Follow me

Discover the secrets of spire

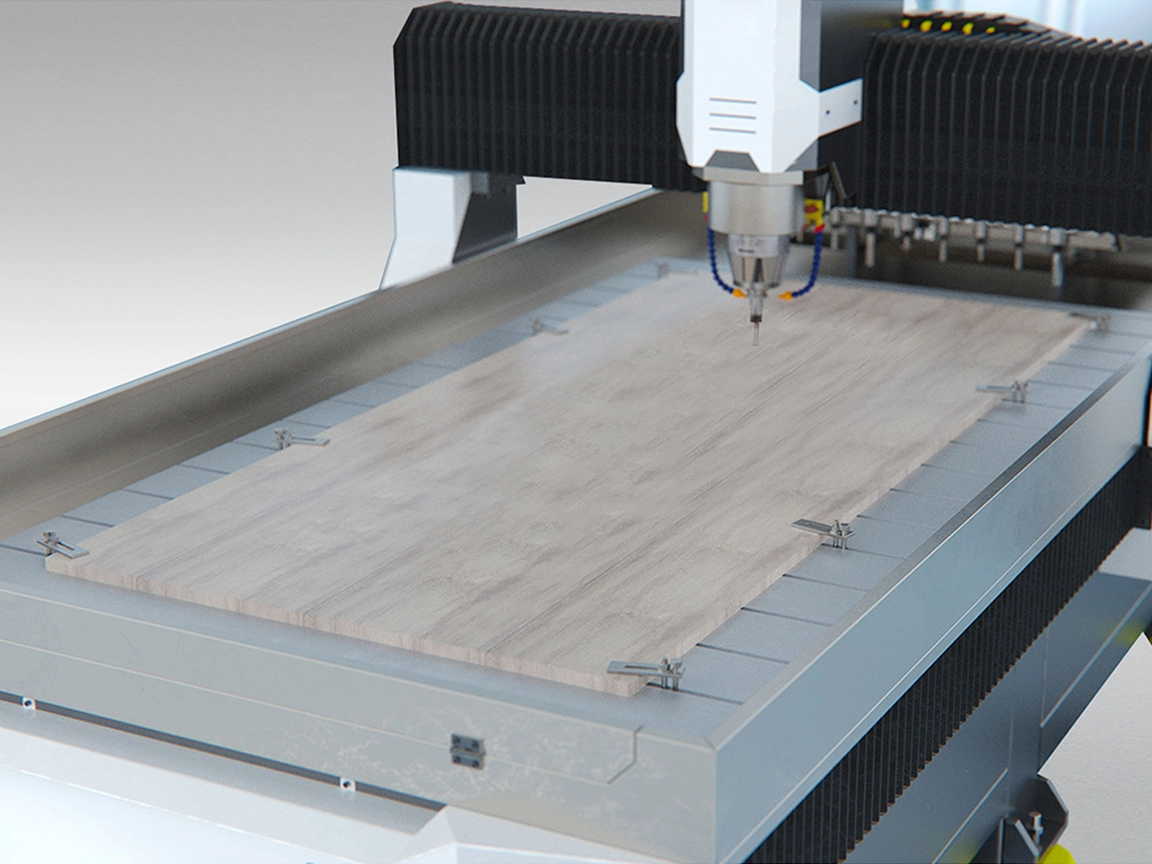

Flagship Precision Crafting | Redefining CNC Wood Router Excellence

Discover the secrets of spire

Discover the secrets of spire

Enjoy the CNC high-speed experience brought by top-level configuration

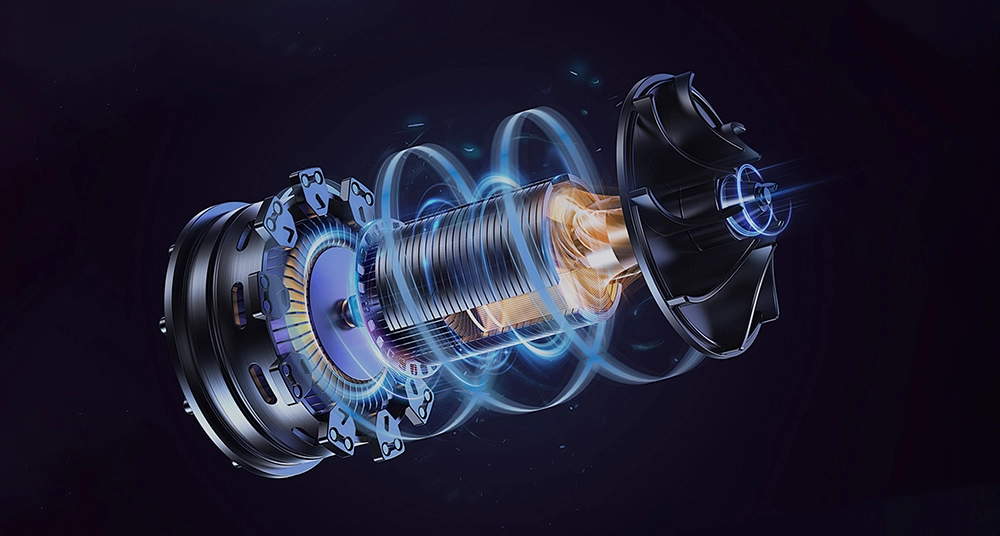

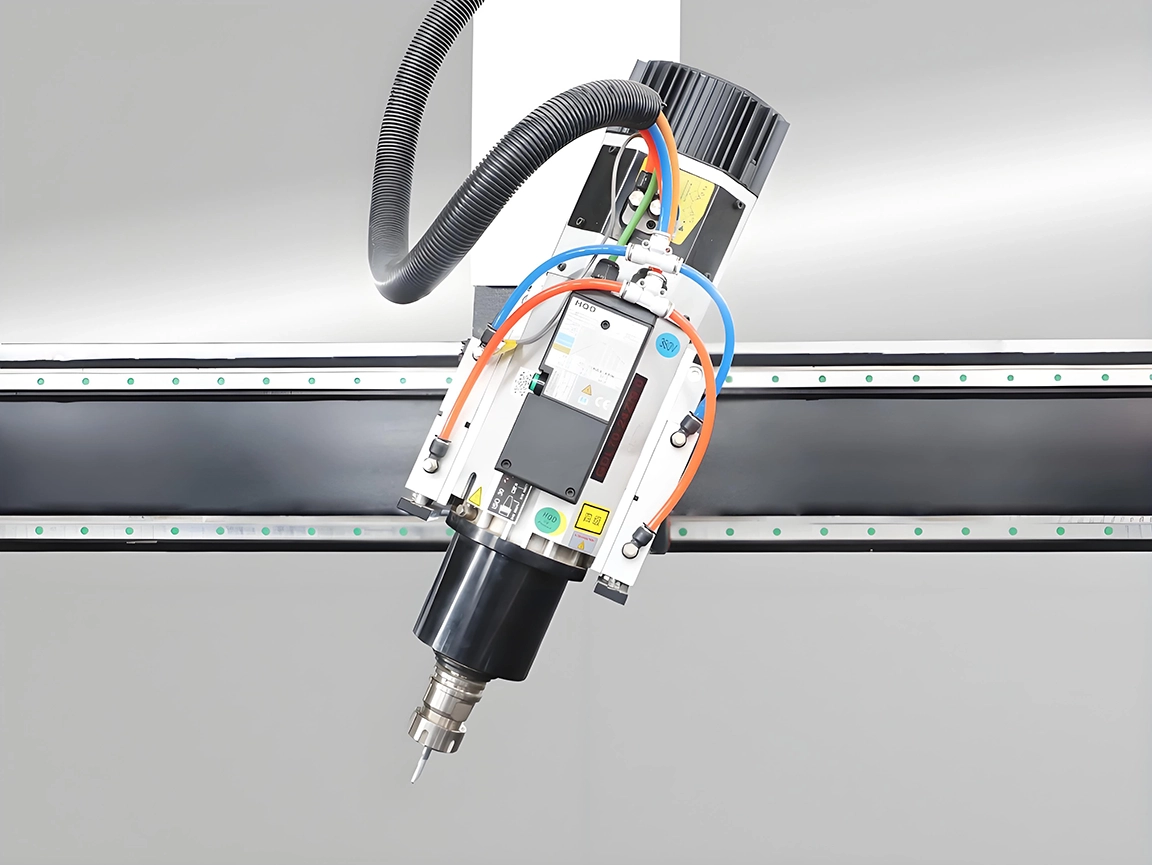

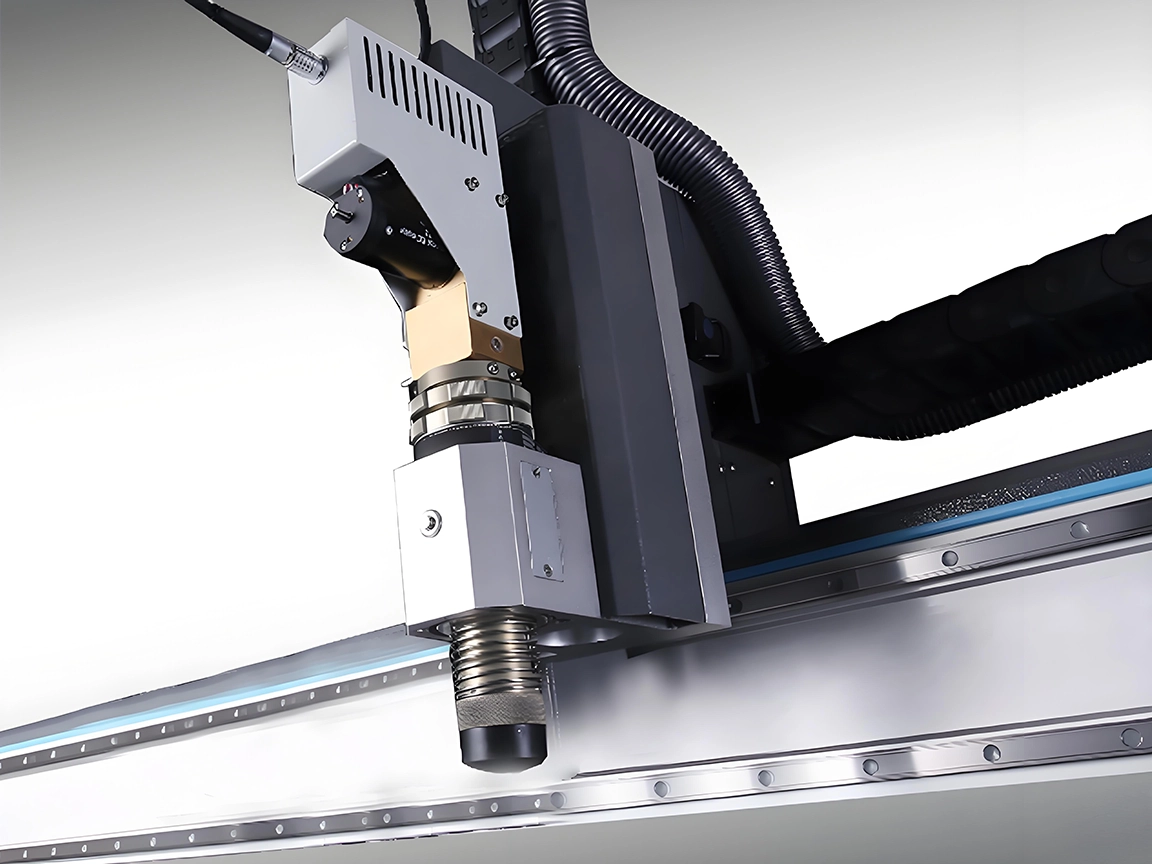

Spindle

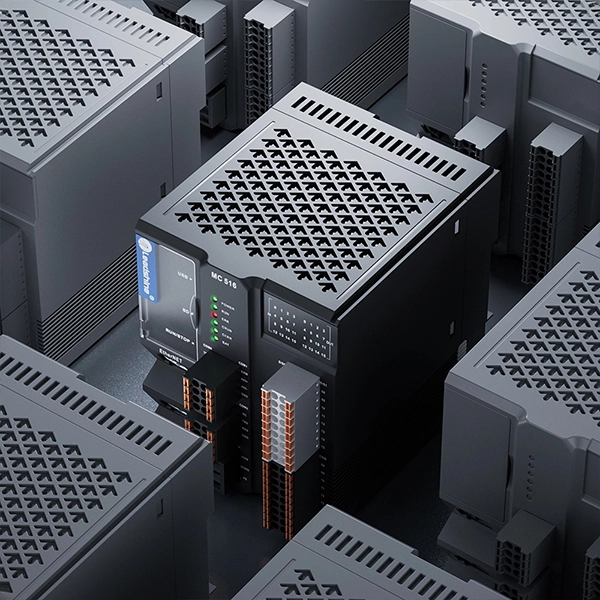

Drive

Optional Function

Control System

We offer a variety of spindle brands for selection, and the corresponding power can be customized according to your requirements.

Available spindle types include air-cooled, water-cooled, ATC, etc. Brands include HQD, HITECO, HSD, among others.

The tool holder options include ISO/HSK/BT or manual tool change spindles.

We provide a variety of well-known brand drives for you to select from.

Additionally, if you have other preferred options,

please let us know, and we can provide various customization services for you.

DSP control handle

The DSP handheld controller features high integration, supports offline operation, and offers simple and flexible control, making it suitable for various types of CNC router machines.

Syntec control system

The Taiwan's Syntec CNC system boasts powerful functionality and user-friendly operation, offering seamless compatibility with both standard CNC routers and 5-axis CNC routers.

LNC control system

The Taiwan's LNC CNC system supports various types of CNC routers, offering comprehensive expansion capabilities and intuitive operation, making it the perfect choice for high-performance CNC routers.

Weihong control system

The China's Weihong CNC system supports various CAD/CAM software, offers wide compatibility, and delivers all essential functionalities required for diverse CNC routers

Mach3 control system

The American's Mach3 CNC system features powerful multi-axis control capabilities, a user-friendly interface, and stable operation, making it exceptionally easy to master.

XDW control system

The XDW CNC system supports a variety of functional expansions, such as oscillating tool and CCD vision, featuring user-friendly operation and suitability for multi-functional CNC router machines.

Provide three appearances for you to choose.No matter which one, it perfectly interprets the aesthetics of the machine

(Optional)

The Spire series offers a variety of machining functions for CNC routers, allowing you to customize the equipment to meet all your processing needs.

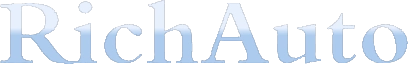

The rotary fourth axis can be used to clamp workpieces for rotation, enabling 3D machining of the workpiece's revolving surface or multiple faces.

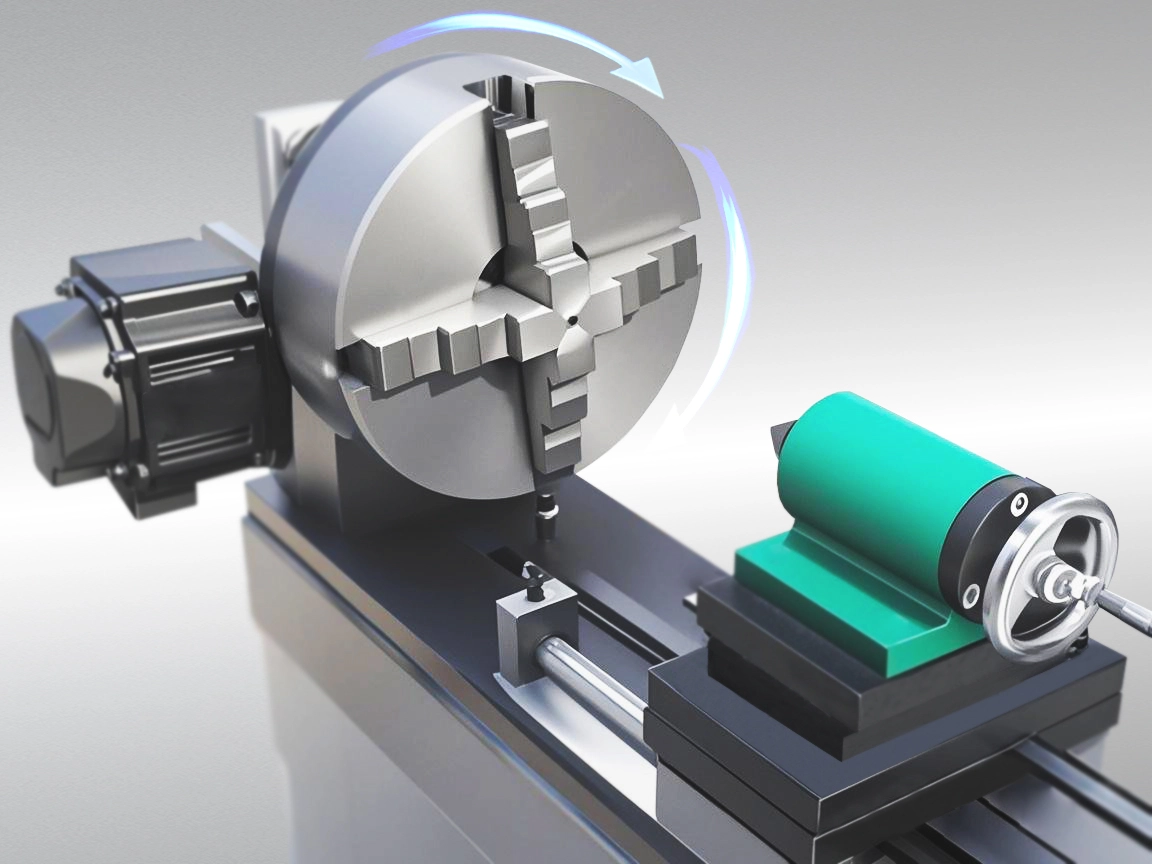

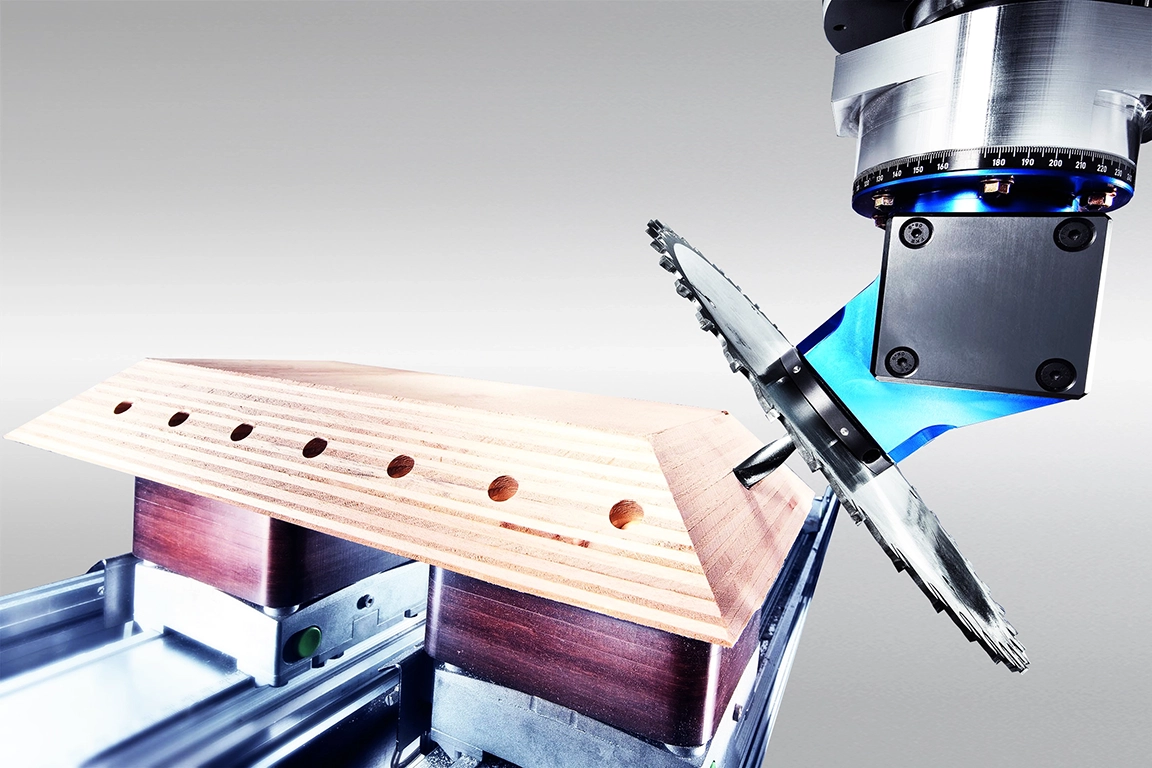

High-power saw blade cutting device can be used for cutting some multi-layer panels to improve processing efficiency. It can cut various types of boards such as solid wood boards, MDF, gypsum boards, PVC, etc.

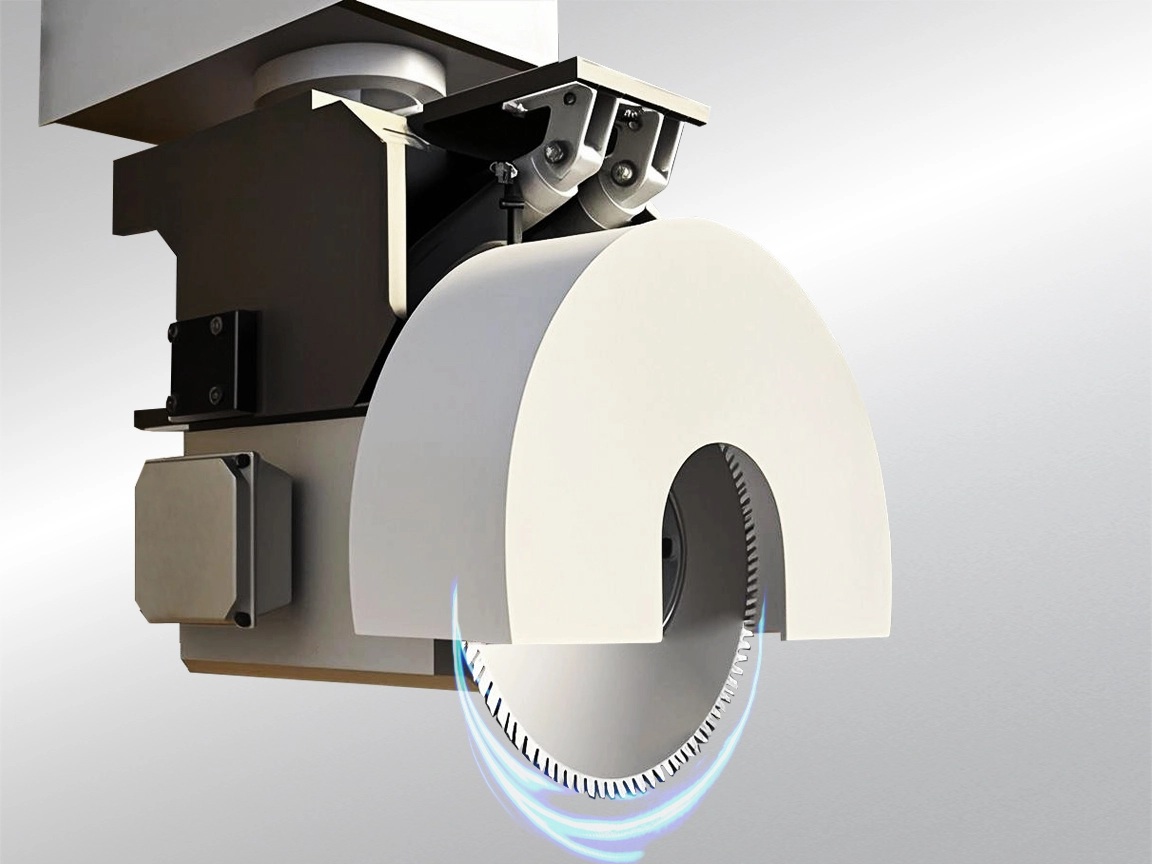

This device is an L-shaped 5+4 drilling unit that can accommodate different types of drill bits, enabling various drilling operations in both horizontal and vertical directions.

The side milling device enables tilting and rotation of the machining tool, allowing for drilling, cutting, and milling operations on inclined surfaces, curved surfaces, and side faces of the workpiece.

The cross side milling device can be equipped with four processing tools, allowing for tool switching as needed during operation. This unit is mainly used for horizontal drilling, milling, and similar tasks.

The control system enables controlled spindle tilting by this device , allowing for machining of curved surfaces, inclined surfaces, and side faces of workpieces.

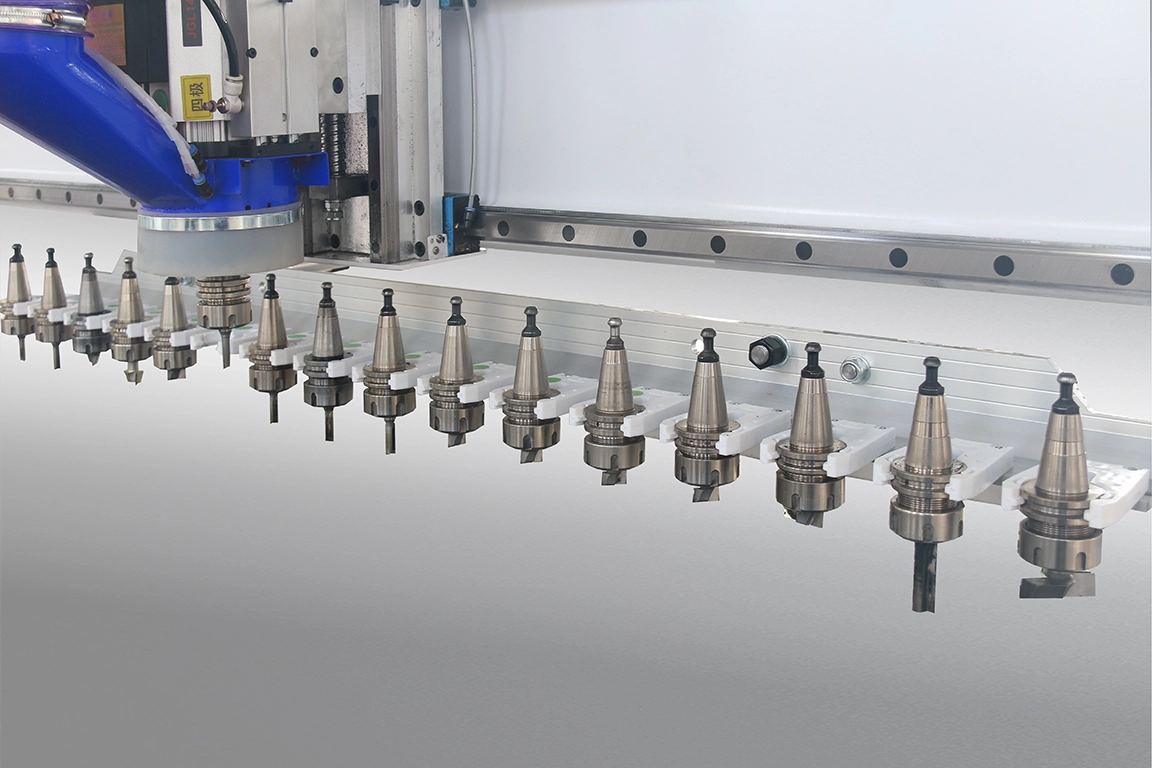

The linear tool magazine offers optional capacities of 8, 12, or 16 slots and can accommodate different types of tools. Controlled by the system, it enables automatic tool changes during the machining process.

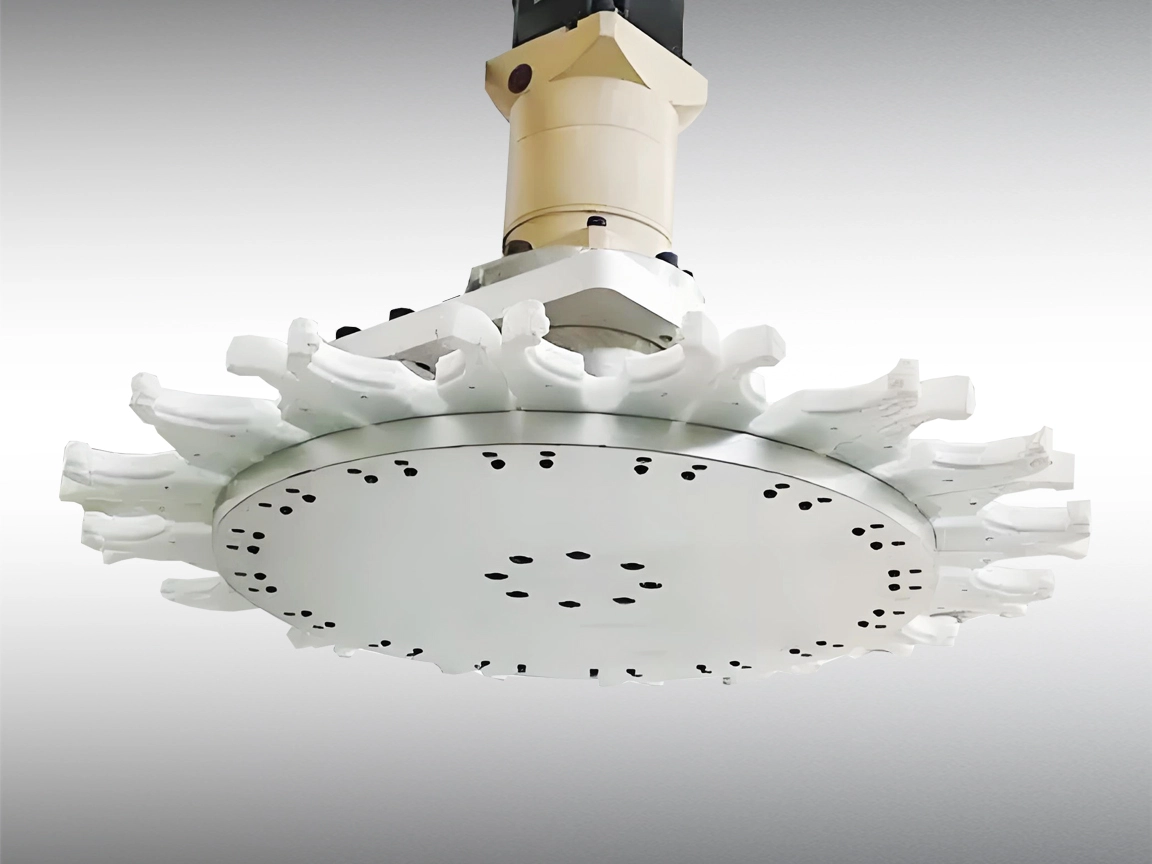

The carousel-style tool changer is mounted on the side of the machine, ensuring it doesn’t affect the maximum working height. The tool magazine capacity options are 8, 12, or 16 tools.

A variety of oscillating tools and their related auxiliary components are available, including electric/pneumatic oscillating knives, drag knives, V-cut knives, kiss-cut knives, creasing wheels, CCD cameras, etc. These tools can quickly cut flexible materials like fabric, sponge, foam, rubber, paper, and more.

The flood cooling system consists of a water sink and a spraying device. It uses circulating water to cool workpieces and tools, and is used for processing materials with high hardness, such as metal and stone.

Multiple processing stations are optional, each equipped with a dedicated machining spindle. This design allows either simultaneous use of all stations for batch processing of the same products or individual use of just one station. Two configurations are optional: independent-spindles-type multi-station and hanging-plate-type multi-station.

The double-rod pneumatic pressing roller offers an economical method for rapidly securing sheet materials. It fixes the sheets by downward pressure, ensuring quick and stable positioning while consuming less power compared to vacuum platforms.

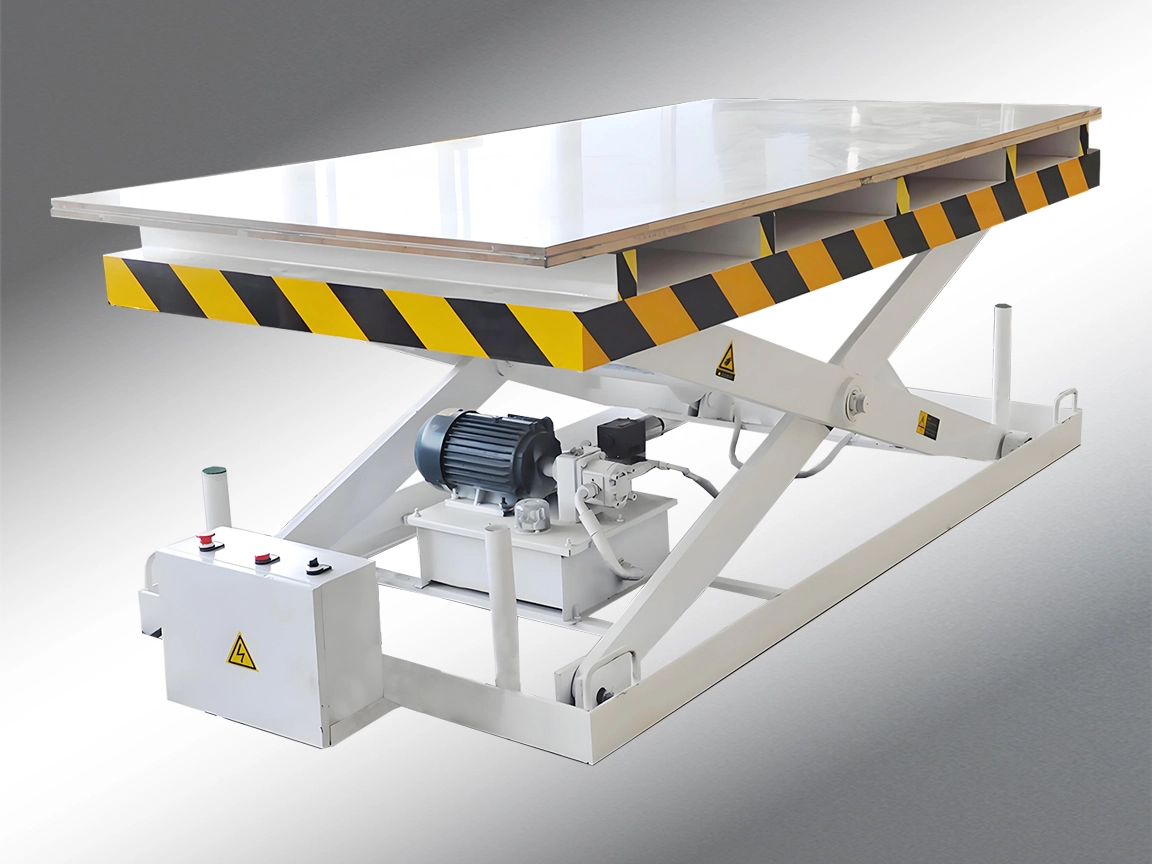

The lifting loading table can automatically adjust its height based on the total thickness of the board to align with the engraving machine's worktable.

The conveyor unloading table can automatically discharge finished products, making it easy to connect with other production lines.

The labeling machine can be placed before the engraving process to tag the boards prior to machining. Once labeled, the boards can be directly transferred to the CNC router machine's worktable.

Whether it is furniture, wardrobe, cabinet, musical instrument, or advertisement, it can handle it with ease.

|

|

|

||

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The following are some common sizes for your reference. If you have other processing size requirements, we can provide you with fully customized.

1300*2500mm(4'×8')

Working Area

200mm

Feed Height

135,000mm/min

Max. Movement Speed

35,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

2300kg

Weight

3500*2000*2100mm

Dimensions

1800*2500mm(6'×8')

Working Area

200mm

Feed Height

135,000mm/min

Max. Movement Speed

35,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

2500kg

Weight

3500*2500*2100mm

Dimensions

1500*3000mm(5'×10')

Working Area

200mm

Feed Height

135,000mm/min

Max. Movement Speed

35,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

2800kg

Weight

4000*2200*2100mm

Dimensions

2100*3000mm(7'×10')

Working Area

200mm

Feed Height

135,000mm/min

Max. Movement Speed

35,000mm/min

Max. Processing Speed

±0.05mm

Positioning Accuracy

±0.02mm

Repositioning Accuracy

3500kg

Weight

4000*2850*2100mm

Dimensions

Learn more about how the CATEK Spire Series can bring you more production efficiency.