best-Selling Linear ATC CNC Router with Automatic Loading and Unloading]() Based on the CK-1325-T, it adds an automatic loading/unloading system, enabling full automation from feeding, machining, tool changing, to unloading.$10,500.00~$11,900.00

Based on the CK-1325-T, it adds an automatic loading/unloading system, enabling full automation from feeding, machining, tool changing, to unloading.$10,500.00~$11,900.00 -

![7X10 ATC CNC Wood Router Machine with HSD Spindle 7X10 ATC CNC Wood Router Machine with HSD Spindle]() This 7x10ft linear ATC CNC router features a 9KW HSD high-speed air-cooled spindle and an 9-zone, 30-hole vacuum adsorption workbench.$11,800.00~$16,800.00

This 7x10ft linear ATC CNC router features a 9KW HSD high-speed air-cooled spindle and an 9-zone, 30-hole vacuum adsorption workbench.$11,800.00~$16,800.00 -

![Linear ATC CNC Nesting Machine with Drilling Bank and 3D Rotary Axis Linear ATC CNC Nesting Machine with Drilling Bank and 3D Rotary Axis]() This router features a vacuum adsorption workbench, linear-type tool changer, 5+4 pneumatic drilling bank, and 3D rotary axis, enabling panel furniture engraving/drilling and rotary carving of wood columns.$13,800.00~$17,500.00

This router features a vacuum adsorption workbench, linear-type tool changer, 5+4 pneumatic drilling bank, and 3D rotary axis, enabling panel furniture engraving/drilling and rotary carving of wood columns.$13,800.00~$17,500.00 -

![Five-Axis CNC Wood Router with Movable Worktable Five-Axis CNC Wood Router with Movable Worktable]() This is a 5-axis worktable-moving-type CNC router, it adds two rotary axes to three linear axes, the C-axis for spindle tilting and A-axis for rotating C-axis , enabling complex small 3D moldel make.$37,000.00~$65,000.00

This is a 5-axis worktable-moving-type CNC router, it adds two rotary axes to three linear axes, the C-axis for spindle tilting and A-axis for rotating C-axis , enabling complex small 3D moldel make.$37,000.00~$65,000.00

-

-

-

![The Most Cost-Effective 7-in-1 Multifunctional CNC Wood Lathe in 2026 The Most Cost-Effective 7-in-1 Multifunctional CNC Wood Lathe in 2026]() This machine is equipped with two turning tools, one large planer driven by a 7.5kW spindle, three 6kW multi-function spindles, and a sanding device. It is particularly suitable for various milling tasks.$9,000.00~$12,150.00

This machine is equipped with two turning tools, one large planer driven by a 7.5kW spindle, three 6kW multi-function spindles, and a sanding device. It is particularly suitable for various milling tasks.$9,000.00~$12,150.00 -

![Professional CNC Wood Lathe with Automatic Tool Changer Professional CNC Wood Lathe with Automatic Tool Changer]() The ATC CNC wood lathe is a versatile CNC lathe that supports up to 6 tool changes. It comes standard with one turning tool position, one large planing knife, an automatic tool-changing spindle, and a sanding device.$12,500.00~$28,500.00

The ATC CNC wood lathe is a versatile CNC lathe that supports up to 6 tool changes. It comes standard with one turning tool position, one large planing knife, an automatic tool-changing spindle, and a sanding device.$12,500.00~$28,500.00 -

![2026 Best Multi-Function 8-in-1 CNC Wood Lathe for Sale 2026 Best Multi-Function 8-in-1 CNC Wood Lathe for Sale]() This lathe is equipped with two types of turning tools, planer, saw blade, sanding wheel, sanding roller, two multi-functional spindles, and an automatic feeding device.$11,999.00~$18,000.00

This lathe is equipped with two types of turning tools, planer, saw blade, sanding wheel, sanding roller, two multi-functional spindles, and an automatic feeding device.$11,999.00~$18,000.00 -

![CNC Wood Carving Lathe with Four-Axis Linkage for Sculptures CNC Wood Carving Lathe with Four-Axis Linkage for Sculptures]() This lathe features a multi-function spindle and an indexable A-axis, with the spindle capable of linear movement in six directions, allowing for complex grooving and engraving on flat surfaces.$5,588.00~$6,350.00

This lathe features a multi-function spindle and an indexable A-axis, with the spindle capable of linear movement in six directions, allowing for complex grooving and engraving on flat surfaces.$5,588.00~$6,350.00 -

![Mini CNC Wood Lathe for Wood Crafts and Toys Mini CNC Wood Lathe for Wood Crafts and Toys]() This mini CNC wood lathe processes small-diameter workpieces, featuring a pneumatic collet and automatic feeder for crafting wooden handles, chess pieces, and handicrafts.$3,600.00~$5,150.00

This mini CNC wood lathe processes small-diameter workpieces, featuring a pneumatic collet and automatic feeder for crafting wooden handles, chess pieces, and handicrafts.$3,600.00~$5,150.00 -

![2-Station Pool Cue CNC Milling Machine with Automatic Loading and Unloading 2-Station Pool Cue CNC Milling Machine with Automatic Loading and Unloading]() The lathe features two workstations, a hopper, and a multi-cylinder automatic loading/unloading system, enabling simultaneous processing of two identical pool cues with fully automated material handling.$6,300.00~$6,760.00

The lathe features two workstations, a hopper, and a multi-cylinder automatic loading/unloading system, enabling simultaneous processing of two identical pool cues with fully automated material handling.$6,300.00~$6,760.00

-

-

-

![5x10 1500W/2000W/3000W Fiber Laser Cutter for Sale at Competitive Price 5x10 1500W/2000W/3000W Fiber Laser Cutter for Sale at Competitive Price]() This is a standard 5x10 ft fiber laser cutting machine with multiple power and configuration options, suitable for cutting various metals and alloys.$5,500.00~$15,800.00

This is a standard 5x10 ft fiber laser cutting machine with multiple power and configuration options, suitable for cutting various metals and alloys.$5,500.00~$15,800.00 -

![5x10 Multi-Function Fiber Laser Plate and Tube Cutting Machine 5x10 Multi-Function Fiber Laser Plate and Tube Cutting Machine]() This is a fiber laser cutting machine capable of both metal sheet and metal pipe cutting. It features an added pipe clamping/rotating device on the side, making it more comprehensive.$22,500.00~$32,800.00

This is a fiber laser cutting machine capable of both metal sheet and metal pipe cutting. It features an added pipe clamping/rotating device on the side, making it more comprehensive.$22,500.00~$32,800.00 -

![Industrial-Grade Professional Fiber Laser Tube Cutting Machine Industrial-Grade Professional Fiber Laser Tube Cutting Machine]() This large metal tube fiber laser cutter is specially designed for tube processing, featuring a large-diameter automatic rotary axis, dual pneumatic chucks, and variable-diameter wheel supports.$16,000.00~$29,000.00

This large metal tube fiber laser cutter is specially designed for tube processing, featuring a large-diameter automatic rotary axis, dual pneumatic chucks, and variable-diameter wheel supports.$16,000.00~$29,000.00 -

![CO2 Laser Cutting Machine for Cutting Acrylic and Wood CO2 Laser Cutting Machine for Cutting Acrylic and Wood]() This compact CO2 laser cutter uses a DC glass tube laser and enclosed housing with viewing window, ideal for cutting or engraving wood, acrylic, plastics, and other non-metals.$2,650.00~$4,050.00

This compact CO2 laser cutter uses a DC glass tube laser and enclosed housing with viewing window, ideal for cutting or engraving wood, acrylic, plastics, and other non-metals.$2,650.00~$4,050.00 -

![2-Station CO2 Laser Engraving Machine Suitable for Batch Processing 2-Station CO2 Laser Engraving Machine Suitable for Batch Processing]() This CO2 laser cutter features dual identical workstations for simultaneous processing, widely used for cutting/engraving wood, leather, epoxy, PE, PP, PVC, carbon fiber, and other materials.$3,400.00~$6,250.00

This CO2 laser cutter features dual identical workstations for simultaneous processing, widely used for cutting/engraving wood, leather, epoxy, PE, PP, PVC, carbon fiber, and other materials.$3,400.00~$6,250.00 -

![6x5ft CO2 Laser Fabric Cutter with Vision Positioning and Conveyor 6x5ft CO2 Laser Fabric Cutter with Vision Positioning and Conveyor]() This CO2 laser cutting machine combines a camera vision system with a conveyor workbench, ideal for batch processing multiple products or performing contour cuts based on patterns.$8,250.00~$9,270.00

This CO2 laser cutting machine combines a camera vision system with a conveyor workbench, ideal for batch processing multiple products or performing contour cuts based on patterns.$8,250.00~$9,270.00

-

-

-

![Cheap Cabinet-Type Fiber Laser Marking Machine Cheap Cabinet-Type Fiber Laser Marking Machine]() This fiber laser marking machine features a cabinet-type design, can be placed directly on the floor for convenient use, and is suitable for marking various metals and some opaque non-metallic surfaces.$1,400.00~$5,150.00

This fiber laser marking machine features a cabinet-type design, can be placed directly on the floor for convenient use, and is suitable for marking various metals and some opaque non-metallic surfaces.$1,400.00~$5,150.00 -

![Desktop Fiber Laser Marker with 3D Rotary Device Desktop Fiber Laser Marker with 3D Rotary Device]() This fiber laser marker features a rotary device that clamps and precisely rotates workpieces at controlled speeds and angles, enabling multi-angle marking for bowls, cups, pens, rings, earrings, guns, doorknobs.$1,470.00~$5,220.00

This fiber laser marker features a rotary device that clamps and precisely rotates workpieces at controlled speeds and angles, enabling multi-angle marking for bowls, cups, pens, rings, earrings, guns, doorknobs.$1,470.00~$5,220.00 -

![4x8 feet Mirror-Specific Fiber Laser Etching Machine 4x8 feet Mirror-Specific Fiber Laser Etching Machine]() This large-format laser etcher is specially designed for the LED smart mirror industry, capable of pattern engraving, frosting, paint removal (mirror transparency), and small-scale perforation on smart mirrors.$14,200.00~$25,700.00

This large-format laser etcher is specially designed for the LED smart mirror industry, capable of pattern engraving, frosting, paint removal (mirror transparency), and small-scale perforation on smart mirrors.$14,200.00~$25,700.00 -

![Large Format CO2 Laser 3D Dynamic Marking Machine Large Format CO2 Laser 3D Dynamic Marking Machine]() This large-format CO2 laser marker offers a 500*500mm marking area with a honeycomb workbench, suitable for engraving leathers, cloths, woods, plastics, and other non-metallic materials.$5,900.00~$6,900.00

This large-format CO2 laser marker offers a 500*500mm marking area with a honeycomb workbench, suitable for engraving leathers, cloths, woods, plastics, and other non-metallic materials.$5,900.00~$6,900.00 -

![Cabinet-Type RF CO2 Laser Marking Machine Cabinet-Type RF CO2 Laser Marking Machine]() This cabinet-type laser marker utilizes an RF CO2 laser, delivering stable power output, superior beam quality, high conversion efficiency, and exceptional lifespan.$1,900.00~$2,200.00

This cabinet-type laser marker utilizes an RF CO2 laser, delivering stable power output, superior beam quality, high conversion efficiency, and exceptional lifespan.$1,900.00~$2,200.00 -

![UV Laser Marking Machine with CCD Vision System and Conveyor Belt UV Laser Marking Machine with CCD Vision System and Conveyor Belt]() This UV laser marker features vision positioning and conveyor systems for automated batch marking of identical products without manual alignment, making it ideal for factory production.$4,000.00~$10,700.00

This UV laser marker features vision positioning and conveyor systems for automated batch marking of identical products without manual alignment, making it ideal for factory production.$4,000.00~$10,700.00

-

Filter & Discover

Choose the right machine by making full comparisons and communicating with our customer service

Fast Shipping

Choose professional and fast delivery solutions according to customer conditions

24/7 SUPPORT

Our team is available 24/7 to help with any questions or concerns.

MONEY BACK

We offer a 100% money-back guarantee for your satisfaction.

WHAT OUR CLIENTS SAY

ABOUT US

We always listen to user feedback and continuously improve product quality and service.

BUSINESS PARTNERS

Our growth is inseparable from the support of our business partners, it is their support that has made us what we are today.