How to Select the Milling Tools for CNC Wood Router?

How to Select the Milling Tools for CNC Wood Router?

- Oct 31, 2024

A milling tool is a cutting tool with a cylindrical shape, featuring cutting edges on its circumference and bottom, which performs rotational motion to cut and machine workpieces.

The milling tool family is very extensive. Together with hole-making tools (drills, reamers, taps, boring tools, etc.), they cover almost all commonly used processing tools on CNC wood router machines.

Types of Milling Tools

Milling tools can be classified into various categories based on different criteria. Below are several classification methods commonly used in the industry:

Classification by Number of Cutting Edges

- Single edge: Offers large chip space and low cutting resistance, suitable for cutting acrylic, non-ferrous metals (e.g., aluminum), and softwoods. It minimizes reduces cutting noise, but surface finish is slightly inferior.

- Double edge: The most balanced option. It combines chip evacuation capability and surface finish, making it the most commonly used type in wood processing, applicable for both roughing and finishing.

- Three or more edges: Provides smaller chip space but allows higher feed per revolution, resulting in the best surface finish. Primarily used for finishing.

Classification by Blade Installation Method

Solid milling tool: The shank, tool body, and cutting part are made or welded from the same material (typically carbide or high-speed steel), forming an inseparable whole. The integrated structure avoids minor runout, enabling extremely high machining accuracy and surface finish. The drawback is that the entire tool is discarded after wear (though regrinding is possible, it is difficult to restore the original precision).

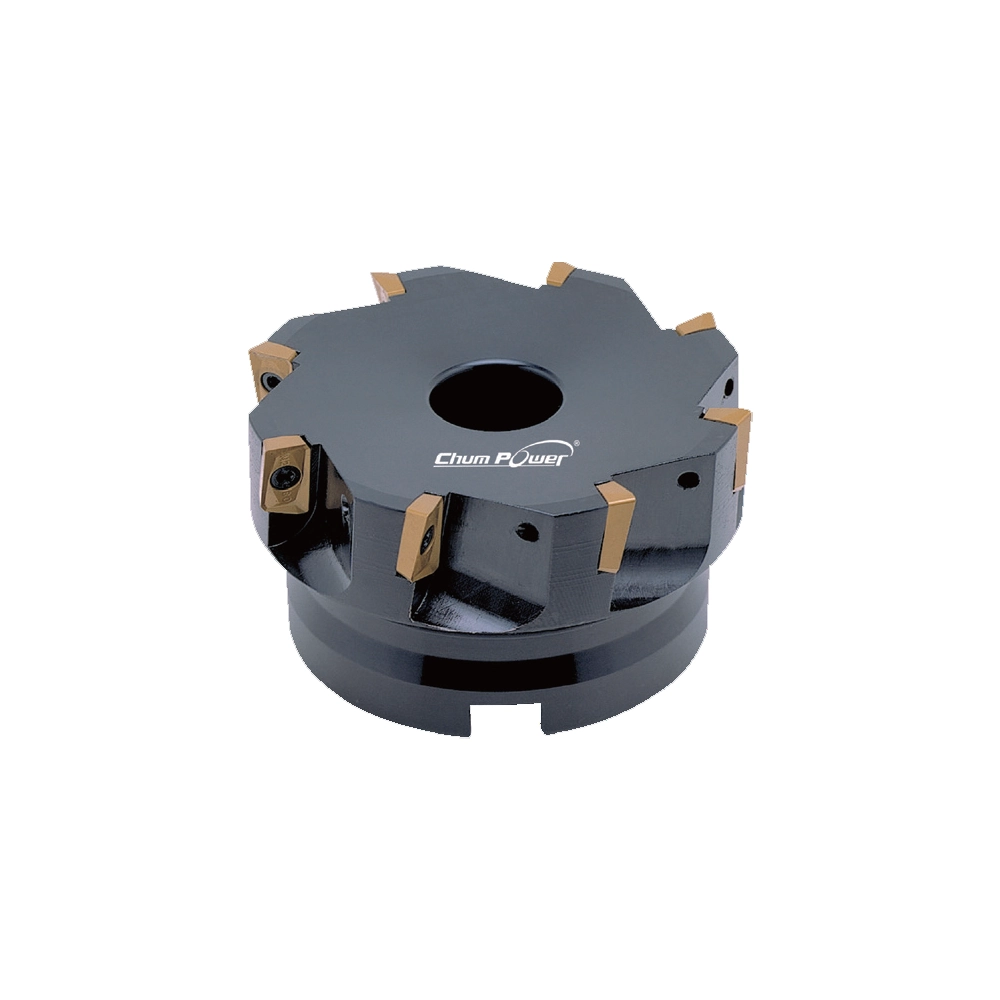

Indexable milling tool: Consists of a steel tool body and indexable inserts secured mechanically. Designed for heavy-duty roughing, it allows strategies with large cutting depths and high feed rates. The tool body holds multiple inserts, usually polygonal (e.g., square, triangular, round), with each insert typically having multiple cutting edges. The inserts are consumables, low-cost, and can be indexed to a new edge or replaced individually when dull, while the tool body is reused permanently, significantly reducing tool costs. Common applications in woodworking include heavy roughing of solid wood and other materials, such as face milling tools and pineapple cutters (a type of multi-edge roughing tool).

Classification by Cutting Edge Shape and Function

Flat-end mill

- Features: This is the most common and basic tool, often referred to as an end mill (though flat-end tools are actually a subset of end mills). The bottom edge is flat, the sides are straight, and the teeth are on the circumference and end face. It cannot feed axially during operation unless equipped with center-cutting teeth.

Applications:

- 2D cutting: Sheet cutting and contour cutting.

- 3D clearing: Cleaning flat areas and right-angle regions at the bottom of models in 3D engraving.

- Step and groove machining: Creating steps or grooves along specified paths on the workpiece surface.

Face mill

- Features: The diameter is typically much larger than that of an end mill, and the tool body is equipped with multiple indexable carbide inserts.

- Applications: High-efficiency milling of large flat surfaces and surface leveling.

Ball mill

- Features: This is a type of end mill with a hemispherical bottom edge.

- Applications: Precision milling of 3D curved surfaces.

Bull-nose mill

- Features: The bottom is flat but with rounded edges. It can be seen as a combination of a flat-end tool and a ball-nose tool.

- Applications: This is the most commonly used roughing tool in 3D engraving. The rounded edges make it more robust than flat-end tools, reducing chipping, and it offers higher cutting efficiency than ball-nose tools.

Point mill (V-type mill)

- Features: The blade has an inverted "V" shape with a specific angle (common angles include 30°, 60°, 90°, and 120°).

- Applications: Primarily used for various types of 2D engraving, such as lines, text, and patterns, as well as chamfering workpiece edges.

Slot mill

- Features: A category of forming tools mainly used to process various target slot types, such as T-slot cutters, keyway cutters, and dovetail cutters. The cutting edge shape matches the cross-section of the target slot, allowing direct machining of the desired slot (some tools may require pre-roughing with an end mill).

- Applications: Used to create specified slot types.

Saw mill

- Features: This tool has a diameter much larger than its thickness (i.e., a high diameter-to-thickness ratio) and densely packed teeth, making it visually similar to a saw blade.

Applications:

- Rapid cutting of workpieces, often used for roughing.

- Machining very narrow grooves.

Chamfering mill

- Features: A milling tool with a conical or inverted V-shaped blade, specifically designed to cut an angled bevel on the sharp edges of a workpiece, a process known as "chamfering."

- Applications: Used for deburring edges, chamfering, or creating decorative beveled edges

How to Select Milling Tools?

Now, let’s return to the main topic of this article: How to choose milling tools for wood router machines?

Material

- Carbide: The absolute mainstream and preferred choice. Modern CNC wood router almost exclusively uses solid carbide milling tools. It offers the best balance of hardness, wear resistance, and toughness, ensuring long service life and suitability for all woodworking materials, including solid wood, engineered wood, and composites.

- High-speed steel (HSS): Largely obsolete. Its hardness, wear resistance, and lifespan are far inferior to carbide. It is only used in manual or low-end equipment and cannot meet the high-speed and efficiency requirements of CNC router.

- Polycrystalline diamond (PCD): Designed for extremely wear-resistant materials. Specifically used for processing highly abrasive materials, such as composite boards containing large amounts of resin, fireproof boards, and aluminum-plastic panels. The adhesives and additives in these materials can rapidly wear down carbide tools, whereas PCD tools offer exceptionally long life but are very expensive.

Coating

- Uncoated: Sufficient for most wood processing applications.

- Coatings (such as TiN): Can reduce the coefficient of friction, enhance wear resistance, and improve chip evacuation performance. Suitable for processing sticky materials or situations where longer tool life is desired.

Shank diameter

Confirm the collet specification (ER specification) supported by your engraving machine, and then select the appropriate milling tool shank diameter (ISO specification) based on the collet specification.

Type

The selection of milling tool type requires comprehensive consideration of multiple factors, including the material category, material condition, geometric shape, and processing technology of the workpiece to be machined.

The relationship between processing technology and milling tool type has been detailed in the previous introduction to milling tool types and will not be repeated here. Below, the focus is on the relationship between the material to be processed and milling tool selection:

- Softwoods (e.g., pine, fir): High cutting resistance necessitates the use of double-edge tools to ensure sufficient chip space and prevent burning. The cutting edges must be sharp.

- Hardwoods (e.g., oak, walnut): High cutting resistance necessitates the use of double-edge tools to ensure sufficient chip space and prevent burning. The cutting edges must be sharp.

- Engineered wood (e.g., MDF, particle board): Highly abrasive (especially surfaces coated with melamine), which rapidly wears down tools. Wear-resistant carbide tools, commonly double-edge, are essential.

- Composite materials (e.g., carbon fiber board, G10): Extremely abrasive. Specialized milling tools designed for composites (often featuring unique edge angles and coatings, such as PCD edges) must be used. Standard woodworking tools will fail almost instantly.

RELATED MODELS

We recommend some related models for you...