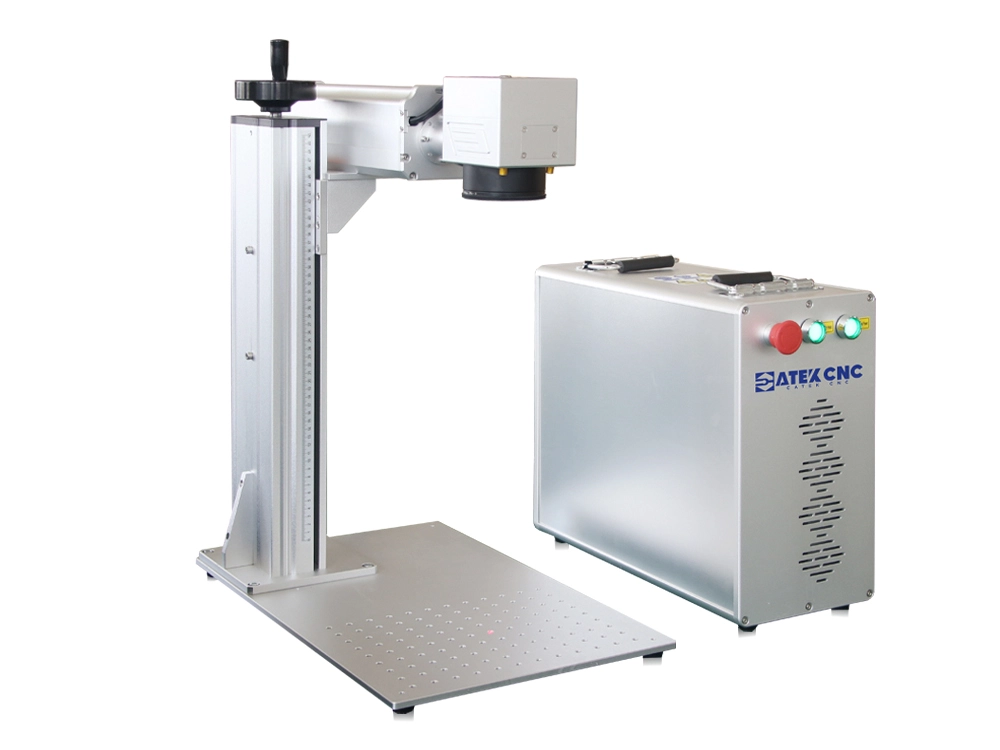

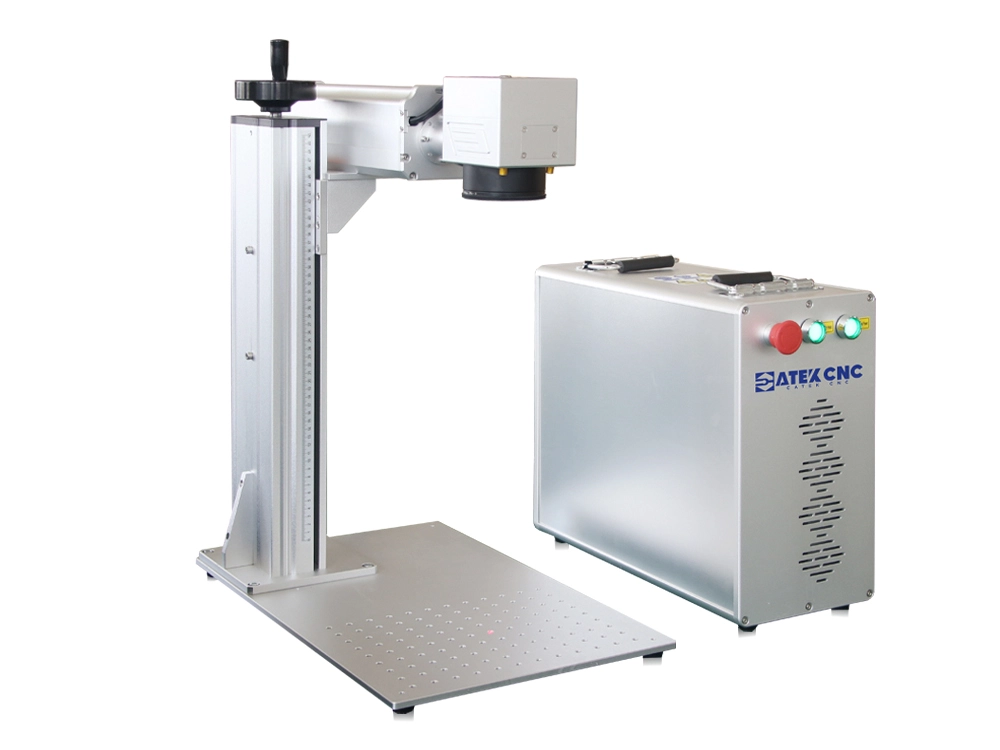

Split MOPA Laser Marker for Color Marking

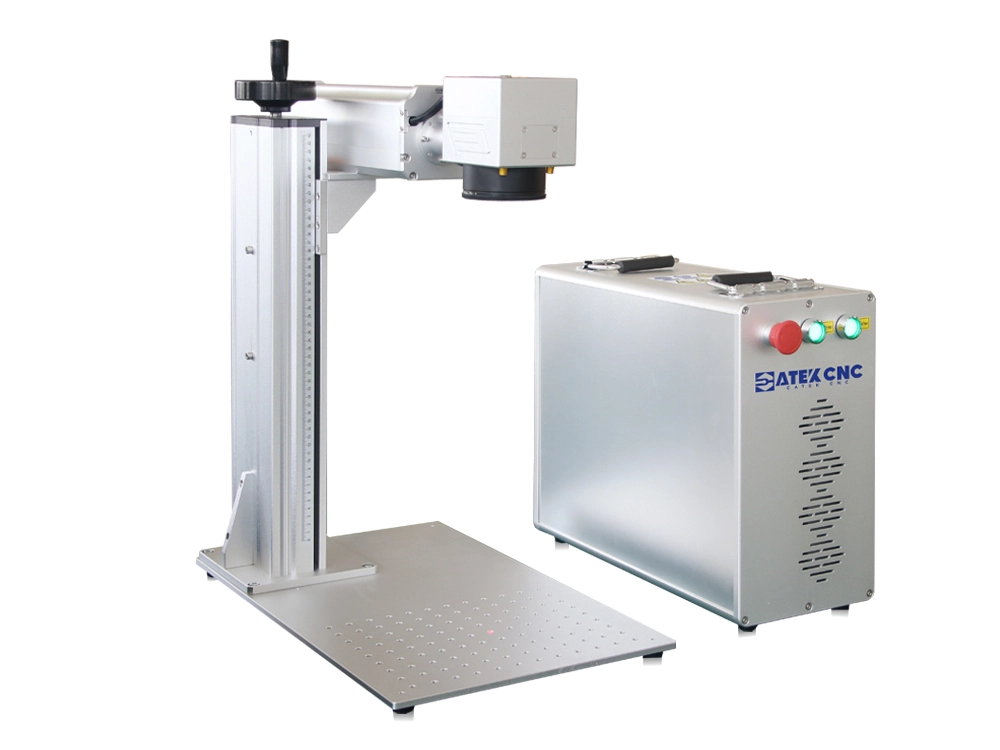

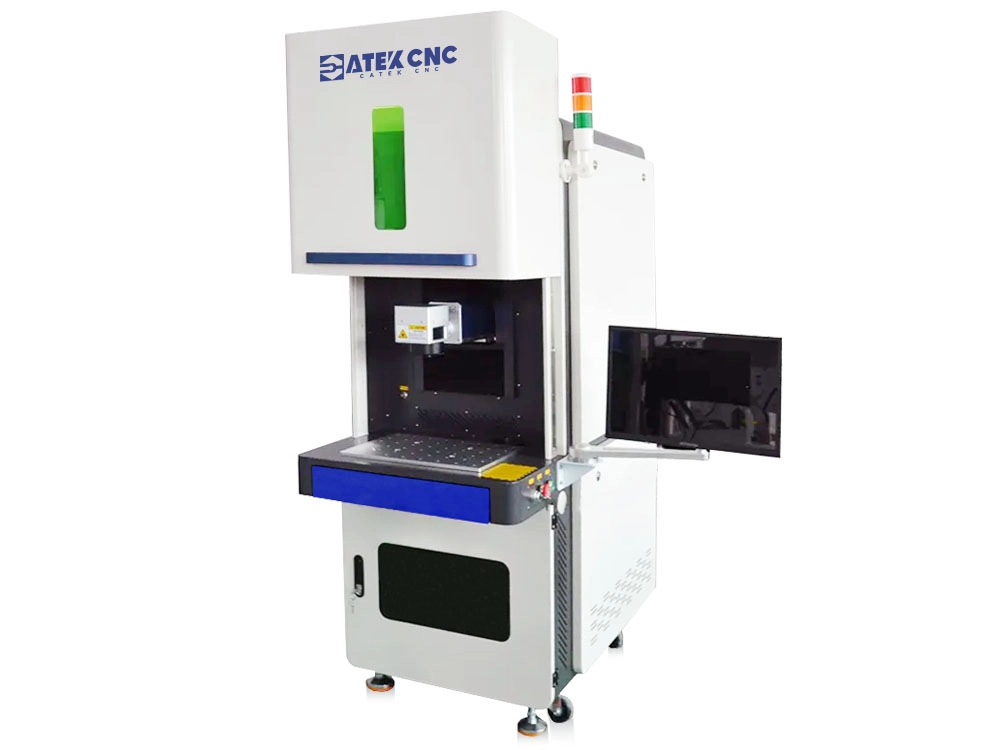

Split MOPA Color Laser Marking Machine

[Function Description]

The MOPA laser color marking machine is an advanced laser device based on MOPA (Master Oscillator Power Amplifier) technology. It uses electrically pulsed semiconductor laser chips as the seed light source and achieves high-power output through a fiber amplifier. The pulse width and frequency can be independently adjusted, enabling the generation of single pulses as short as a few nanoseconds or as long as tens of nanoseconds. By precisely controlling laser parameters (such as energy density, power, operating frequency, etc.) and leveraging the thermal effects of the laser and changes in the material's microstructure, the MOPA laser color marking machine can achieve high-quality color marking on specific metals.

The MOPA laser marking machine offers extremely high marking precision and stability, with a working accuracy of ±0.01 mm and a repeatability accuracy of up to ±0.001 mm. Its multi-color marking capability allows it to flexibly meet the needs of different materials and application scenarios. The wavelength of the MOPA laser is 1064 nm, enabling nanosecond-level pulse widths, with the pulse width adjustable between 2 and 500 ns. By adjusting laser parameters, the MOPA laser can generate a variety of color marks, such as black, red, blue, yellow, purple, and pink, on surfaces of metals like stainless steel, titanium alloy, aluminum alloy, and chromium. Additionally, the MOPA laser can achieve a smaller heat-affected zone (HAZ), reducing material damage and improving processing precision.

The MOPA laser color marking machine is not only suitable for metal materials but can also be used for various non-metal materials such as plastics, stones, and electronic components. It employs non-contact laser processing, eliminating the need for chemical dyes, inks, or other consumables, making it more environmentally friendly and compliant with European RoHS certification. The marks produced are durable, resistant to fading and wear, and can be permanently preserved.

How Does the MOPA Laser Color Marking Machine Achieve Color Processing?

The MOP laser color marking machine can achieve color marking on the surface of specific metal materials such as stainless steel and titanium alloys by adjusting laser parameters such as pulse frequency, pulse width, and power. By focusing a high-energy-density laser beam, the material surface is heated to high temperatures, triggering chemical changes. This results in the formation of colored oxides or a colorless transparent oxide film on the material surface. The oxide film produces an interference effect, creating colors. Under different laser actions, oxide layers of varying thicknesses are formed. The color of the oxide layer changes with its thickness. When the laser energy is low, the formed oxide layer is thin, usually appearing blue. As the laser energy increases and the oxide layer thickens, the color gradually changes, forming green, yellow, orange, and other colors.

The MOPA laser features independently adjustable pulse width and frequency functions, allowing precise control over the laser energy distribution by tuning these parameters to achieve various color changes. A larger pulse width tends to produce deeper colors, while a smaller pulse width is more likely to result in lighter hues. By adjusting the laser power and marking speed, color performance can also be optimized. Low power and slow speed are used to create smooth color transitions, whereas high power and high speed enhance color contrast.

Different materials, due to their varying compositions and elemental contents, produce distinct colors after being subjected to laser action. By controlling the laser energy density, various color markings can be achieved. Below are some common colors associated with specific oxides:

| Fe 3 O 4 | Fe 2 O 3 | FeO | Cr 2 O 3 | CrO 3 | MnO | MnO 2 |

|---|---|---|---|---|---|---|

| Black | Reddish-brown | Black | Green | Dark red | Green | Dark brown |

Advantages of MOPA Fiber Laser Color Marking Machine

- Utilizes JPT MOPA color fiber laser, with a long service life, capable of continuous operation for 100,000 hours without maintenance.

- Excellent marking effect with high precision, marking accuracy of 0.01mm, and a maximum marking speed of 10,000mm/s, ensuring high production efficiency.

- Employs pulse width adjustable technology, allowing flexible adjustment of the duration of individual pulses to meet various processing needs.

- The laser uses air-cooling technology, resulting in low operating noise, no pollution, and greater energy efficiency, making it suitable for use in natural environments.

- Simple operation with computer control and equipped with control software, making it easy for beginners to operate.

- Wide range of applications, suitable for various metal materials and some non-metal materials.

- Split design, easy to carry, and adaptable to various working environments.

- No need for any consumables or inks, capable of achieving color marking on metal surfaces such as stainless steel, enhancing the aesthetic appeal of products.

Technical Parameters of MOPA Fiber Laser Color Marking Machine

| Model | CK-11-FS-MOPA |

| Cooling | Air cooling |

| Laser Power | 20W/30W/50W/100W/200W |

| Laser Wavelength | 1064nm |

| Pulse Width | 2-350ns |

| Repetition Frequency Range | 1-4000kHz |

| M2 | <1.3 |

| Maximum Single Pulse Energy | 0.8mJ |

| Output Power Stability | <5% |

| Output Beam Diameter | 7±0.5mm |

| Power Range | 0-100% |

| Marking Range | 110*110mm/200*200mm/300*300mm |

| Air cooling | Yes |

| Minimum Line Width | 0.01mm |

| Minimum Number Of Characters | 0.1mm |

| Marking Speed | ≤9000mm/s |

| Marking Depth | Depends on the materials |

| Repeatability Accuracy | ±0.003mm |

| Supported Graphics Formats | Ai, plt, dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

| Fiber Cable Length | 3m |

| Operating Voltage | 110V/220V 50/60hz |

| Unit Power | <0.5kw |

| Working Environment | Clean and dust free or dust less |

| Working Condition Humidity | 5%-75%, 0-40 degree, free of condensed water |

| Laser Lifetime | >100000 hours |

| Weight | 85kg |

| Dimensions | 750*600*850mm |

Details of Split MOPA Fiber Laser Color Marking Machine

- Sino-Galvo galvanometer

sino-galvo galvanometer uses photoelectric sensors imported from the United States to ensure accurate detection of the motor rotor position. It has the advantages of zero drift and high precision, supports high-speed scanning, and meets various production requirements.

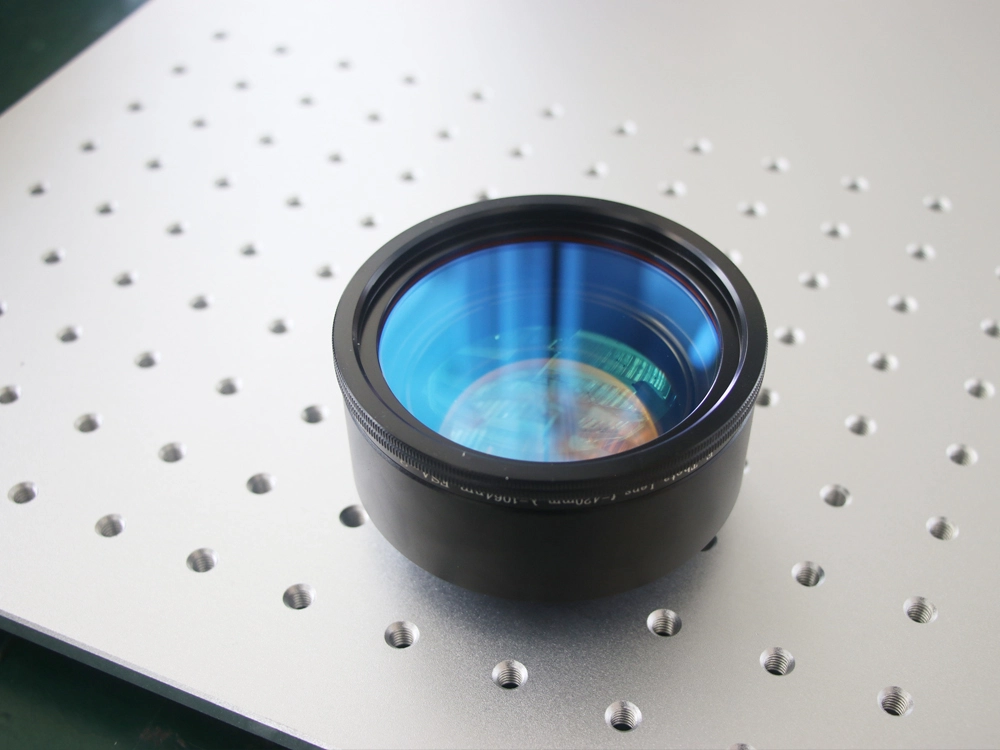

- Field lens

High-quality imported field lens effectively improves the incidence efficiency of edge beams, ensuring uniform distribution of the laser beam on the detector, thereby significantly enhancing marking precision and quality.

- JPT laser source

The JPT laser source has better beam quality, higher stability and higher cost.

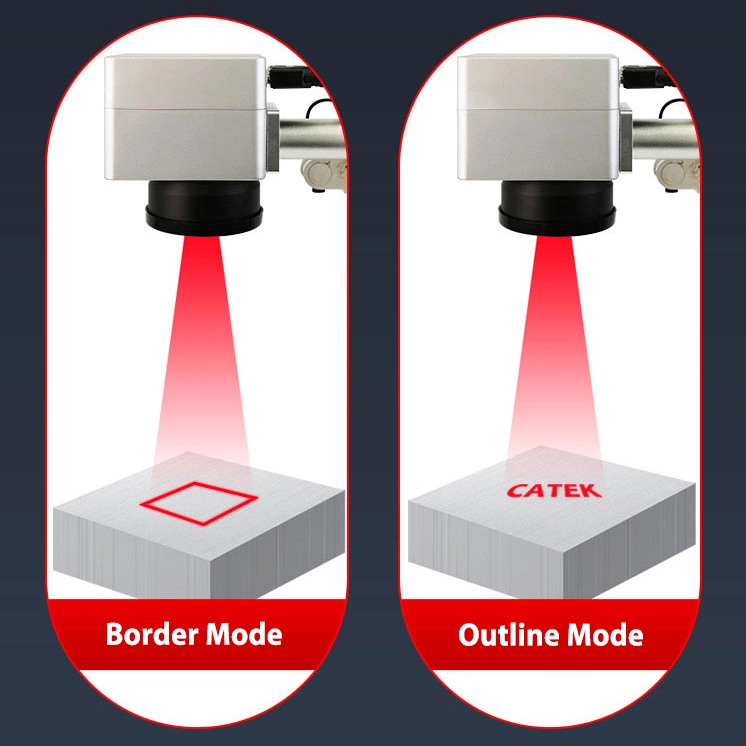

- Double red light indication

The combination of two red light emitter can project a red rectangular preview border or the outline of the edge of a font pattern.

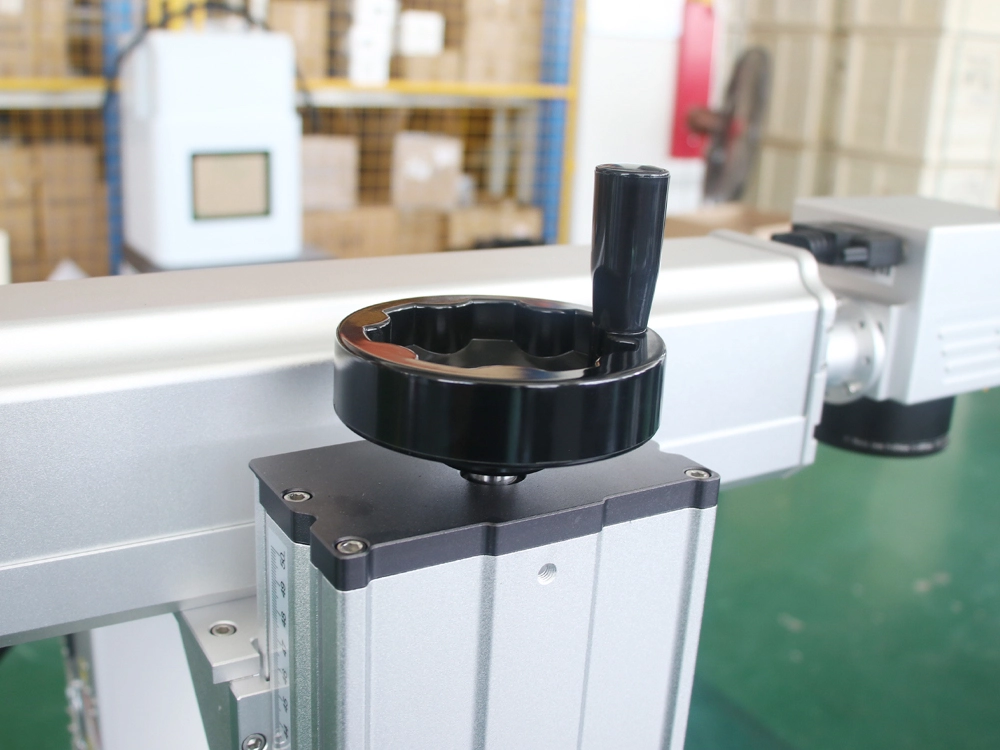

- Hand crank

The marking head can be raised and lowered using a hand crank.

- Control panel

Multiple protection switches equipped with an emergency stop button to handle various emergency situations.

- External interface

The back of the machine is equipped with multiple aviation plugs, and the head can be separated from the main unit to prevent cable damage.

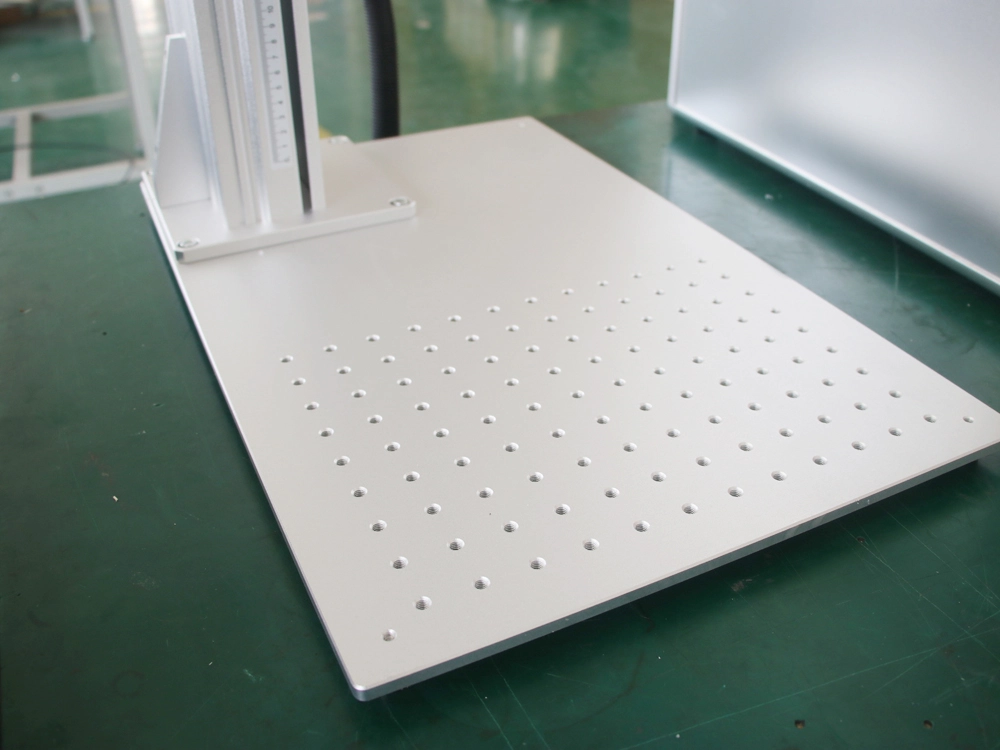

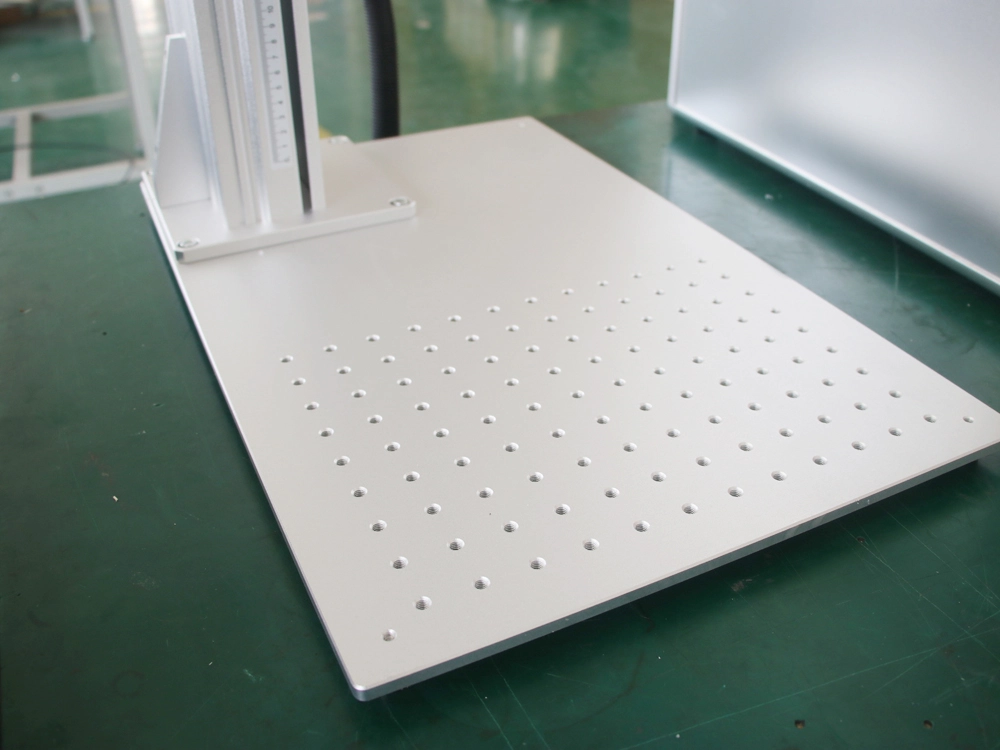

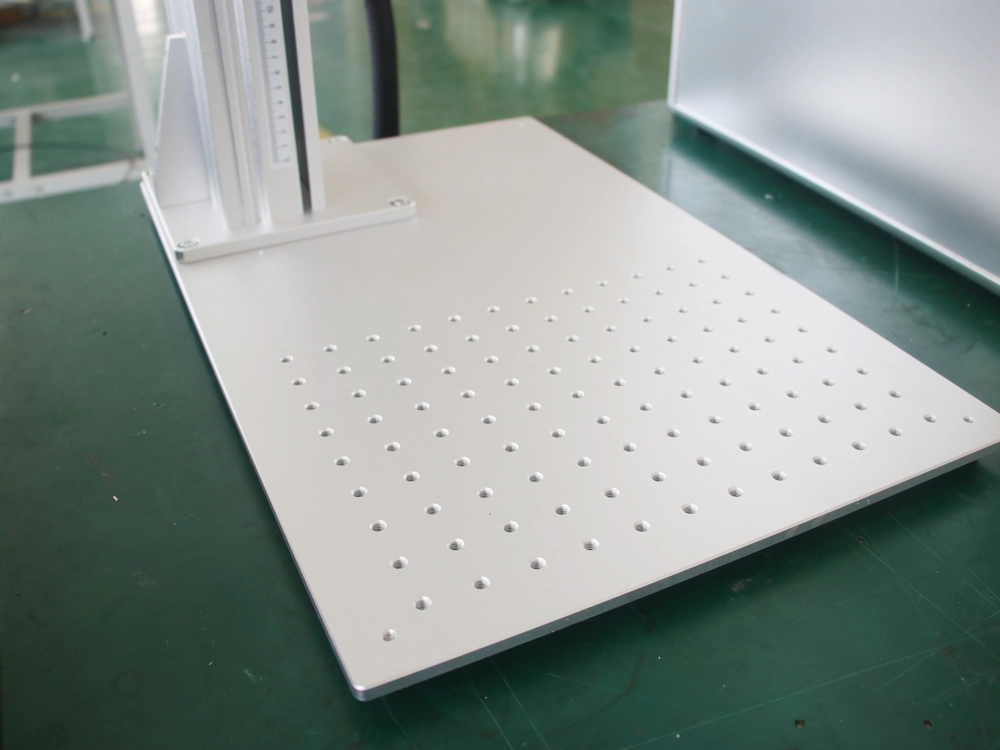

- Flat worktable

Can secure various thin sheet parts.

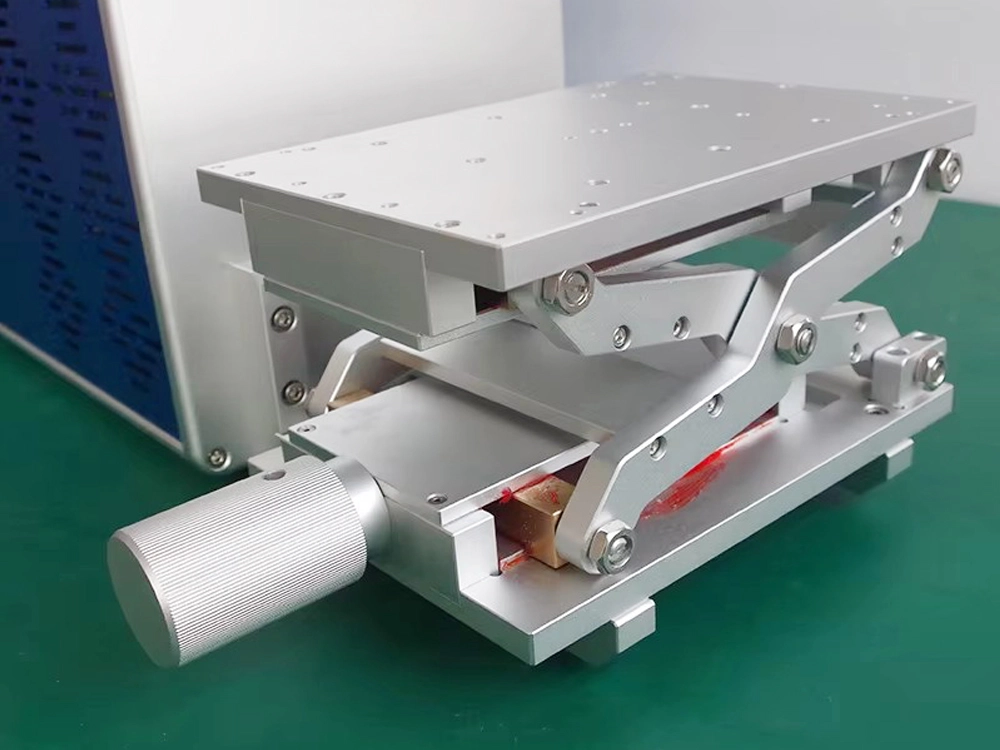

- Optional Liftable flat workbench

Suitable for products with varying heights.

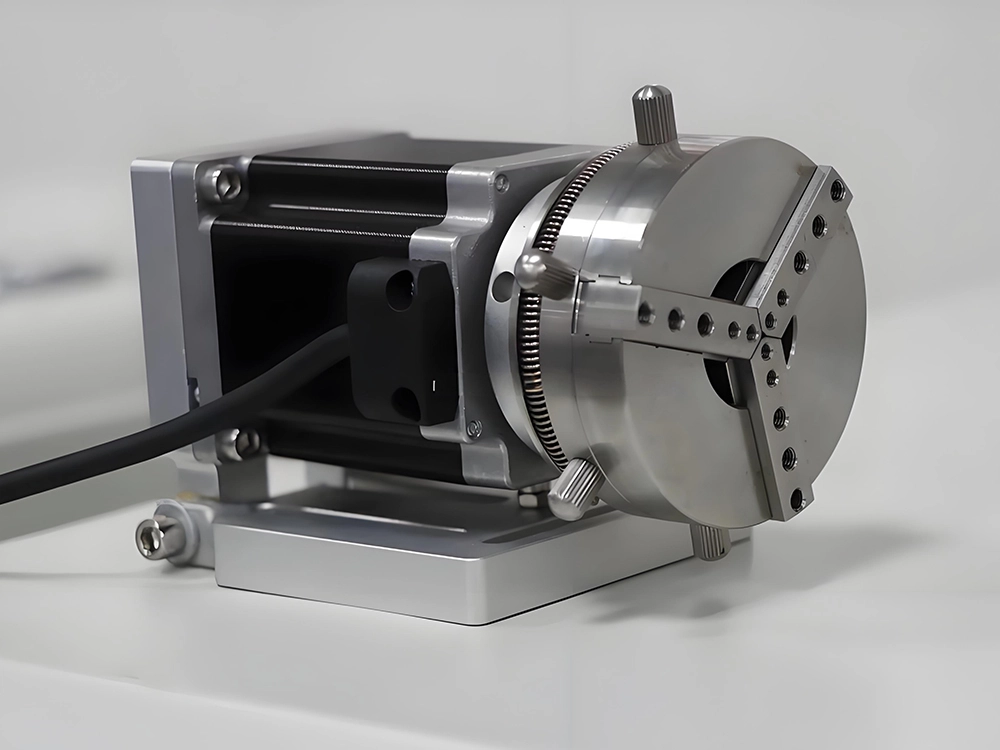

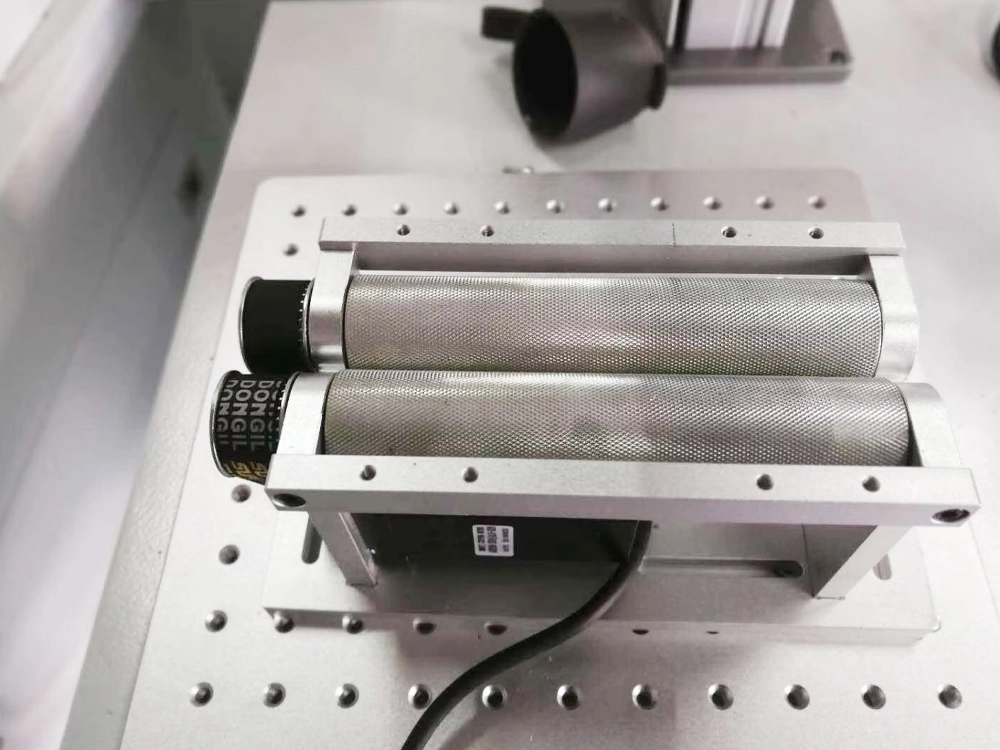

- Optional Rotary device

It can secure cylindrical products such as cups and bottles and process all facs of the product by rotation.

- MOPA fiber laser marking machine in the warehouse

The processed MOPA fiber laser marking machines will be tested and debugged one by one, and then placed in a dedicated warehouse for storage.

Application Scope of Split MOPA Fiber Laser Color Marking Machine

Color marking of metal materials:

MOPA lasers are capable of color marking on metal materials such as stainless steel, titanium alloy, copper, etc. By adjusting laser parameters such as focal diameter, sample power, marking speed, etc., different colors of oxide coatings can be achieved, thereby achieving a uniform and reliable color marking effect.

Black marking of anodized aluminum:

Split MOPA color marking machines are also widely used for black marking on anodized aluminum materials. This marking technology does not destroy the protective oxide layer, and has high contrast and beautiful touch. It is suitable for various products such as mobile device housings and keyboard keycaps.

Marking of non-metallic materials:

In addition to metal materials, split MOPA color marking machines can also mark on a variety of non-metallic materials such as plastics, wood, ceramics, leather, etc.

Other applications:

In addition, split MOPA color marking machines are also used in fine processing fields such as 3C product marking and micro-carving, as well as marking work in multiple industries such as automotive accessories, electronic products, and communication products.

Examples of Split MOPA Color Desktop Marking Machine

How to Determine if a Material is Suitable for Color Marking When Using the Machine?

To determine whether the surface of a material is suitable for MOPA color laser marking, it is necessary to comprehensively consider factors such as the material's properties, its condition, the technical parameters of the laser marking machine, and the actual application scenarios. Below are some analysis and judgment criteria prepared by our engineers for you:

- Ensure the material is metallic, such as stainless steel, aluminum, chromium, titanium, titanium alloys, copper, etc. These metal materials can achieve color marking by adjusting laser parameters.

- The flatness and thickness of the material surface will affect the marking results. A smooth and flat surface is conducive to producing vivid color markings; for very thin materials, special attention should be paid to heat control to avoid deformation.

- If used in complex environments, consider the material's corrosion resistance to ensure the markings can be preserved for a long time.

- During processing, flexibly adjust the pulse width and frequency to test the final color marking effect.

- Before formal production, it is recommended to conduct small-scale marking experiments to explore the best marking effect by adjusting laser parameters, and then proceed with batch processing.

- CATEKCNC provides 24/7 online engineer support. If you are unsure whether a material is suitable for color marking or how to adjust laser parameters, feel free to consult our engineers at any time for online assistance.

| Model | CK-11-FS-MOPA |

|---|---|

| Cooling | Air cooling |

| Laser Power | 20W/30W/50W/100W/200W |

| Laser Wavelength | 1064nm |

| Pulse Width | 2-350ns |

| Repetition Frequency Range | 1-4000kHz |

| M2 | <1.3 |

| Maximum Single Pulse Energy | 0.8mJ |

| Output Power Stability | <5% |

| Output Beam Diameter | 7±0.5mm |

| Power Range | 0-100% |

| Marking Range | 110*110mm/200*200mm/300*300mm |

| Air cooling | Yes |

| Minimum Line Width | 0.01mm |

| Minimum Number Of Characters | 0.1mm |

| Marking Speed | ≤9000mm/s |

| Marking Depth | Depends on the materials |

| Repeatability Accuracy | ±0.003mm |

| Supported Graphics Formats | Ai, plt, dxf, dst, svg, nc, bmp, jpg, jpeg, gif, tga, png, tiff, tif |

| Fiber Cable Length | 3m |

| Operating Voltage | 110V/220V 50/60hz |

| Unit Power | <0.5kw |

| Working Environment | Clean and dust free or dust less |

| Working Condition Humidity | 5%-75%, 0-40 degree, free of condensed water |

| Laser Lifetime | >100000 hours |

| Weight | 85kg |

| Dimensions | 750*600*850mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.