Enjoy Spire's exclusive top-level service

Reliability, confidence, and ease

-

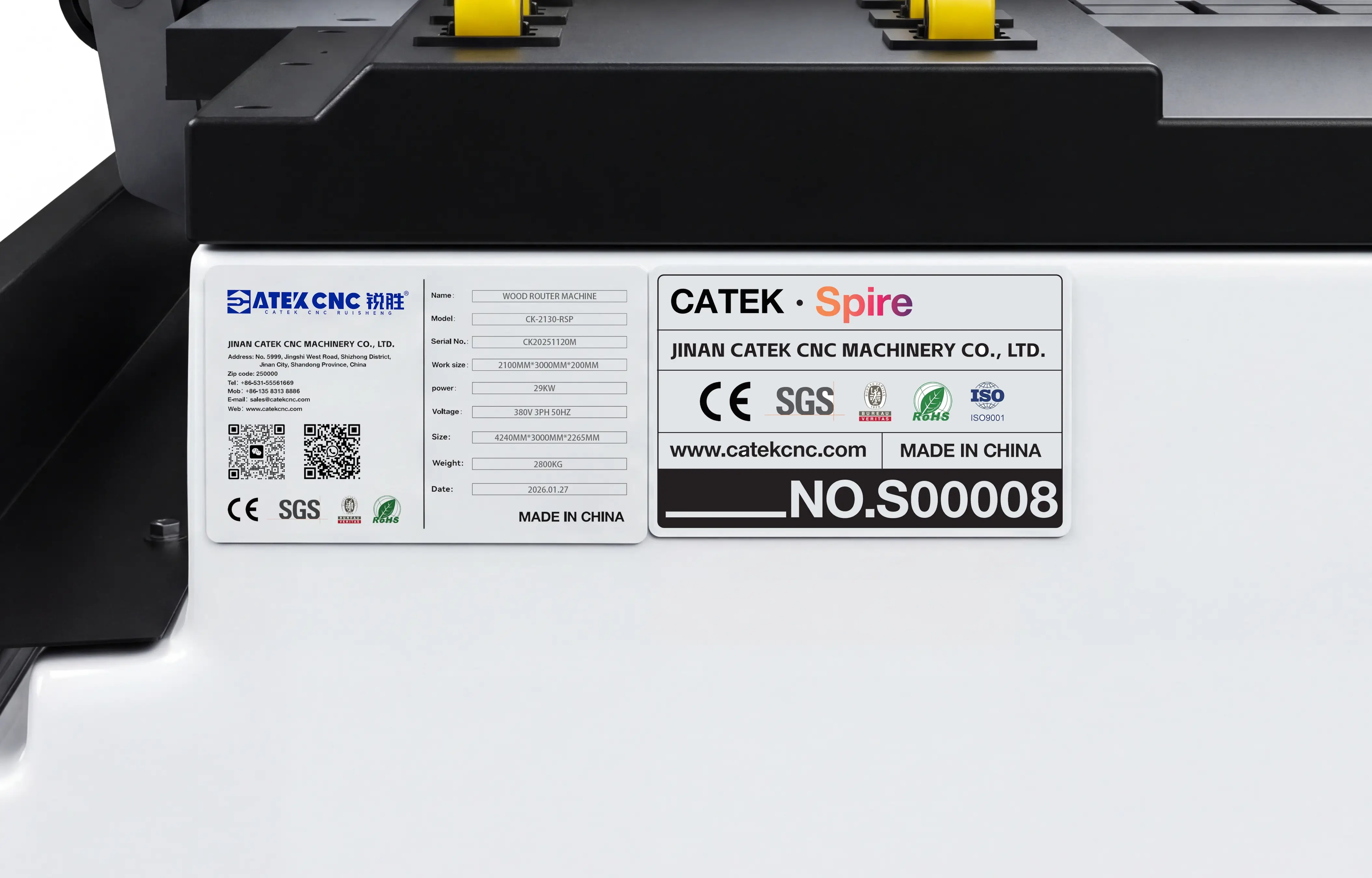

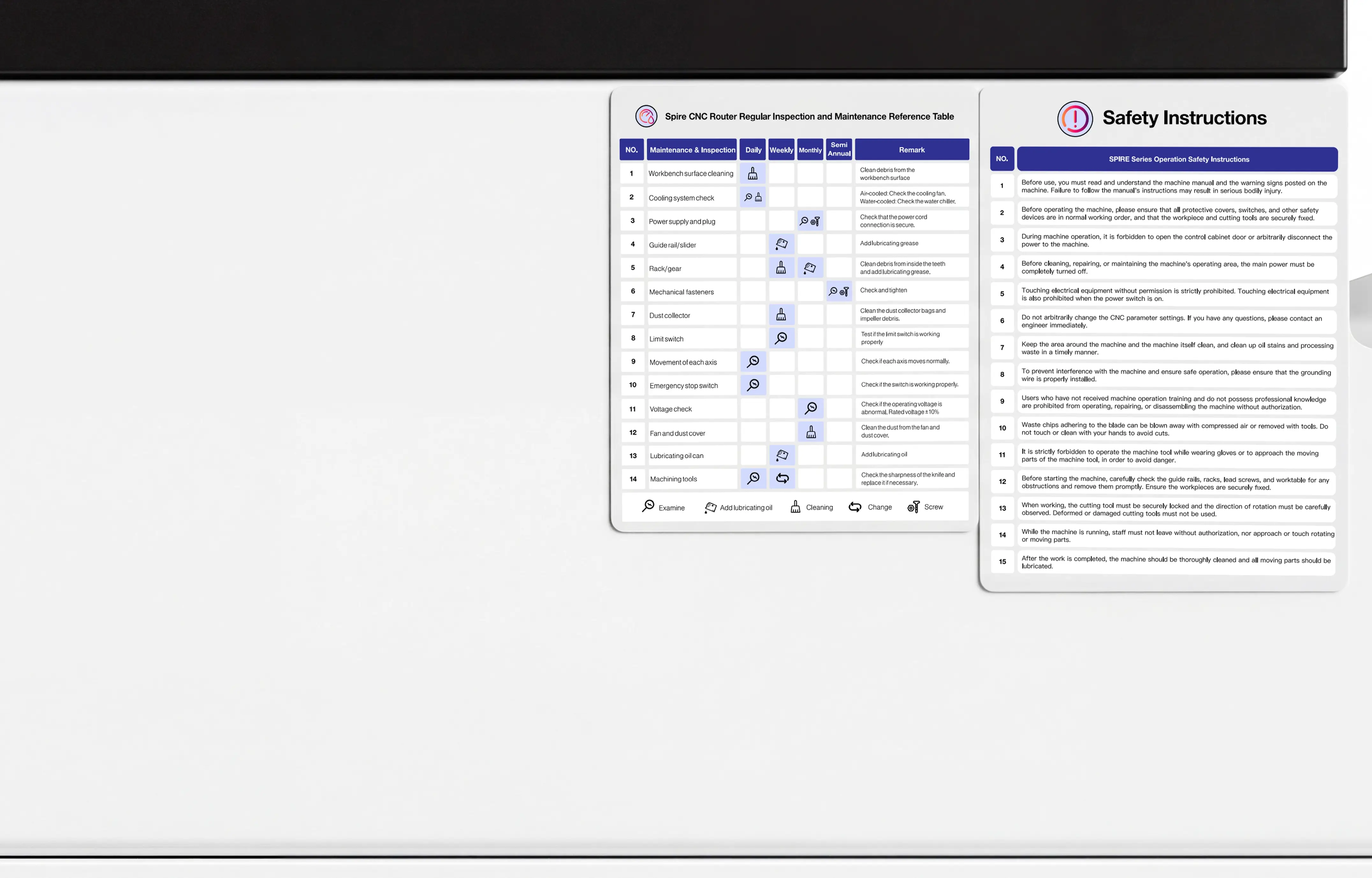

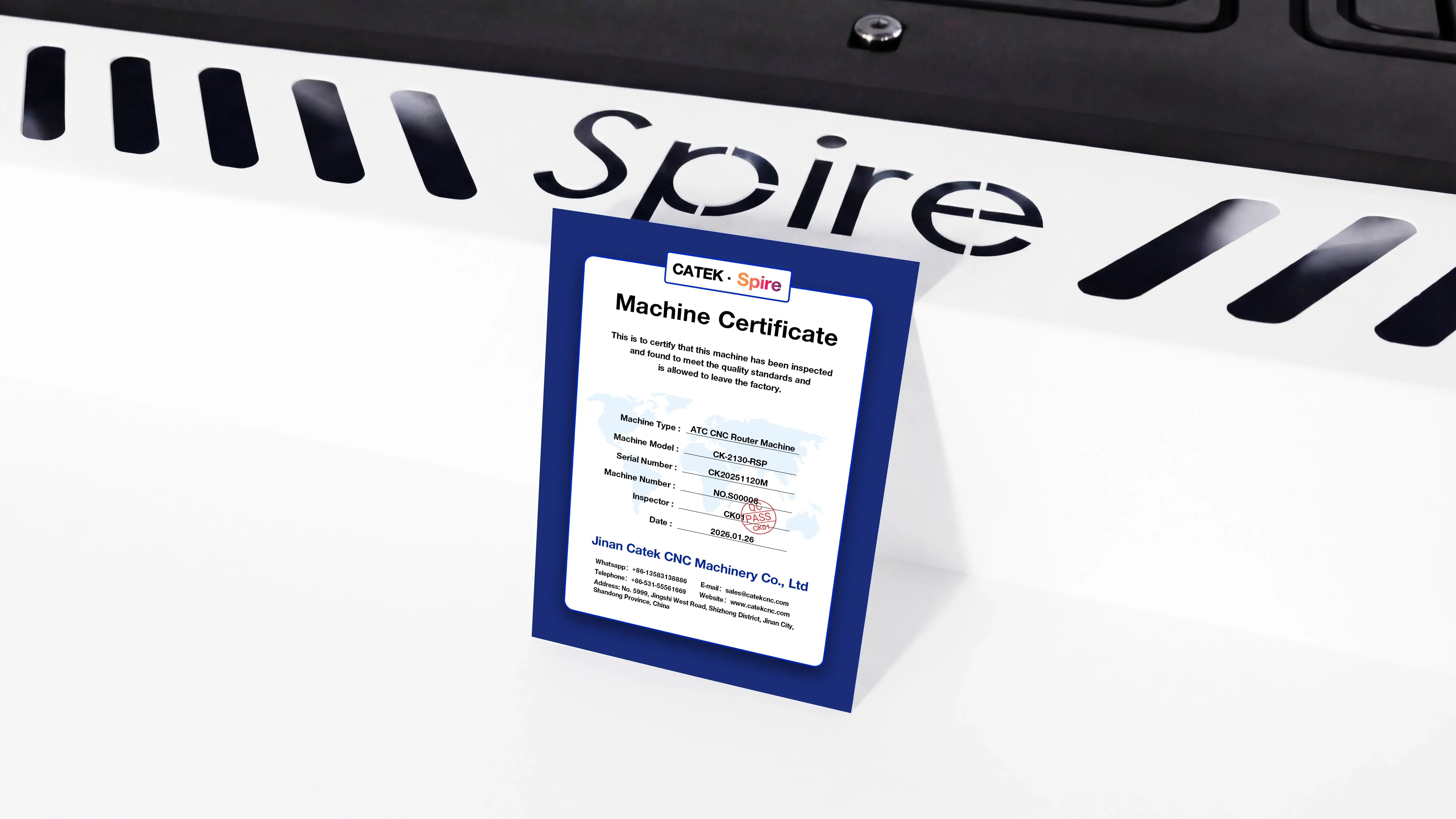

Five-years free warrantyEnjoy Spire VIP service, providing free warranty and maintenance for the entire machine, bringing you a worry-free experience.

Five-years free warrantyEnjoy Spire VIP service, providing free warranty and maintenance for the entire machine, bringing you a worry-free experience. -

Exclusive private customer service and after-sales team7*24 hours online service, on duty around the clock, to solve any problems for you as soon as possible.

Exclusive private customer service and after-sales team7*24 hours online service, on duty around the clock, to solve any problems for you as soon as possible. -

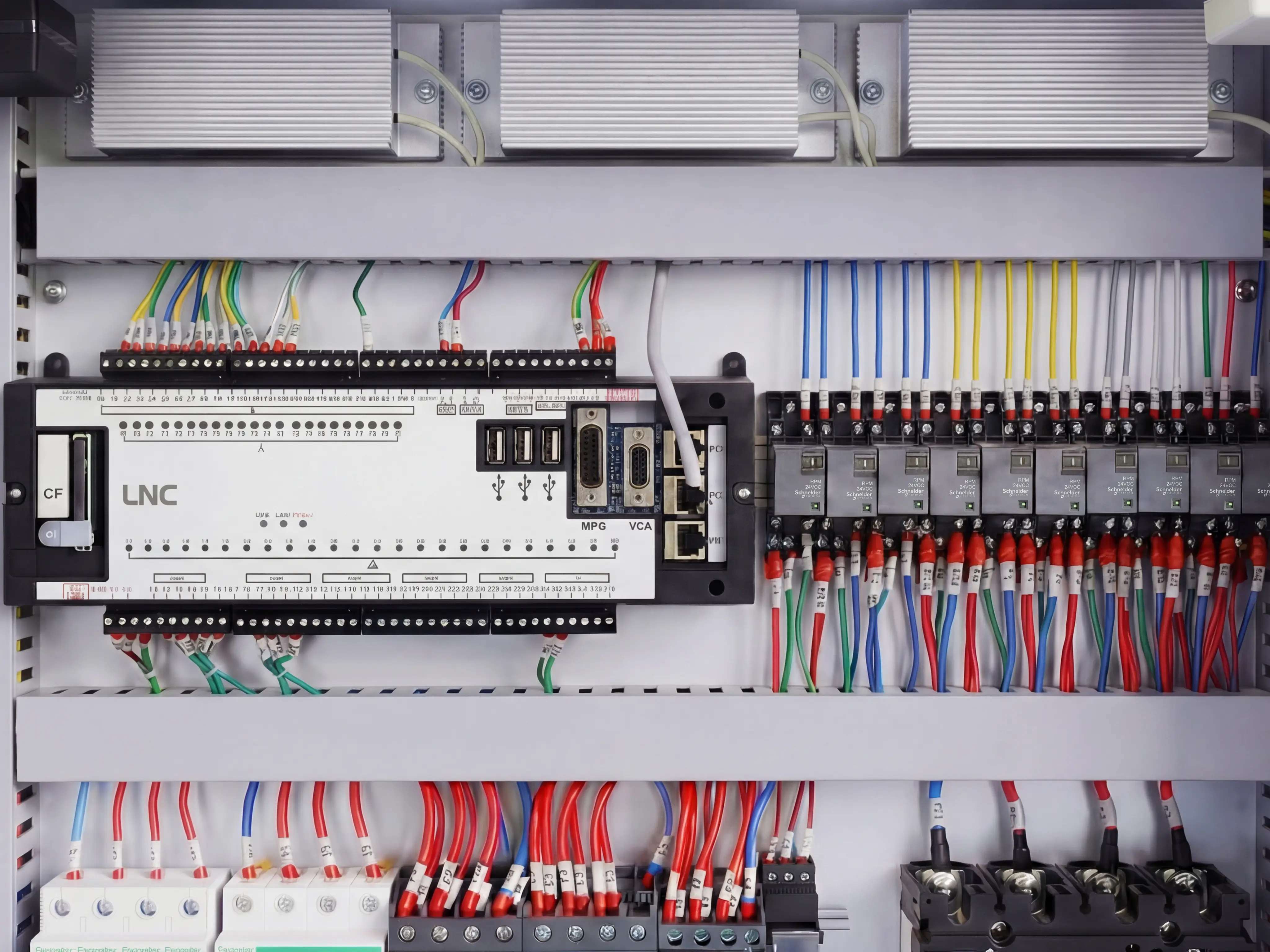

The matching CNC software is given for freeEnjoy lifetime free software upgrades, supporting software updates and free programming services.

The matching CNC software is given for freeEnjoy lifetime free software upgrades, supporting software updates and free programming services.