What is a spire?

Follow me to learn what a spire is.

Flagship Customized Mode | Explore a New Chapter of CNC Wood Lathe

What is a spire?

Follow me to learn what a spire is.

Standard configuration is also the top configuration

7 advantages

to help you understand the secrets of the spire

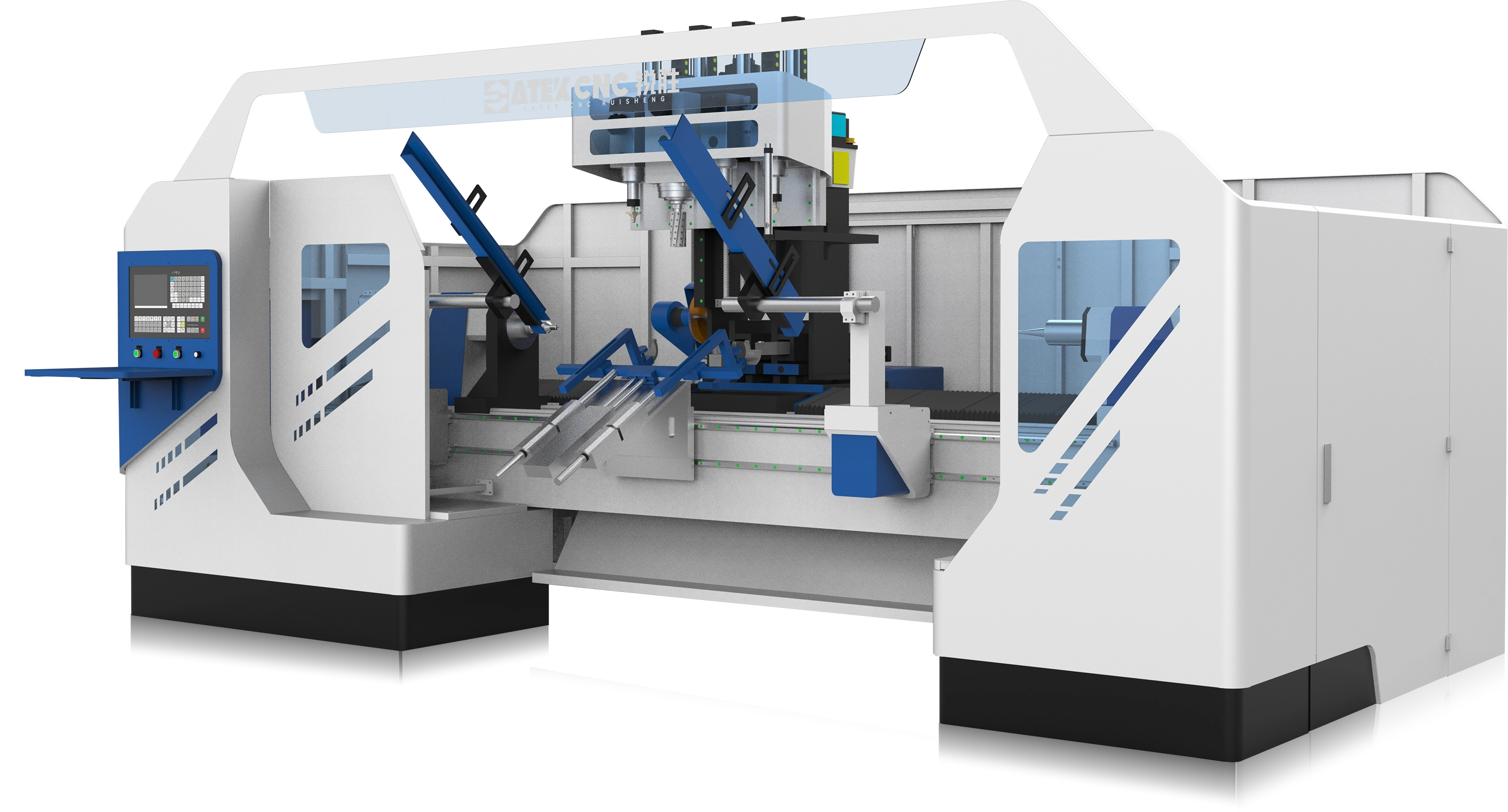

Completely subvert the traditional CNC wood lathe and change the traditional concept of woodworking processing.

The Spire series CNC wood lathes feature top-tier configurations and optimized mechanical designs, enabling faster operation and significantly improved processing efficiency.

Equipped with an automatic loading/unloading system, the machine autonomously completes the entire process from material feeding to positioning and machining, eliminating the need for manual intervention.

The machine incorporates a high-precision transmission system with repeat positioning accuracy of up to 0.02mm. Workpieces require only a single clamping to complete all processes, minimizing errors caused by repeated reclamping. This ensures higher workpiece precision, more standardized dimensions, and superior quality.

The machine utilizes a heavy-duty reinforced cast bed, premium transmission components, and drive systems, along with an automatic lubrication system, ensuring stable operation, low noise, and 24/7 continuous productivity.

7 advantages

to help you understand the secrets of the spire

Completely subvert the traditional CNC wood lathe and change the traditional concept of woodworking processing.

Multiple functions can be optionally equipped as needed. Whether turning, drilling, grooving, engraving, sanding, or saw-milling, all can be seamlessly integrated into the Spire.

A single machine meets diverse processing needs, reducing the procurement costs of multiple machines. Additionally, it minimizes workpiece reclamping, lowering time costs.

Features a fully enclosed safety housing and dust collection system, preventing dust and wood chip splatter during processing while automatically collecting waste, ensuring operator safety and a clean production environment.

Our full-spectrum machine customization covers drives, spindle, control systems, and functional configurations.

Drive

Control System

Spindle

Optional Function

Any brand, Any function,

The Spire can meet any of your needs.

Select Your Favorite

CNC SYSTEM

Here are eight common CNC systems for you to select from, all of which are perfectly adapted to the CNC wood lathe.

CATEKCNC's Self-Developed Control System features built-in macros for auto DXF/DBF-to-G-code conversion, offering user-friendly operation, and stable performance.

The LNC CNC System from Taiwan offers control fully solution supporting pulse control or fieldbus control for wood lathes, from single-process tomulti-process machining.

The SYNTEC CNC System from Taiwan, supports product lines from standard 2-axis lathes to 5-axis machining centers.

The Delta CNC System from Taiwan is equipped with a high-performance CPU. It can automatically optimize machining trajectories and speed planning, effectively improving the overall machining speed and thereby saving labor and time costs.

Japan's Fanuc CNC System is renowned for its exceptional precision control and high reliability. The 0𝑖-F Plus Series provides powerful multi-axis control capabilities and customizable functions for CNC multi-functional lathes.

The Siemens CNC System from Germany takes high integration, intelligence, and modularity as its core advantages. It supports multi-axis simultaneous machining and is suitable for various complex multi-axis CNC wood lathes.

The OSAI CNC System from Italy is widely used in various multi-functional machining centers and five-axis machines. It supports modular upgrades, as well as rapid program monitoring and axis control, thereby enhancing work efficiency.

The TPA CNC System delivers robust control performance with PC connectivity, touchscreen operation, and stable, comprehensive functionality.

In addition, if you have other brands you like, we can also customize them for you.

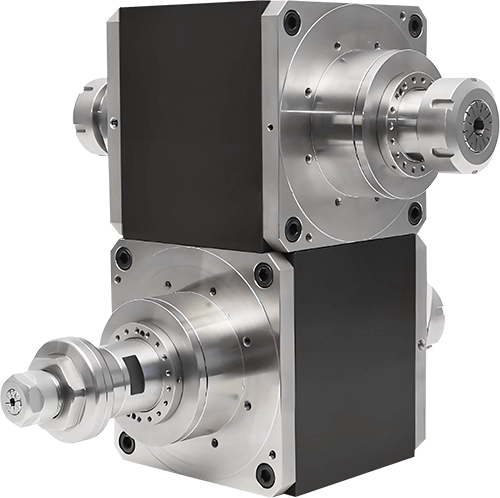

The Spire series offers multiple spindle options for your selection,

featuring HSD spindles, HITECO spindles, and Italian-branded HSD spindles,

including air-cooling spindles, ATC spindles, and planer-specific spindles, 4-head spindles, among other categories.

(Optional)

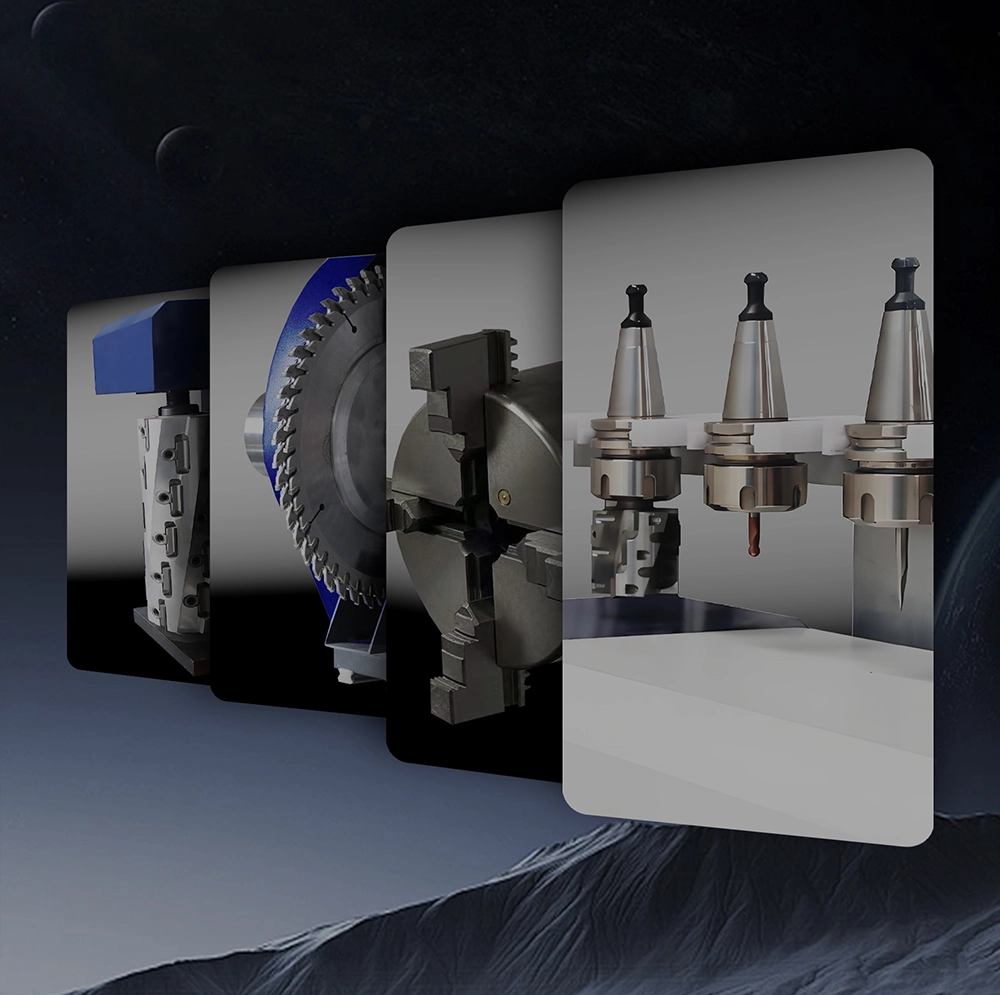

The Spire series offers multiple expandable functions for CNC wood lathes. Whatever products you process, you'll find the right features for your applications.

The ATC spindle paired with a linear tool magazine enables on-demand automatic tool replacement, making it ideal for complex machining processes that require multiple tools.

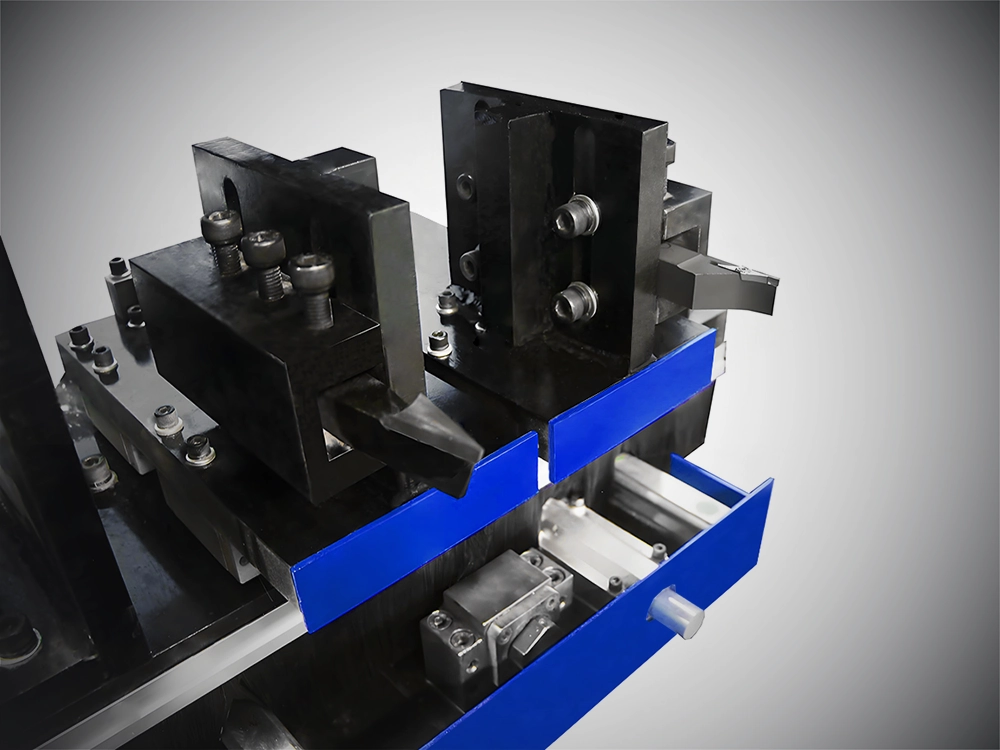

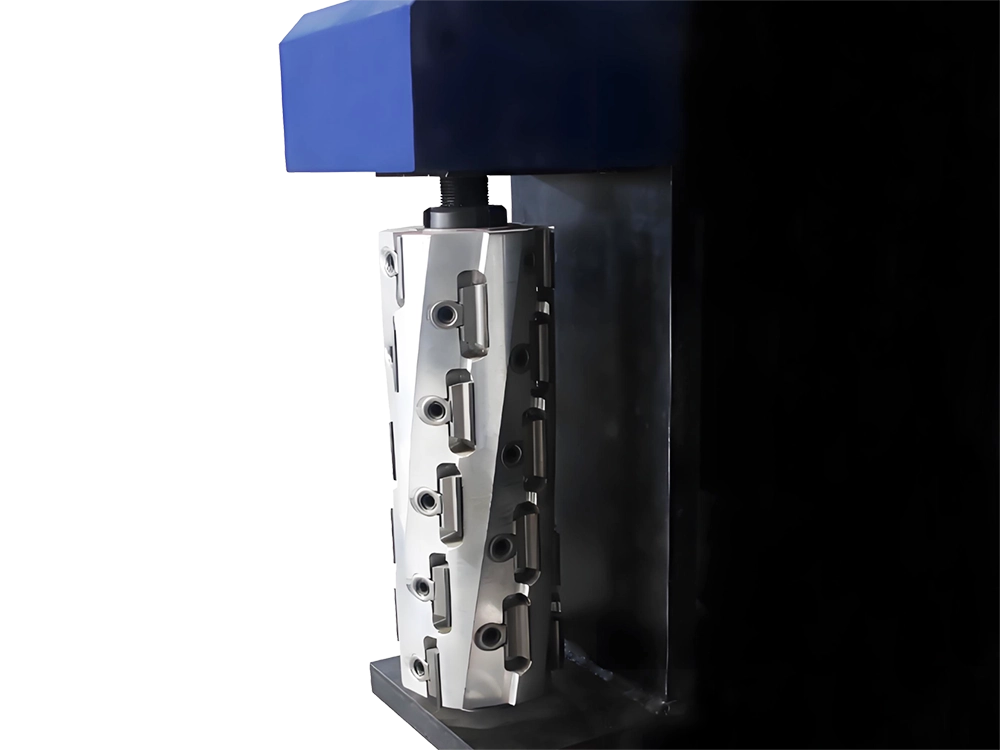

The machine can be optionally equipped with multiple turning tool station, allowing the installation of several turning tools. While these tools cannot be used concurrently, different types of tools can be switched on-demand during machining, eliminating the hassle of manual tool changes.

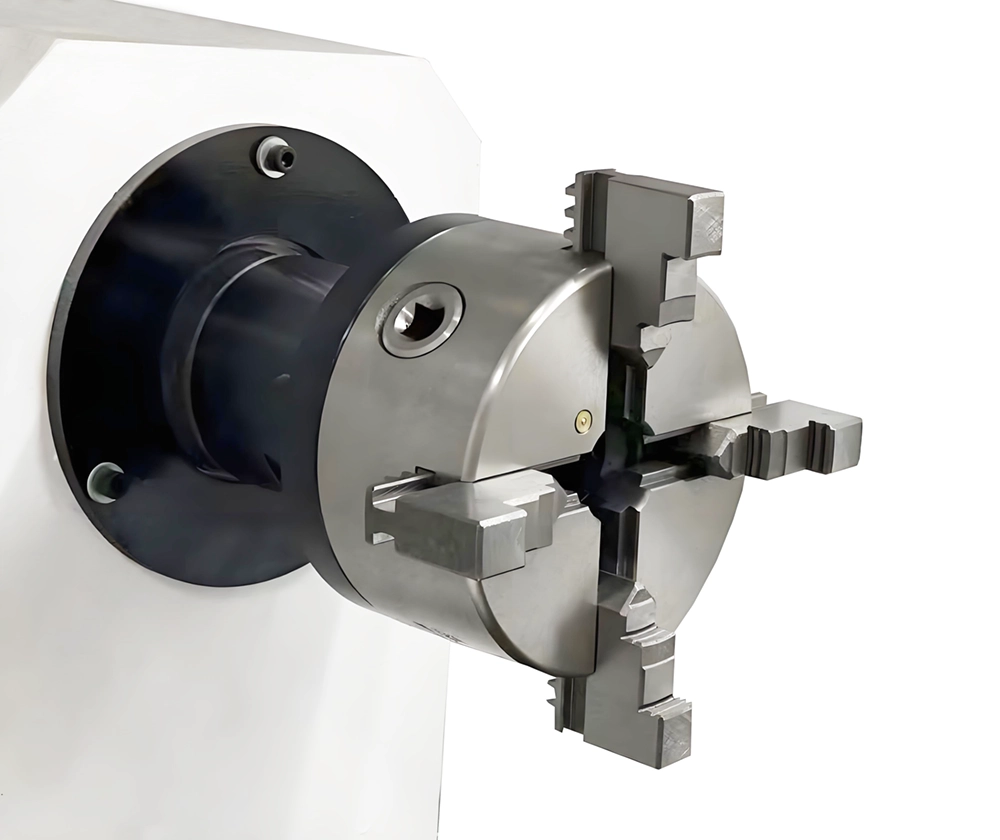

The chuck can clamp irregularly shaped workpieces or be used for machining workpiece end faces. Options include 3-jaw, 4-jaw, and 6-jaw chucks.

The sanding wheel is mounted with multiple sanding blades, utilizing whipping force generated by high-speed rotation to polish workpieces. This configuration is suitable for polishing most types of workpieces.

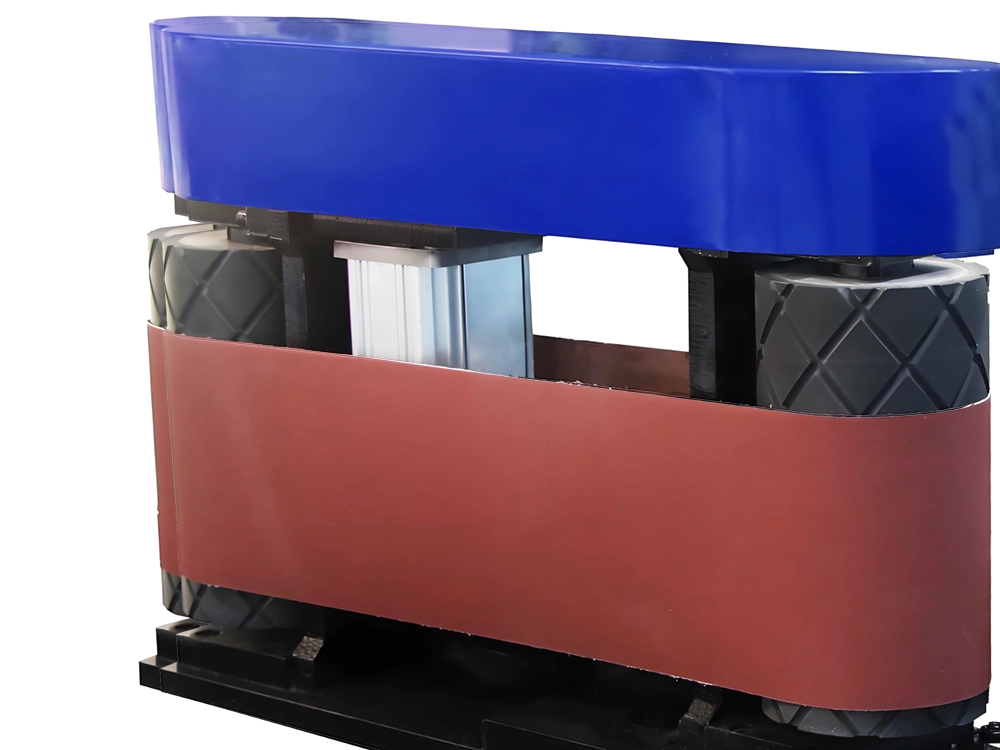

The sanding belt is a sanding device featuring a tensioned looped sanding belt. Its design maintains optimal contact with curved workpiece surfaces, making it ideal for sanding rod-shaped or spherical components.

The oscillating sanding shaft is a reciprocating sanding belt mechanism equipped with wide sanding belts. Its bidirectional sanding motion delivers superior finishing results compared to unidirectional systems.

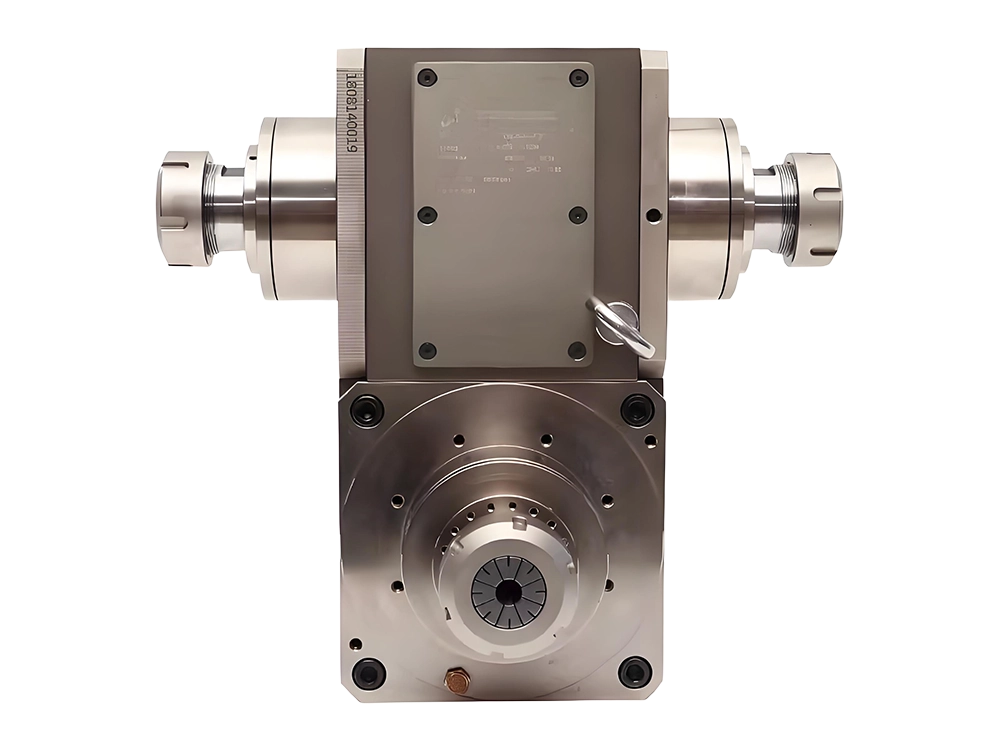

The multi-function spindle significantly expands the processing capabilities of CNC wood lathes. It can accommodate various types of spindle-mounted tools, enabling the CNC wood lathe to perform not only turning operations but also milling, drilling, planing, and other machining processes.

The spindle can be tilt-controlled at specific angles via the CNC system, enabling angular machining operations such as drilling and milling on workpiece side surfaces and inclined planes.

7.5KW integrated four-head electric spindle for five-axis machining center, capable of installing four tools, automatically rotates and switches during machining, and can perform angular machining on workpieces through indexing rotation. This spindle requires a five-axis control system (such as a LNC Control System).

The multi-blade saw offers high material removal rates and rapid processing speeds, making it ideal for rapid roughing operations or large-scale milling across extensive workpiece areas.

The large planer enables rapid workpiece planing, featuring replaceable blades for easy maintenance. Multiple planer sizes and blade densities are available.

The fixed drill bit can be mounted on the tailstock for simple drilling operations on workpiece end faces. It is easy to install, and offers flexible and convenient use.

Whether it is furniture, wardrobe, cabinet, musical instrument, or advertisement, it can handle it with ease.

|

|

|

|

|

|

|

|

|

|

|

|

We provide customization of any processing size, you can tell us your needs.

1200mm

Max. Machining Length

200mm

Max. Machining Diameter

80,000mm/min

Max. Movement Speed

18,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

2300kg

Weight

3782*2123*2200mm

Dimensions

1500mm

Max. Machining Length

300mm

Max. Machining Diameter

80,000mm/min

Max. Movement Speed

18,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

2500kg

Weight

3982*2123*2200mm

Dimensions

2000mm

Max. Machining Length

400mm

Max. Machining Diameter

80,000mm/min

Max. Movement Speed

18,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

2900kg

Weight

4482*2200*2250mm

Dimensions

2500mm

Max. Machining Length

300mm

Max. Machining Diameter

80,000mm/min

Max. Movement Speed

18,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

3300kg

Weight

4982*2123*2200mm

Dimensions

Learn more about how the CATEK Spire Series can bring you more production efficiency.