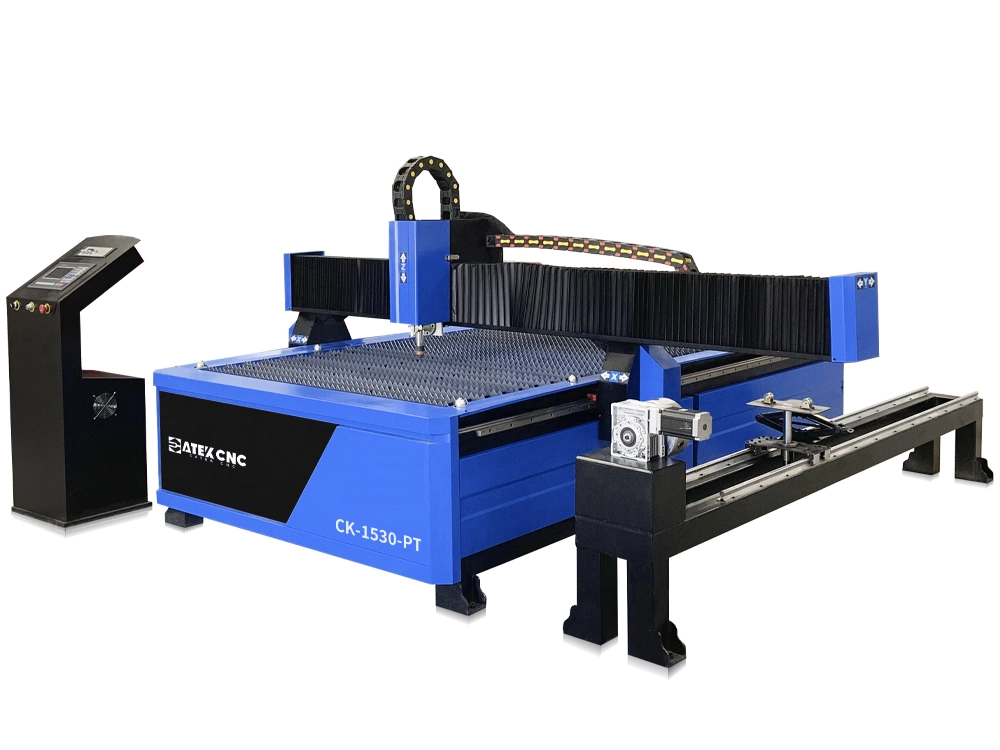

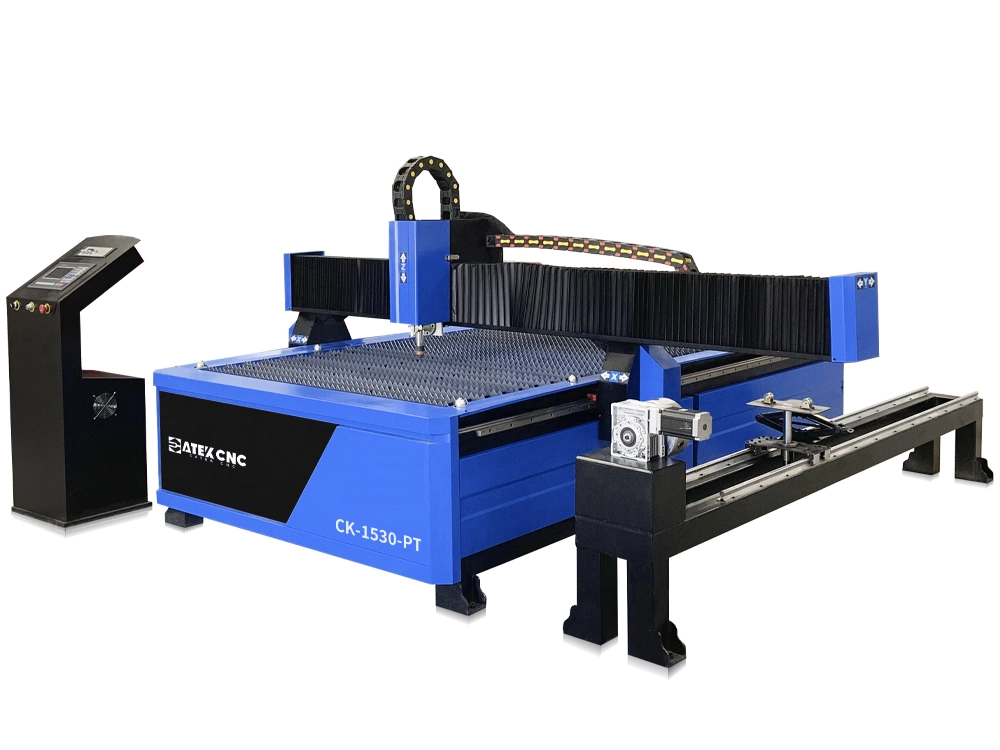

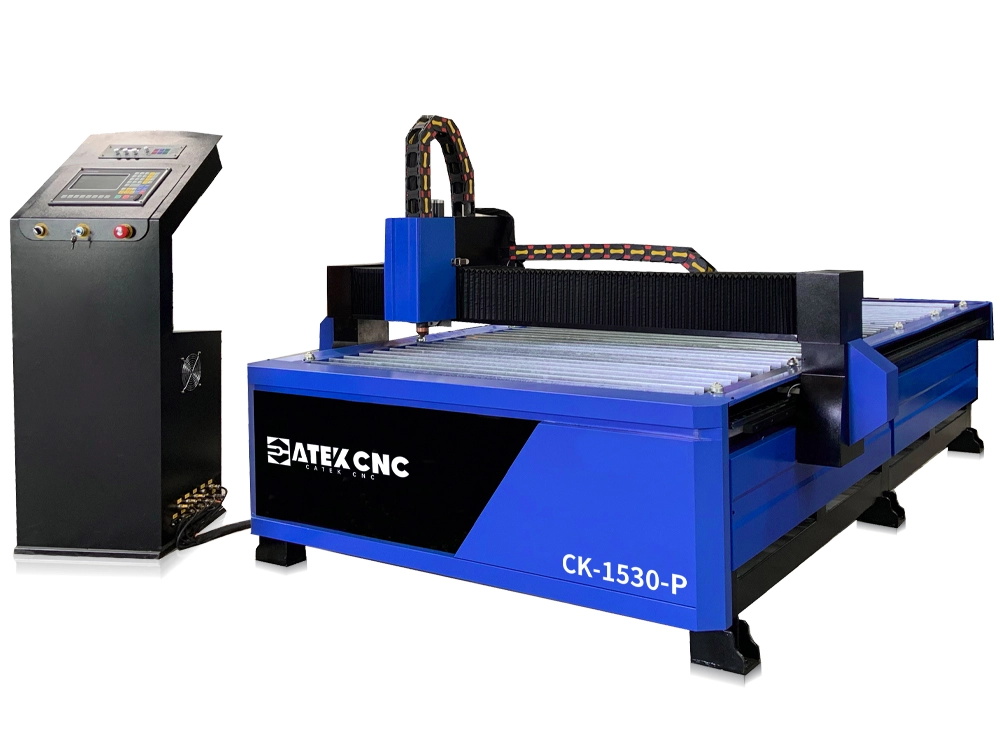

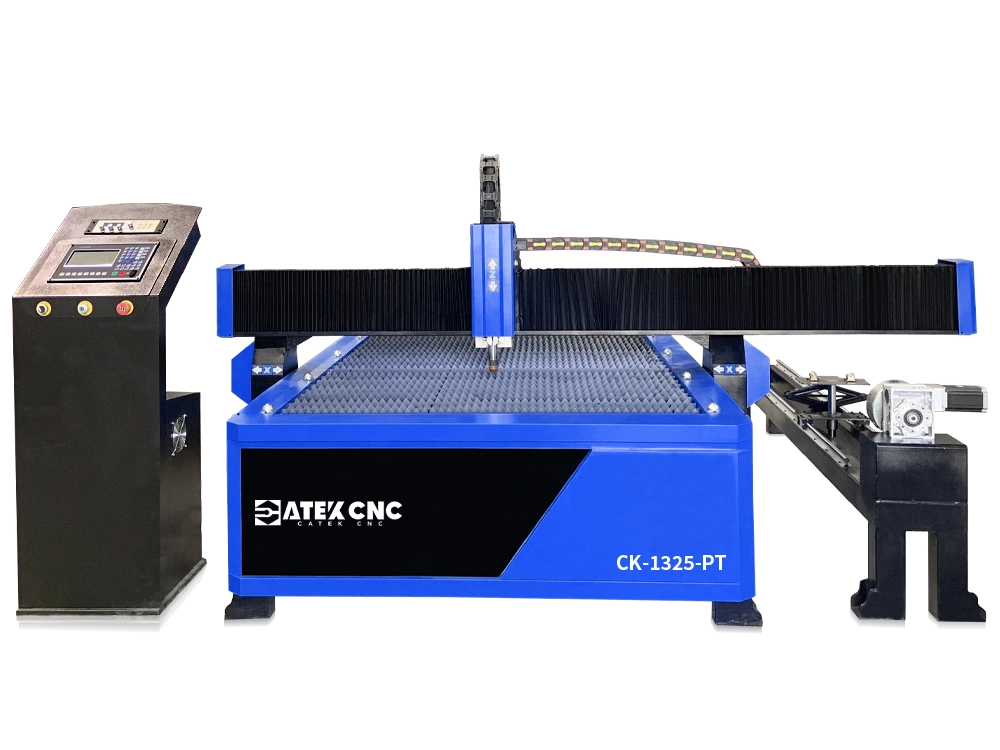

5x10ft CNC Plasma Metal Cutting Machine for Plate and Tube for Sale at a Great Price

5x10ft CNC Plasma Cutting Machine for Sheet and Pipe

[Function Description]

The CK-1530-PT is a multifunctional CNC plasma cutting machine that integrates metal sheet cutting and metal tube cutting, suitable for processing various metal materials such as carbon steel, stainless steel, aluminum, and titanium alloys. Its flat worktable is designed for sheet cutting, while the rotary axis cutting device is used for tube cutting, capable of cutting round tubes, square tubes, elliptical tubes, and other types of tubes. It supports tube cutting, through-line cutting, and complex pattern cutting. Additionally, the rotary cutting device is equipped with a lift-type support bracket with a load capacity of over 400kg, enabling fully automated processing without manual intervention. The dual cutting functions of this machine effectively save on procurement costs and floor space, making it suitable for various working environments. Its cutting speed far exceeds traditional cutting methods, making it particularly ideal for small and medium-sized workshops. Users can flexibly switch processing modes and quickly change processing programs, efficiently producing custom orders and significantly reducing machine idle time.

Features of 5x10 CNC Plasma Cutting Machine with Rotary Cutting Device

- High Efficiency and Precision: Cutting speeds can exceed 10,000 mm/min, with higher precision compared to flame cutting. The CNC system ensures automatic and precise control of the cutting process, delivering clean and consistent cuts.

- Wide Material Compatibility: Capable of cutting various metal sheets, including stainless steel, cast iron, copper, aluminum, and other non-ferrous metals. It can also handle materials that are difficult to process with traditional methods.

- Energy Efficiency and Environmental Friendliness: Offers significant energy savings and can use a water tank worktable to effectively reduce noise, dust, harmful gases, and arc light pollution, improving the working environment.

- Ease of Operation and Maintenance: Fully functional with a modular design for quick installation and easy mobility. The CNC system features automatic arc ignition, ensuring stable performance and supporting G-code path files generated by various software. It is user-friendly and includes a central lubrication system for automatic machine lubrication, simplifying maintenance.

- Reduced Secondary Processing Needs: Plasma cutting produces minimal dross, and any attached dross is easy to remove, significantly reducing the time required for secondary processing. The cutting surface has a high finish, minimal thermal deformation, and almost no heat-affected zone.

- Flexibility and Versatility: Suitable not only for flat cutting of regular shapes but also for complex shapes. With the addition of a rotary axis, it can cut various metal tubes.

- Cost-Effectiveness: Uses nesting software for automatic layout optimization, saving materials and improving labor productivity. The cost is much lower than laser cutting, while the cutting quality is close to that of fiber laser cutting.

Advantages of 5x10 CNC Plasma Cutter for Cutting Metal Sheets and Tubes

- Heavy-duty thickened square steel welded structure, offering excellent rigidity and high transmission accuracy.

- Y-axis uses dual-side drive, and the beam support adopts a gantry-style steel structure, ensuring stable operation.

- Flame + plasma dual-use CNC cutting system, providing convenient operation.

- Automatic CAM graphic programming software, making nesting and layout simpler.

- Optional multi-torch configuration for simultaneous flame and plasma cutting, improving efficiency.

- Flame and plasma cutting can be equipped with capacitive automatic arc voltage adjustment for ease of use.

- Uses Taiwan HIWIN high-precision linear square guides, surface-treated for higher accuracy and wear resistance.

- High-precision ground-level racks and gears, surface carburized and quenched for enhanced precision.

- Simple operation with real-time method prompts below the display, allowing beginners to use it without training.

- The control system can automatically nest graphics; simply input the cutting quantity and arrangement direction for batch automatic cutting.

- Free full set of CNC plasma cutting machine videos and manuals provided, with 24-hour online support.

Details of 5x10 Plasma Cutter For Metal Sheet & Tube

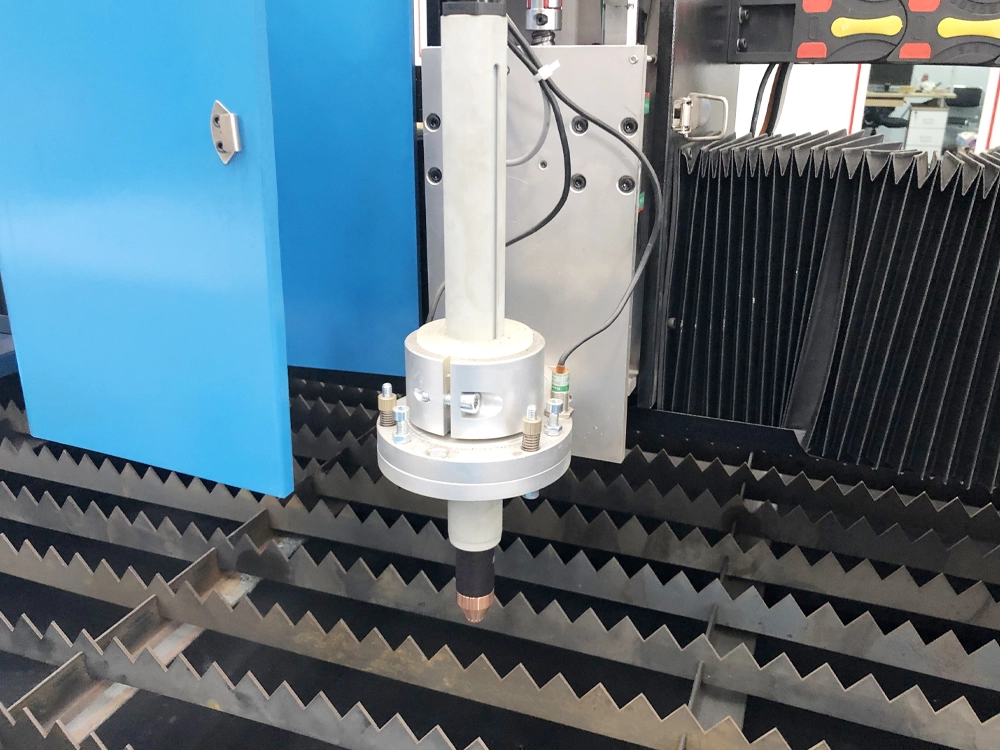

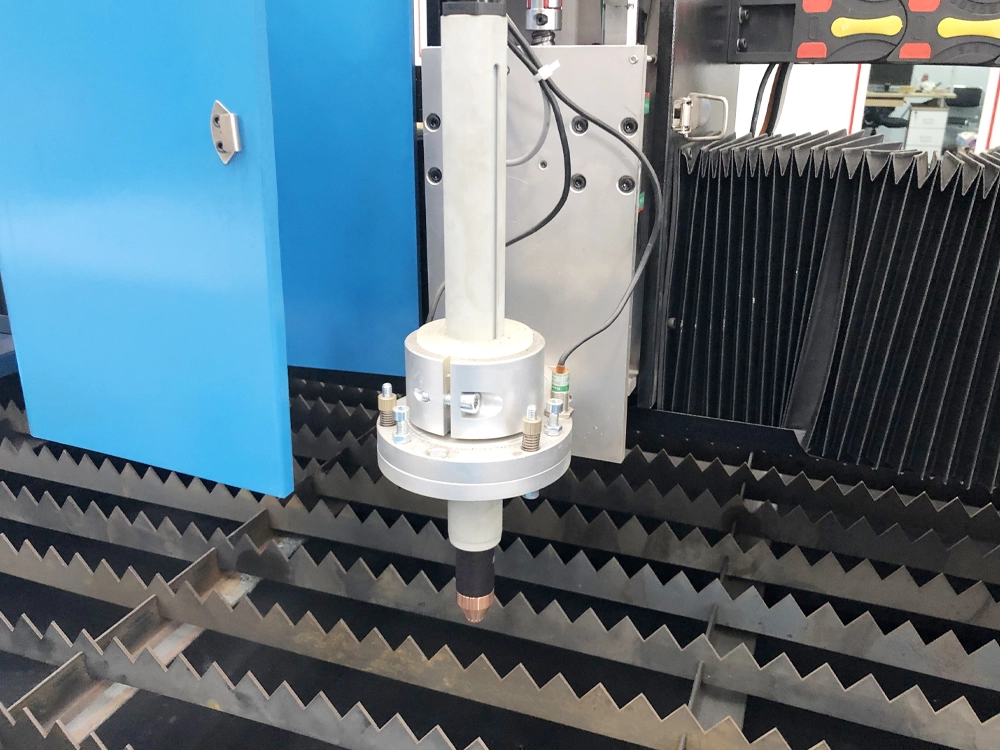

- Plasma cutting gun

-

CNC plasma cutting torch with fast perforation and cutting of metal materials.

- Tooth-type slats workbench

-

Distributed tooth-type slats workbench with good thermal conductivity and without easy to stick.

- Plasma source

-

Optional plasma source from American Hypertherm or China Huayuan.

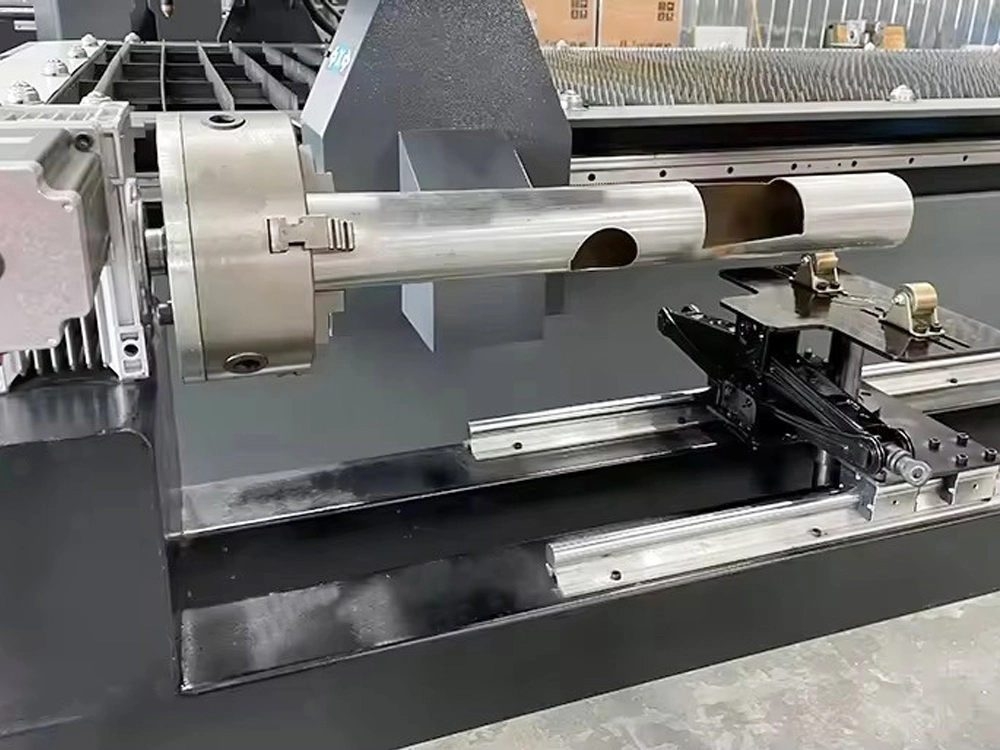

- Rotary device for cutting tube

-

The indexing chuck on the side of the machine can rotate and cut the pipe.

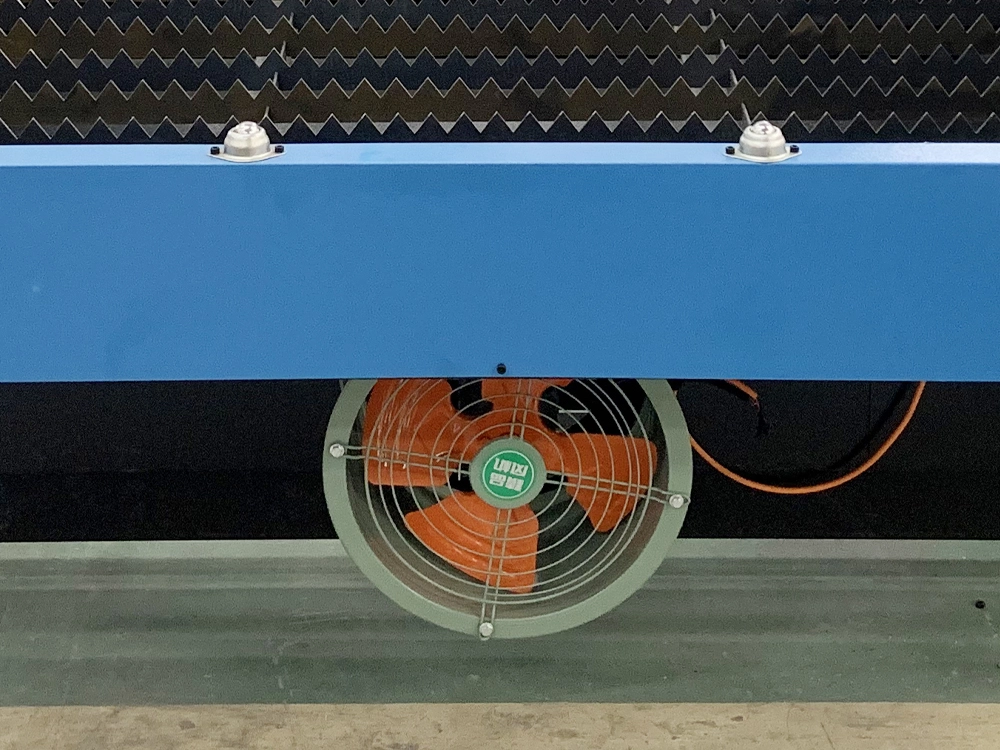

- Exhaust fan

-

The exhaust fan can remove smoke and odors generated during the processing.

- Starfire control system

-

The control system can be selected from STARFIRE or FL.

Technical parameters of 5x10 CNC plasma sheet and pipe cutting machine

| Model | CK-1530-PT |

| Work Area | 1500mm*3000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1600kg |

| Dimensions | 3830*3060*1580mm |

What are the Differences between Flame Cutting, Plasma Cutting and Laser Cutting?

| Cutting Mode/Comparison Items | Flame Cutting(Oxy-Fuel Cutting) | Plasma Cutting | Fiber Laser Cutting |

|---|---|---|---|

| Cutting Accuracy | ±0.5mm/m | ±0.5mm/m | ±0.01mm/m |

| Cutting Material | Pure iron, carbon steel, low alloy steel, titanium, etc. | Carbon steel, cast iron, stainless steel, aluminum, copper, alloy, etc. | Carbon steel, cast iron, stainless steel, aluminum, copper, galvanized sheet, alloy, etc. |

| Cutting Method | Oxygen + LPG (propane) or coal gas or acetylene | Compressed air | Compressed air, Oxygen, Nitrogen |

| Power requirements | AC220V | AC380V | AC380V |

| Roughness of Cutted Surface | Generally | Smooth | Very smooth |

| Perpendicularity of Cutted Surface | Perpendicular | Slope 2-4 degrees | Essentially Perpendicular |

| Cutting Speed | 50-750mm/min | 260-7500mm/min | 300-30000mm/min |

| Recommended Cutting Thickness | 6-100(200)mm | 0.5-50mm | 0.1-50mm |

| Cost | Generally | Low | Relatively high |

| Main Consumables | Combustion gaes (oxygen, propane, acetylene, etc.) | Electric + electrode protection nozzle | Electricity + lens + nozzle + ceramic body, etc. |

| Minimum Cutted Hole Size | φ≥20mm | φ≥15mm | φ≥2mm |

Features of the Mechanical Structure of CNC Plasma Cutting Machines

- Structural Design: CNC plasma cutting machines adopt a gantry structure, providing a stable operating platform. Steel components undergo stress-relieving treatment to ensure long-term precision.

- Materials and Processes: The bed is constructed using thickened square tube materials welded together, and it undergoes aging and quenching treatments to enhance stability and precision retention.

- Transmission System: The bed's transmission system employs precision gear racks to ensure smooth operation and high accuracy.

- Heat Dissipation and Chip Removal: The hollow bed design facilitates heat dissipation, and the rigid support structure improves bed rigidity.

- Automation and Environmental Protection: CNC plasma cutting machines are equipped with smoke and dust extraction systems, making them more environmentally friendly. An optional underwater cutting table effectively isolates smoke and dust, protecting the working environment.

What Can a 5x10 CNC Plasma Cutting Machine with a Rotary Axis Process?

Material:

- Carbon steel: Q235, 45# steel, SPHC cold-rolled plate, etc.

- Stainless steel: 304, 316, 201 series, etc.

- Aluminum alloy: 5052, 6061, 6063, etc.

- Copper and copper alloy: copper, brass, bronze, copper alloy, etc.

- Titanium alloy: TC4, TA2, etc.

- Other metals: nickel alloy, zinc plate, galvanized plate, etc.

Technology:

- Plate processing: plane cutting, straight lines, curves, complex contours, hollow cutting, text, patterns, ventilation holes and other decorative patterns.

- Pipe processing: straight cutting, bevel cutting, cutting, intersecting line cutting, end face forming cutting, flange interface, threaded end face, spiral line, special-shaped hole, I-beam, etc.

The Following Are the Processable Products of 5x10 CNC Performance Plasma Cutter

| Model | CK-1530-PT |

|---|---|

| Work Area | 1500mm*3000mm |

| Rotation Size | Diameter 10-500mm, Length 3000mm-6000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1600kg |

| Dimensions | 3830*3060*1580mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.