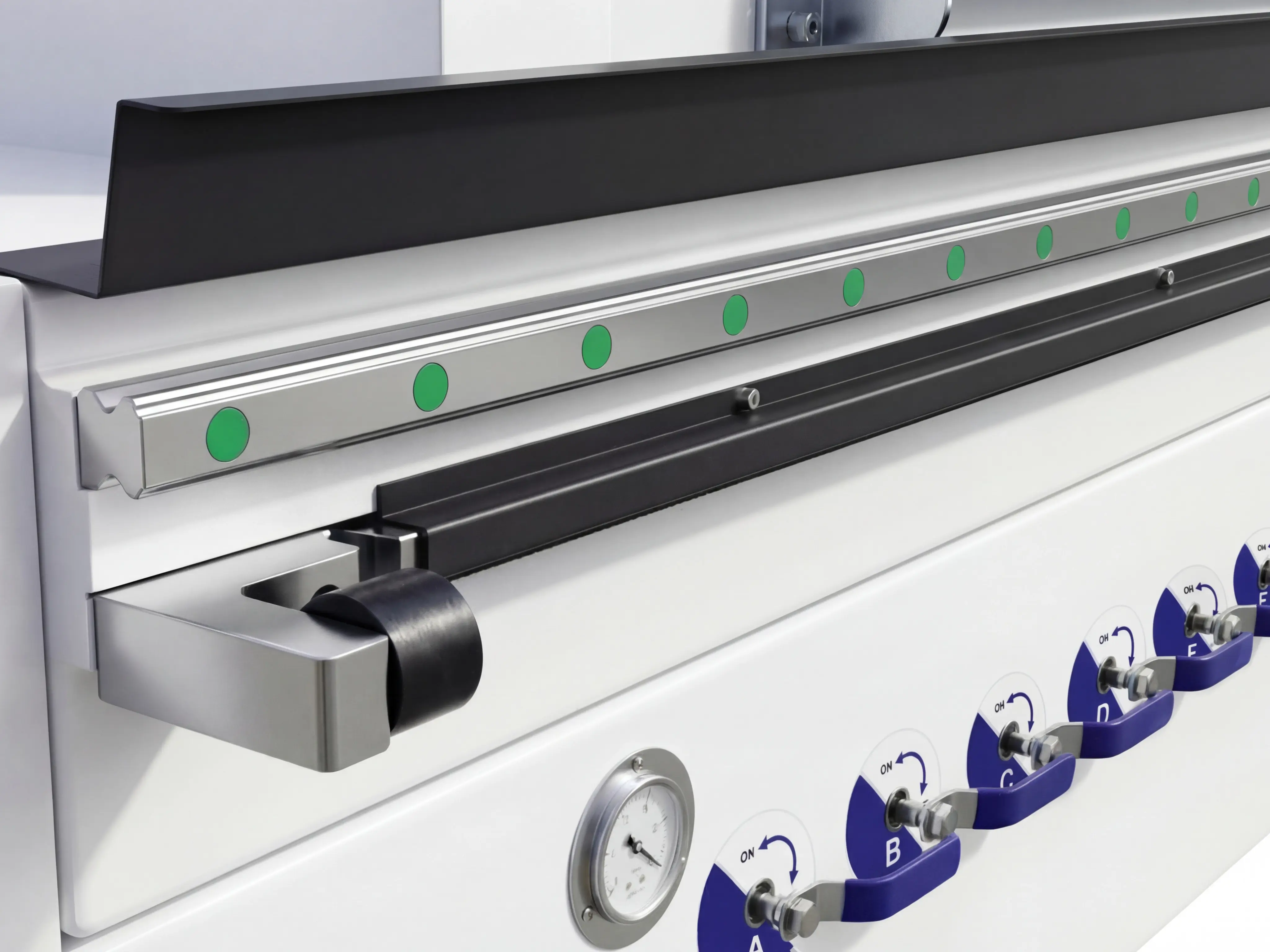

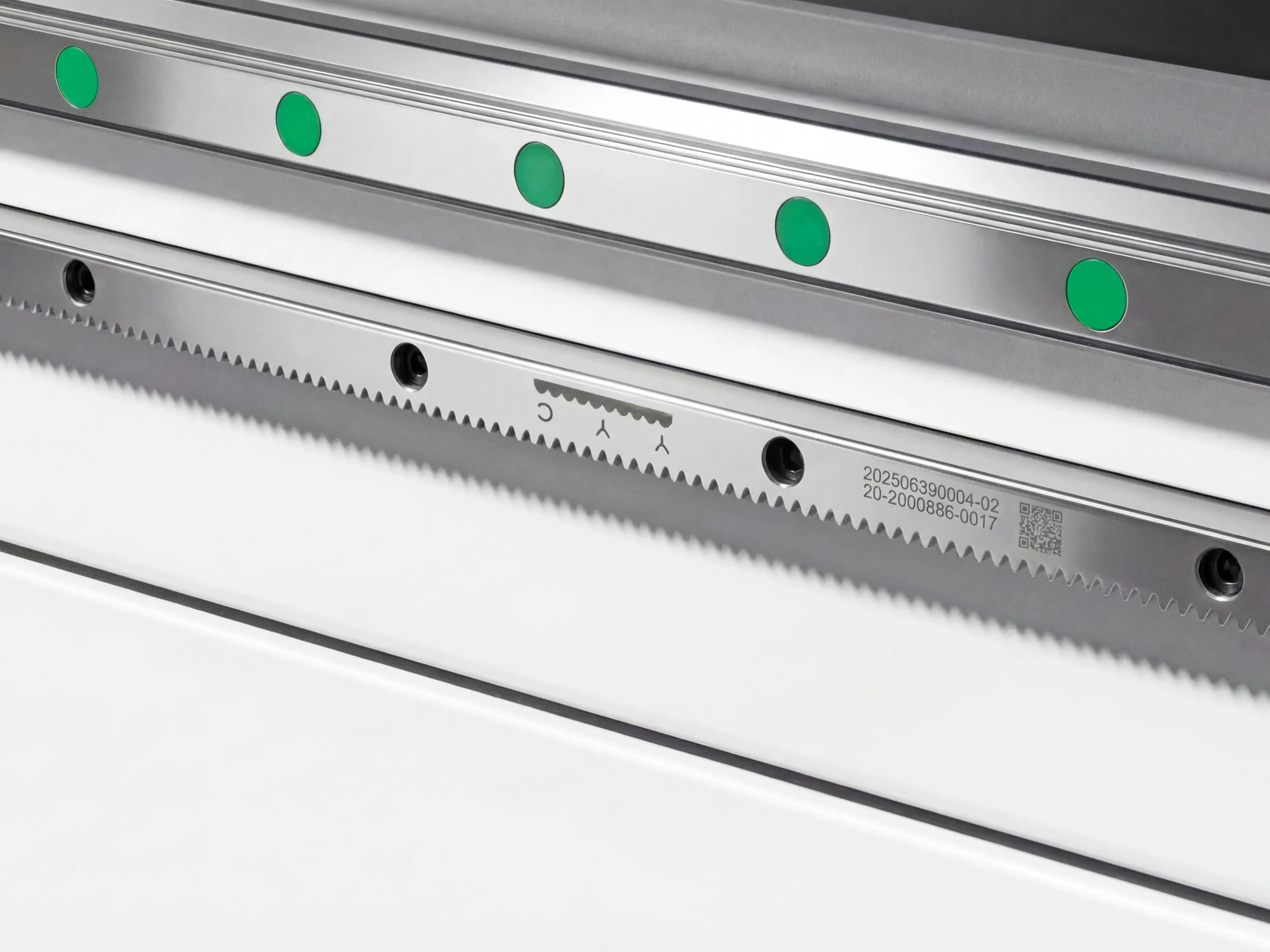

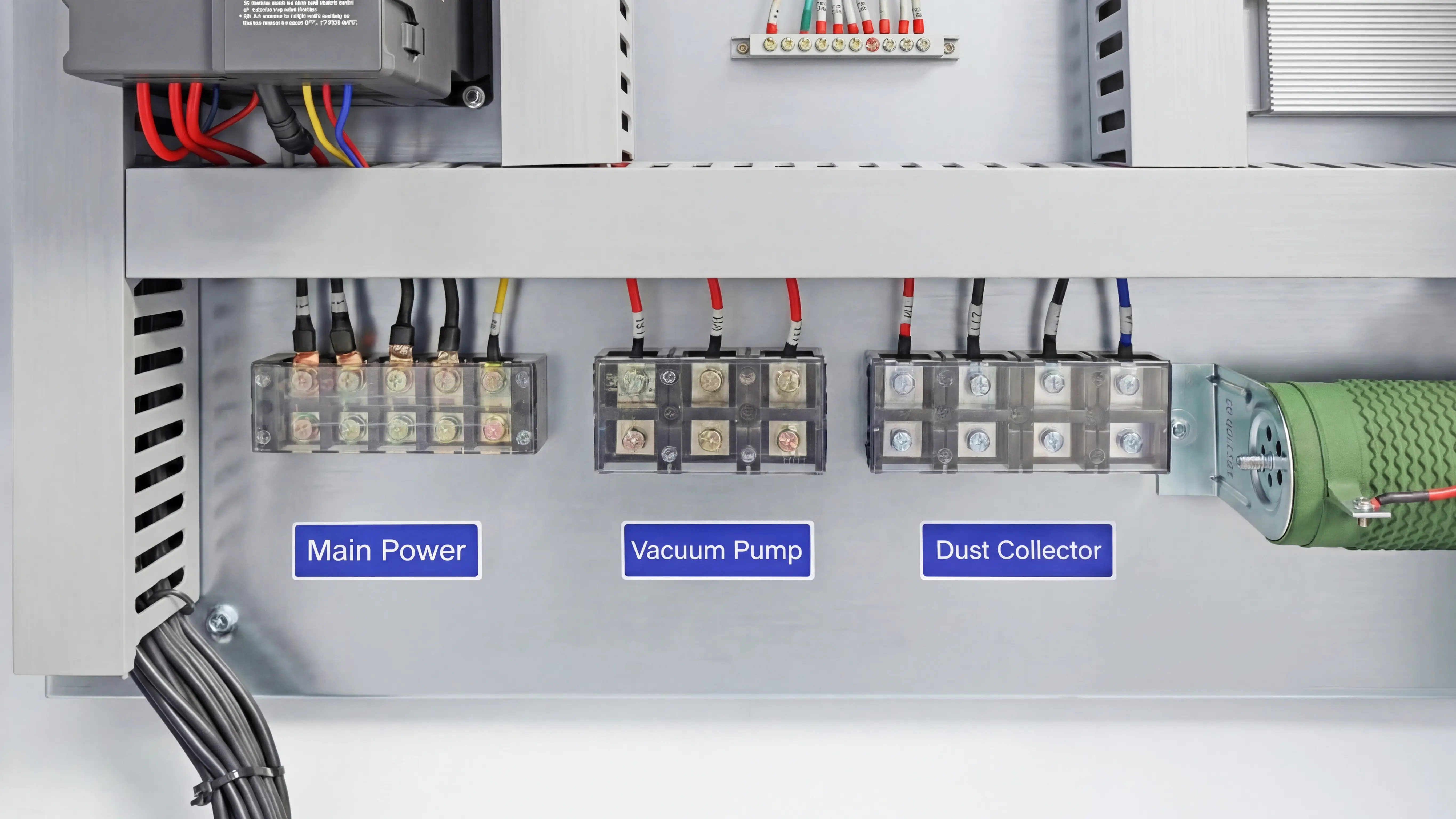

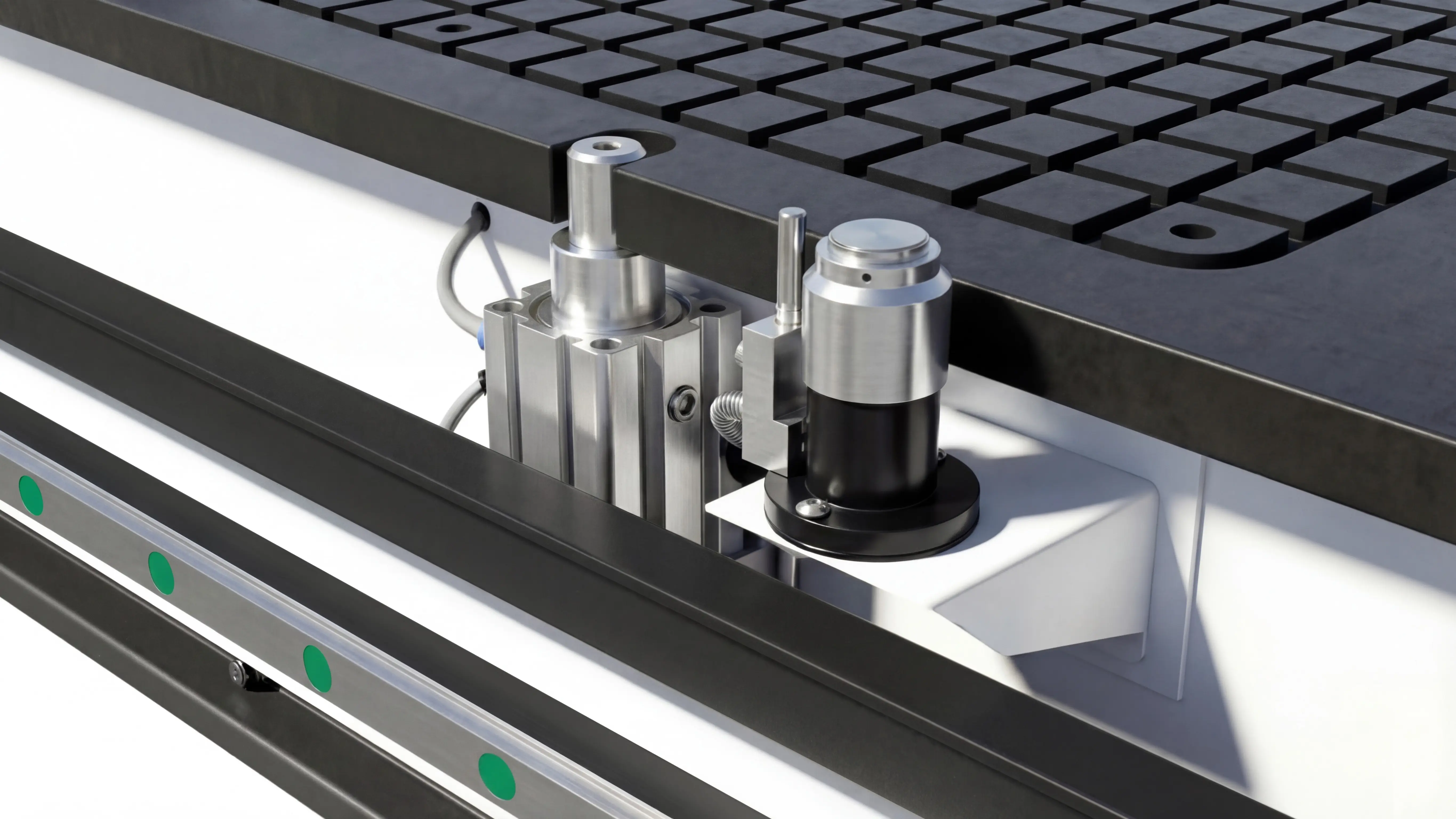

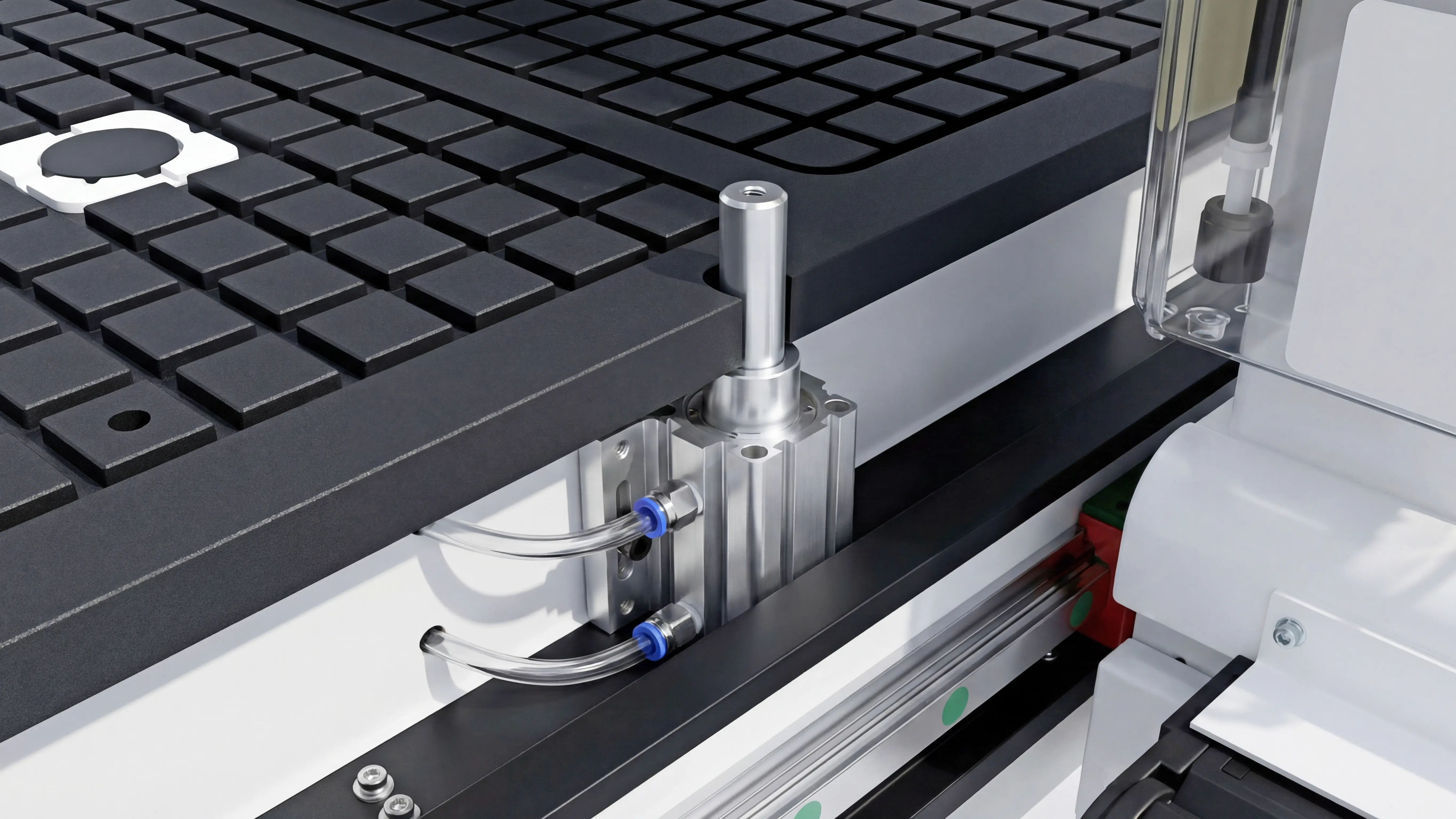

High-Capacity Electric Lubricator

- The ATC CNC router machine is equipped with a programmable timed and quantitative lubrication system, which allows users to customize the lubrication duration and intervals according to the equipment's operating frequency. This achieves full automation of the lubrication process with no manual intervention required.

- The system integrates pressure protection and oil shortage alarm functions. It automatically issues alerts when oil levels are low, effectively preventing equipment malfunctions caused by insufficient lubrication.

- Initiating lubrication operations fully automatically, it saves over 80% of labor compared to manual lubrication methods, improves maintenance efficiency by more than 50%, and ensures the equipment can operate continuously at high speed and stability 24 hours a day.

Lubrication System

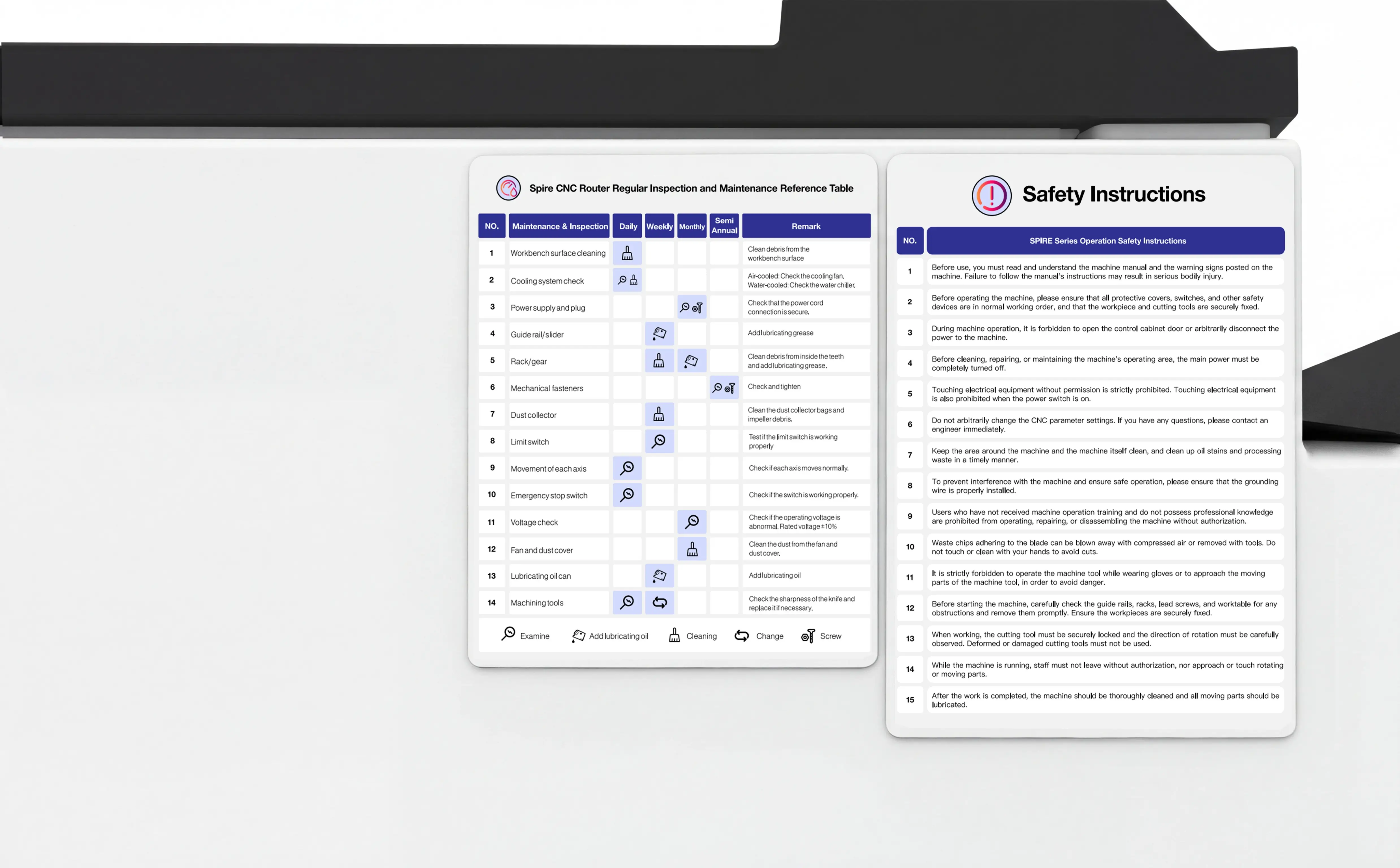

Regular Maintenance

Fully Automatic