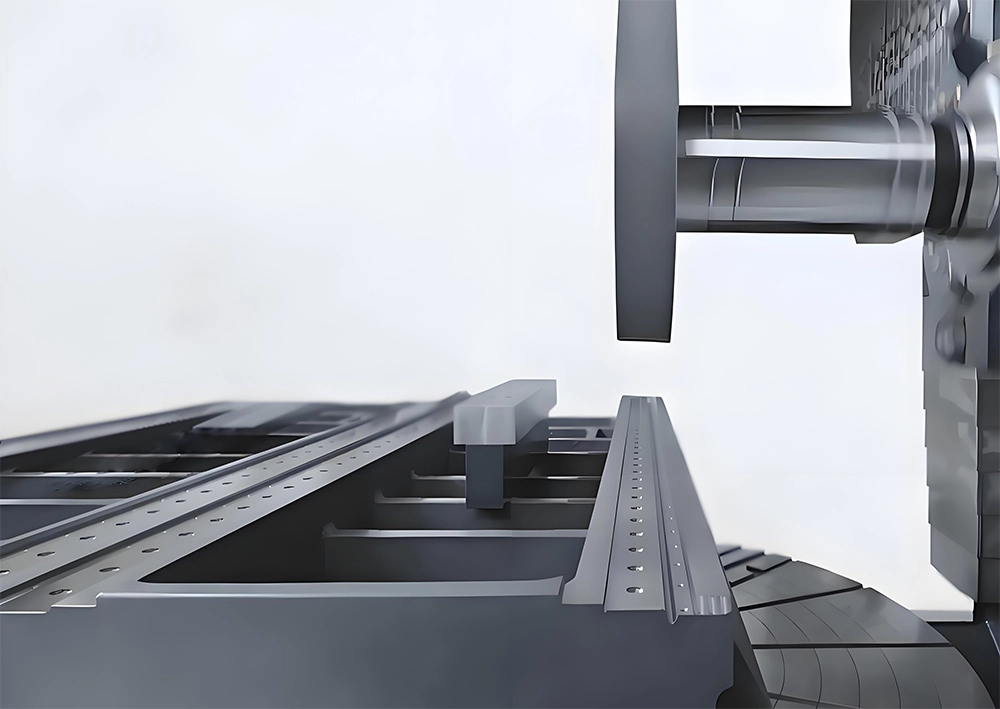

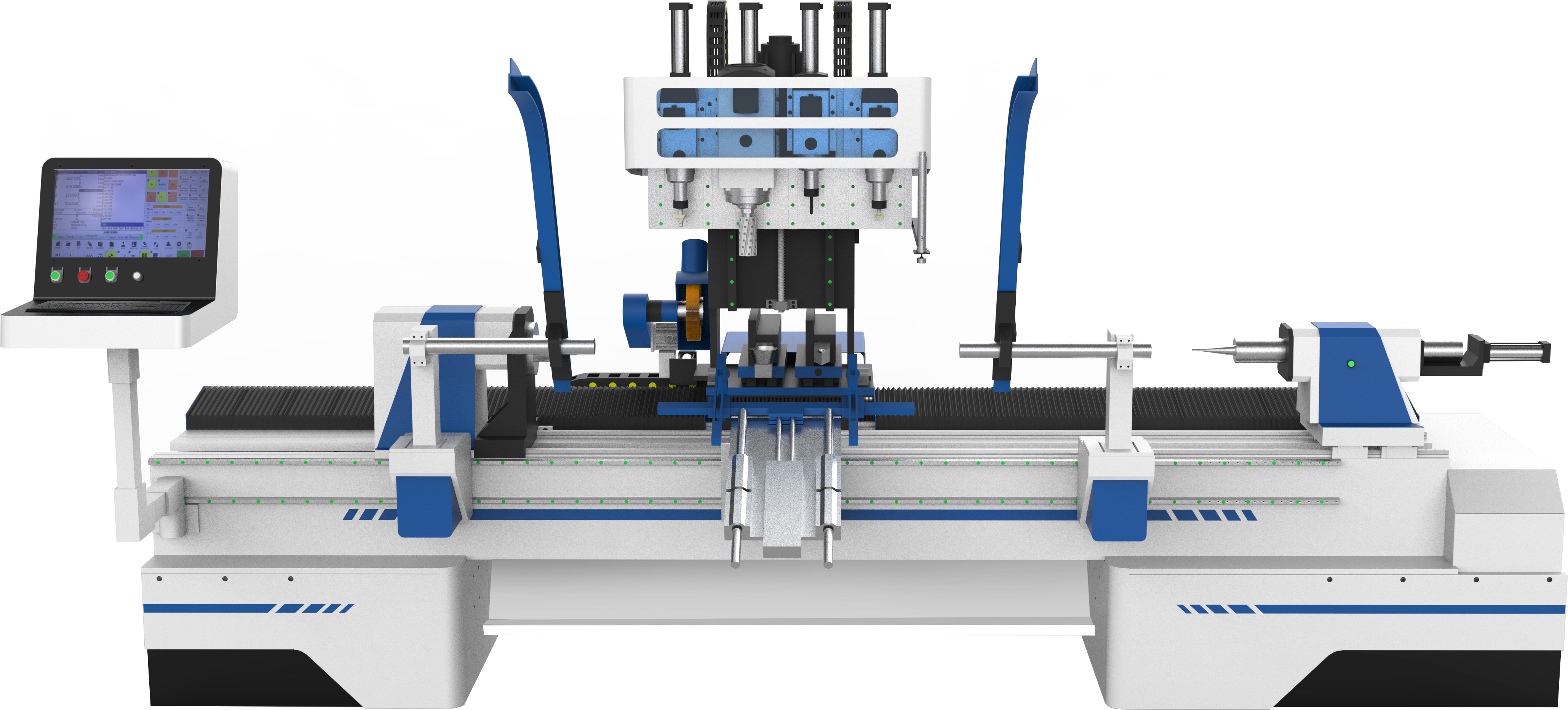

- Cast Bed

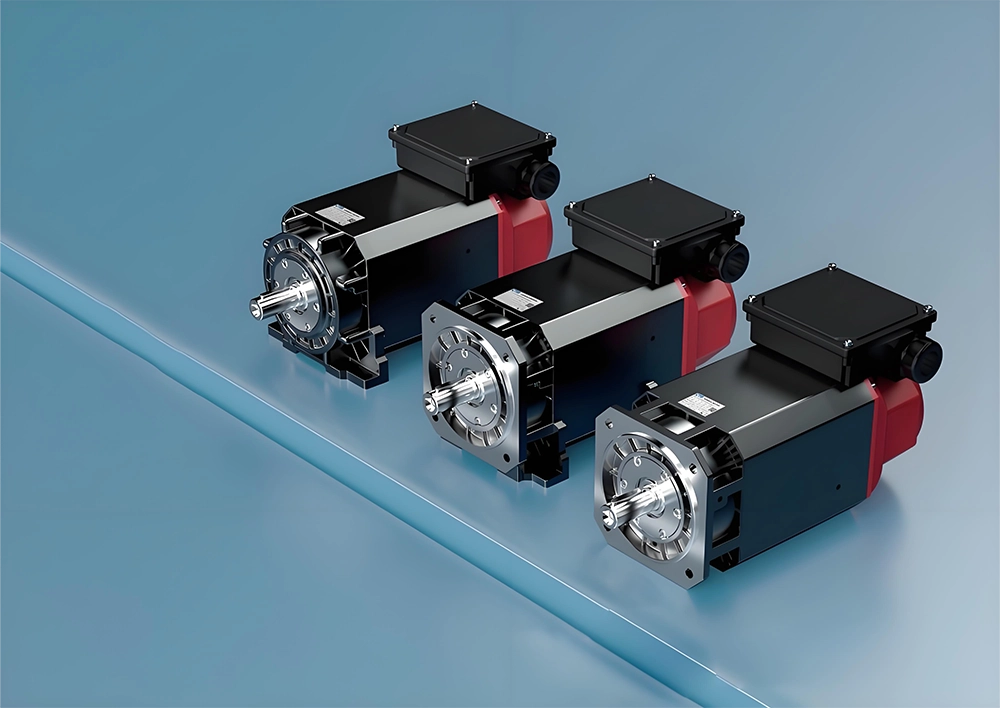

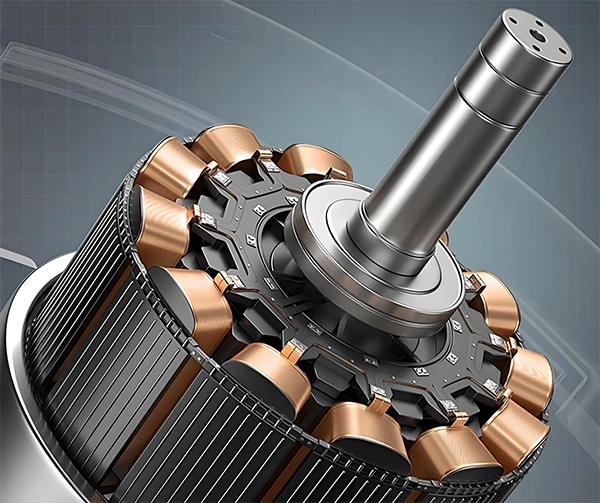

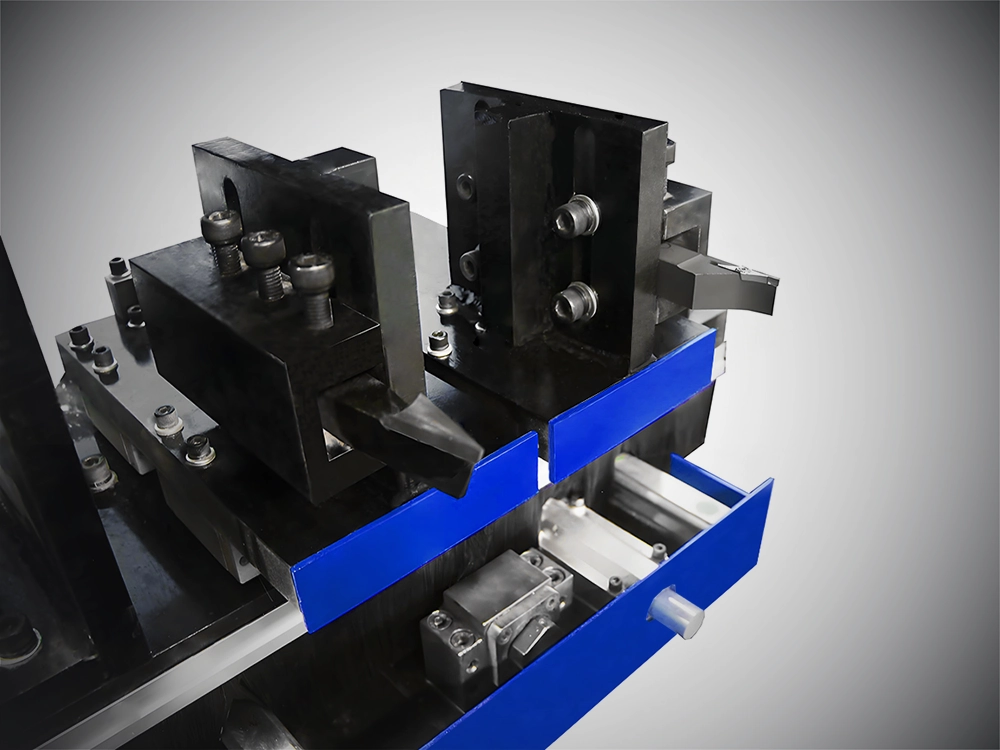

- Spindle Motor

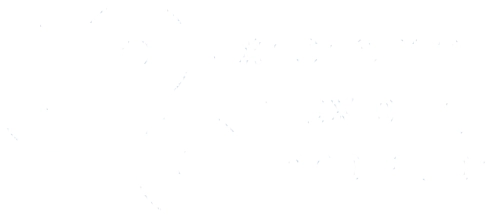

- Ball Screw

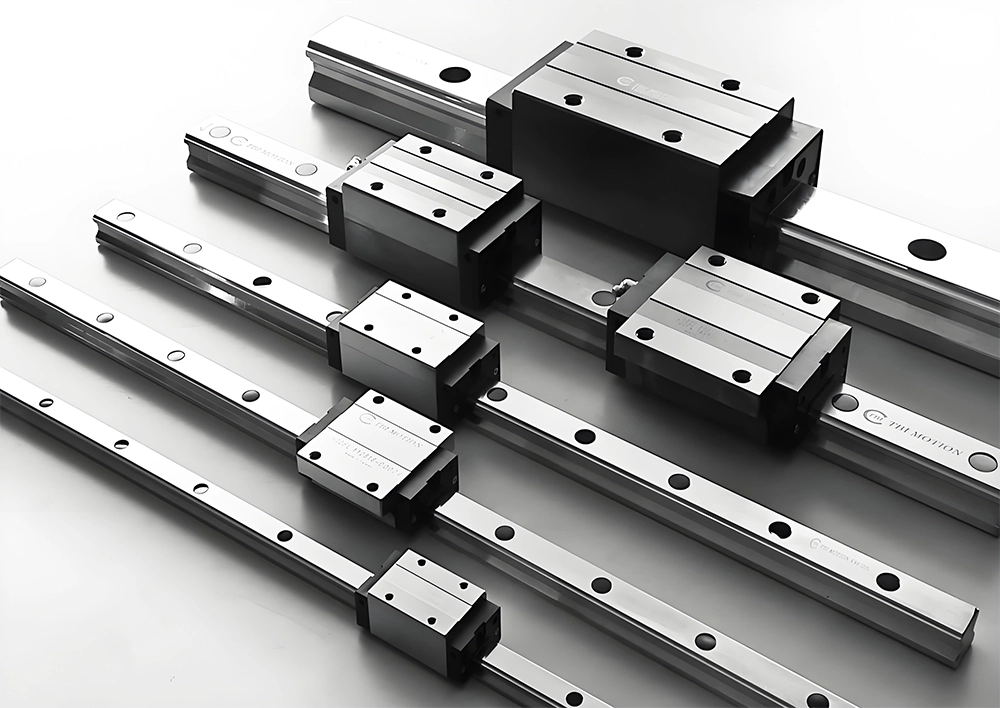

- Linear Guide

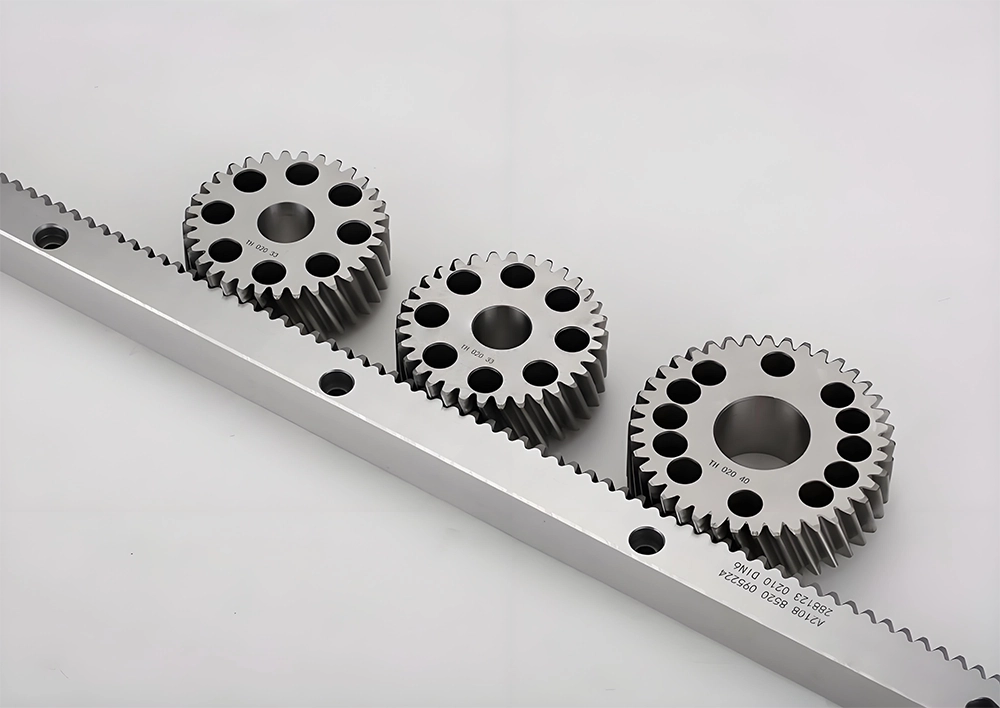

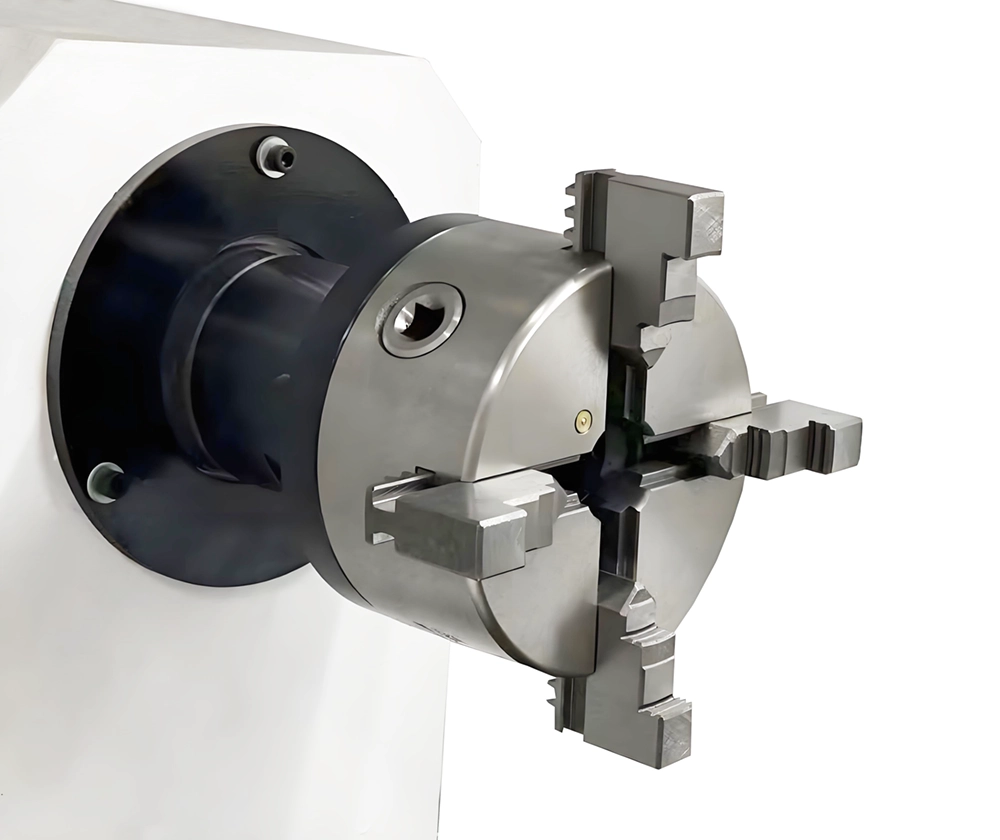

- Rack/Gear

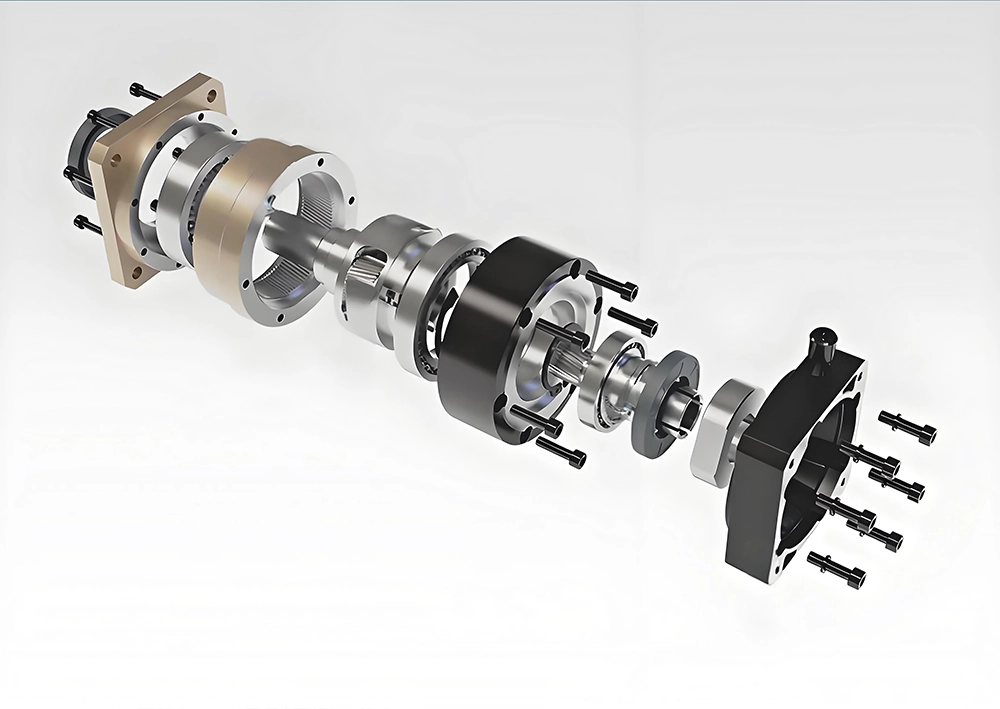

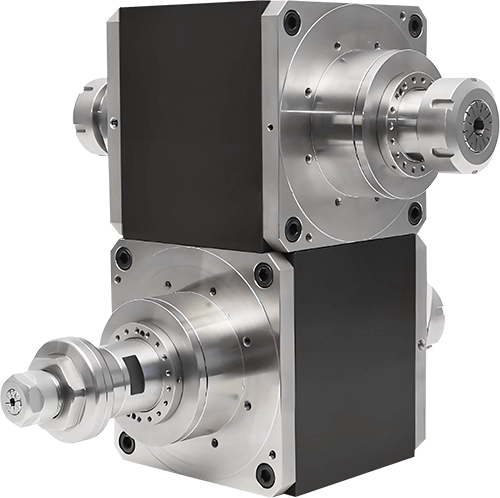

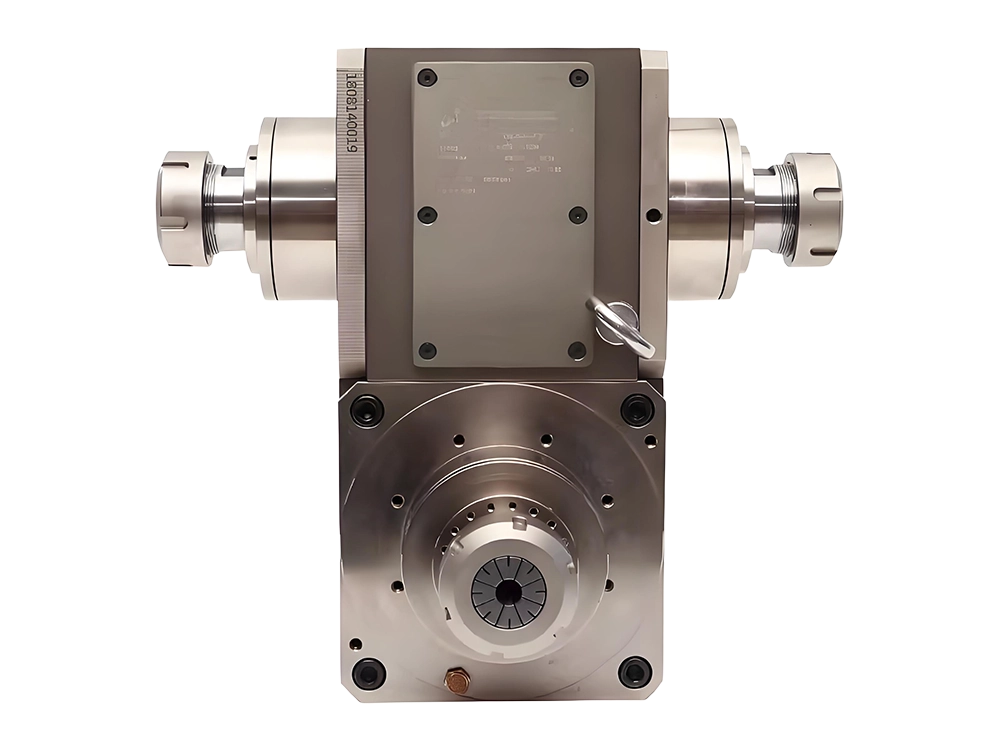

- Reducer

- Home

- Products

-

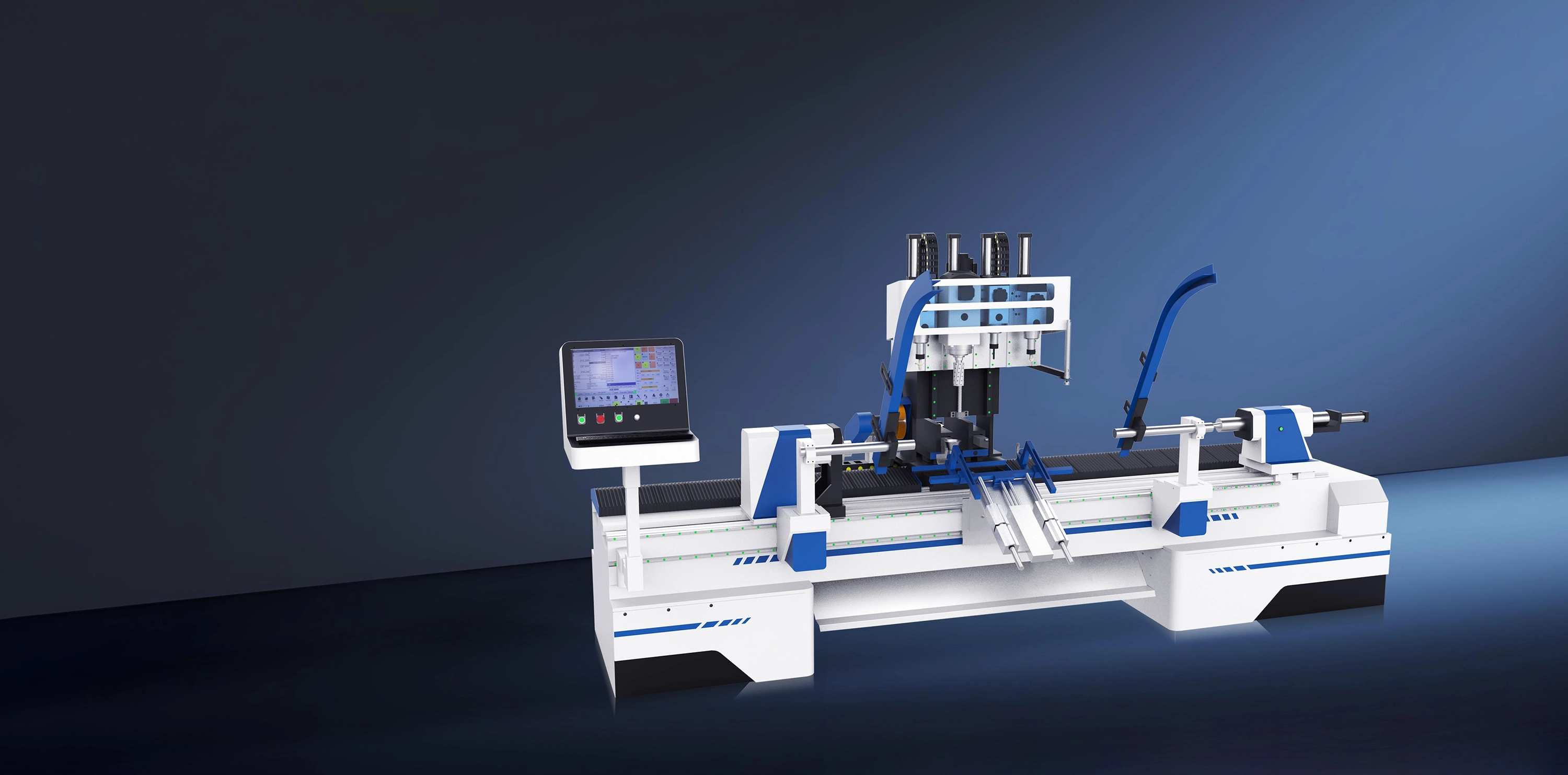

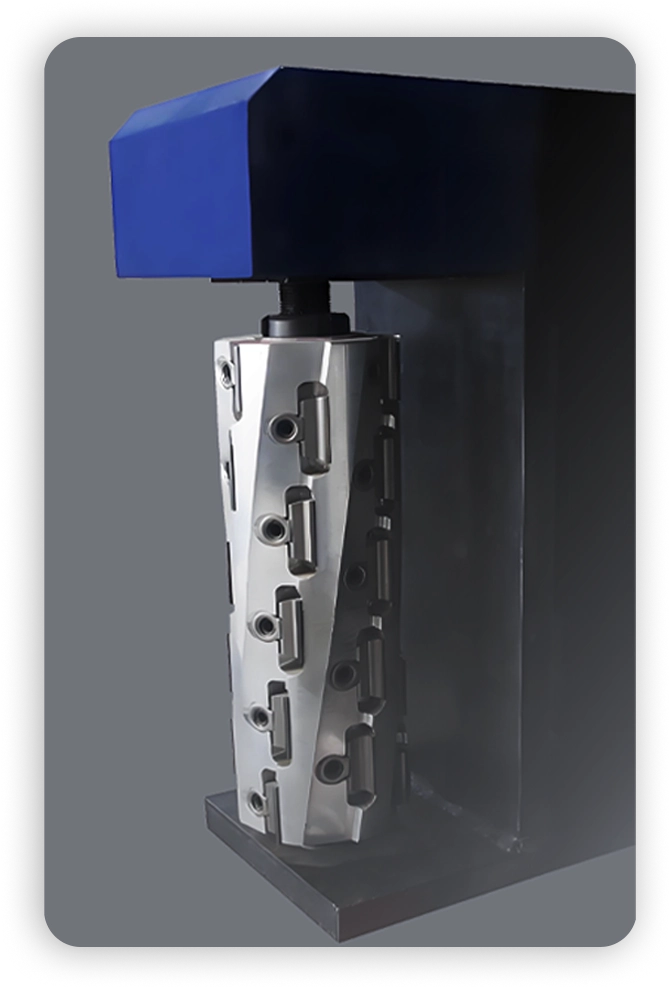

CATEKSpire

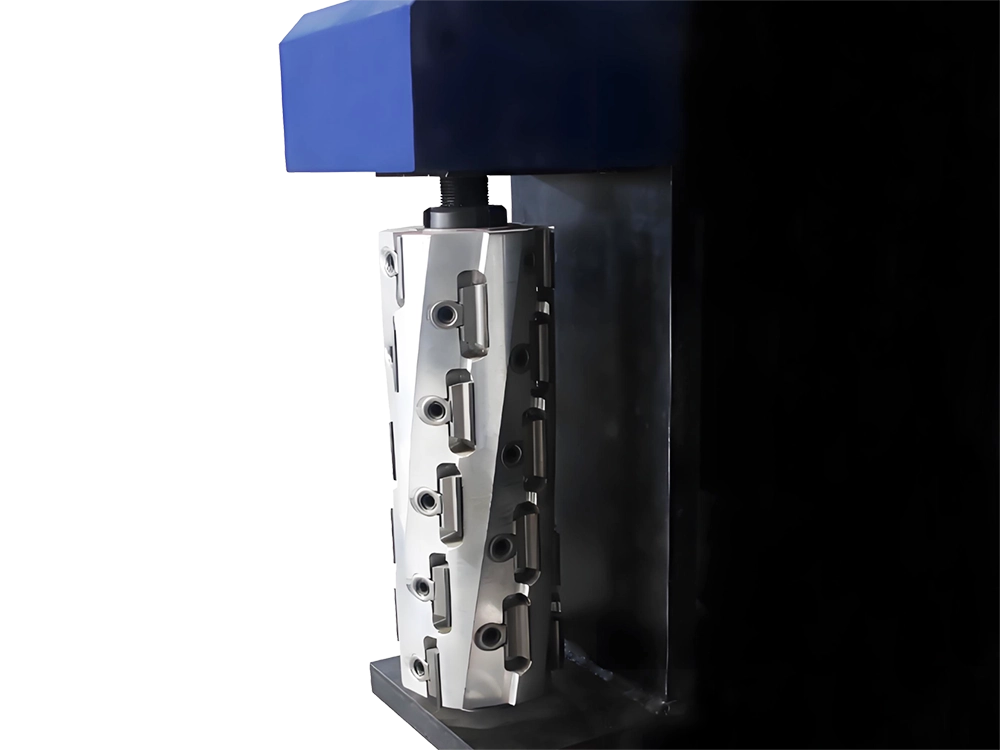

Spire Series

The Spire series is the high-end custom series of CATEKCNC, featuring a completely redesigned exterior and mechanical structure. It incorporates top-tier components from first-tier downstream suppliers and includes exclusive one-on-one customer service.

All Machine - Projects

- Support

- Blog

- About

- Contact Us