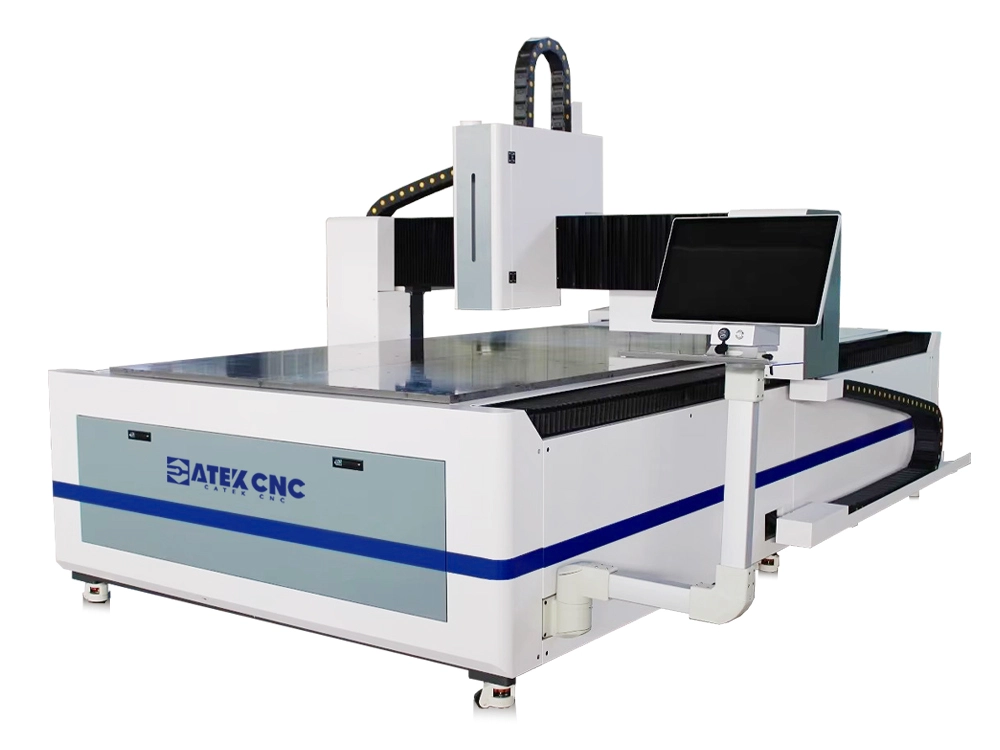

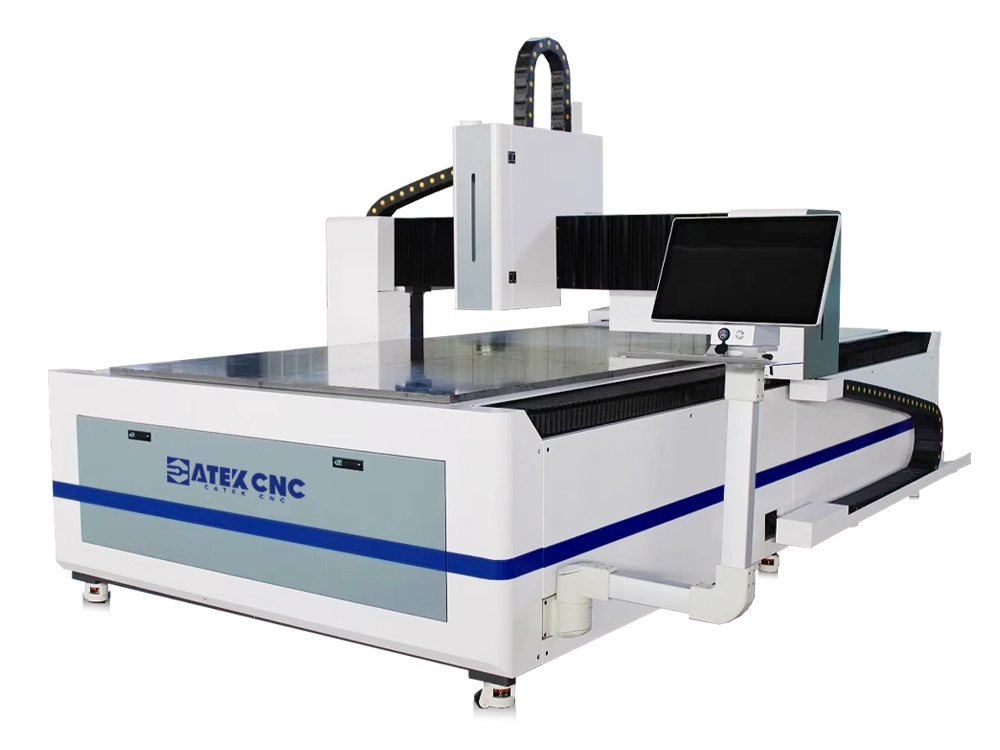

4x8 Fiber Laser Engraver for LED Smart Mirror

4x8 feet Mirror-Specific Fiber Laser Etching Machine

[Function Description]

Fiber laser mirror marking or fiber laser mirror etching machine (also called fiber laser mirror blasting machine), using galvanometer-based fiber laser technology, is designed for fine engraving and marking of mirror surfaces. This equipment features high precision and non-contact processing capabilities, meeting the complex and refined technical requirements of LED smart mirrors. It can not only perform marking or small-scale drilling on mirrors or glass but also remove silver coatings or paint through stripping or etching, restoring the mirror to a transparent state. This enables the mirror surface to incorporate touch-sensitive buttons, decorative patterns, and functional markings (such as temperature control, light switches, etc.), giving the mirror integrated display and interactive functionalities. The processing is characterized by precise stripping, no residue or burrs, and exceptionally high-quality results.

During the mirror processing, the laser marking machine can replace traditional chemical etching and film engraving processes, ensuring a pollution-free operation throughout. Compared to conventional processing methods, laser etching offers higher precision, faster efficiency, and simpler operation, allowing for the completion of more complex tasks in a shorter time.

Features of 4x8 Large Format Fiber Laser Mirror Engraving Machine

- Industrial-grade high-quality laser, supports one-time completion of white marking, black marking, deep engraving, mirror paint stripping, frosted surface, and drilling on metal materials.

- High-precision marking, using high-precision galvanometer-type marking head, ensures fine marking effect and repeatable processing, with high depth, smoothness, positioning accuracy, and fineness.

- Using high-speed quartz galvanometer, the scanning speed of the galvanometer can reach 8000mm/s, and the engraving of a 1200mm ultra-large mirror surface takes less than 2 minutes.

- Large-format marking, for graphics with a size of 300*2000mm, can be completed in one marking, without seams. For a ring with a width of 30mm and an outer diameter of 1000mm, one circular motion can complete the process, with fast processing speed.

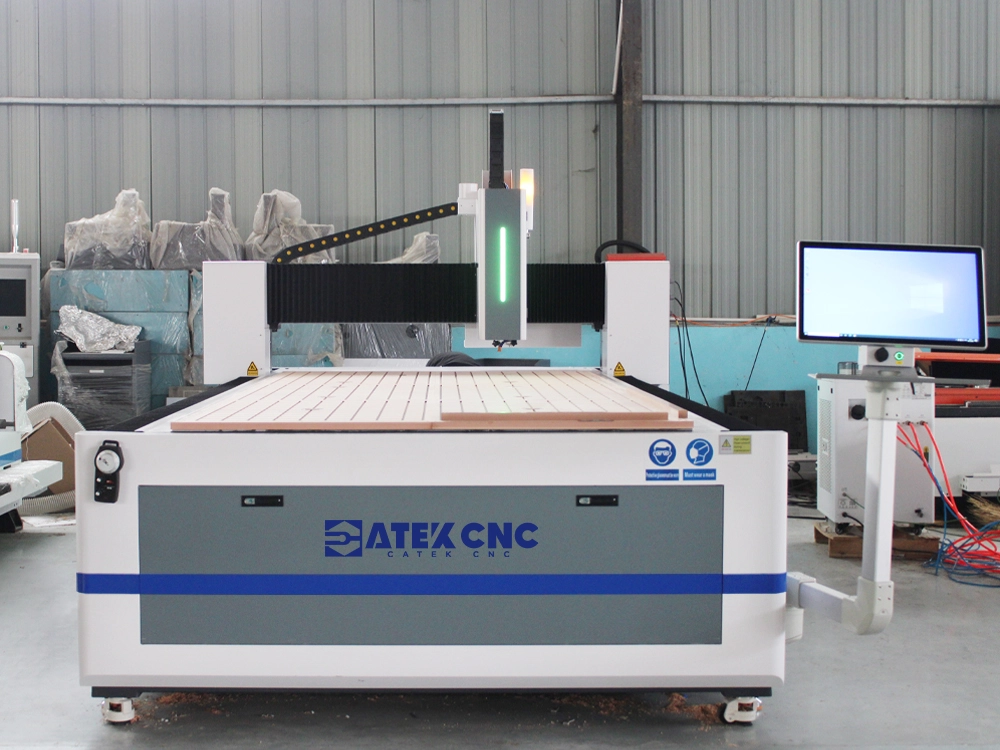

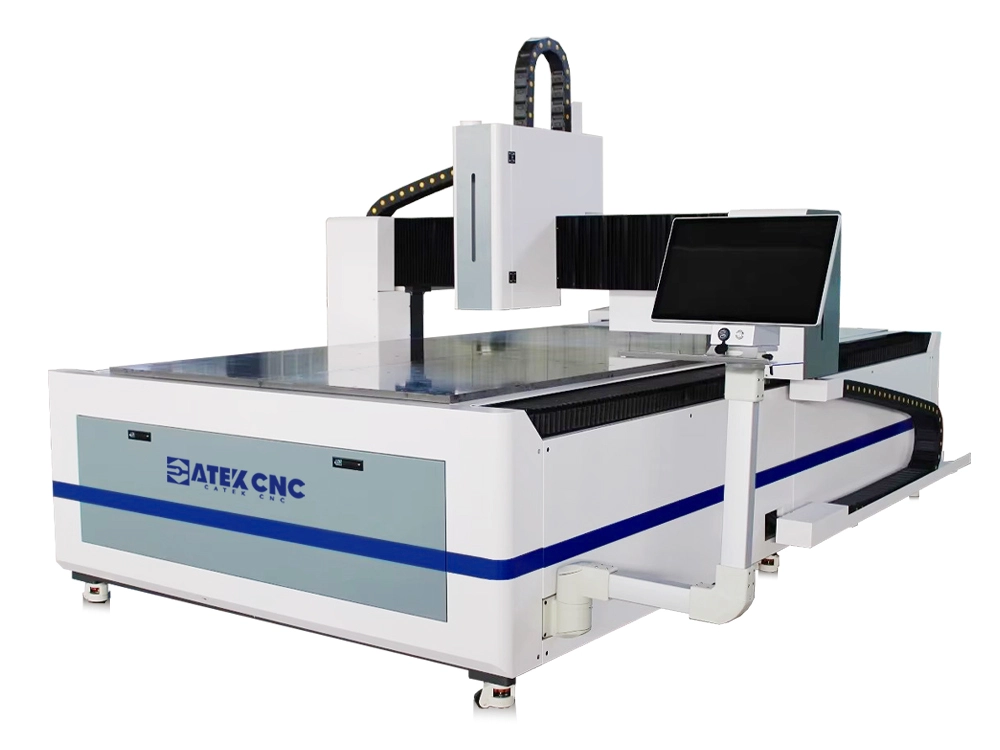

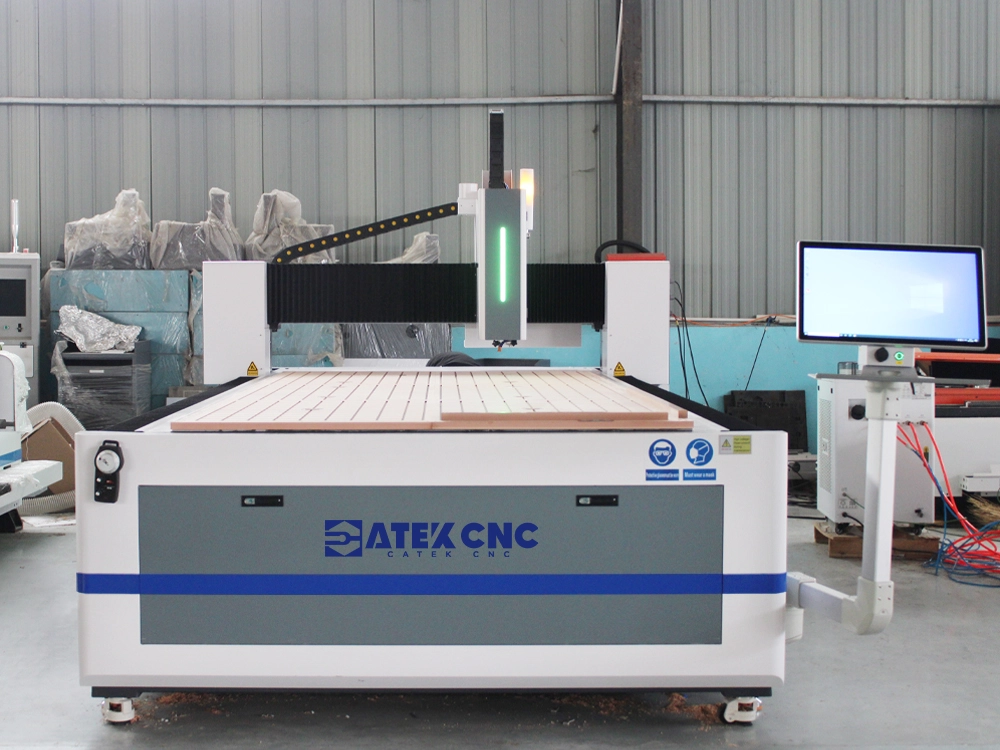

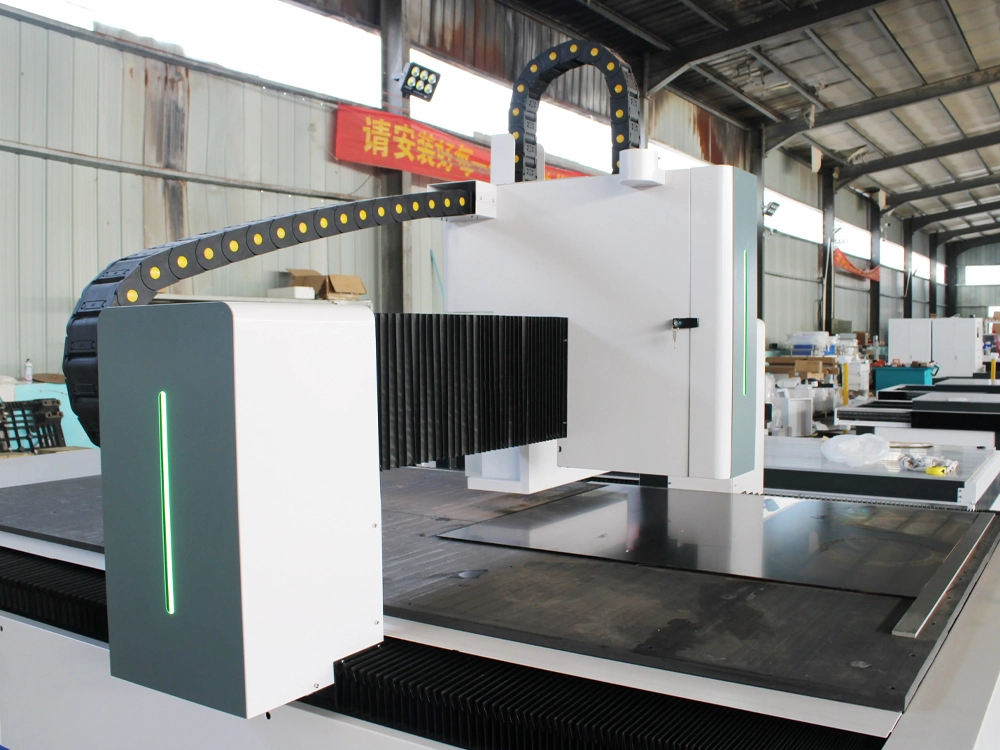

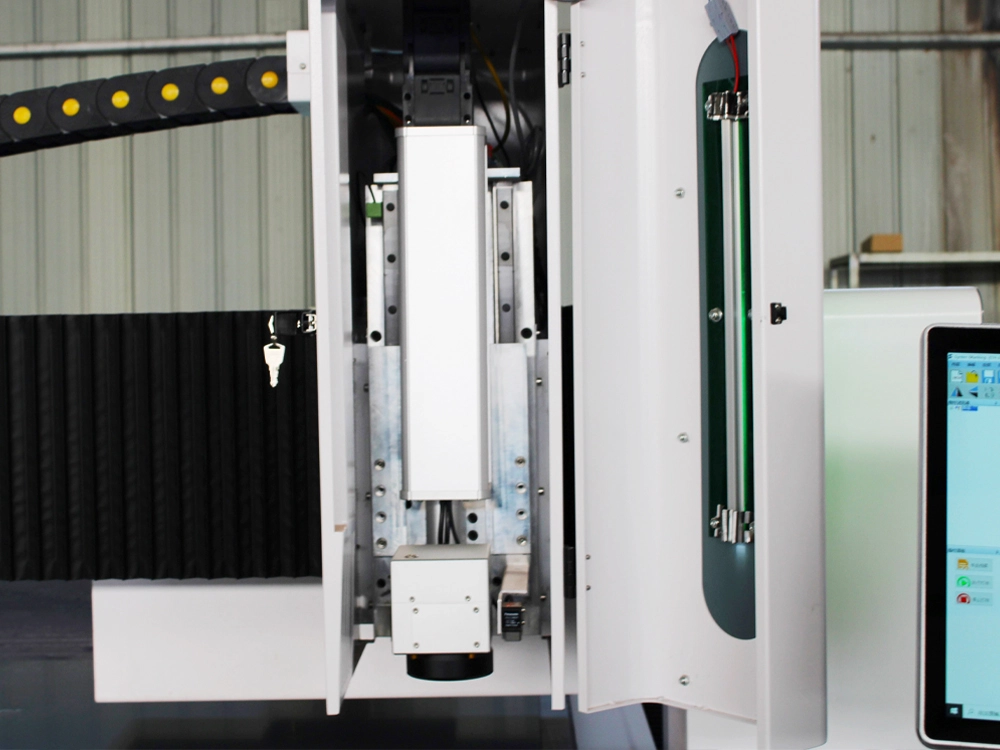

- Gantry structure and high-precision linear axis, heavy-duty bed base, tempered, the mounting surface and worktable are precision milled, with flatness ≤0.1mm. X, Y dual-axis linkage, during marking, the gantry beam drives the marking head to move, marking while moving, achieving seamless laser marking.

- Supports ultra-fine line width (minimum 0.02mm), can engrave personalized text, patterns, or brand LOGO on the back of cosmetic mirrors, enhancing the product's fashion sense and added value.

- Equipped with a three-axis dynamic focusing system, can automatically adjust the focal length, maintaining spot consistency on workpiece surfaces at different distances, with better processing quality and effect.

- Special control system for mirror laser blasting engraving machine, simple operation, supports multiple file formats, compatible with various CAD type software and Illustrator, CorelDRAW, etc.

- No chemical etching or film is required, non-contact processing, no consumables, no waste smoke or exhaust gas during processing, and complies with EU ROHS environmental certification

Details of Laser Mirror Marking Engraving Machine

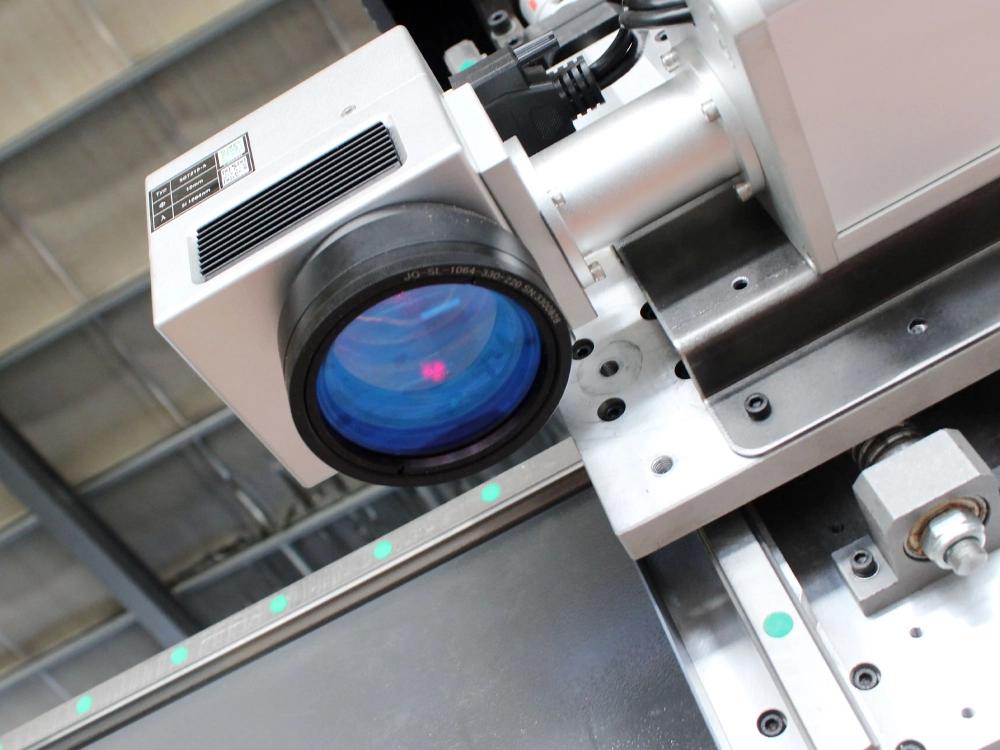

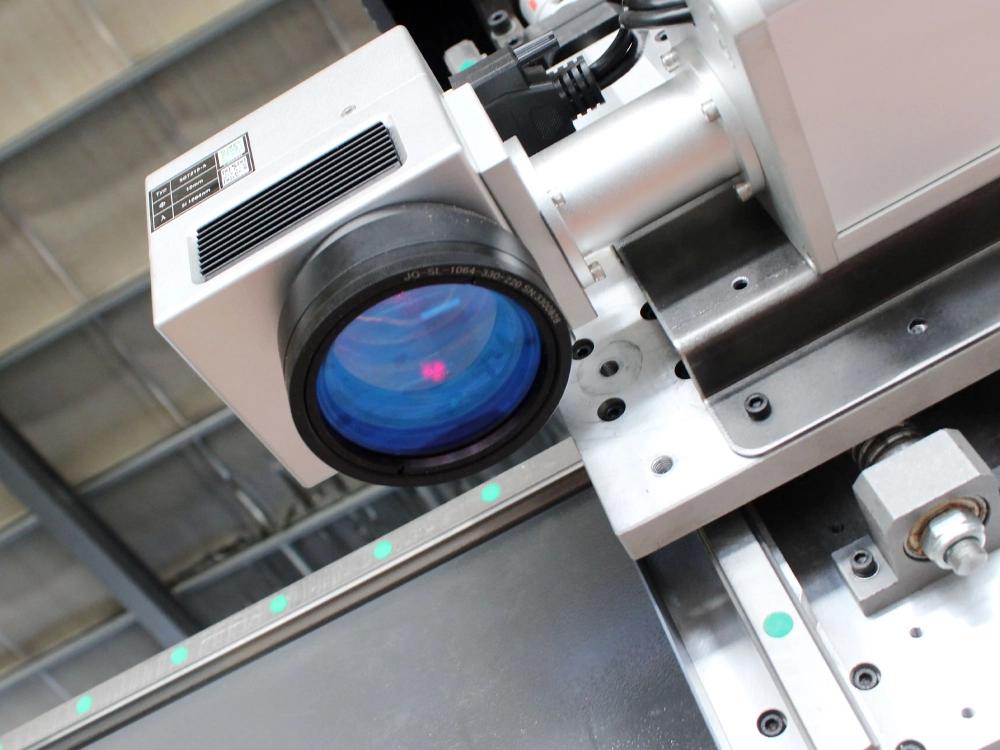

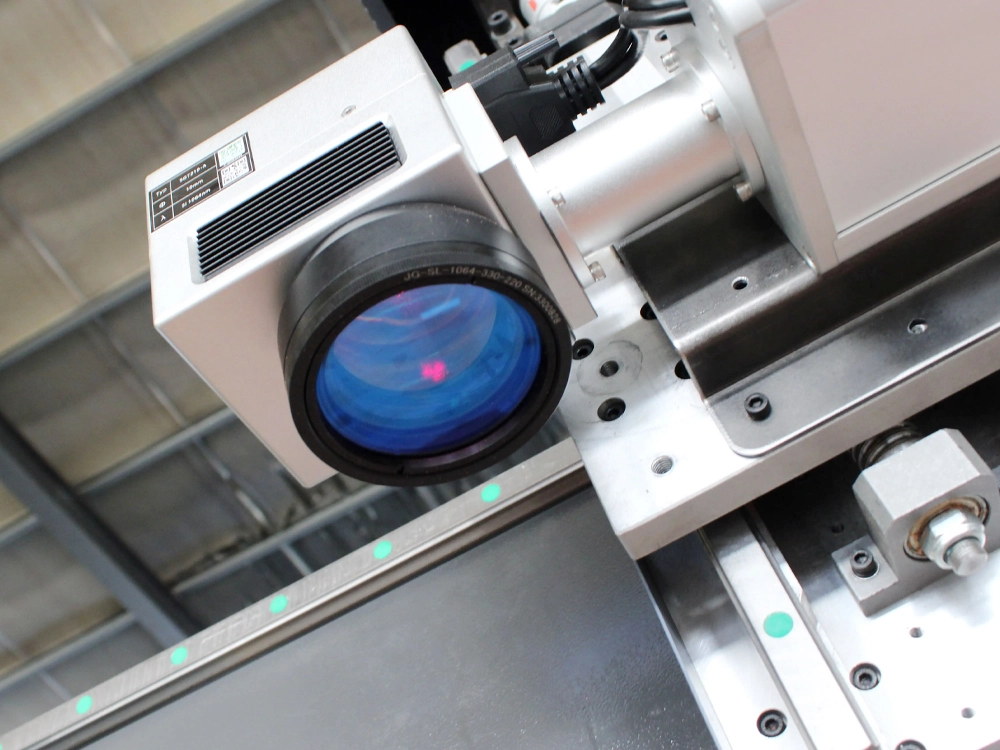

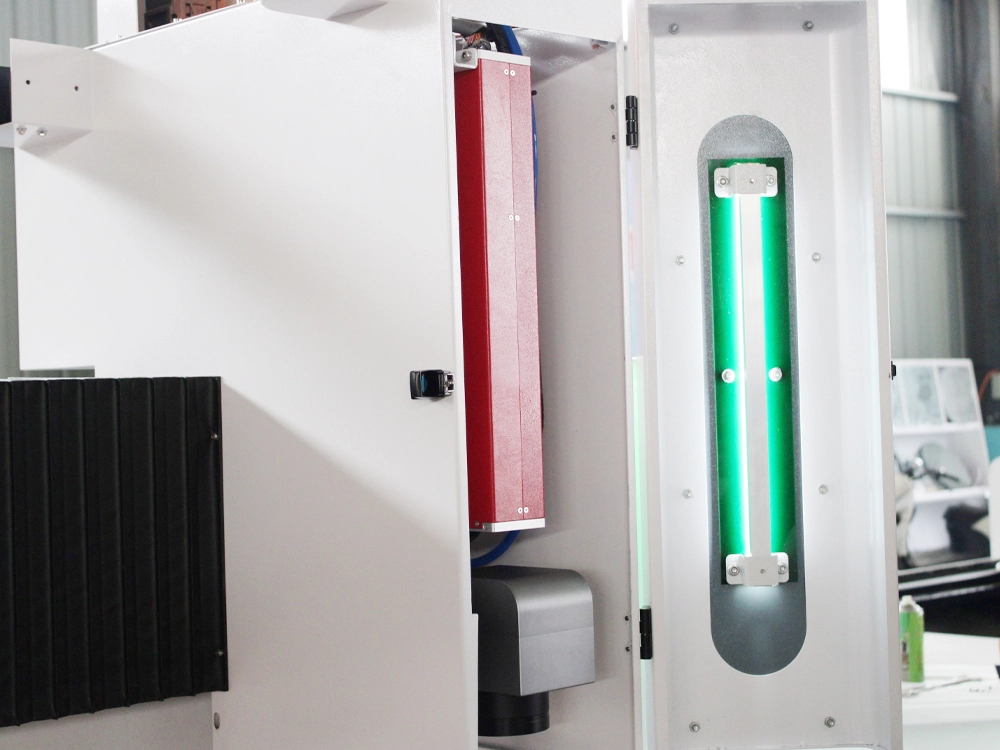

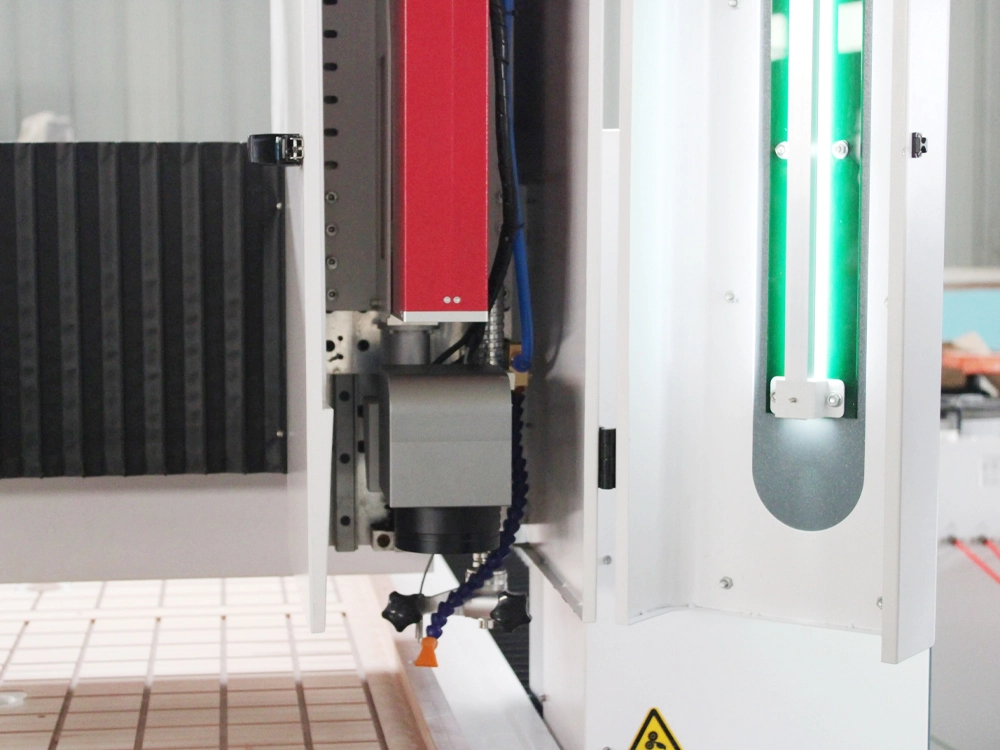

- Galvanometer scanner

High-speed Sino Galvo digital galvanometer, fast scanning speed, high precision.

- Field lens

JGZ telecentric f-theta lens, it can make the principal ray of the focused beam perpendicular to the focal plane at any angle and effectively reduce distortion in the focal point and drilling angle.

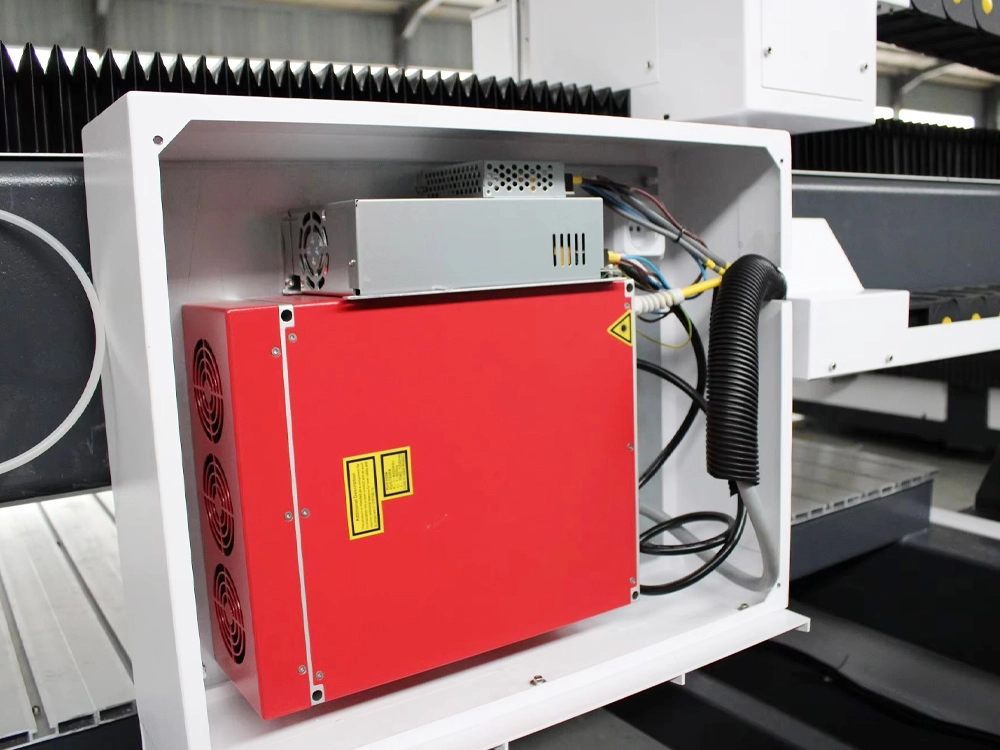

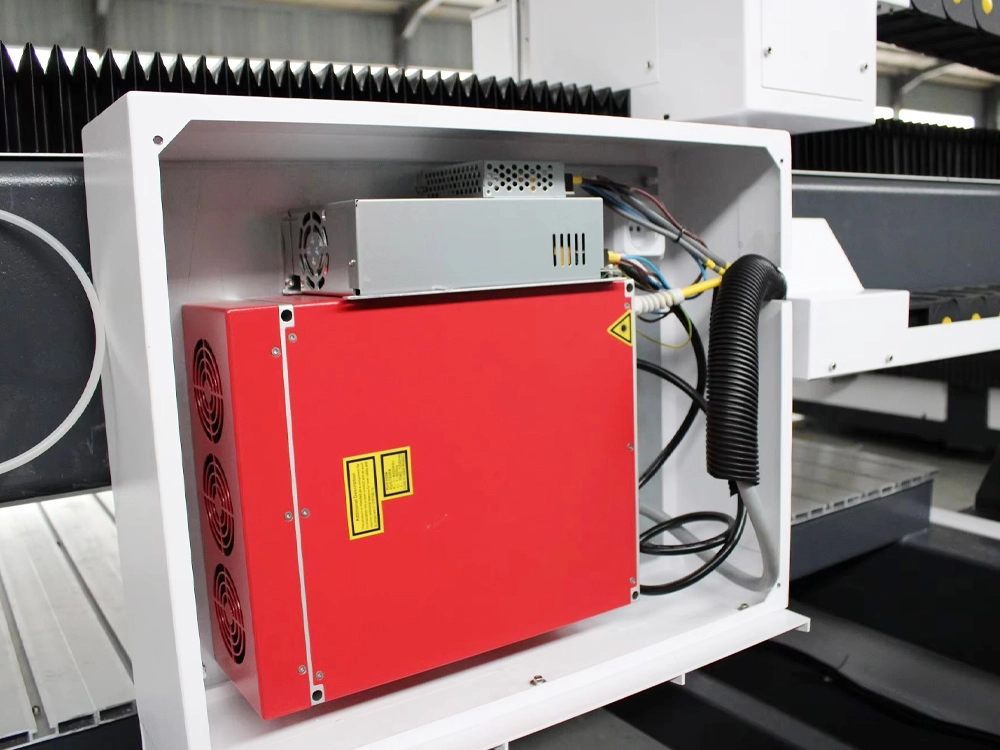

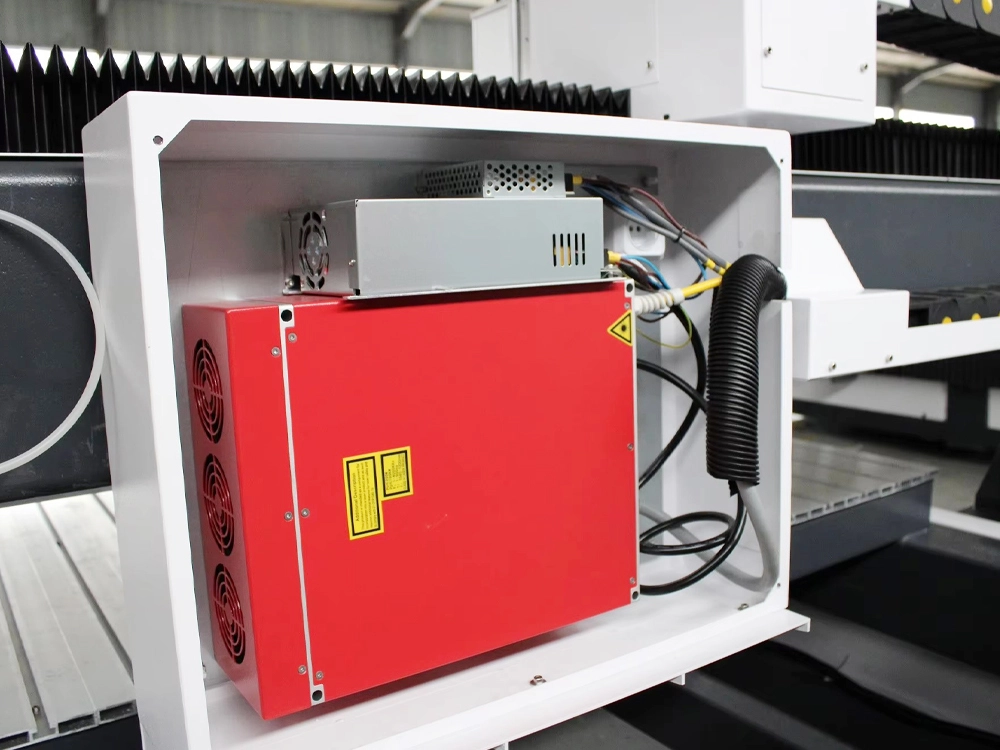

- Laser source

JPT MOPA fiber laser source, it is recognized in the industry for its good stability and marking accuracy.

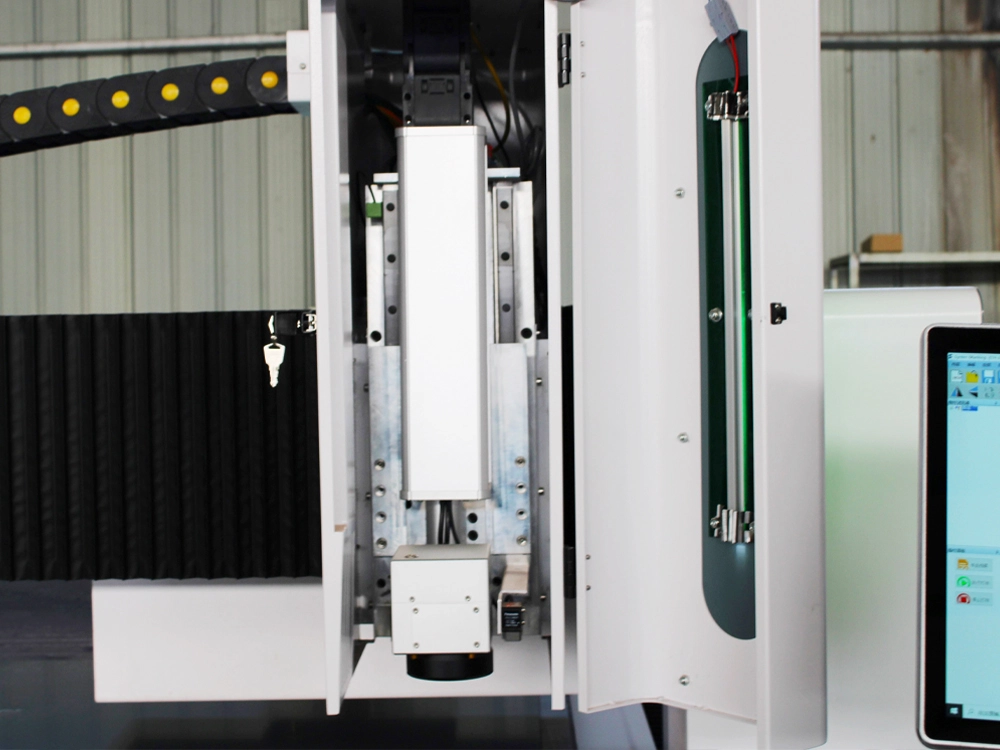

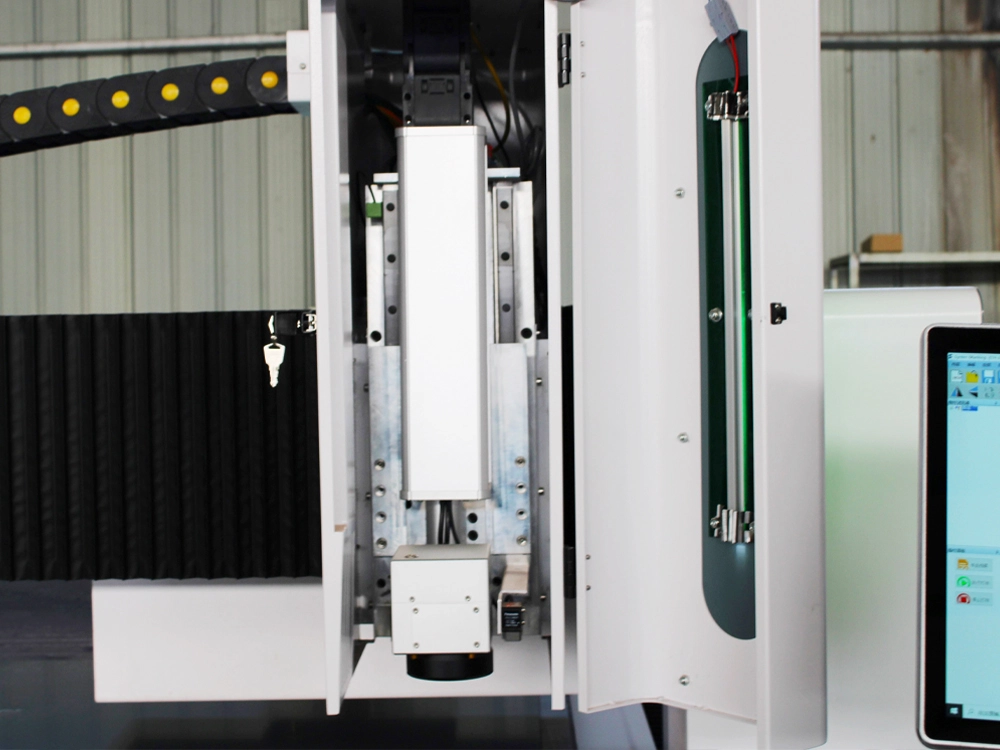

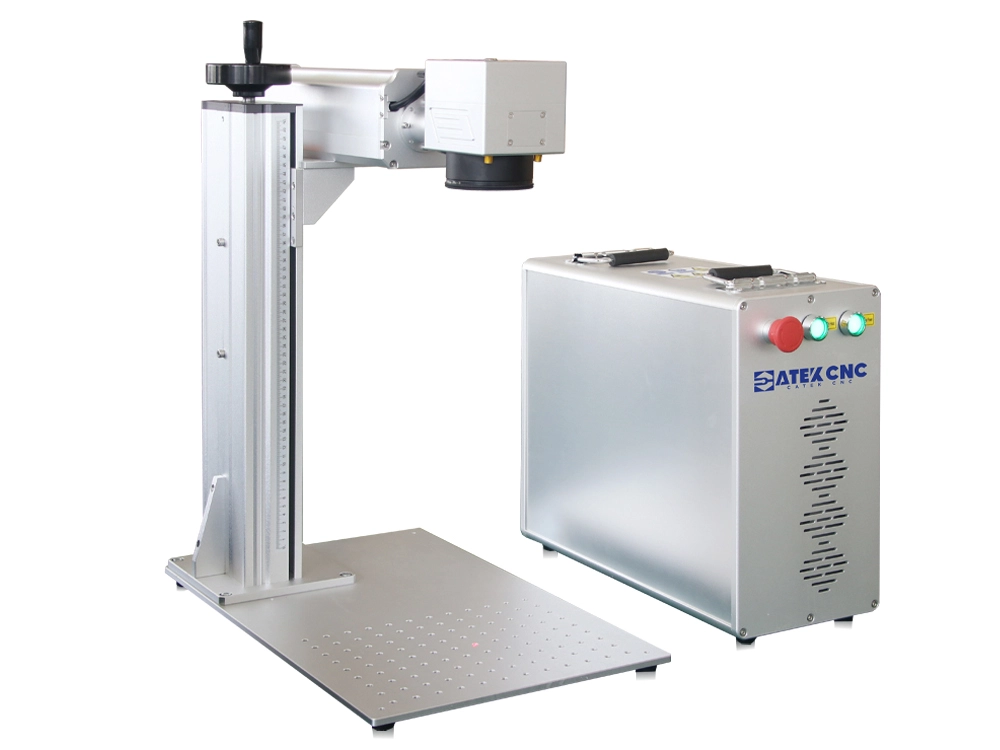

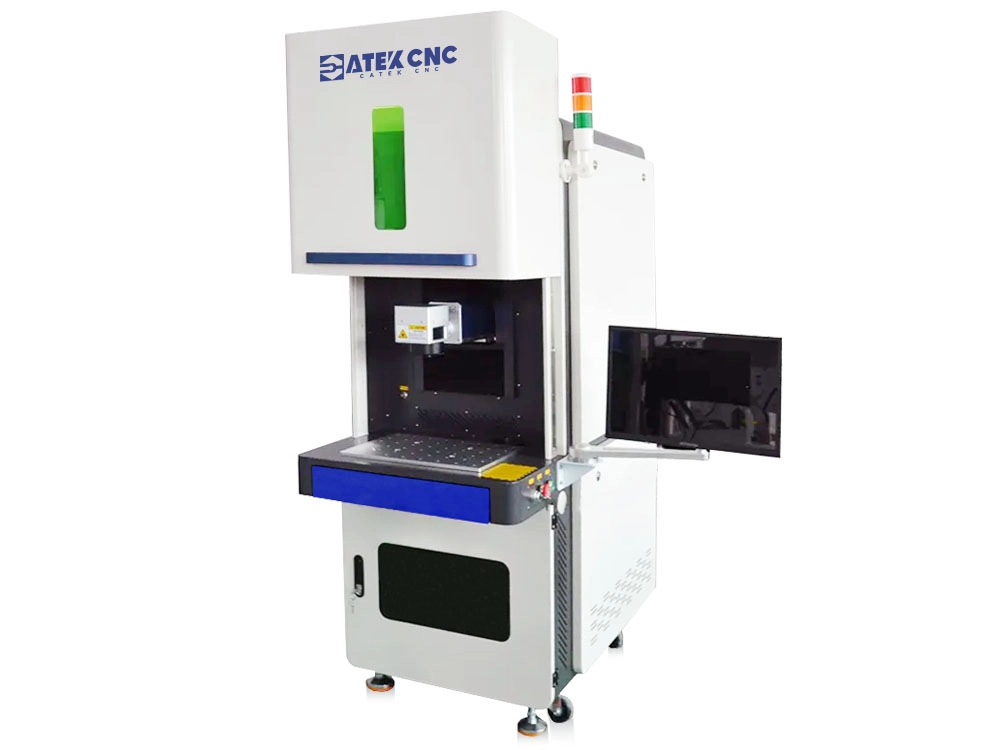

- Closed design

The electronic components and laser heads of the entire machine are protected by dust covers or metal enclosures to prevent damage from harsh environments and reduce the harm caused by laser scattering to the human body.

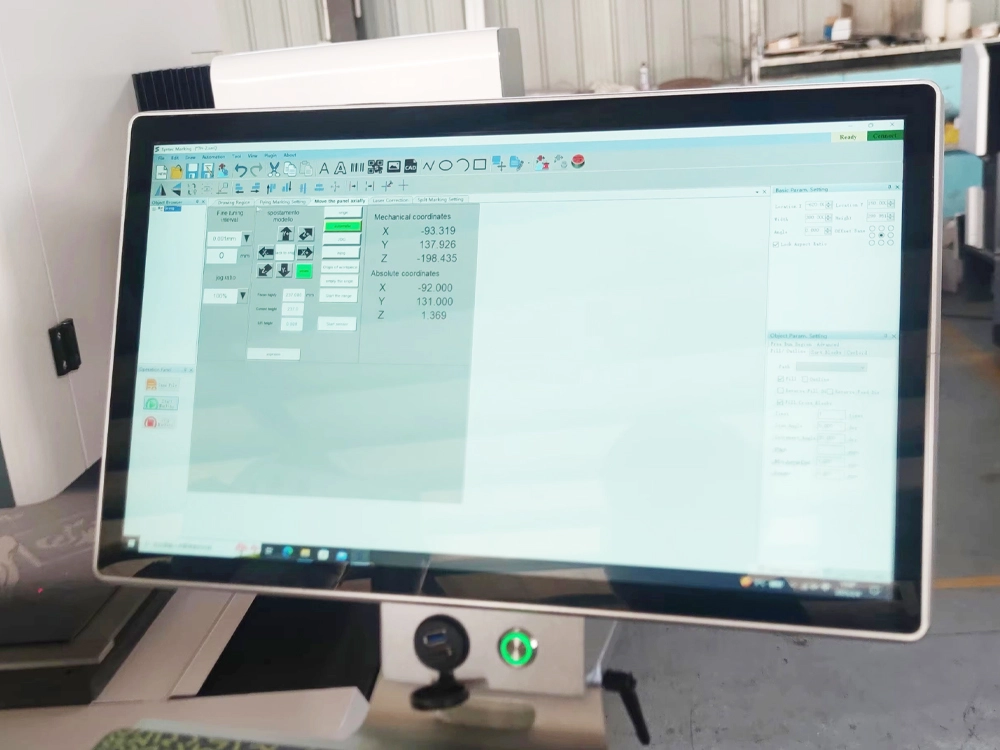

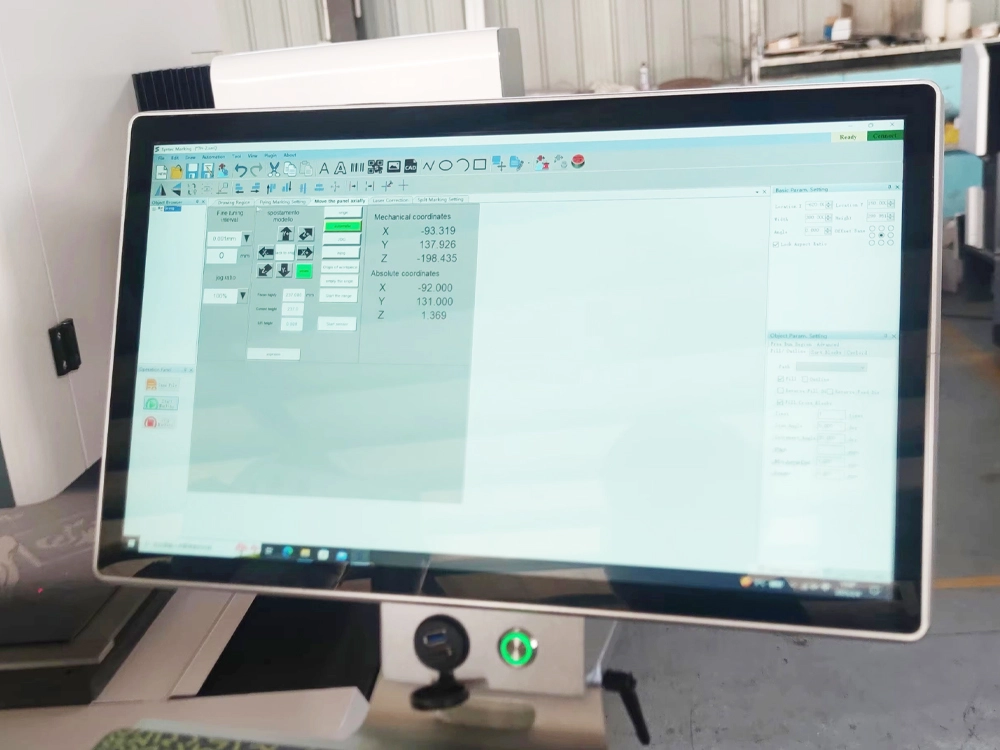

- Control panel

Large LCD monitor for precise control of machining process.

The monitor stand integrates frequently used functions such as the master switch, emergency stop button, and USB ports for user convenience.

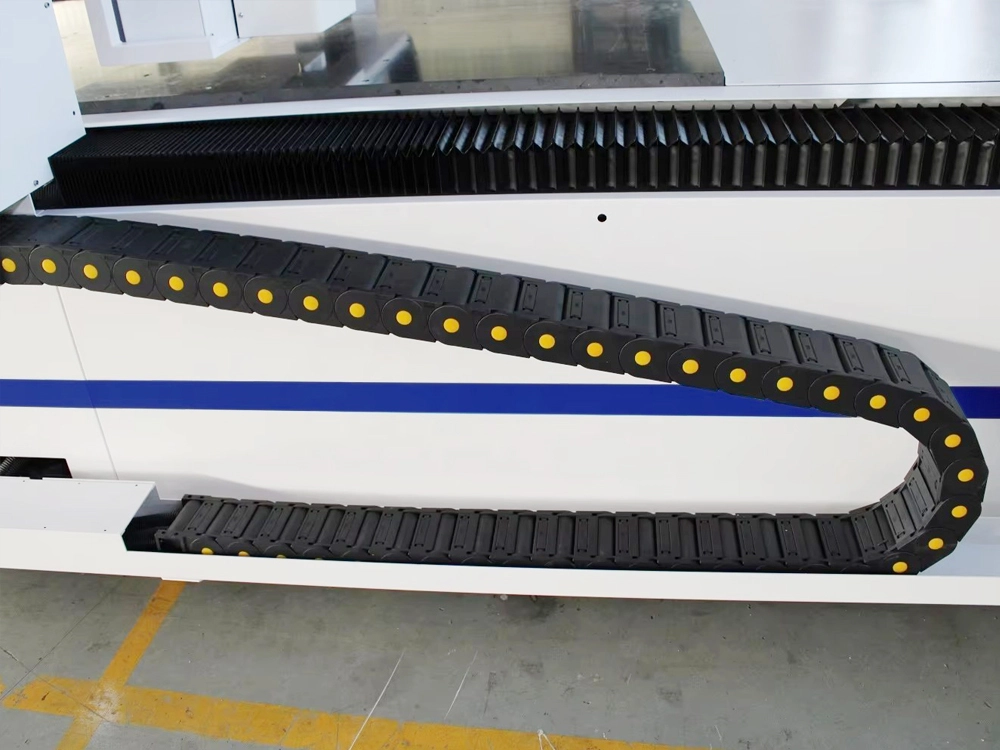

- Drag chains

Flame-retardant tank chains made of nylon are used to organize cables.

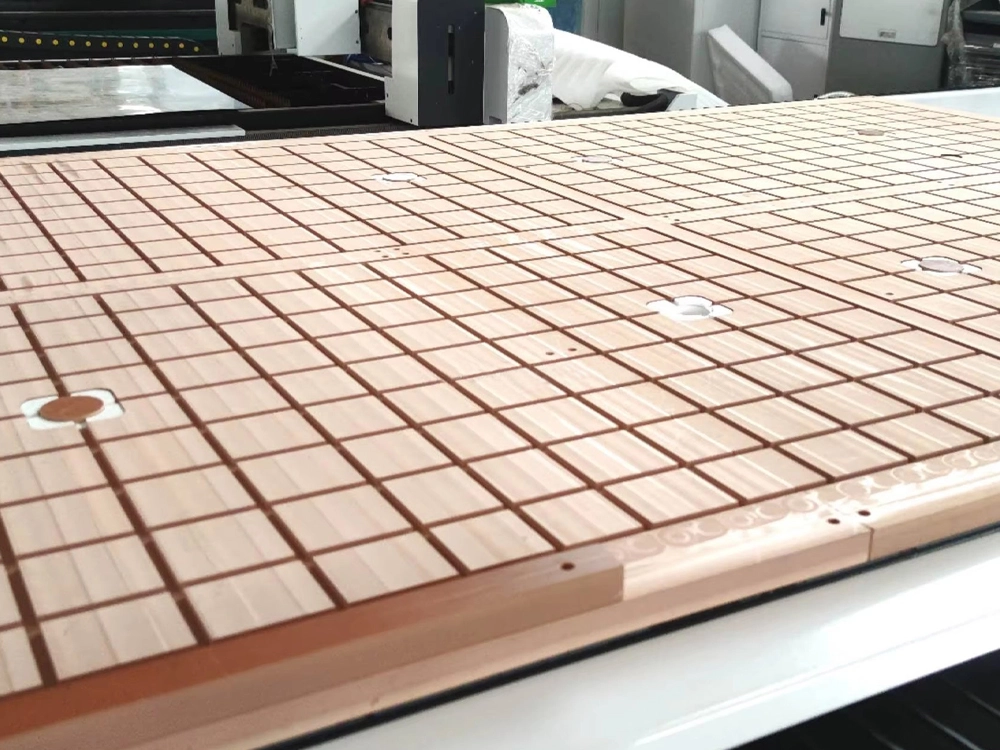

- Workbench

Made of high density PVC board. (flatness ≤ ± 0.40 mm/m).

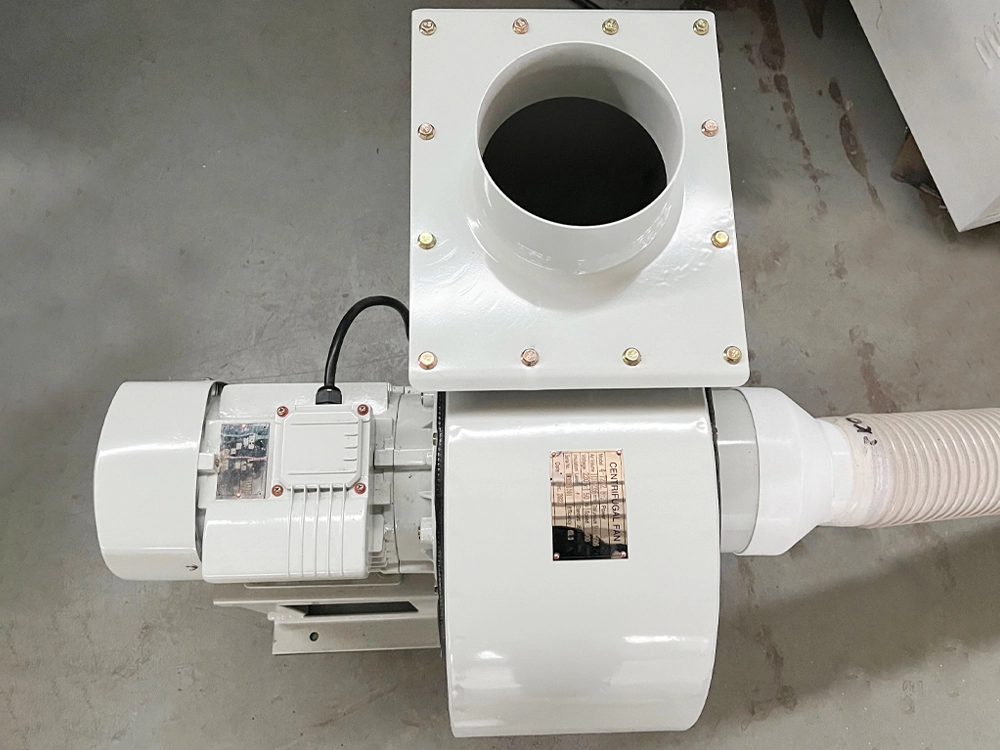

- Water ring air pump

The air pump can be connected to a dust collection device to suction away material debris and smoke generated during processing.

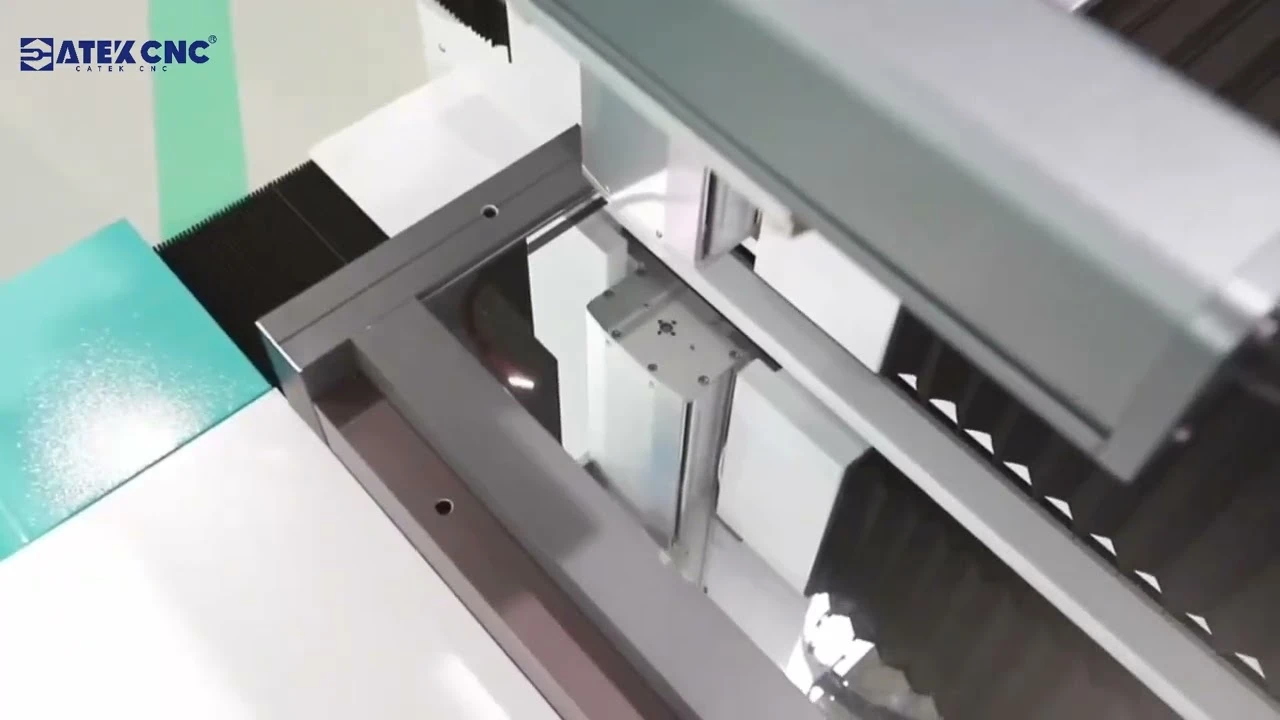

- Transmission system

Taiwan CSK linear slides, linear bearings, high-precision helical racks, and gears.

The Syntec servo motor can very precisely control the stroke, speed, and torque.

- Cooling system

The low-power machines are equipped with air coolers, while the high-power ones are equipped with water coolers.

- Cleaning system

The machine is equipped with a cleaning system that uses nozzles to blow out compressed air during processing to remove debris and smoke.

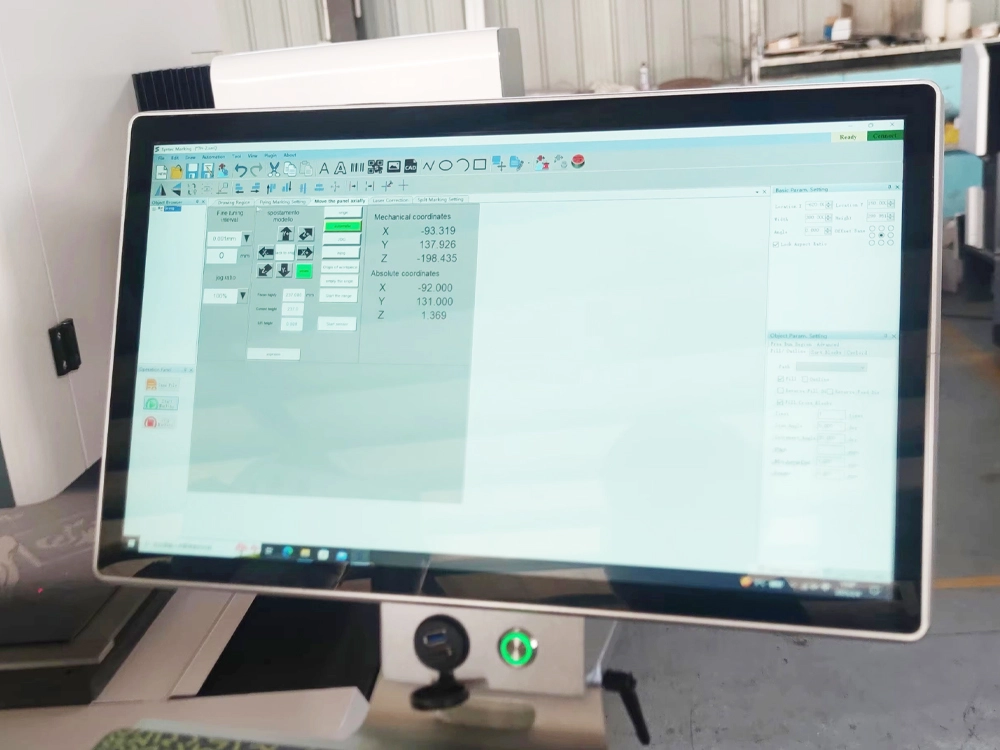

- Control software

Taiwan Syntec professional laser control system, compatible with AUTO CAD and other drawing software; with automatic correction function to ensure scanning accuracy. specially for large size splice marking. It will divide the marking file equalization with the 200mm*200mm, after first area etching, the machine will continue to etch the next marking area automatically.

Technical Parameters of 4x8 Fiber Laser Mirror Marking Machine

| Model | CK-1325-F |

| Working Area | 1300mm*2500mm (processing size can be customized) |

| Bed Frame | Thickened square tube welding bed, integrated control |

| Driving Mode | Leadshine servo motor/Syntec servo motor |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Electrical Components | Schneider/Delixi |

| Cooling | Air cooling |

| Control System | JCZ/Syntec |

| Maintenance System | Daily cleaning, lubricating with engine oil |

| Laser Generator | JPT |

| Laser Power | 100W/120W/200W |

| Laser Wavelength | 1064nm |

| Pulse Width | 2-500ns |

| Frequency Regulation Range | 1-4000kHz |

| Maximum Single Pulse Energy | 1.5mJ |

| Output Beam Diameter | 7±0.5mm |

| Power Range | 0-100% |

| Marking Speed | ≤10000mm/s |

| Focus | Autofocus |

| Anti-High Reflection | Yes |

| Supported Graphics Formats | Dxf, plt, dwg, etc. |

| Operating Voltage | Single item:two phase(220V),1.5-2KWH per hour;Vacuum pump:three phases(380V) |

| Total Power | 1.8kw |

| Working Temperature Range | 0-40℃ |

| Storage Temperature Range | -10-60℃ |

| Laser Lifetime | >100000 hours |

| Weight | 1300kg |

| Dimensions | 4000*2100*1800mm |

Efficiency Table of Glass Drilling for 200W Mirror Marking Machine

| Glass Thickness (mm) | 2 | 5 | 10 |

|---|---|---|---|

| Drilling Diameter (mm) | Drilling Time (s) | ||

| 0.3 | 0.8 | 1.1 | 3.4 |

| 10 | 1.0 | 1.6 | 3.3 |

| 20 | 1.8 | 2.4 | 6.7 |

| 30 | 2.8 | 4.8 | 11.5 |

| 40 | 4.7 | 6.8 | 15.9 |

| 50 | 5.5 | 8.6 | 20.0 |

| 60 | 9.1 | 13.3 | 23.0 |

| 70 | 13.2 | 16.0 | 29.0 |

| 80 | 22.7 | 27.0 | 40.0 |

| 100 | 30.4 | 43.0 | 81.0 |

| 120 | 39.0 | 80.0 | / |

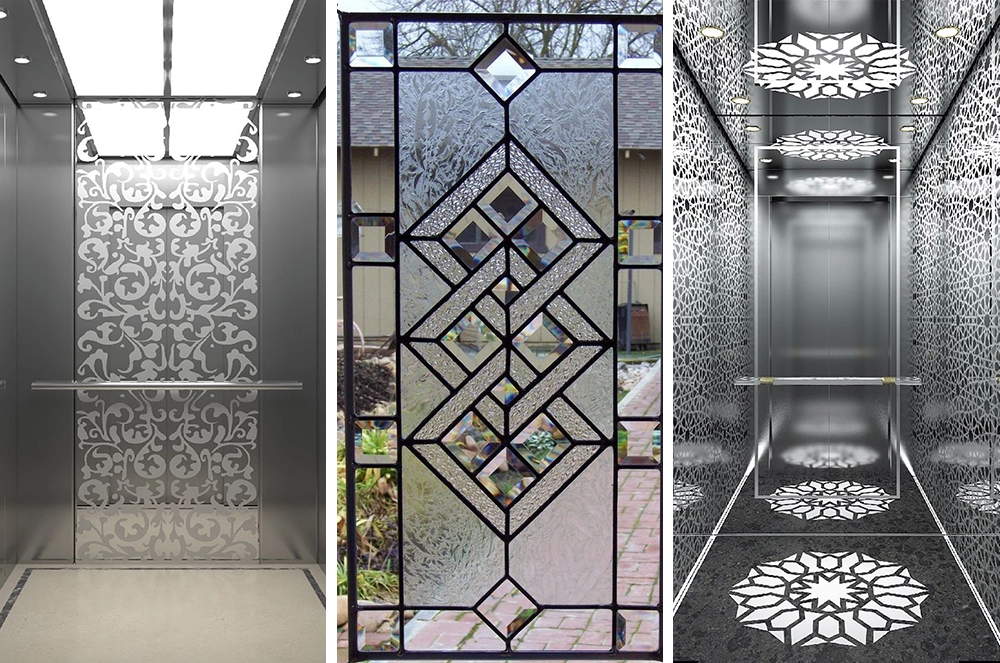

Application of Fiber Laser Mirror Marking Machine

Widely applied in industries such as automotive, advertising, sanitary ware, and elevator industries that require large-scale marking and engraving.

Glass, stainless steel, aluminum plates, wooden boards, yoga mats, electronic products, elevator stainless steel doors, elevator wall panels, etc.

Smart home mirrors, touch-controlled bathroom mirrors, smart dressing mirrors, engraved makeup mirrors, wedding gift mirrors, LED smart mirrors, layered mirrors, abyss mirrors, smart bathroom mirrors, dressing mirrors, car rearview mirrors, glass walls, fitness mirrors, AR dressing mirrors, hotel art mirror walls, fire escape mirror signs, temporary stage decorative mirrors.

Mirror processing cases

Elevator processing cases

Compared with traditional processes, the use of mirror laser marking machines to process LED smart mirrors and elevator stainless steel guard plates has more obvious advantages.

| The process of making smart mirrors using old processes | The process of processing LED smart mirrors using fiber laser engraving machines |

|---|---|

|

|

| The operation is cumbersome, the labor cost is high, the precision is low, the consumables are many, and frequent maintenance is required, which pollutes the environment and is harmful to the human body. | Simple and safe operation, high processing precision, no consumables, and no manual operation. |

| The process of making stainless steel corrosion using old technology | The process of processing elevator stainless steel doors using fiber laser engraving machine |

|---|---|

|

|

| The operation is complicated, the labor cost is high, the processing precision is low, the consumables are many, there is pollution, and it is unsafe. | The processing speed is fast, the efficiency is high, the operation is safe, there is no consumables, and the processing quality is high. |

| Model | CK-1325-F |

|---|---|

| Working Area | 1300mm*2500mm (processing size can be customized) |

| Bed Frame | Thickened square tube welding bed, integrated control |

| Driving Mode | Leadshine servo motor/Syntec servo motor |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Electrical Components | Schneider/Delixi |

| Cooling | Air cooling |

| Control System | JCZ /Syntec |

| Maintenance System | Daily cleaning, lubricating with engine oil |

| Laser Generator | JPT |

| Laser Power | 100W/120W/200W |

| Laser Wavelength | 1064nm |

| Pulse Width | 2-500ns |

| Frequency Regulation Range | 1-4000kHz |

| Maximum Single Pulse Energy | 1.5mJ |

| Output Beam Diameter | 7±0.5mm |

| Power Range | 0-100% |

| Marking Speed | ≤10000mm/s |

| Focus | Autofocus |

| Anti-High Reflection | Yes |

| Supported Graphics Formats | Dxf, plt, dwg, etc. |

| Operating Voltage | Single item:two phase(220V),1.5-2KWH per hour;Vacuum pump:three phases(380V) |

| Total Power | 1.8kw |

| Working Temperature Range | 0-40℃ |

| Storage Temperature Range | -10-60℃ |

| Laser Lifetime | >100000 hours |

| Weight | 1300kg |

| Dimensions | 4000*2100*1800mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.