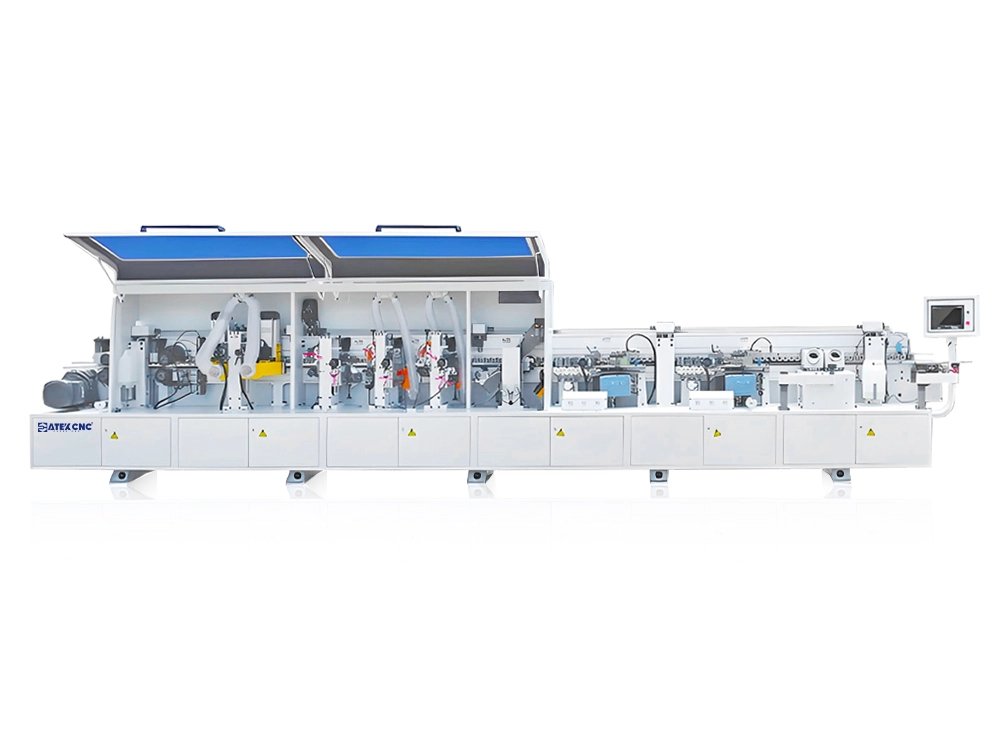

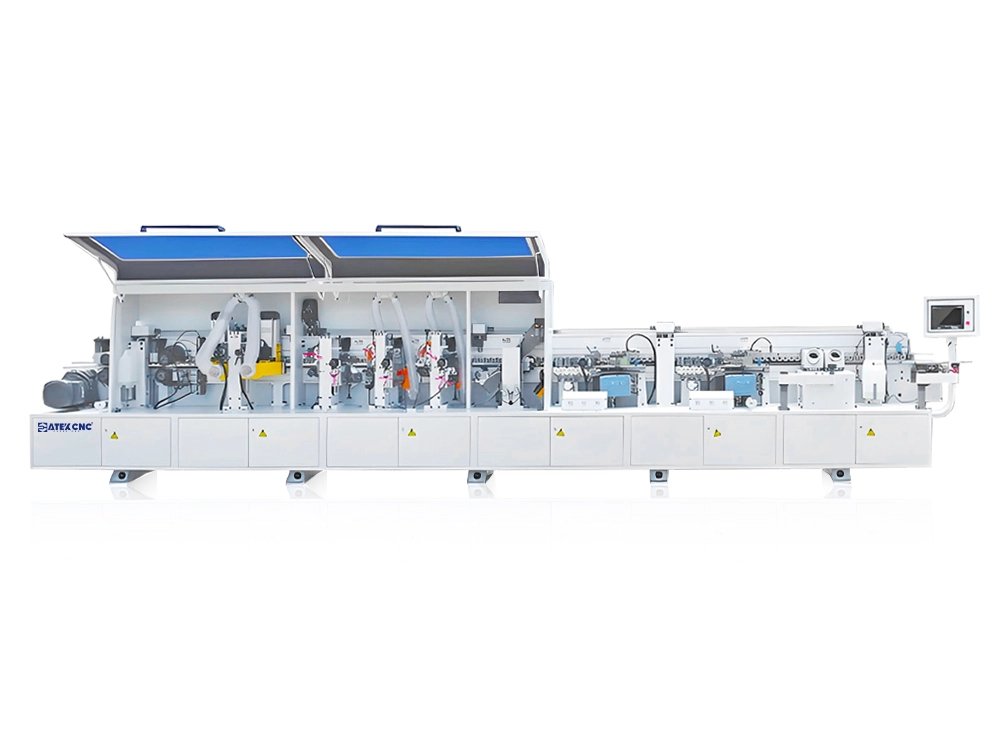

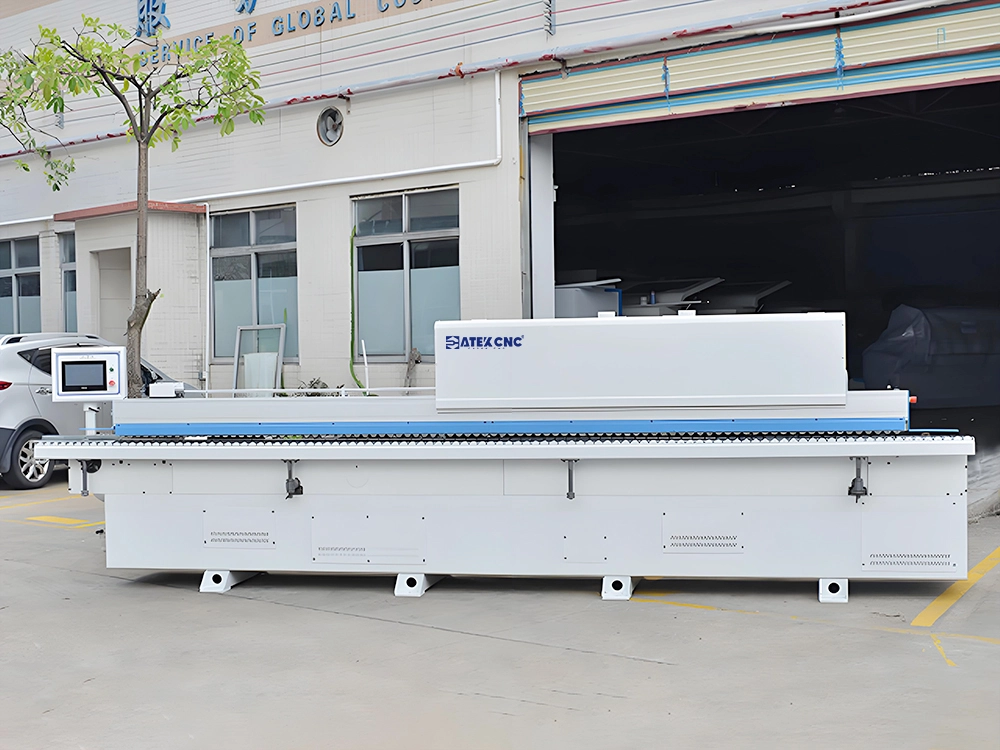

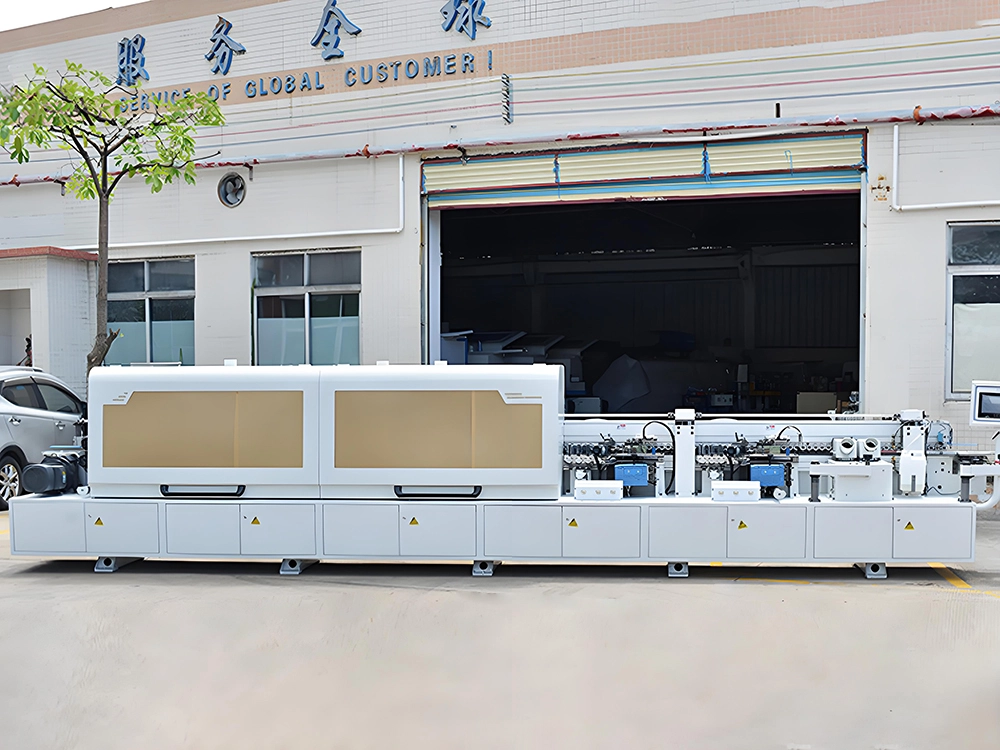

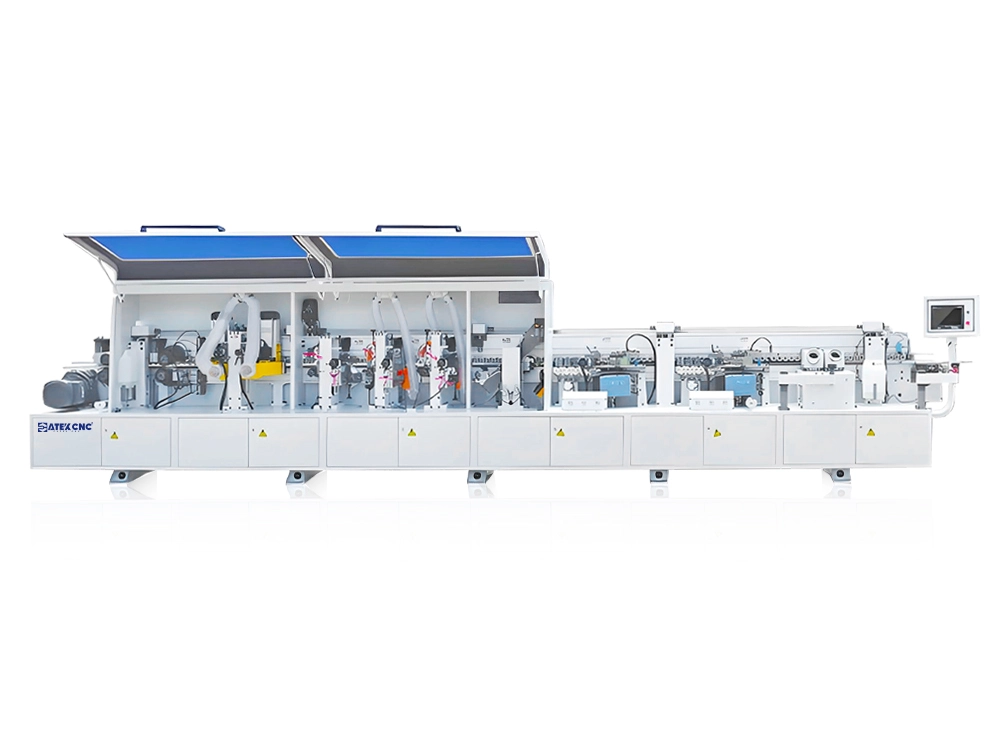

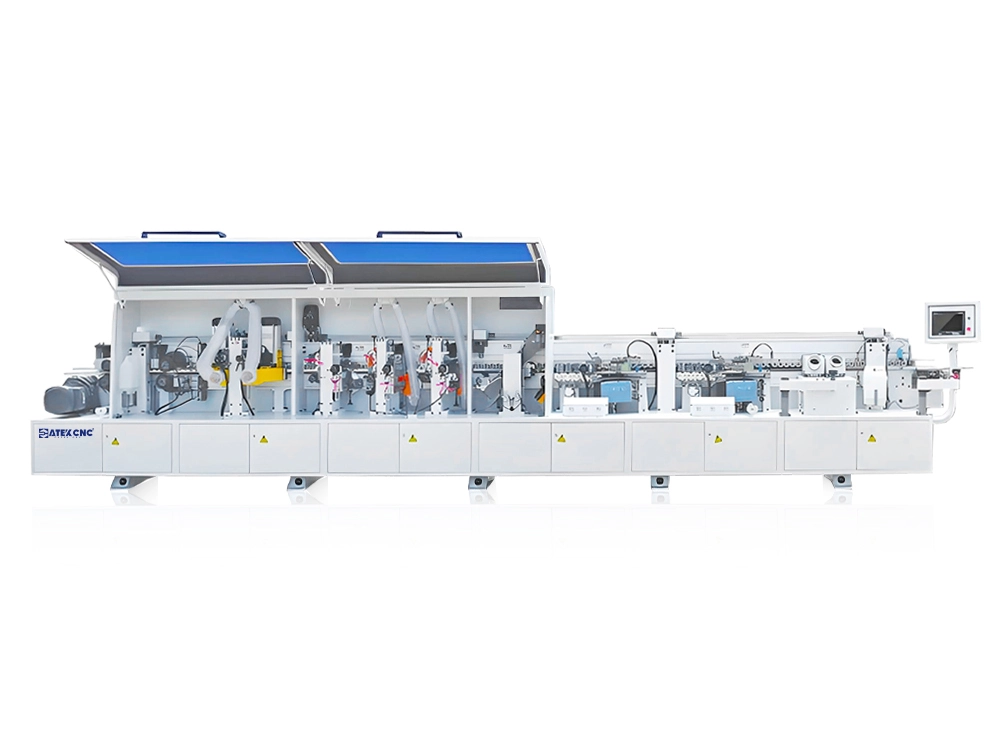

Automatic Edge Bander for Woodboard and MDF on Sale

8-in-1 Automatic Edge Banding Machine for Furniture Manufacturing

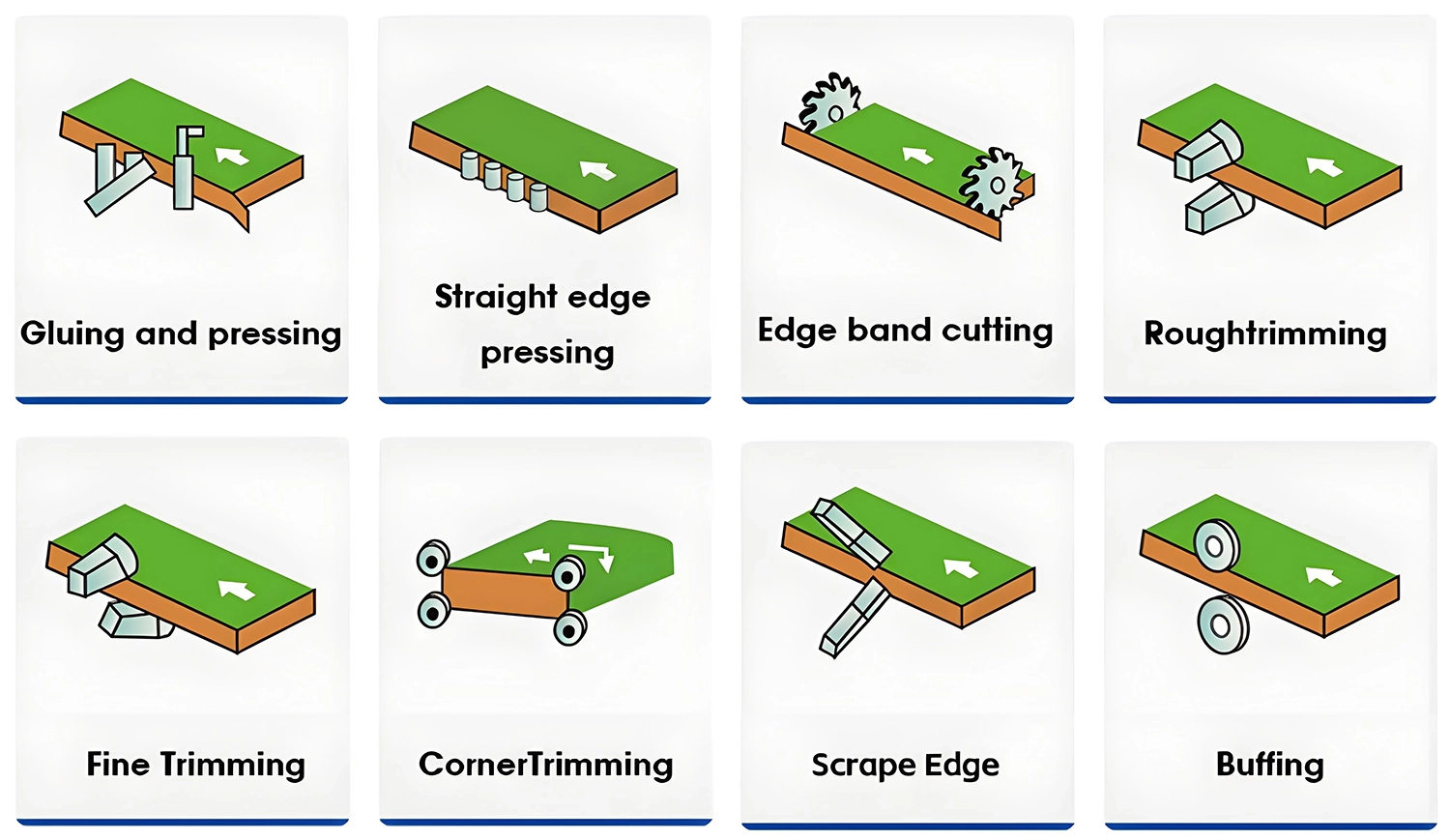

[Function Description]

CK-468-J is a fully automatic edge banding machine specially designed for the production of panel furniture (such as custom wardrobes, cabinets, office desks and chairs, etc.). It is equipped with 8 commonly used and key functions of edge banding machines, including:

- Pre-milling: A high-speed air-cooled spindle paired with a milling tool is used for micro-milling of the panel edge, trimming burrs and edge chipping on the cut edge of the panel to ensure the edge is flat. This lays the foundation for subsequent edge banding & bonding and improves the sealing performance of furniture edge banding.

- Hot melt adhesive gluing: The hot melt adhesive heated to a molten state is delivered to the surface of the gluing roller. When the panel is conveyed to the gluing station through the feeding structure, the gluing roller will be in close contact with the panel edge, and the hot melt adhesive will be evenly applied to the panel edge to ensure firm bonding between the edge strip and the panel.

- Edge strip pressing and bonding: After the panel reaches the pressing area, the edge strip is pressed by pressure wheels to make it closely adhere to the panel edge. This covers the internal structure of the panel and improves the appearance texture.

- Front and rear end trimmin: When the panel is conveyed to the end trimming station, the edge band that exceeds the length at the front and rear ends of the panel is quickly cut off by a high-speed rotating cutter, so that the edge banding length fully matches the panel length and meets the precise splicing requirements of furniture components.

- Rough trimming: A high-speed rotating rough trimming cutter is used to efficiently remove most of the excess margin of the edge band that exceeds the upper and lower surfaces of the panel, solving the problem of the edge band exceeding the thickness of the panel.

- Fine trimming: A fine trimming cutter is used for secondary processing of the edge after rough trimming with a smaller cutting margin and more precise angle control.

- Contour tracking trimming: The panel contour data is identified through the contour recognition function. The system automatically generates the movement path of the trimming cutter based on the contour data fed back by the sensor. The upper and lower groups of trimming cutters are used to remove the excess edge band, realizing high-quality edge banding for irregular corners of furniture.

- Edge scraping: The edge scraping cutter is used to remove residual adhesive stains and fine burrs on the edge band surface, ensuring the edge strip surface is clean.

- Buffing: A polishing wheel is used for fine polishing of the processed edge to improve the glossiness of the edge banding.

This 8-in-1 fully automatic edge bander can be used for various wood panels, MDF (Medium-Density Fiberboard), OSB (Oriented Strand Board), LVL (Laminated Veneer Lumber), melamine-faced panels, plywood, etc. It is also compatible with panels of different thicknesses, which can meet diverse furniture processing needs. The 8 functions operate fully automatically without frequent manual process switching. Compared with ordinary manual edge banding machines, the processing efficiency is improved by more than 60%.

By trimming panel burrs through the pre-milling function, and automatically optimizing the panel edge through the rough trimming, fine trimming and polishing functions, the flatness error of the panel edge can be less than to ±0.05mm, with no burrs, no adhesive stains and firm adhesion. It can effectively isolate moisture, prevent the panel from getting damp and deforming, extend the service life of furniture, and improve the appearance quality of products.

With fully automatic processing, only 1-2 people are needed to complete all operations, which reduces labor costs and operation errors. It is also compatible with multiple materials without frequent adjustment of machine parameters. It can not only meet the efficiency requirements of batch standardized furniture production, but also adapt to the flexible size adjustment of custom furniture. It is a key machine for small and medium-sized furniture factories to realize efficient and high-quality furniture edge banding operations.

Advantages of the 8-in-1 Automatic Edge Bander for Furniture Manufacturing

- Fully automated whole-process operation, from material feeding to the completion of processing, the panels are driven by the conveying mechanism throughout the entire process, without the need for mid-process shutdowns or manual operations, effectively improving processing efficiency.

- Three adjustable gears for panel conveying speed (16/18/22 m/min), the speed can be adjusted according to the panel thickness and edge strip material as needed, ensuring flexible and convenient use.

- Equipped with Delta/MCGS PLC touch screen control system, supports multiple languages, featuring an intuitive interface, simple function adjustment, and easy operation for new users.

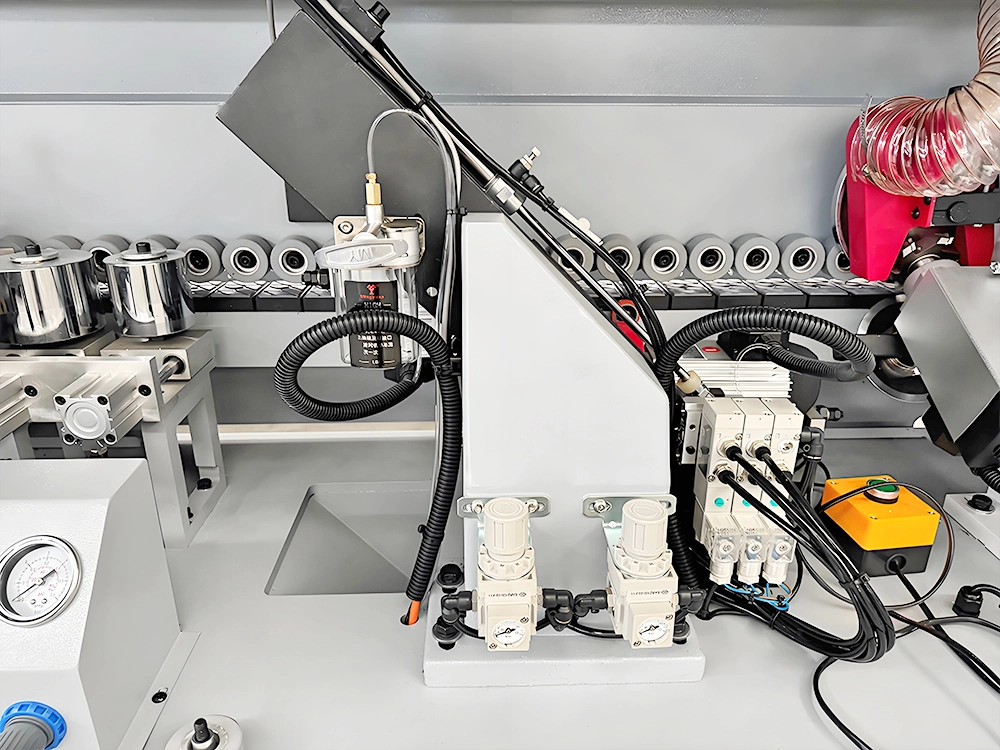

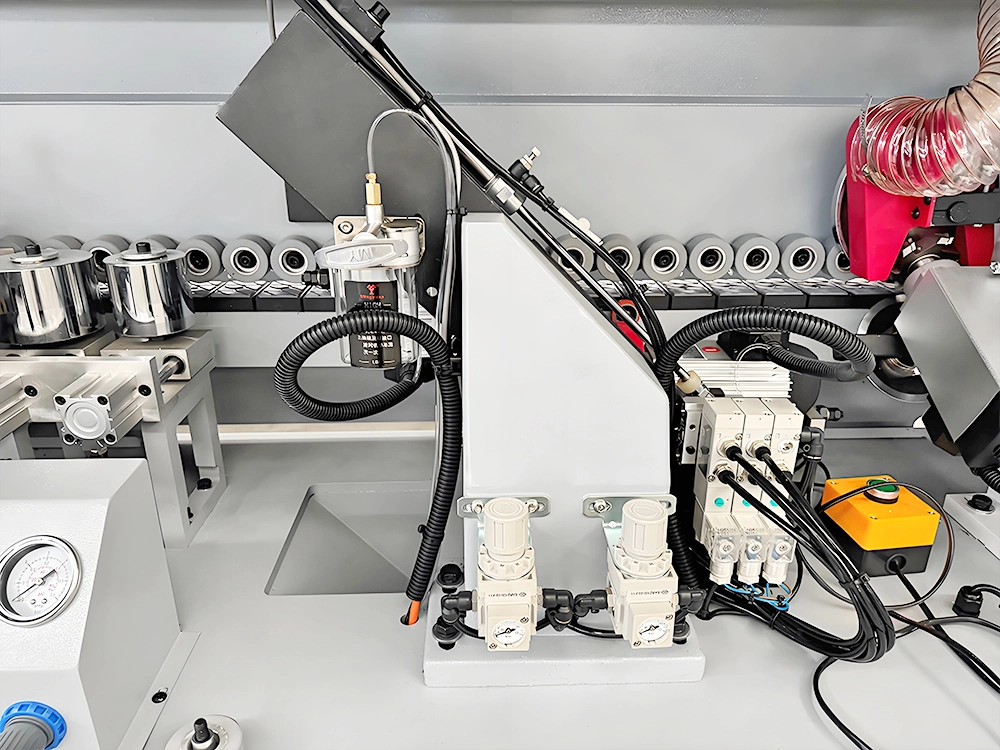

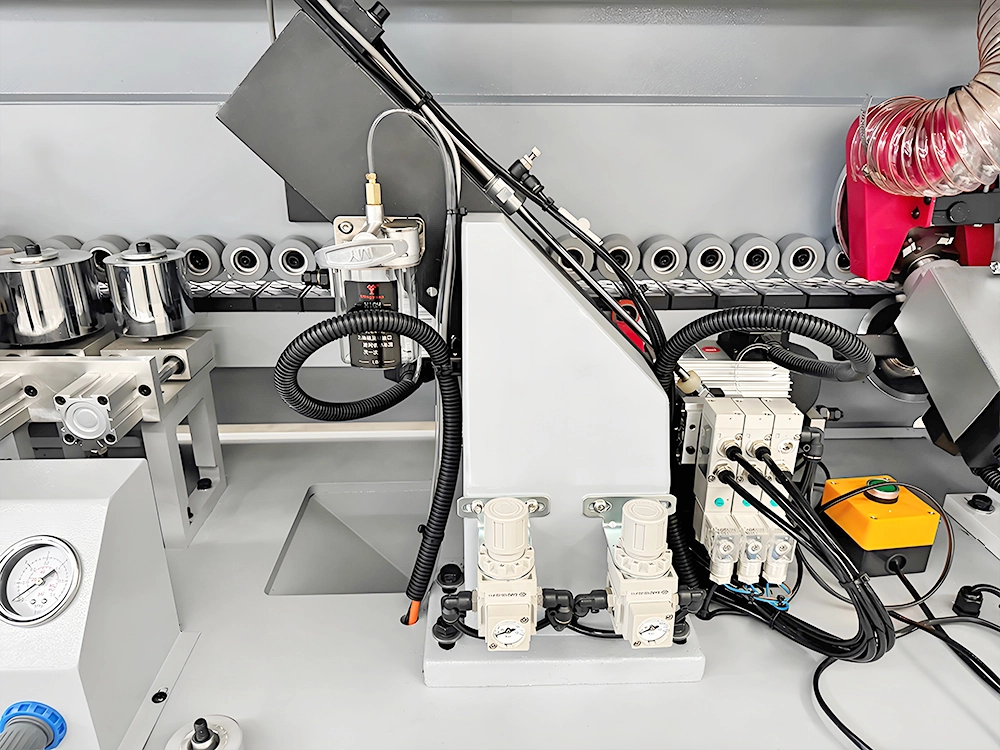

- Adopts Taiwan AirTAC cylinders and solenoid valves, ensures the working accuracy of pneumatic components.

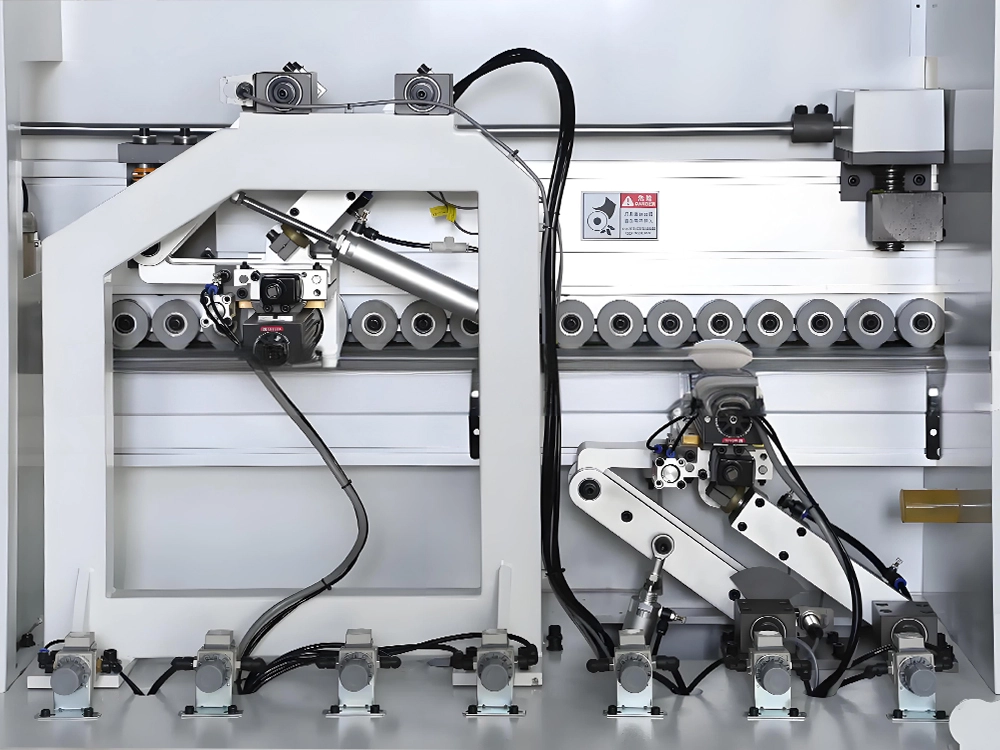

- Equipped with Taiwan HIWIN linear guideways, provides stable guidance for the contour following device, enabling more stable operation.

- Supports panel edge banding thickness of 10-60 mm, covers the thickness range of various wardrobes, cabinets, and wooden doors, meeting the processing needs of different products.

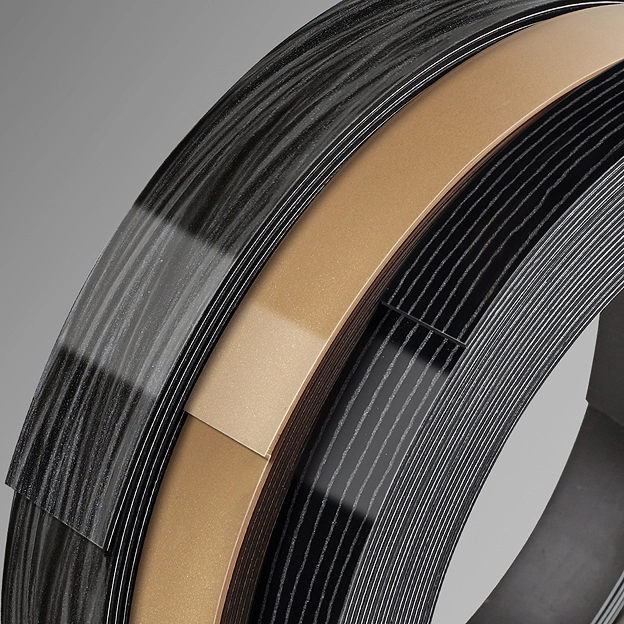

- Supports edge strip thickness of 0.4-3 mm, compatible with edge strips of various materials (including PVC, ABS, acrylic, etc.).

- Precise control for hot melt adhesive coating, can accurately control the adhesive dosage and temperature, achieving perfect control of adhesive bonding strength. It can effectively reduce adhesive consumption by more than 15% and significantly minimize issues such as weak adhesion and peeling of edge strips.

- Adjustable edge banding arc, the arc angle of edge strips (R1-R3) can be controlled with cutters according to requirements, meeting the personalized process needs of custom furniture.

- Comprehensive safety protection, equipped with safety devices such as emergency stop buttons and fully enclosed protective covers for functional areas. In addition, all moving parts are equipped with safety sensors, complying with safety standards.

- Reduced skill requirements for operators, only requires operators to load and unload, saving labor costs.

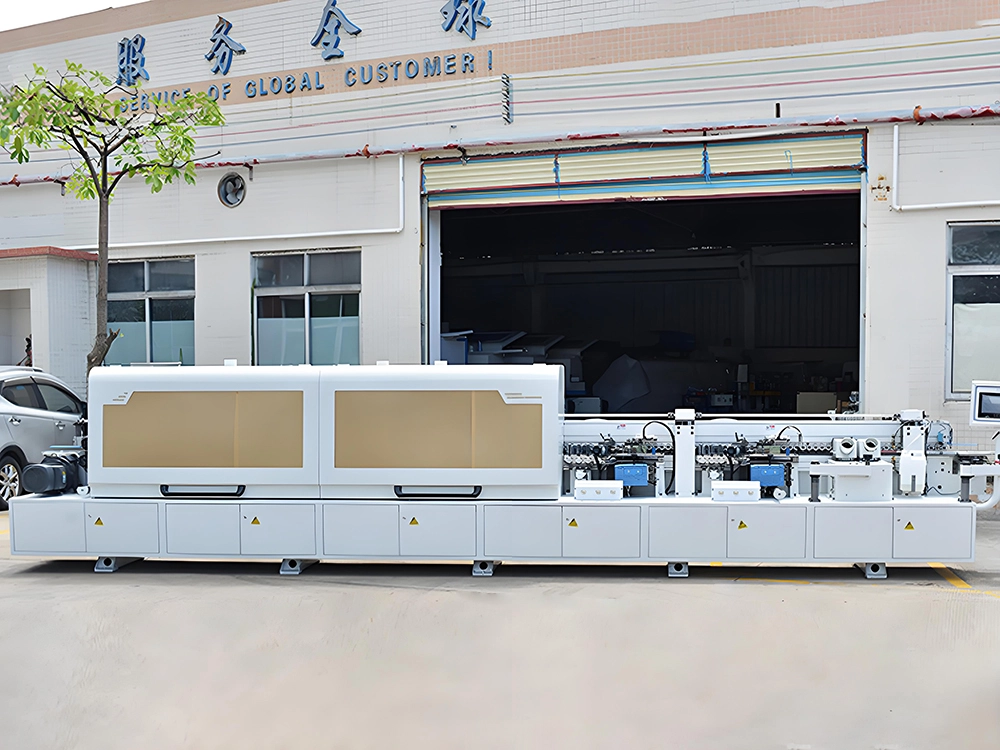

Details of the 8-in-1 Automatic Edge Banding Machine for Furniture Manufacturing

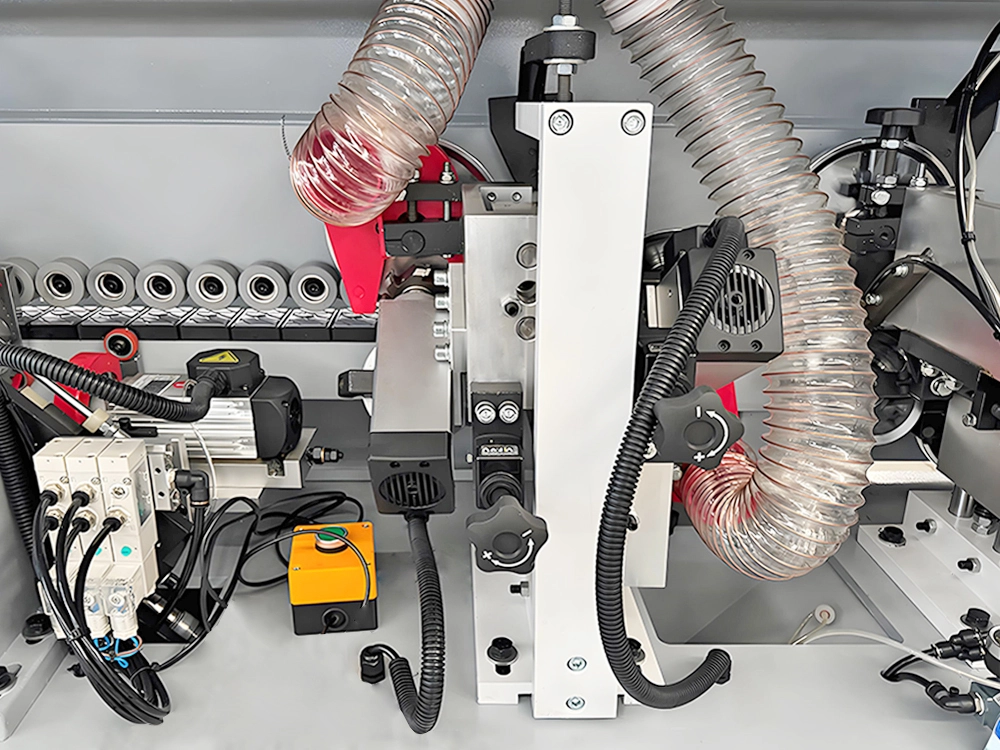

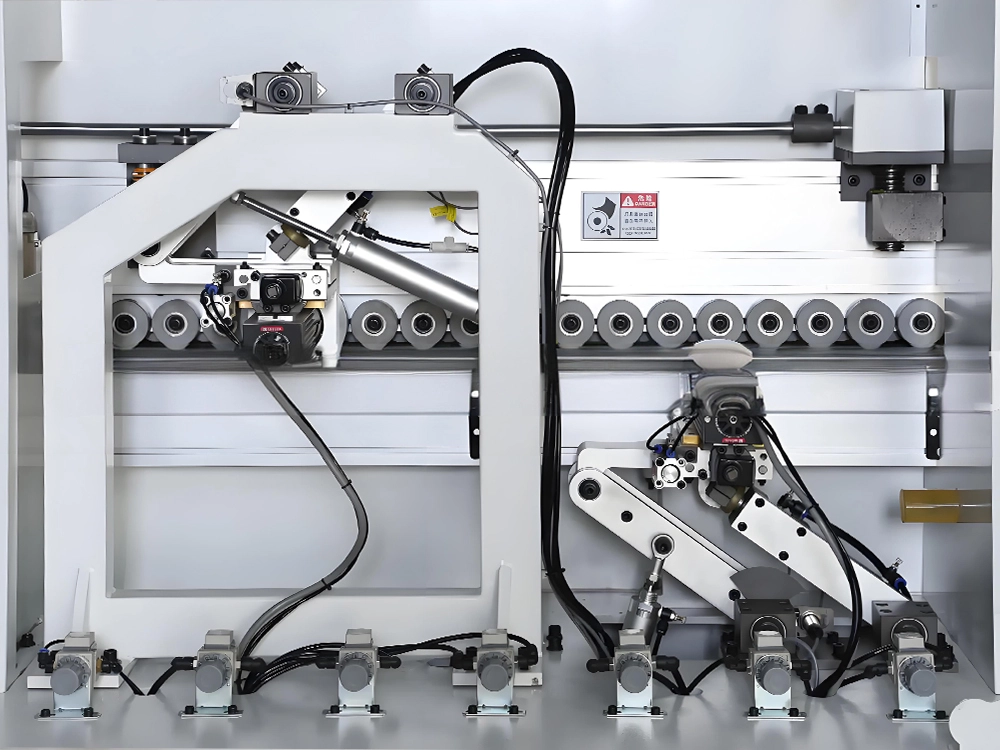

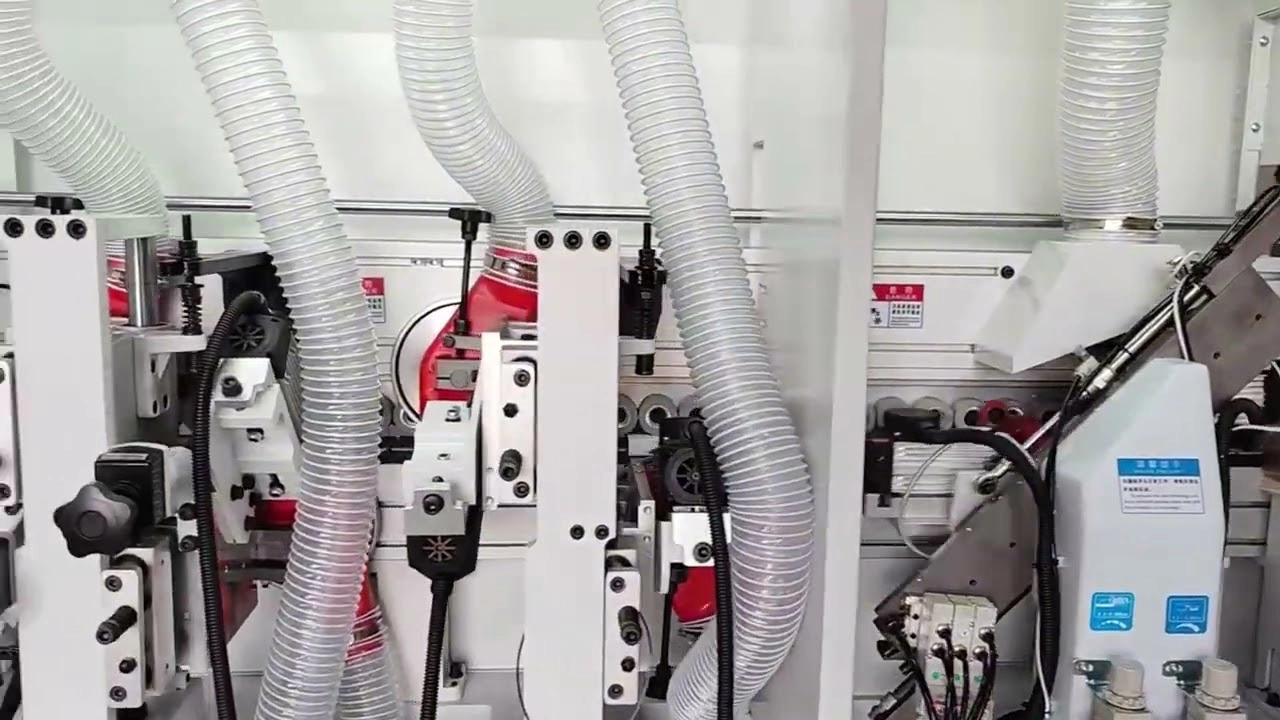

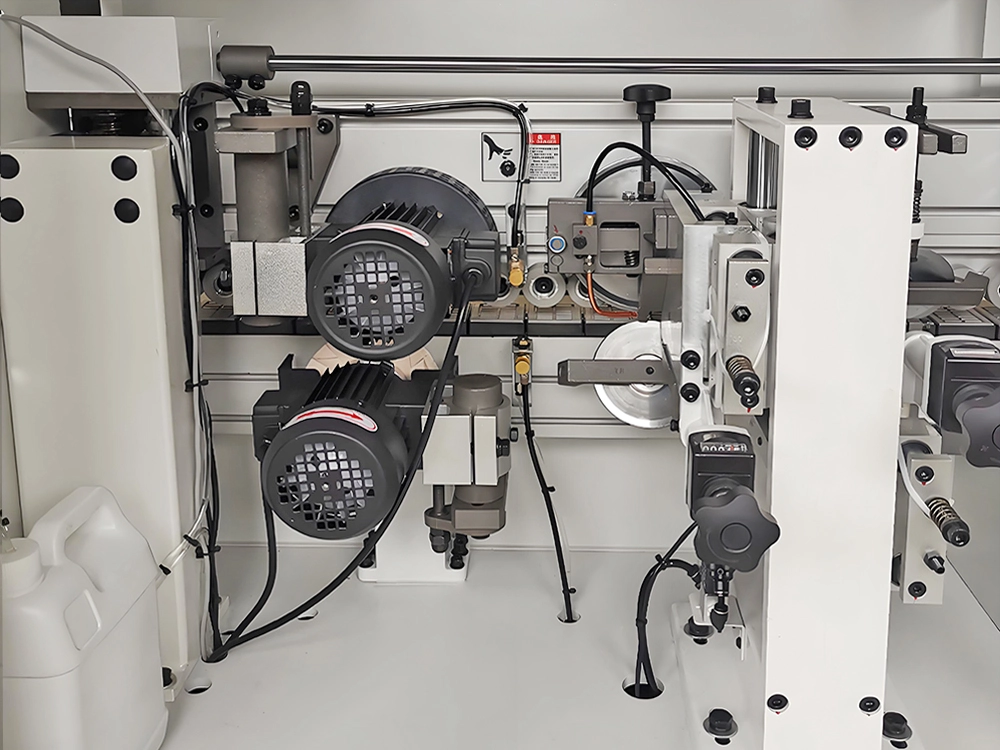

- Pre-milling unit

Equipped with two high-speed air-cooled spindles and milling cutters, it re-finishes traces such as ripples and burrs caused by panel cutting and processing. This allows the edge strips to fit more closely to the panel edges, achieving a better edge banding effect.

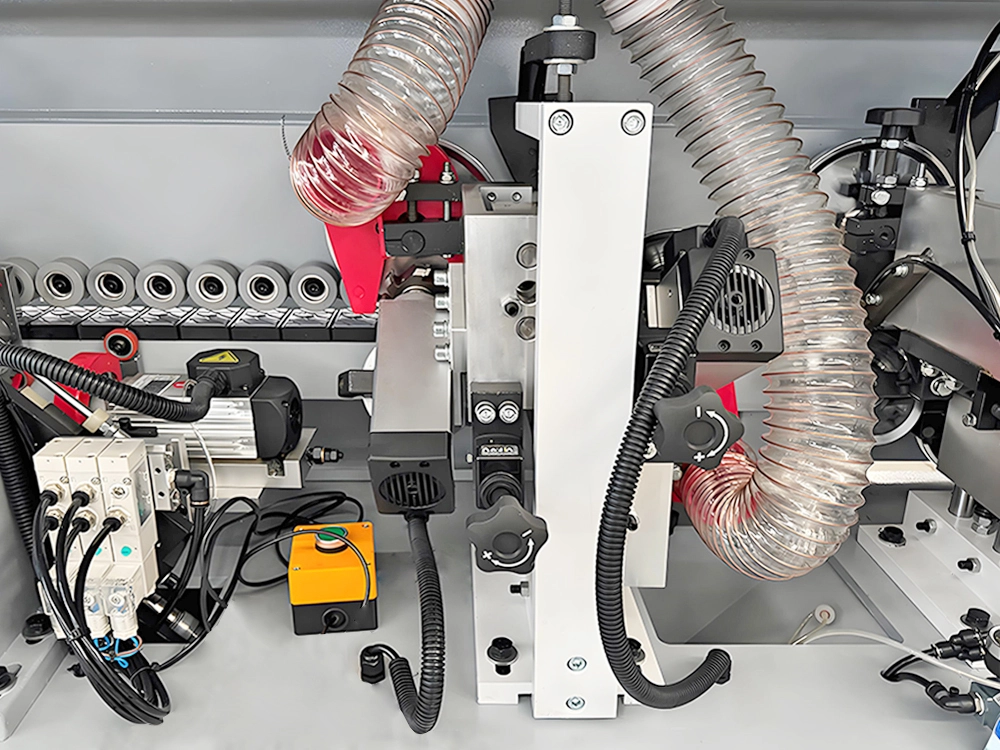

- Gluing and pressing unit

By a special roller structure, it ensures uniform gluing on the panel edges and edge strips, achieving a better bonding effect and guaranteeing stronger adhesive force.

- Front and rear end trimming unit

Uses a high-speed spindle to trim the excess edge strip material from the front and rear parts of the panels. It adopts a profiling automatic tracking structure to ensure the cut surface is flat and smooth.

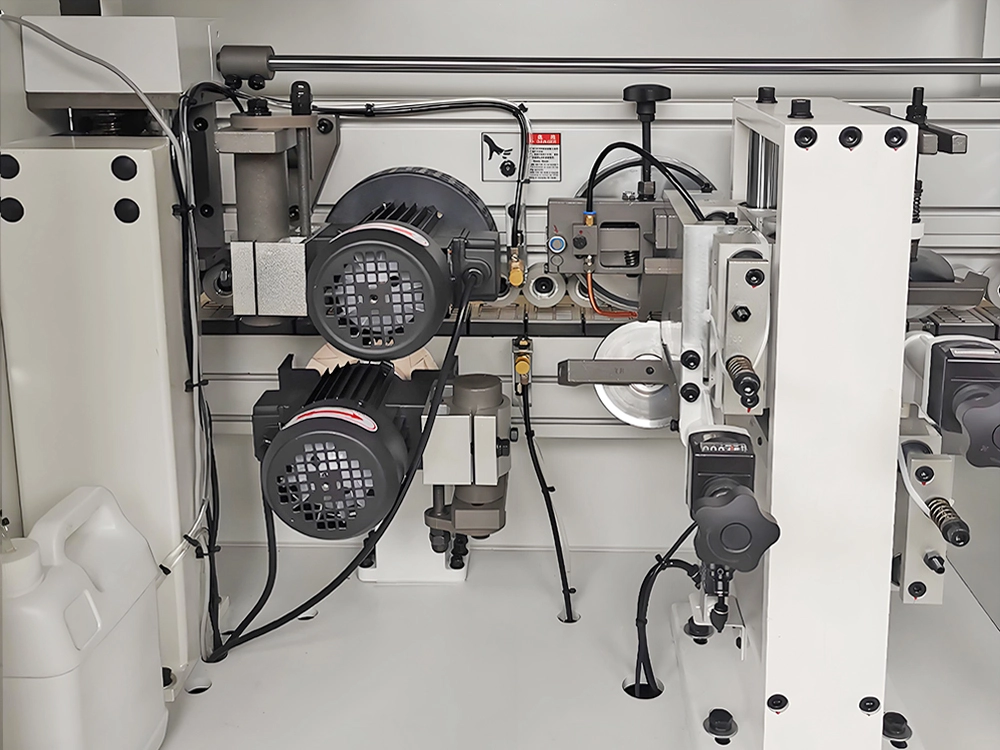

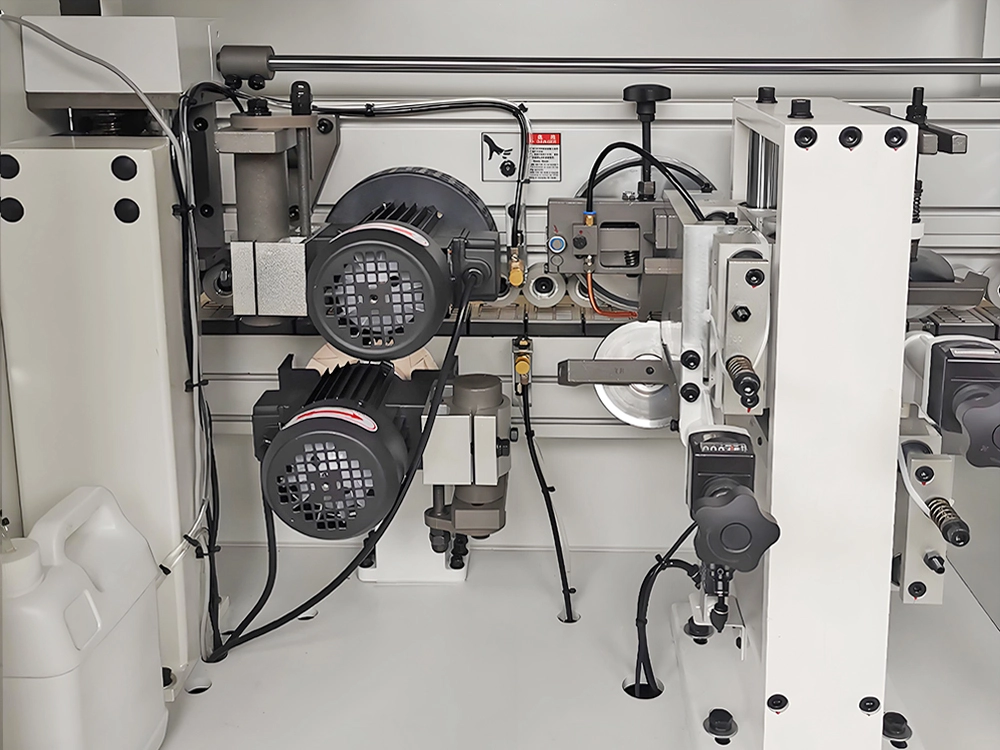

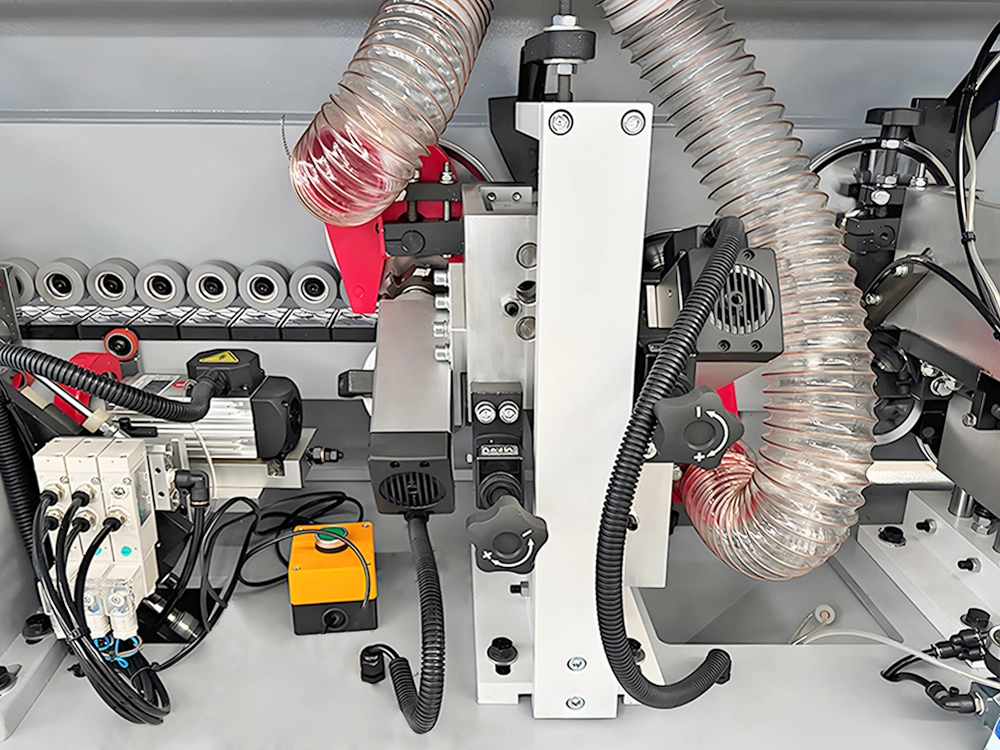

- Rough and fine trimming unit

Driven by a high-speed motor, it is used to remove the excess edge strip material from the upper and lower parts of the panel’s edge strips, ensuring the upper and lower parts of the panel are flat and smooth.

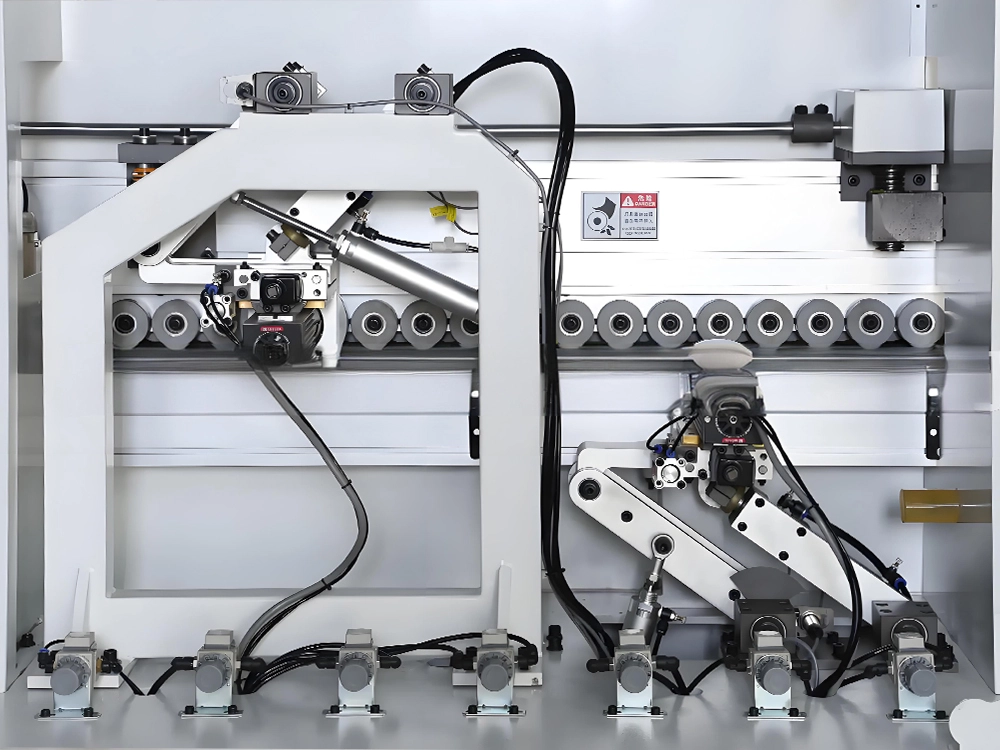

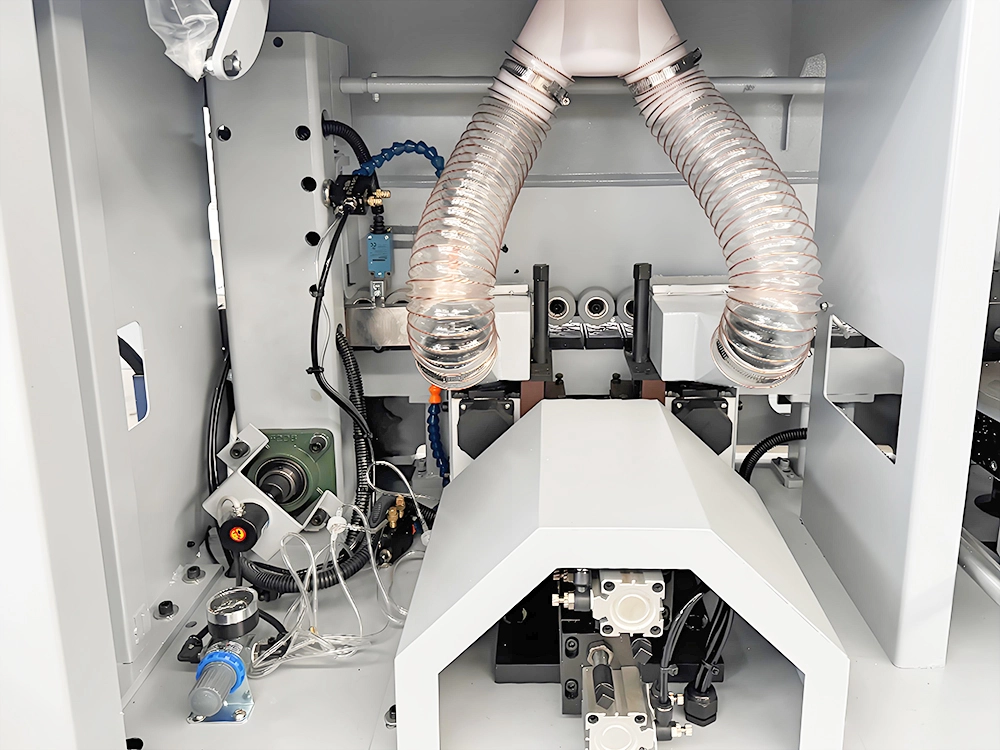

- Profiling and tracking chamfering unit

Automatically processes rounded corners on the panel edges, making the panel processing effect more aesthetically pleasing.

- Edge scraping unit and buffing unit

Uses a scraper to eliminate ripple traces on the panel, making the edge of the edge strips smoother and cleaner.

Uses a cotton buffing wheel to buff the processed panel edges at high speed, making the edge banding edges smoother. Buffing can be completed in one pass, without the need for subsequent manual buffing, improving processing efficiency.

- Control system

Adopts a dedicated PLC control system for edge banders, with touch screen control for simple operation. It supports English interface display, and processing can start only with simple parameter adjustment.

- High-power motor for conveying

With a gear reducer, it operates at a stable speed and can work continuously for 24 hours.

- Aluminum alloy press beam

Uses a thickened and heavy-duty aluminum alloy press beam, equipped with feeding rollers. It operates stably, with high stability and durability.

- Edge strip rotary table

Used to support edge strips, equipped with rollers for automatic conveying of edge strips.

Optional function

- PUR glue melting unit

PUR glue melting unit: Heats up faster, ensures even and stable glue application, suitable for mass production of panels, and enables edge strips to adhere better to the boards.

- PUR glue pot melting system

Allows for glue replacement in as little as 15 minutes, with quick-change glue cartridges to maintain the cleanliness of the edge banding glue, preventing yellowing edges, and enhancing the waterproofing and durability of the panels.

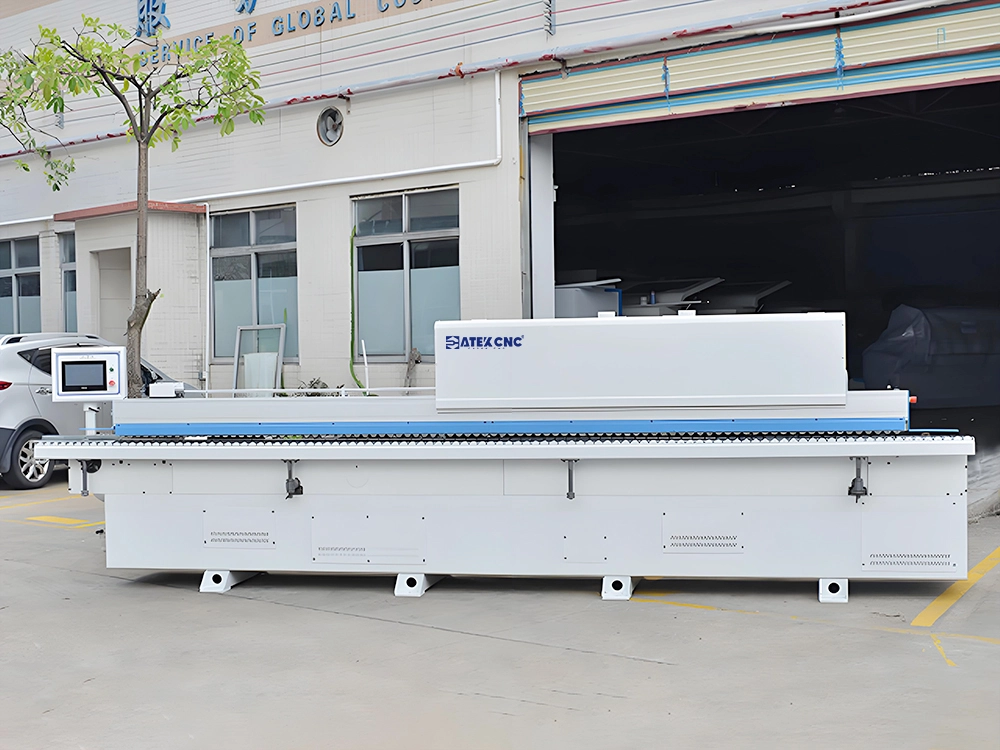

Technical Parameters of 8-in-1 Automatic Edge Bander for Furniture Manufacturing

| Model | CK-468-J |

|---|---|

| Minimum Board Width | ≥60mm |

| Minimum Board Length | ≥30mm |

| Board Thickness | 10-60mm |

| Edge Strip Thickness | 0.4-3mm |

| Edge Banding Speed | 16/18/22 m/min |

| Control System | Delta / MCGS |

| Cylinders | EASUN & AirTAC |

| Solenoid Valves | EASUN & AirTAC |

| Guideways | HIWIN |

| Pressure Regulating Valve | ENSUN |

| Spindle | CC MOTOR |

| Air Pressure | 0.6 MPa |

| Total Machine Power | 16.8 kW |

| Functions | Pre-milling, glue application & pressing, front/rear trimming, rough trimming, fine trimming, contour tracking, scraping, buffing |

| Dimensions | 6800*950*1600mm |

| Weight | 2300kg |

Application of the 8-in-1 Edge Bander for Furniture Manufacturing

- Furniture cabinets: Wardrobes, kitchen cabinets, shoe cabinets, sideboards, wine cabinets, cabinet doors, cabinet bodies, drawers, coffee tables, TV cabinets, tatami units, panel beds, cabinet side panels, top panels, bottom panels, shelves, etc.

- Office furniture: Office desks, filing cabinets, storage cabinets, conference tables, etc.

- Commercial cabinets: Display cabinets for clothing stores, jewelry and gem showcases, cosmetic display counters, supermarket shelves, checkout counters, service desks, etc.

- Decorative panels: Living room and bedroom wall panels, TV feature walls, wall decorative panels, ceiling panels, etc.

- Doors: PVC film laminated doors, wooden doors, PET door panels, sliding wardrobe doors, balcony partition doors, etc.

Types of Edge Banding Strips Compatible with the 8-in-1 Automatic Edge Banding Machine

PVC edge strips: Made from polyvinyl chloride (PVC), it is an economical option and one of the most cost-effective choices among edge banding materials. It bonds well with hot melt adhesive, is easy to bend, and is highly suitable for mass production. PVC edge strips can accurately mimic various wood grains and stone patterns, offering a wide range of color options to meet diverse design needs.

ABS edge strips: Composed primarily of acrylonitrile butadiene styrene (ABS), a ternary copolymer that combines the advantages of its three components, ABS edge strips is more environmentally friendly. It is ideal for children's furniture and high-end furniture with stricter environmental requirements. It offers structural stability, a longer service life, and more vibrant colors. ABS edge strips can also achieve a finer matte finish with a comfortable texture. However, it is generally more expensive than PVC edge strips.

Acrylic edge strips: Made from polymethyl methacrylate (PMMA), acrylic edge strips features a high-gloss surface with a lacquered mirror effect. It is free from harmful substances such as formaldehyde and heavy metals, complying with EU environmental standards. Suitable for furniture manufacturing with extremely high environmental requirements, it offers high surface hardness and superior scratch resistance compared to ABS and PVC, providing better protection for furniture edges.

Solid wood edge strips: Crafted from natural wood, it retains the grain, color, and texture of real timber, enabling a seamless and color-matched integration with furniture panels. Non-toxic and harmless, it is one of the most eco-friendly edge strips options. However, its surface is relatively soft and prone to scratches or wear.

PP edge strips: Primarily made from polypropylene, PP edge strips is non-toxic, odorless, and more environmentally friendly. It can be recycled, making it an eco-conscious choice. PP material is stable, resistant to aging and yellowing, and maintains color stability over extended periods. It is particularly suitable for outdoor furniture or commercial applications.

| Model | CK-468-J |

|---|---|

| Minimum Board Width | ≥60mm |

| Minimum Board Length | ≥30mm |

| Board Thickness | 10-60mm |

| Edge Strip Thickness | 0.4-3mm |

| Edge Banding Speed | 16/18/22 m/min |

| Control System | Delta / MCGS |

| Cylinders | EASUN & AirTAC |

| Solenoid Valves | EASUN & AirTAC |

| Guideways | HIWIN |

| Pressure Regulating Valve | ENSUN |

| Spindle | CC MOTOR |

| Air Pressure | 0.6 MPa |

| Total Machine Power | 16.8 kW |

| Functions | Pre-milling, glue application & pressing, front/rear trimming, rough trimming, fine trimming, contour tracking, scraping, buffing |

| Dimensions | 6800*950*1600mm |

| Weight | 2300kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.