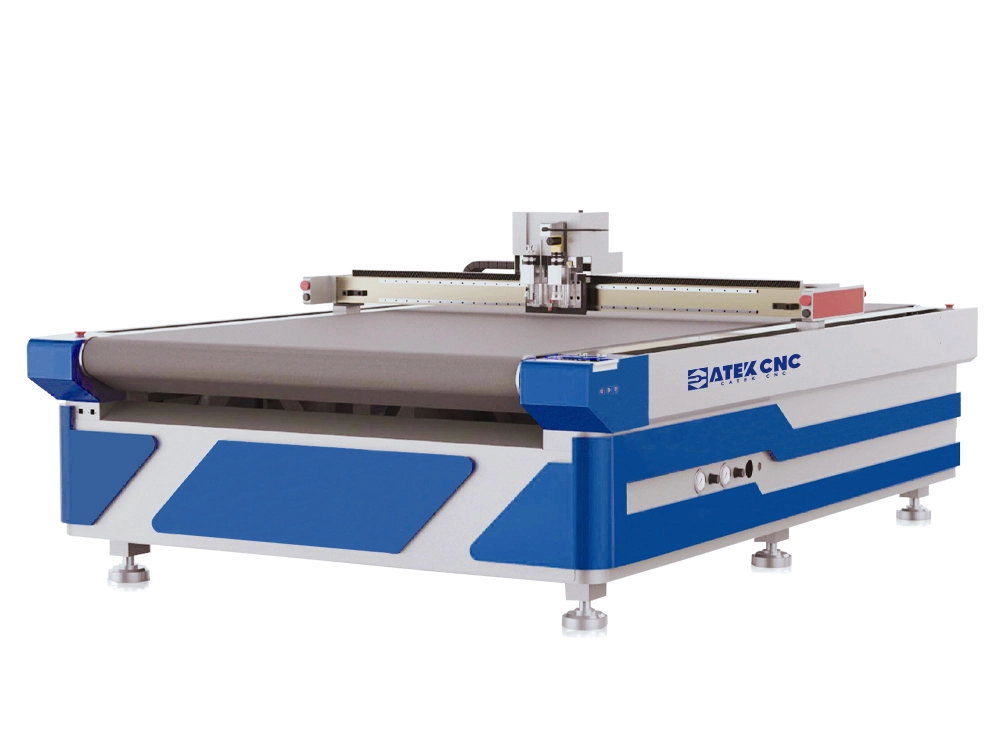

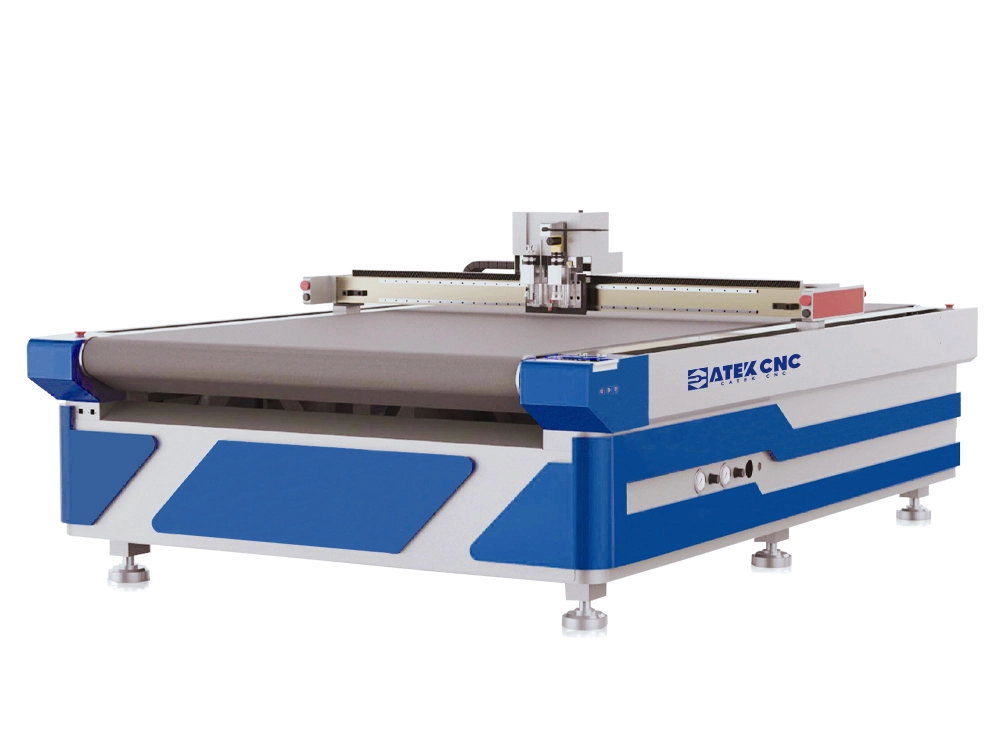

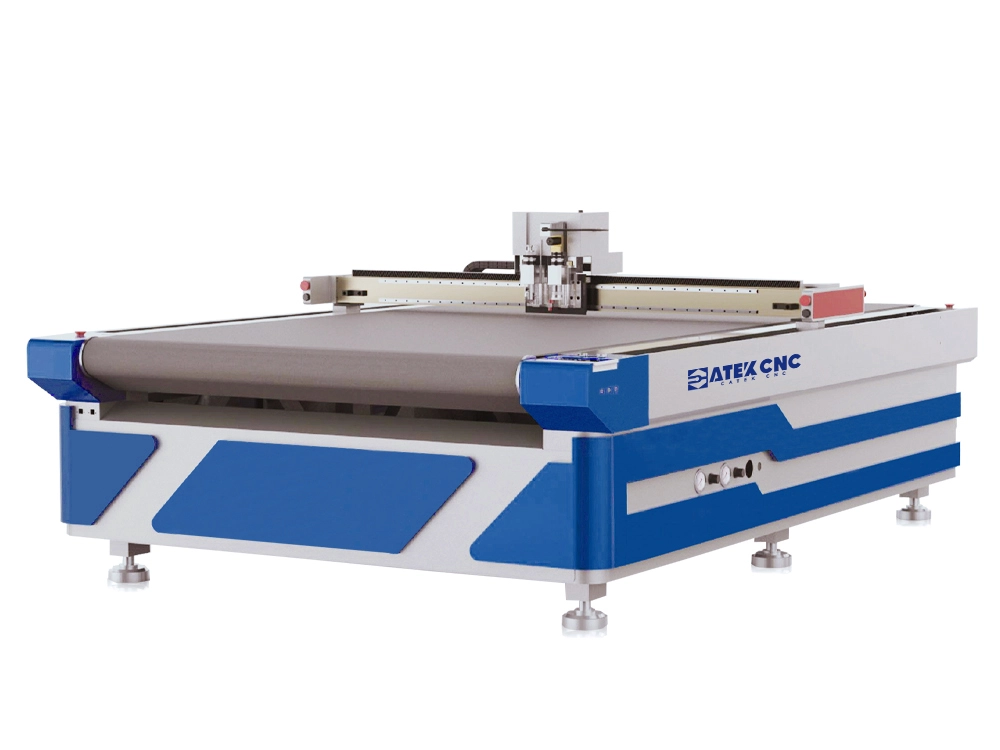

Industrial Grade Automatic Oscillating Tool Cutter for Various Flexible Materials

Best Selling High Speed CNC Oscillating Knife Cutting Machine for Fabric and Leather

[Function Description]

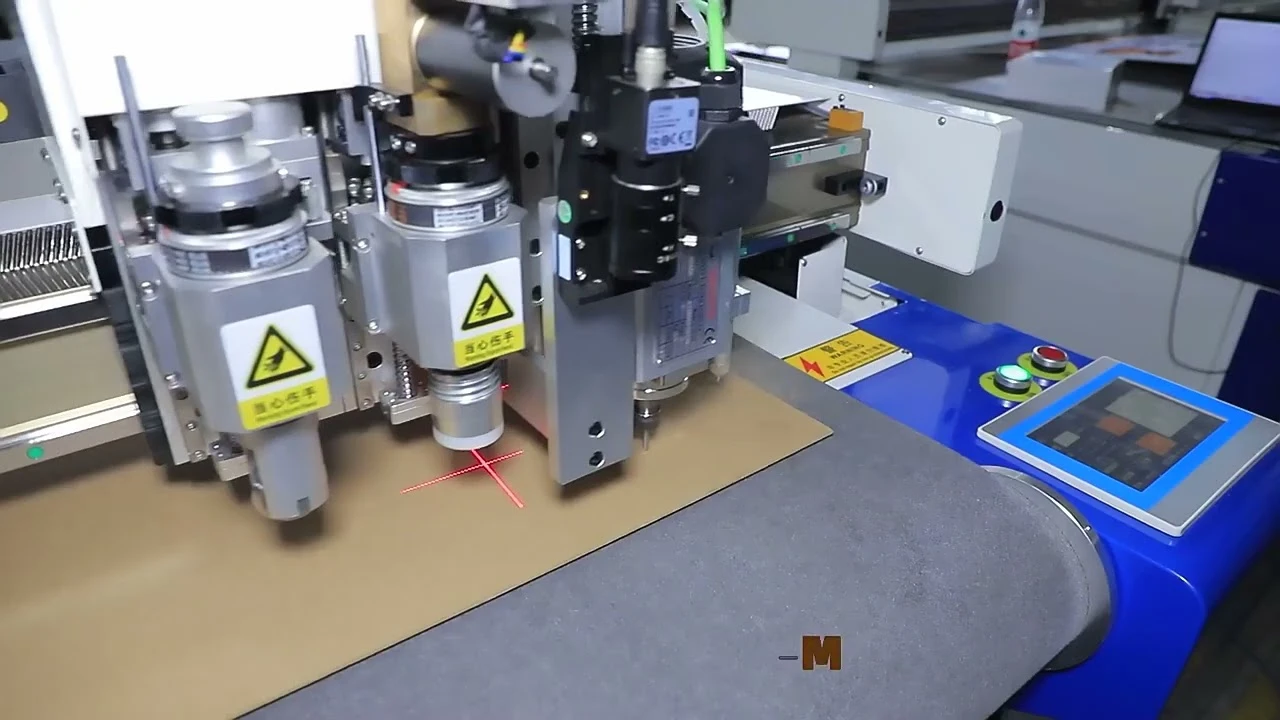

CNC oscillating knife cutting machines are numerically controlled machines that use a high-frequency oscillating knife head to cut products. The tool is driven by a servo motor to vibrate up and down at a high frequency, allowing the blade of the cutting knife to rapidly penetrate the material. Through continuous oscillation and advancement, the material is gradually cut open. The CNC system enables precise control of the cutting depth and trajectory, with machining accuracy controllable within 0.1mm, and the cutting speed is more than 6 times that of traditional manual cutting. It can be used for various flexible materials (including rubber, foam, fabric, leather) and carbon fiber, glass fiber, etc., meeting the processing needs of different industries.

The CNC oscillating knife does not produce any smoke or odor during the cutting process, nor does it cause any dust pollution, making it very environmentally friendly and compliant with the EU ROHS environmental certification requirements. Compared to CO2 laser cutting machines, it has lower energy consumption and better cutting effects, equipped with an intelligent CNC system that supports graphical programming, making operation simple. The software can automatically layout, saving material and improving material utilization. It can also be equipped with an automatic feeding system, CCD visual positioning system, and other types of tools to fulfill more complex process requirements.

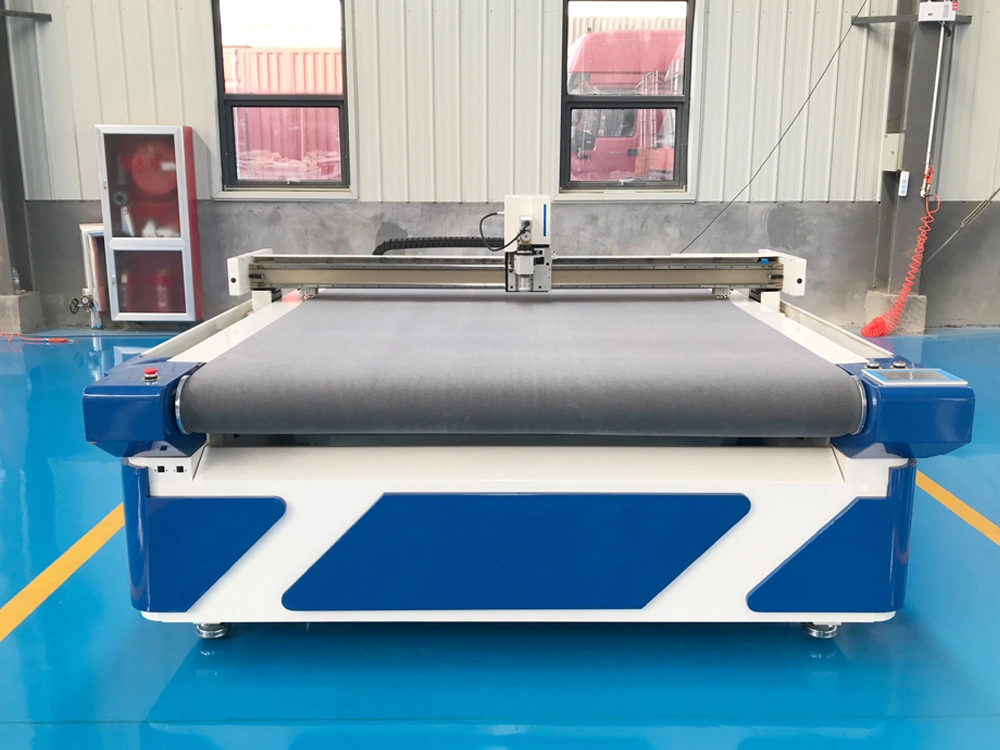

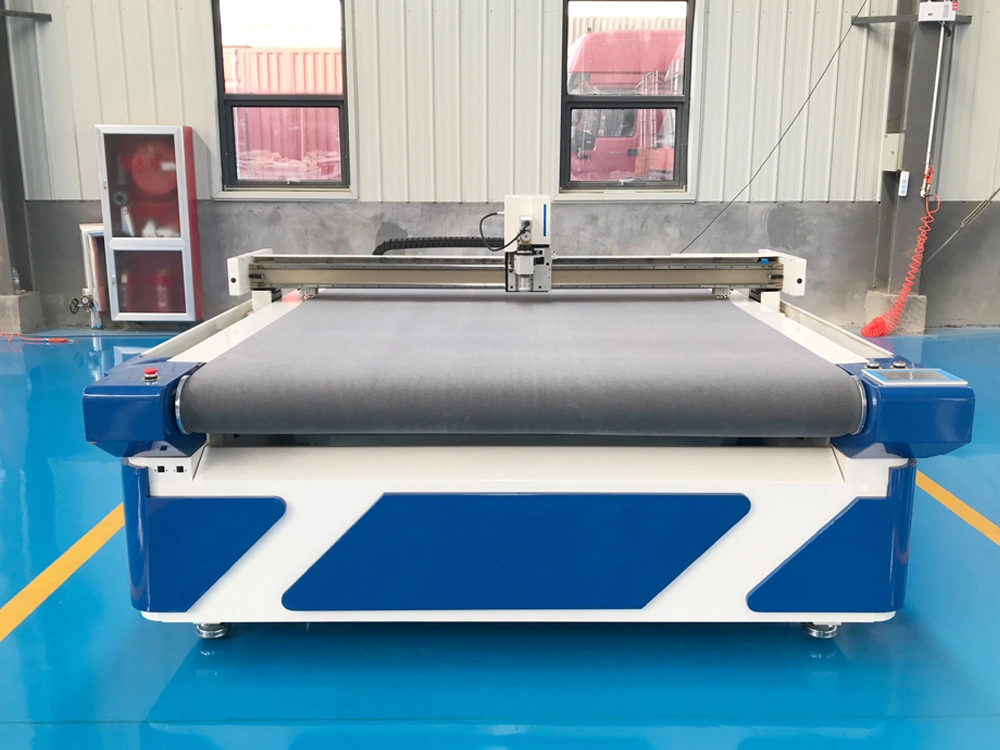

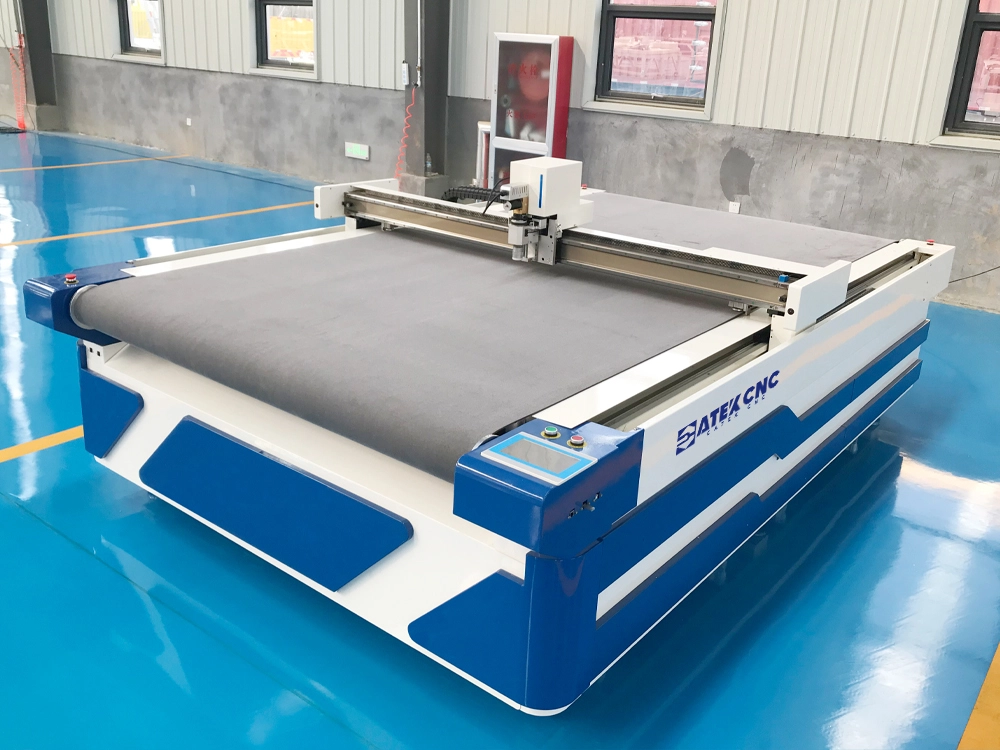

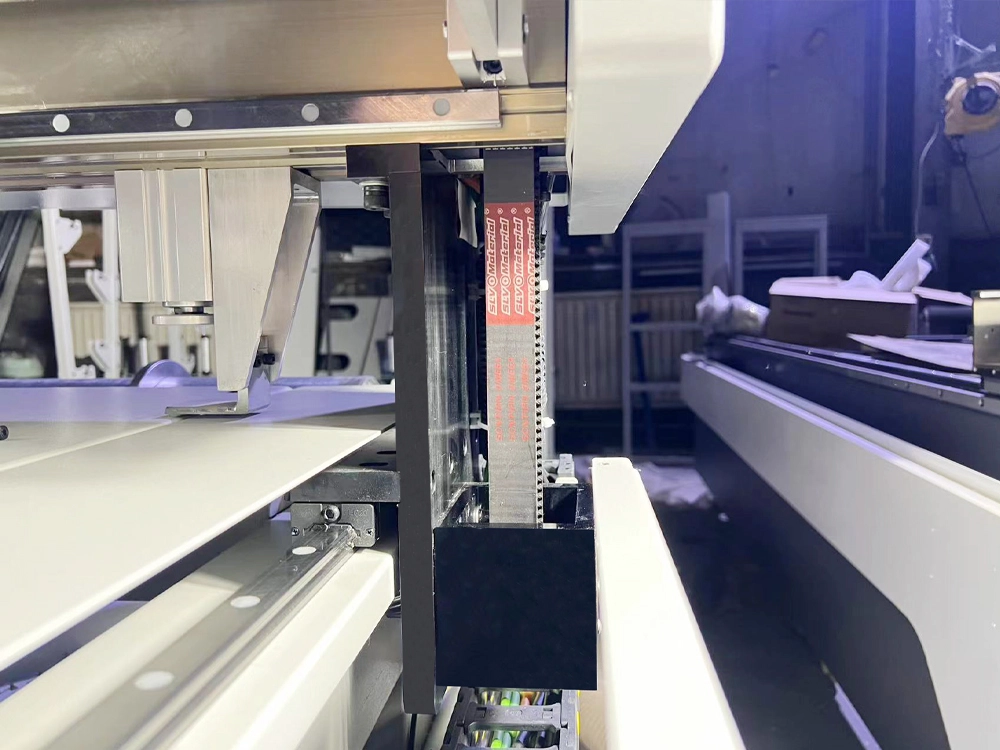

What Is the Conveyor Belt Automatic Feeding Platform of the CNC Oscillating Knife Cutting Machine?

The automatic feeding system of the CNC oscillating knife cutting machine is mainly composed of a coil material holder, conveyor belt-type vacuum adsorption worktable, servo motor, infrared sensor, and control system. During processing, the vacuum adsorption platform is used to adsorb flexible materials onto the table surface, effectively ensuring the material surface is flat and preventing material displacement during the cutting process. After the processing and cutting are completed, the conveyor belt platform automatically transports the material to the processing position, realizing automatic feeding → automatic cutting → automatic unloading, with the entire process being unmanned, saving manual labor.

Advantages of Industrial-grade Intelligent CNC Oscillating Knife Cutting Machine

- Industrial-grade bed made of sheet metal and thickened square steel with seamless welding structure, tempered to relieve stress, and then all planes and mounting holes are processed at once by a high-precision gantry mill, ensuring the strength, precision, and service life of the machine.

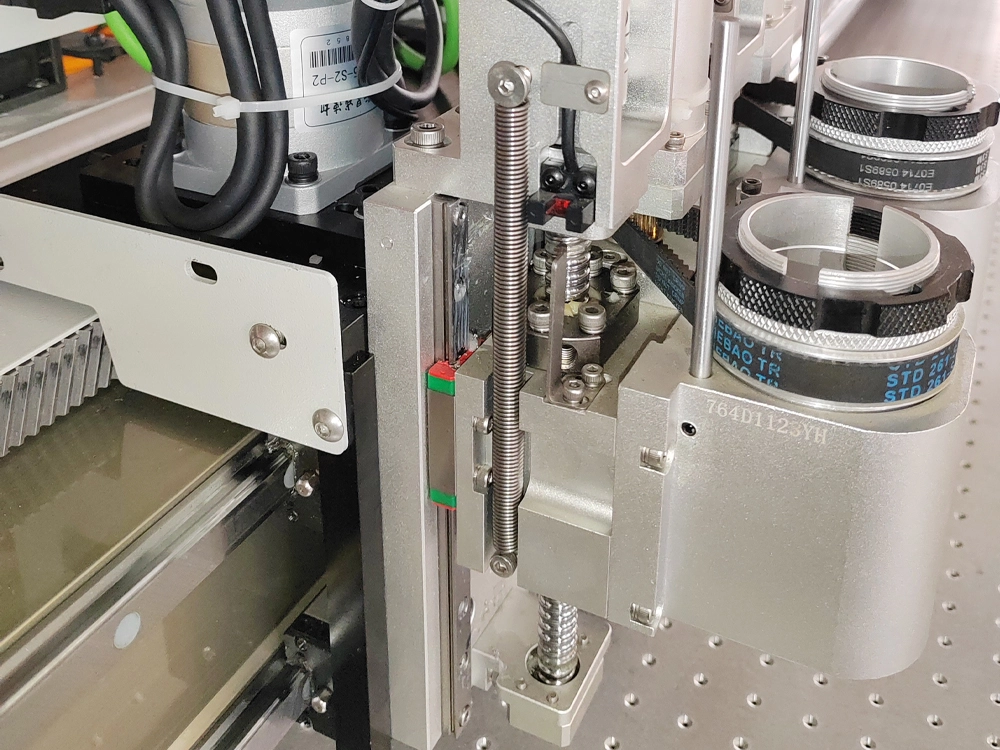

- X/Y axis adopts high-precision ground helical gears/racks, Z axis transmission adopts TBI ball screws, combined with servo drive, ensuring the accuracy and stability of the equipment at high speeds.

- Intelligent CNC cutting, no need for any molds, suitable for a variety of materials, simple operation, and fast cutting speed.

- Equipped with an automatic oiling maintenance system, it can stably and automatically maintain the machine's transmission system for a long time, extending the machine's service life.

- Aluminum alloy integrated honeycomb hole vacuum adsorption worktable, flatness error ±0.15mm, suction force can be freely adjusted.

- High-breathability adsorption felt table, excellent breathability, cut-resistant, and long service life.

- More environmentally friendly to use, does not produce any dust or waste, ensuring a clean working environment.

- Uses a high-pressure vortex vacuum pump, strong wind force, strong adsorption force, and more uniform adsorption area.

- The oscillating knife device has a oscillation frequency of up to 20000vpm per minute, with a oscillation amplitude within 1mm.

- The cutting head can be freely replaced according to different cutting materials, and various tools such as round knives, half-cut knives, drag knives, bevel knives, and milling cutters can be selected.

Details of Automatic CNC Oscillating Knife Cutting Machine

- Workbench

Aluminum honeycomb vacuum adsorption workbench with a large number of air holes on the table top.

- Felt pad

4mm highly breathable felt pad is laid on the vacuum adsorption workbench to prevent the knife from being damaged by direct contact with the table.

- Vortex vacuum pump

Strong suction power, stable operation, no need to use a water tank.

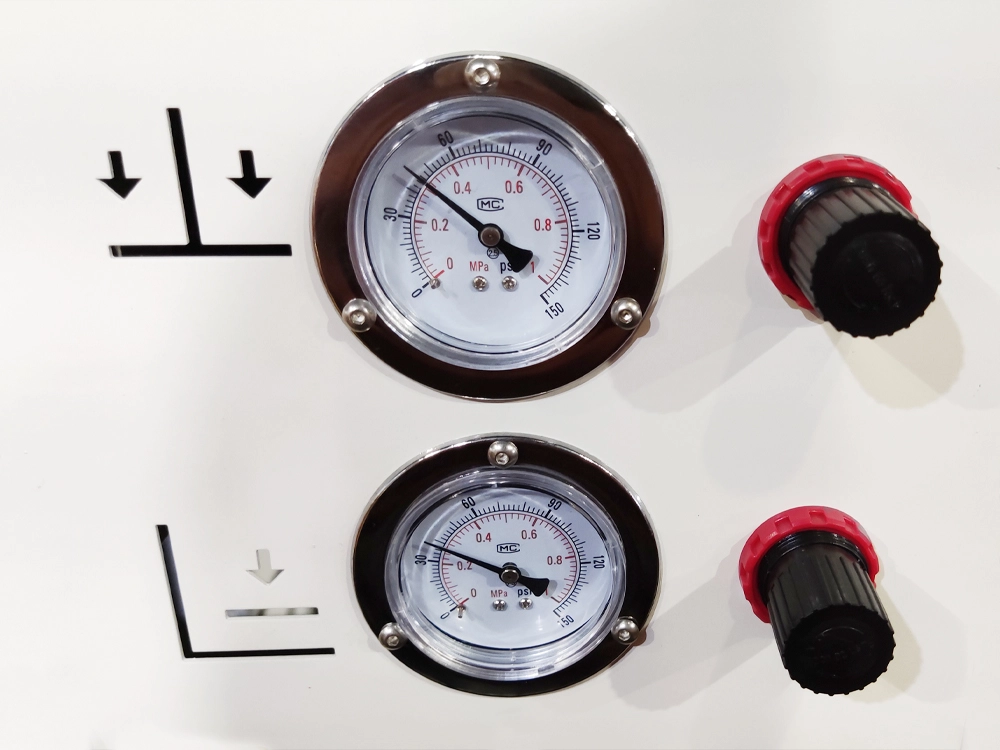

- Air pressure control panel

The material adsorption and pressing cylinders are controlled separately, and a pressure gauge is provided to check the suction force in real time.

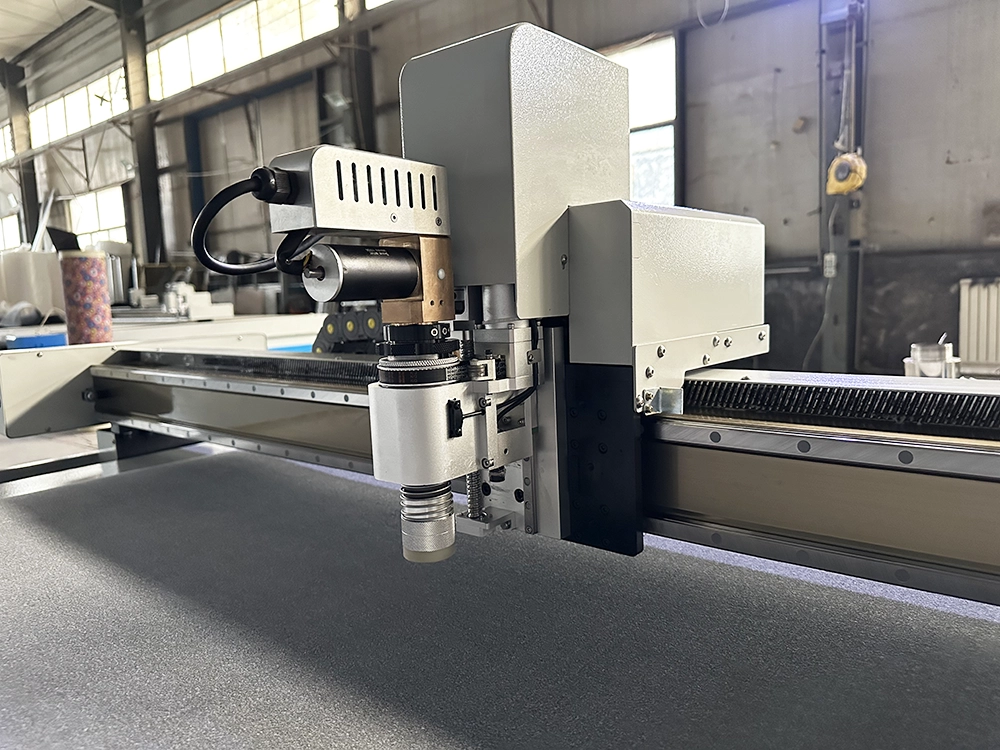

- Digital cutting head

- Tool holder

Widely compatible, can hold various types of digital tools

- Transmission system

High-precision helical rack/gear, Taiwan Hiwin guide rail.

- Control system

Full touch LCD display, supports multiple languages.

- Optional auto roll loader

The continuous cutting of the whole roll of fabric is realized, and the feeding error is controlled within 3mm.

Can be equipped with multiple digital tools of different types.

Technical Parameters of Automatic CNC Oscillating Knife Cutting Machine

| Model | CK-1610-K | CK-1625-K | CK-1825-K | CK-2125-K | Customized models |

| Processing Dimensions | 1600*1000mm | 1600*2500mm | 1800*2500mm | 2100*2500mm | Customized sizes |

| Body Structure | Overall precision welding | ||||

| Gantry | High-strength aviation aluminum integrated gantry structure | ||||

| Feeding Method | Manual feeding/automatic feeding (optional) | ||||

| Driving Mode | Servo motor / servo drive | ||||

| Transmission Mode | Precision rack + linear guide | ||||

| Table | Aviation aluminum vacuum adsorption platform + 4mm felt blanket workbench | ||||

| Material Fixing Method | Vacuum adsorption | ||||

| CNC System | Ruida RDC | ||||

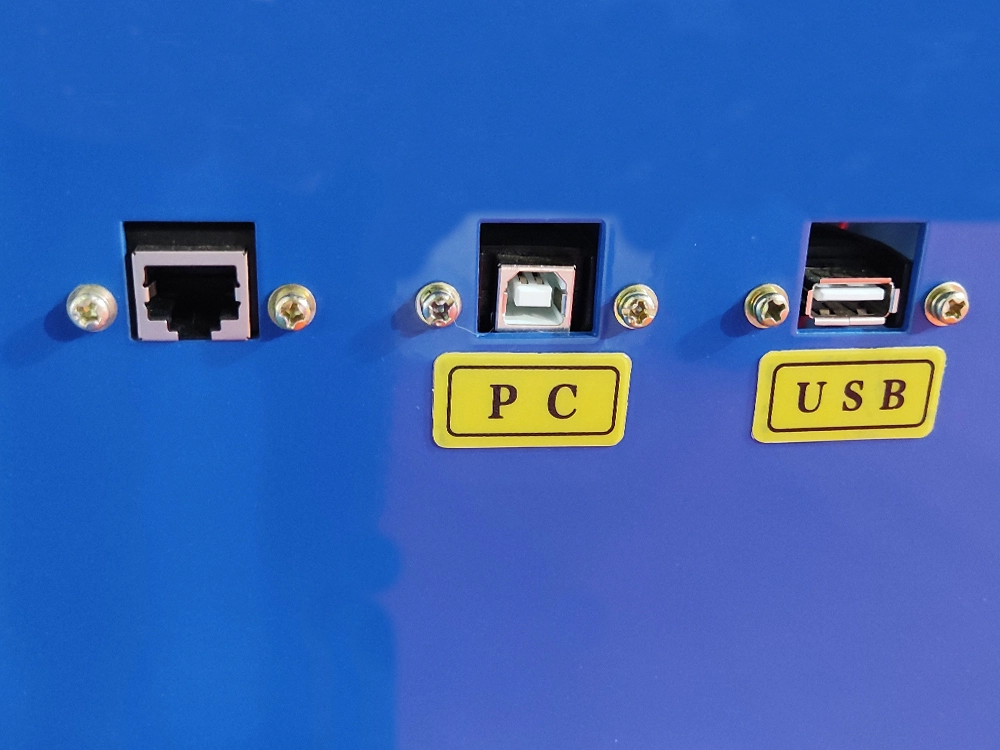

| Transmission Port | USB, network port | ||||

| Air pump | 5.5KW/7.5KW/9KW (optional) three-phase AC vortex vacuum air pump | ||||

| Optional Vision Positioning System | Camera, projector | ||||

| Optional Tools | Oscillating knife, rotary cutting knife, pneumatic knife, drag knife, creasing wheel, beveling knife, punching knife, etc. | ||||

| Operating Voltage | AC 220V/380V 50Hz-60Hz | ||||

| Security System | Infrared sensor + emergency stop switch (double protection) | ||||

| Maximum Pocessing Speed | 0-1500mm/s (depending on the material) | ||||

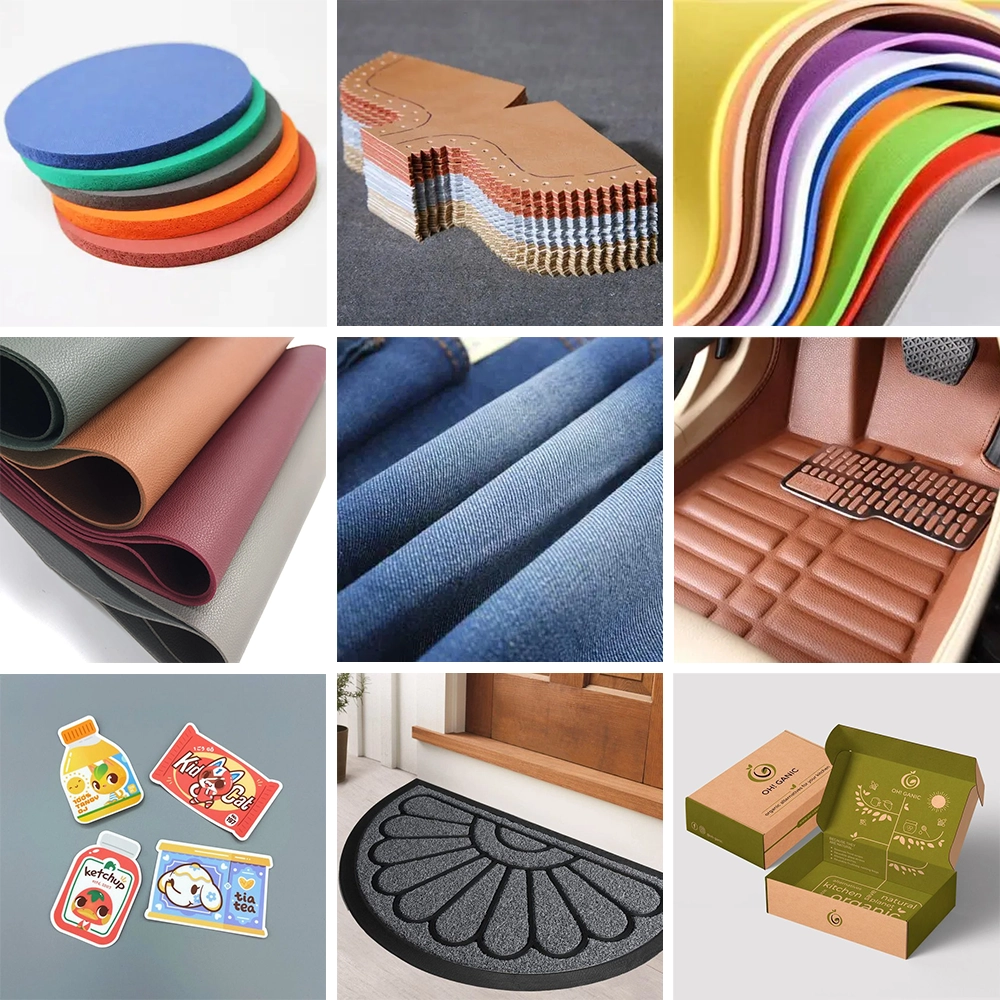

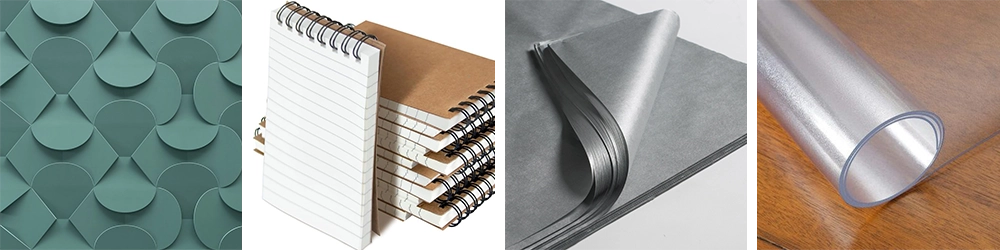

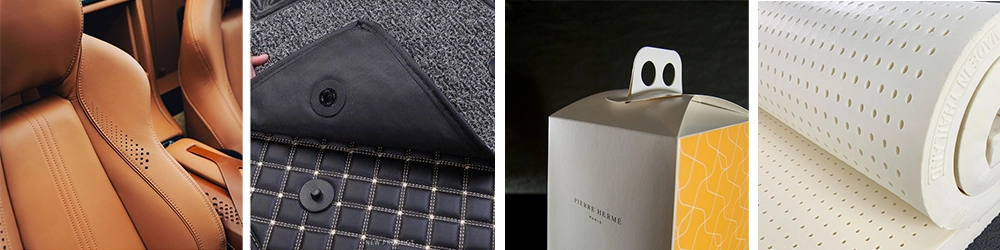

Application Scope of CNC Oscillating Knife Cutting Machine

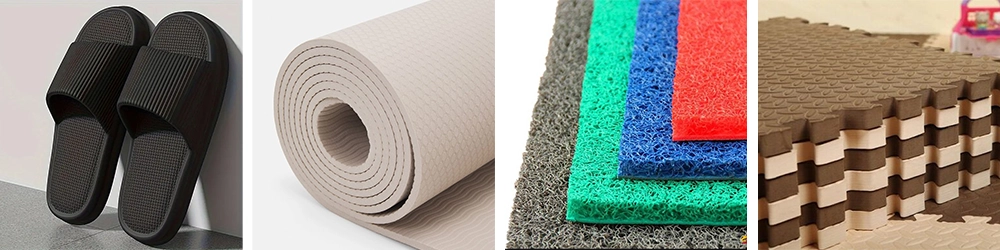

- Furniture industry: fabric sofas, carpets and mats, curtains, soft beds, tablecloths and table mats, etc.

- Apparel industry: fabric cutting for clothing, cutting for high-end custom clothing, cutting for fur and leather.

- Automotive interiors: cutting for car mats, leather seats, steering wheel covers, car covers, curtains, etc.

- Footwear and luggage: brand luggage, wallets, suitcases, various leather shoes, leather bags, etc.

- Composite materials: carbon fiber, fiber cotton, pearl cotton, fiber cotton, soundproofing cotton, foam boards, etc.

- Sealing gaskets: graphite, asbestos, non-asbestos, rubber, PTFE, cork, silicone, etc.

- Advertising industry: KT boards, adhesive labels, color box packaging, advertising light boxes, etc.

The Following Are the Processable Products of Automatic CNC Oscillating Knife Cutting Machine

Introduction of Cutting Tools for Automatic CNC Oscillating Knife Cutting Machine

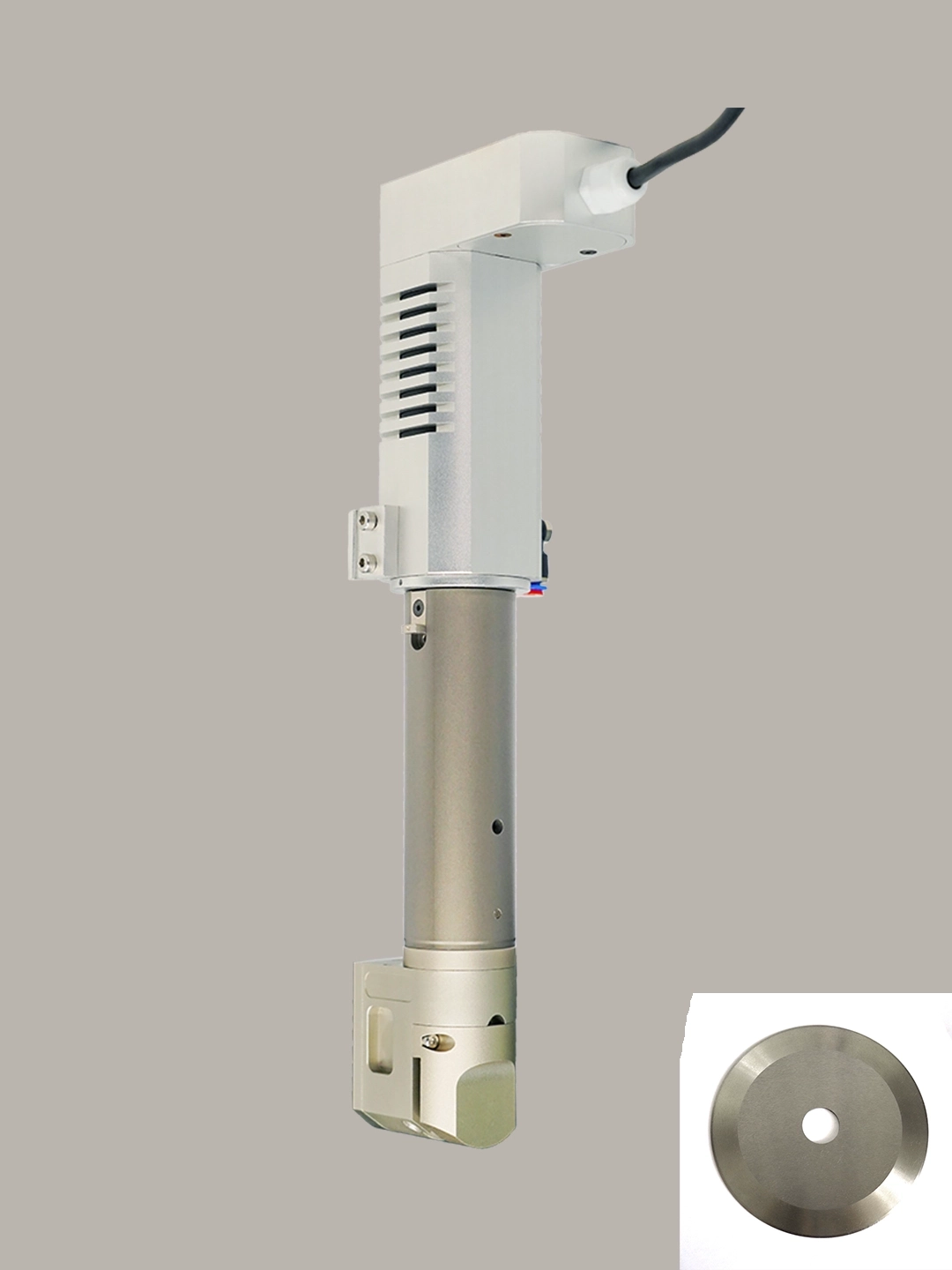

Electric Oscillating Knife

Electric Oscillating Knife- Cutting thickness: 15mm Blade angle: 16°, 26°, 39°.

- Functional features: high frequency oscillation, smooth cut surface, fast cutting speed.

- Applicable materials: corrugated paper, silicone, PVC, KT board, honeycomb board and other hard materials.

Large Amplitude Electric Oscillating Knife

Large Amplitude Electric Oscillating Knife- Cutting thickness: 100mm.

- Functional features: high frequency oscillating, large amplitude, suitable for cutting and shaping of medium density materials.

- Applicable materials: Advertising KT board, foam board, ABS plastic, corrugated plastic board, corrugated cardboard, cardstock, gray paperboard, loop pile floor mats, carpet, sealing rings, carbon fiber prepreg, etc.

Pneumatic Oscillating Knife

Pneumatic Oscillating Knife- Cutting thickness: 110mm.

- Functional features: High frequency oscillation, can cut thicker materials, as well as soft foam materials or materials with a hardness of less than 70 degrees.

- Applicable materials: EPE, corrugated paper, honeycomb paperboard, sound-absorbing cotton, gaskets, etc.

V-Cut Knife

V-Cut Knife- Cutting thickness: 30mm Blade angle: 30°, 45°, 60°, 75°, 90°.

- Functional features: V-groove cutting is achieved, and the required cutting effect is achieved by equipping two tool heads of different sizes and adjusting the blade installation angle. The cutting angle can be customized.

- Applicable materials: Gray card, corrugated paper, insulation board, silencer board, cat claw board, honeycomb board, EPE, etc.

Drag Knife

Drag Knife- Cutting thickness: 15mm Blade angle: 16°, 26°, 39°.

- Functional features: The speed is much faster than the oscillating knife, and the cutting edge is smooth.

- Applicable materials: PVC, PET, copper plate paper, gray card, floor leather, soft glass, etc.

Rotary Cutting Knife

Rotary Cutting Knife- Cutting thickness: 10mm Blade diameter: 16-40mm.

- Functional features: The circular blade is driven by the motor and rotates at high speed to cut the material, with fast cutting speed and smooth edges.

- Applicable materials: Non-woven fabrics, protective clothing, textile fabrics, fur products, mesh cloth, canvas, etc.

Kiss-Cut Knife (Half-Cut Knife)

Kiss-Cut Knife (Half-Cut Knife)- Cutting thickness: 2mm.

- Functional features: can achieve half-cut effect, can be used to cut tiny and fine graphics, half-cut effect is stable and can be precisely adjusted, and does not require high machine flatness.

- Applicable materials: Self-adhesive, reflective film, photo adhesive, advertising paper cardboard, gaskets, etc.

Punching Tool

Punching Tool- Punching thickness: round holes, pinholes, slotted holes from 0-10mm diameters.

- Functional features: It can punch holes on materials with low hardness. V-punch, needle punch, round punch and slotted punch are available.

- Applicable materials: Genuine leather, imitation leather, PU, PVC, EVA, SBR, cloth, cardboard, kraft paper and other materials.

Milling Cutter

Milling Cutter- Cutting thickness: 20mm Milling cutter diameter: 0-7.5mm.

- Functional features: It can perform engraving and hollowing processing on non-metallic materials with high hardness above 60 degrees, suitable for advertising, packaging, molds, woodworking and other industries.

- Applicable materials: Acrylic, aluminum-plastic board, density board, plywood, PTFE board, hard rubber, etc.

Creasing Wheel

Creasing Wheel- Cutting thickness: 10mm Creasing wheel tool thickness: 0.5-5mm.

- Functional features: Indentation processing on the surface of the material is convenient for product molding, and different pressures in the X and Y directions can be set.

- Applicable materials: Corrugated, cardboard, PVC, PET, etc.

| Model | CK-1610-K | CK-1625-K | CK-1825-K | CK-2125-K | Customized models |

|---|---|---|---|---|---|

| Processing Dimensions | 1600*1000mm | 1600*2500mm | 1800*2500mm | 2100*2500mm | Customized sizes |

| Body Structure | Overall precision welding | ||||

| Gantry | High-strength aviation aluminum integrated gantry structure | ||||

| Feeding Method | Manual feeding / automatic feeding (optional) | ||||

| Driving Mode | Servo motor / servo drive | ||||

| Transmission Mode | Precision rack + linear guide | ||||

| Table | Aviation aluminum vacuum adsorption platform + 4mm felt blanket workbench | ||||

| Material Fixing Method | Vacuum adsorption | ||||

| CNC System | Ruida RDC | ||||

| Transmission Port | USB, network port | ||||

| Air pump | 5.5KW/7.5KW/9KW (optional) three-phase AC vortex vacuum air pump | ||||

| Optional Vision Positioning System | Camera, projector | ||||

| Optional Tools | Oscillating knife, rotary cutting knife, pneumatic knife, drag knife, creasing wheel, beveling knife, punching knife, etc. | ||||

| Operating Voltage | AC 220V/380V 50Hz-60Hz | ||||

| Security System | Infrared sensor + emergency stop switch (double protection) | ||||

| Maximum Pocessing Speed | 0-1500mm/s (depending on the material) | ||||

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.