2026 Most Popular 7x10 ATC CNC Router with Automatic Feeding Hopper

7x10 ATC CNC Wood Router with Automatic Loading and Unloading

[Function Description]

With the update of modern industrial manufacturing and furniture production technology, the more common 4x8ft CNC router has been difficult to meet the requirements of modern industrial manufacturing, because its size specifications are relatively limited and it is difficult to meet the production and processing needs of large-size products.

In this case, the 7x10ft CNC router has gradually developed into the most popular CNC router for cabinet and furniture production. It has powerful functional integration and can be used with a linear tool change magazine to achieve full-automatic switching of multiple tools during the processing process, greatly improving the processing efficiency and processing accuracy, and effectively reducing the time loss and error accumulation caused by manual tool change. The equipment is also equipped with an automatic feeding and unloading platform to realize the automatic flow of materials, reduce the cost of manual intervention, and improve the continuity and stability of the production process. The application of vacuum adsorption table is not only convenient to operate, but also can fix the processing materials more firmly, ensuring that the materials are always in a stable state during the processing process, avoiding the impact of material displacement on the processing quality. In addition, after using the dust collection device, it can effectively collect the wood chips and dust generated during the processing process, keep the production environment clean, and reduce the harm of dust to equipment and operators.

In terms of the degree of production automation, the 7*10 feet CNC router performs particularly well. The operator only needs to use professional nesting software in advance to set the parameters of the products to be processed, and import the processing program into the control system through a USB flash drive. The equipment can automatically complete the feeding and subsequent fully automatic processing process. The entire process does not require real-time human intervention, truly realizing intelligent and unmanned production.

What Is a 7x10 CNC Router with Automatic Feeding?

7*10 CNC router is a large-size CNC router with a 7*10 feet (84*120 inche or 2100*3000mm) CNC worktable. The wide worktable is enough to meet the cutting, milling and other processing needs of various plates. It is equipped with a 9KW automatic tool change spindle, a high-power 1.5KW servo motor, a Japanese planetary reducer, a Taiwan LNC control system, an 8/12/16 linear automatic tool change kit, a lifting loading platform, a rolling unloading platform, a full-size 9-zone, 30-hole vacuum adsorption worktable, two pneumatic pressure roller, and a double-drum dust collector. Moreover, its CNC system is simple to operate, easy to use, and very friendly to beginners. It is compatible with various common cad/cam software such as artcam, type3, UcanCAM, powermill, etc.

Advantages and Features of 7x10 Large Size ATC CNC Router with Automatic Feeding Hopper

- The bed body welded with thickened steel pipes is processed by welding and quenching process, with sufficient load-bearing capacity and seismic resistance, and through stress relief treatment, it ensures stability and precision during long-term, high-intensity processing.

- 9KW high-speed air-cooled automatic tool change spindle, using ISO30 tool holder, ER32 tool holder, can clamp any tool with 20mm tool holder.

- High torque 1500w servo drive motor + Japanese planetary reducer, stable operation, fast idle speed, high positioning accuracy.

- 8/12/16 linear tool change tools, can support the installation of 8/12/16 tools at a time, meet all the needs of processing, and can achieve automatic and fast switching during processing.

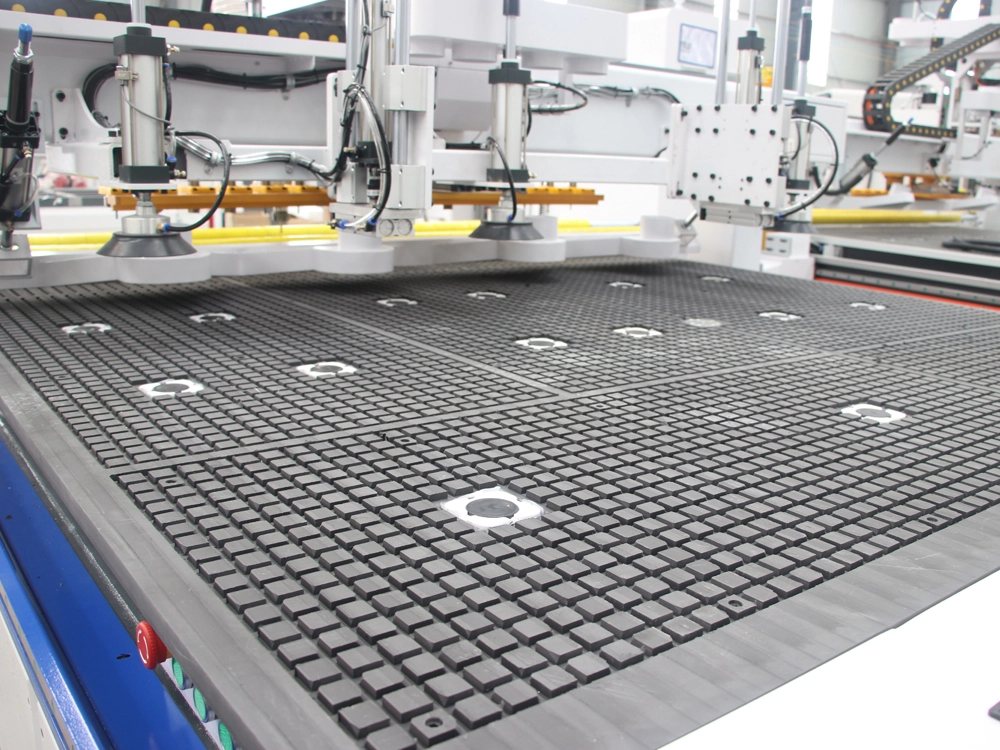

- 9 zones, 30 holes vacuum adsorption adsorption workbench, each zone can control the switch independently.

- Central lubrication and oiling system, fully automatic lubrication of screw rods, guide rails, and bearing systems.

- Equipped with two pneumatic pressure rollers, it can directly fix smaller plates, eliminating the trouble and cost waste of using vacuum adsorption.

- Central dust collection system, used to absorb wood chips generated during processing.

- Automatic feeding platform, intelligent sensing, hydraulic lifting.

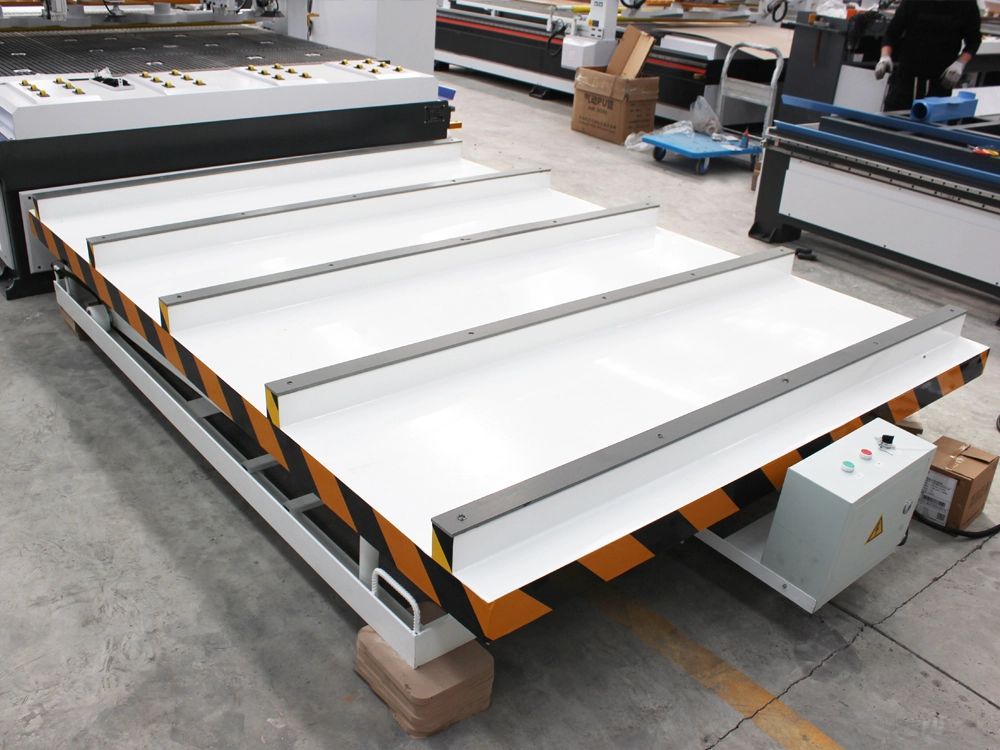

- Automatic unloading platform, using conveyor belt to transport wood, the speed can be adjusted by variable frequency.

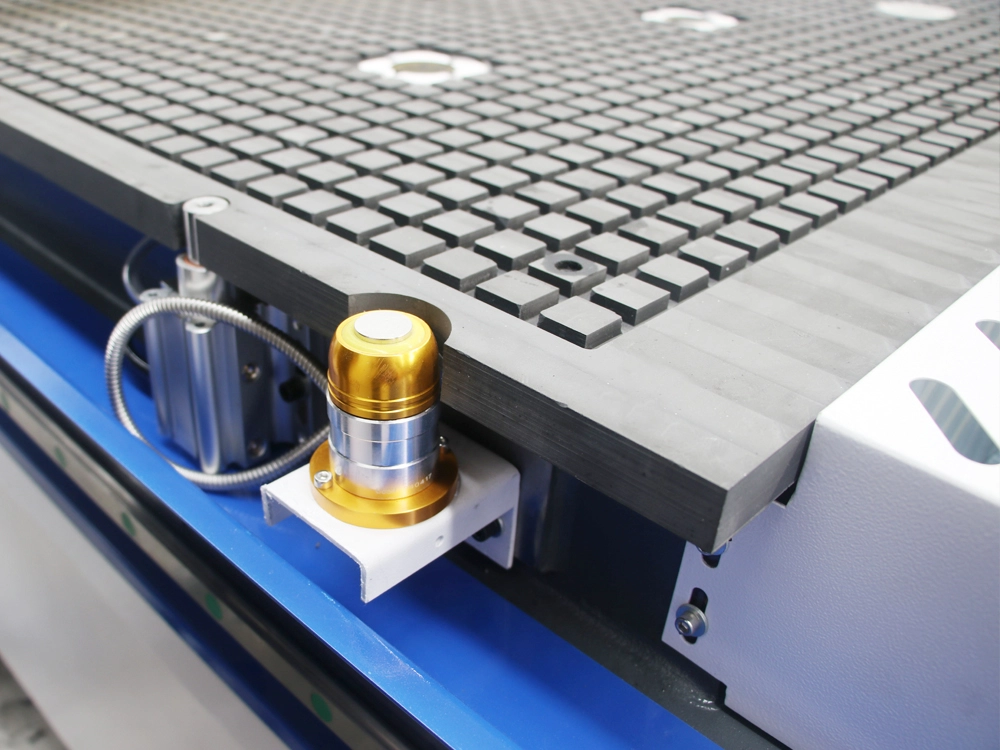

- Automatic tool setting instrument, regardless of the length of the tool, can achieve one-click tool setting.

- Taiwan LNC control system, the interface is simple and intuitive, the operation is simple and easy to use.

- Compatible with various cad/cam software such as artcam, type3, UcanCAM, powermill, etc., and free nesting software.

Details of 7x10 ATC CNC Router with Automatic Loading and Unloading

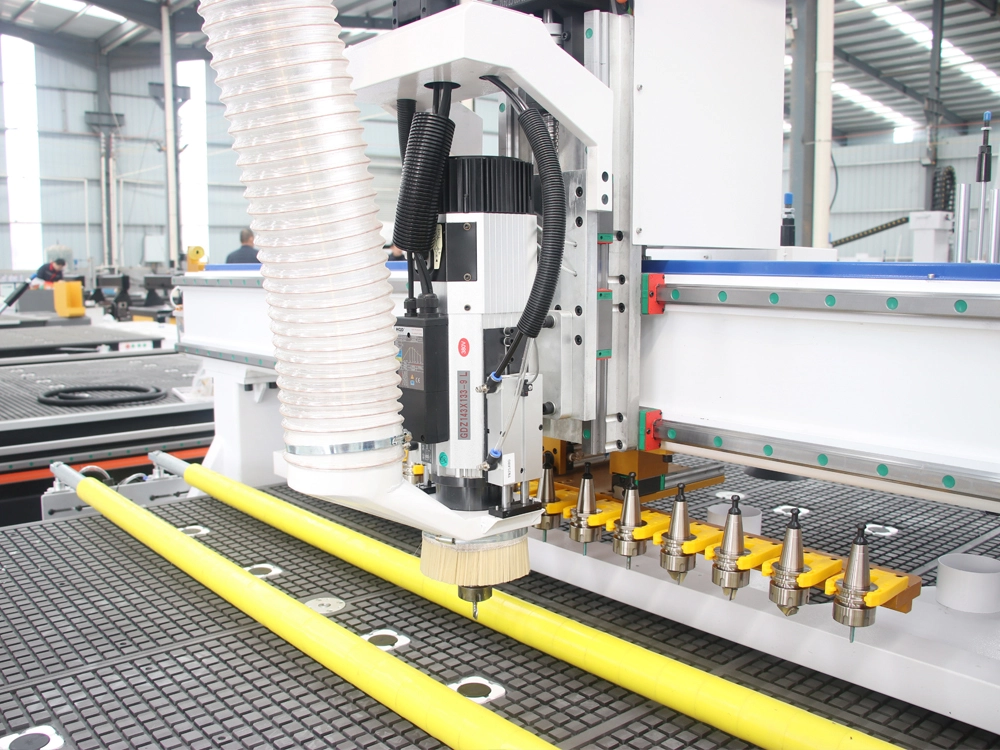

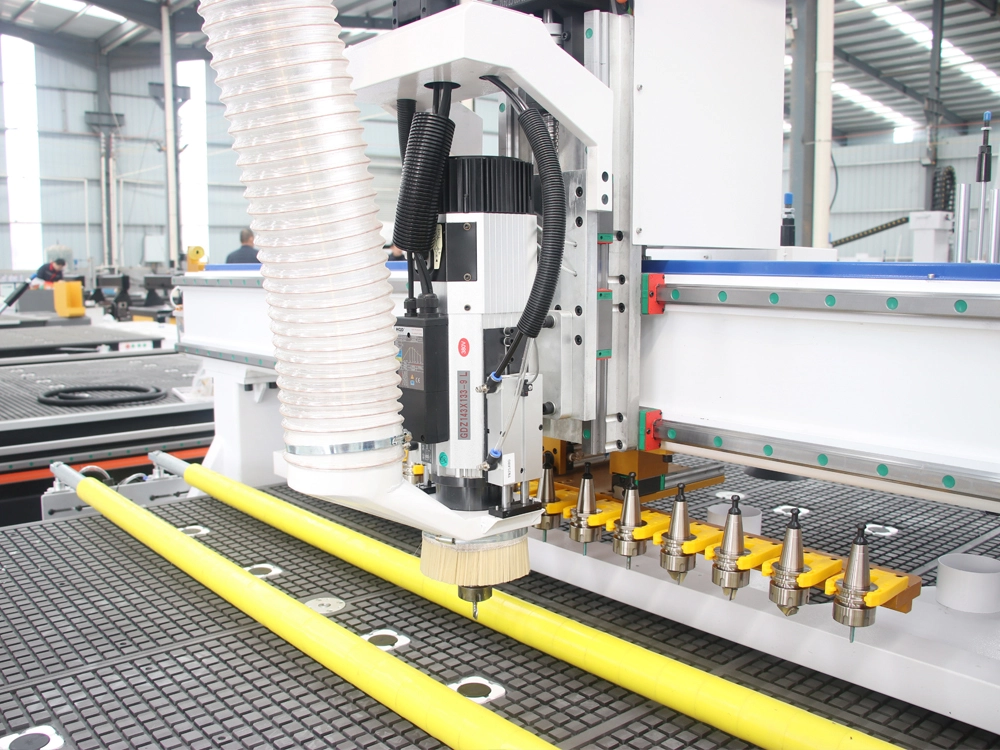

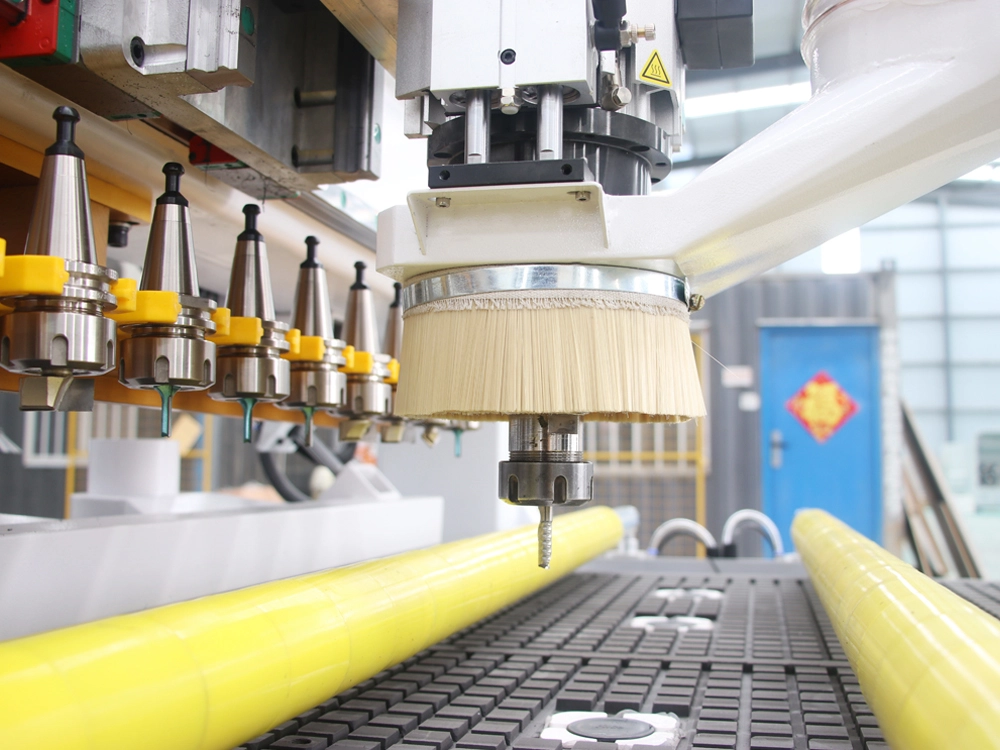

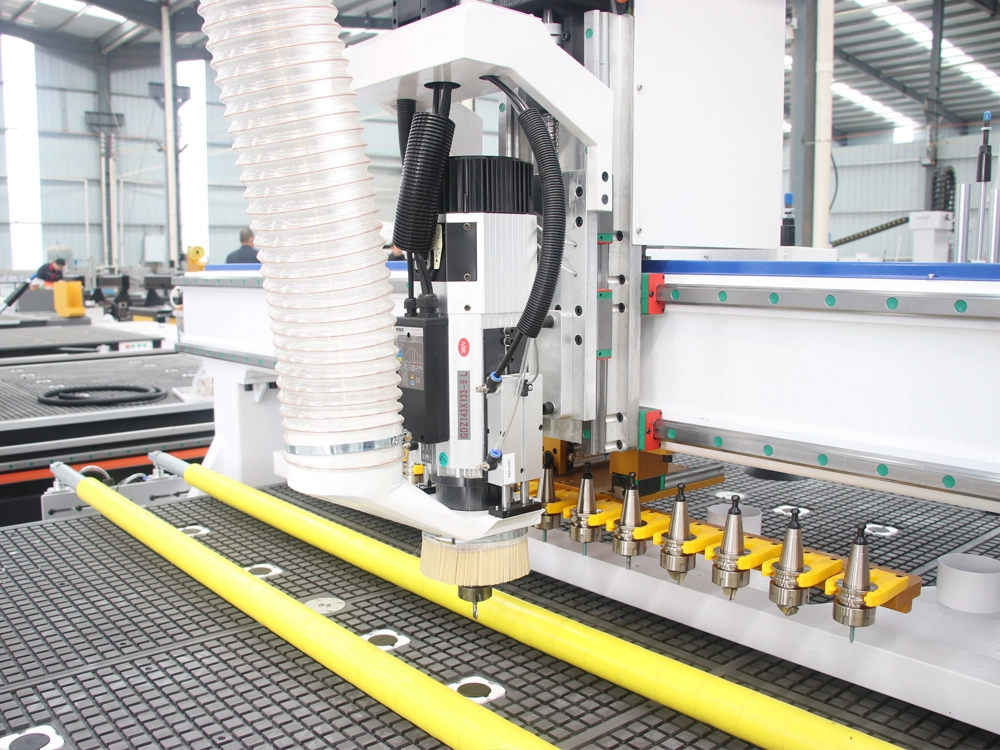

- 9KW automatic tool change spindle

-

High power, high torque, high processing speed, and support for automatic tool change.

- Drag chains

-

Organize and protect the machine's wires, oil and water lines, etc.

- Linear automatic tool changer

-

8/12/16 linear tool change magazine, moves with the gantry, fast tool change speed.

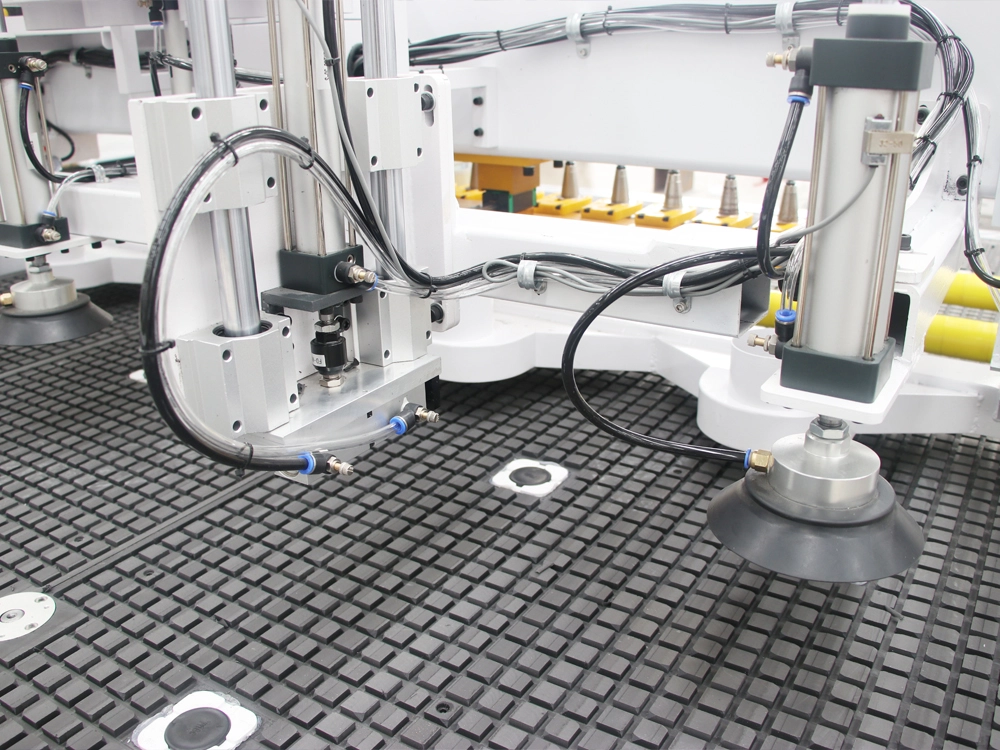

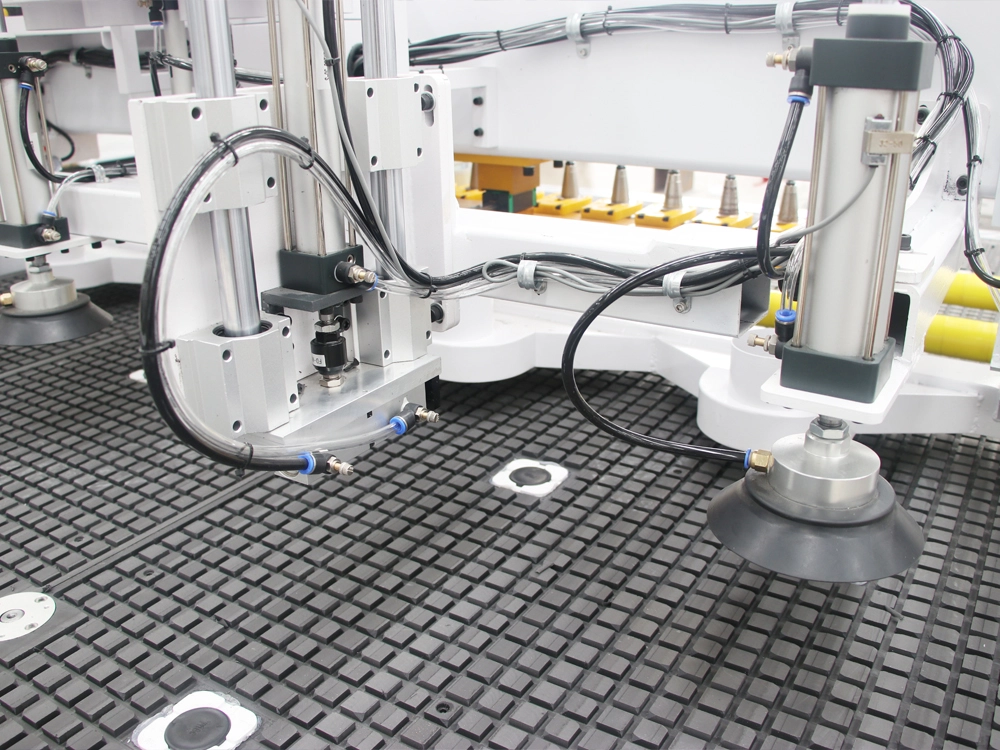

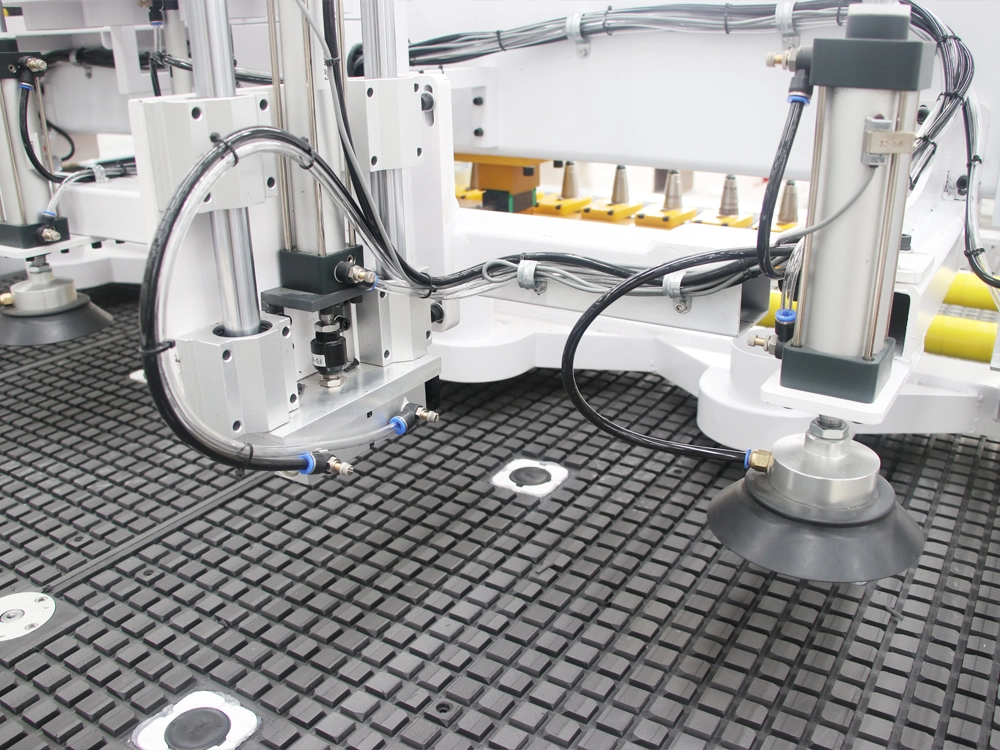

- Hold the plate with two suction cups

-

Suction cups are used to transfer the sheets from the loading platform to the workbench.

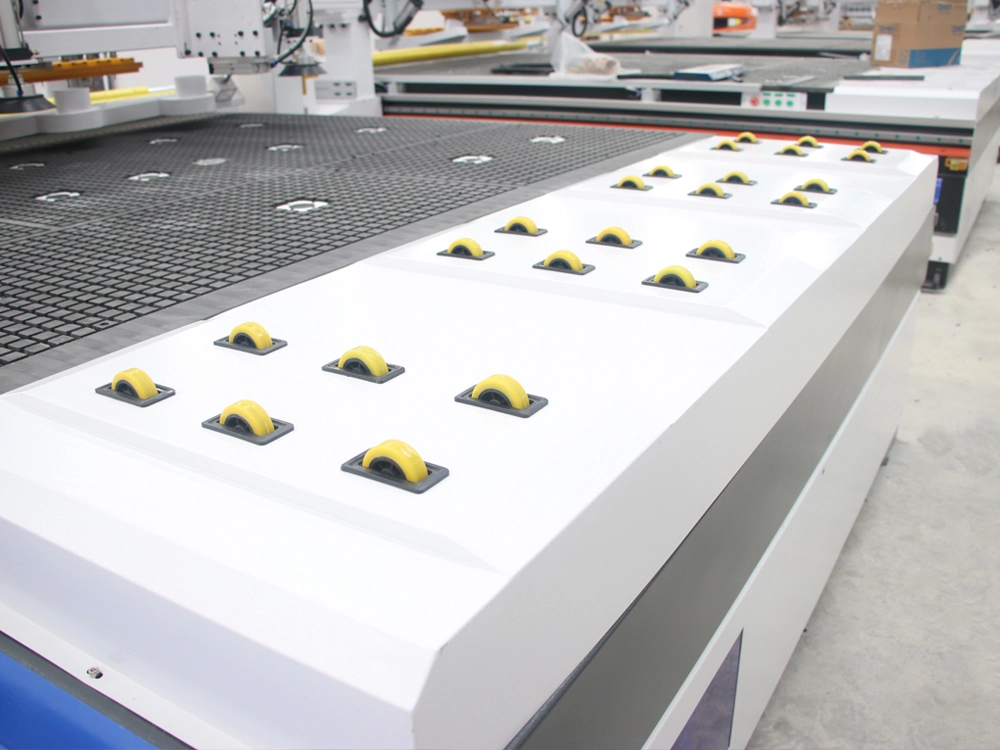

- Feeding roller

-

Reduce the static friction between the board and the tabletop, make loading easier, and avoid board wear.

- Plate push mechanism

-

After the plate is placed on the workbench, the positioning cylinder rises and this device is used to push the material to the positioning cylinder.

- Vacuum adsorption workbench

-

Negative pressure can be used to quickly fix the board.

- Vacuum adsorption zone control valve

-

This valve group can control the opening and closing of the air holes in each partition.

- Double rod pneumatic pressure roller

-

The pneumatic pressing roller can directly fix small-sized plates, which is simple and convenient to use.

- Automatic tool setter

-

It can automatically measure the length and tip position of the tool and instruct the system to calculate the corresponding compensation amount.

- Automatic loading platform

-

The loading platform can hold multiple panels and can be automatically raised and lowered.

- Automatic unloading platform

-

The unloading platform is equipped with a conveyor belt to realize the automatic transfer of the plates.

- Pulse handwheel

-

The coordinates of each axis of the machine can be fine-tuned directly and quickly and conveniently.

- LNC control system

-

Taiwan LNC control system, mature and stable, with user-friendly operation interface.

Technical Parameters of 7x10 ATC CNC Router with Automatic Feeding

| Model | CK-2130-TA |

|---|---|

| XYZ Working Travel | 2100*3000*200mm |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | HSD 9KW air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Collet | ISO30 ER32 |

| Driving Mode | Yaskawa servo motor drive (Z-axis brake motor) |

| Frequency Converter | Best/Hpmont inverter |

| Reducer | Japan Shimpo reducer |

| Table | Vacuum table 9 zones, 30 holes, and with two pneumatic pressure roller |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision 30 linear square rail/flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Vacuum Pump | 11KW (or two 5.5KW) water ring vacuum pumps |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Central lubrication oil filling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 30000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4500kg |

| Dimensions | 9500*2100*2250mm |

| Optional Parts | Drilling bank |

| Rotary 4th axis | |

| Saw blade cutting spindle | |

| Side milling device | |

| Yaskawa/Delta Servo |

What Is the Price of a 7x10 Industrial CNC Router?

7*10 CNC router is mainly composed of bed base, gantry support, CNC system, spindle, drive system and transmission system, the price of 7*10 CNC router is mainly determined by the configuration of these structures. The price of the more common 7*10 CNC router starts from $4,000, and if you have higher demand for optional configurations such as automatic feeding device, automatic tool changer, fourth axis rotary axis, saw blade spindle, drilling package, vacuum adsorption table, etc., the price will rise accordingly. Moreover, different brands and manufacturers provide the same configuration, there are differences in quality and price, which in turn affects the final selling price of the equipment. Most 7*10 industrial grade CNC routers are priced at $4,000 to $7,000, with prices starting at $11,000 for CNC routers equipped with automatic tool changers. In addition, if you want to add other special configurations, the price will be further changed according to the specific circumstances, and the specific offer will depend on the configuration you choose.

What Can Be Processed by An 7x10 CNC Router with Automatic Loading and Unloading?

Applicable Materials:

- Wood: Includes softwood, hardwood, mahogany, ash, beech, oak, pine, walnut, teak, merbau, and various other types of wood.

- Plastics and composite materials: Such as PVC, ABS, dual-color boards, acrylic, polycarbonate (PC), carbon fiber, polyurethane (PU), medium-density fiberboard (MDF), particleboard, plywood, artificial stone, etc.

- Metal materials: Includes soft metal materials like copper, aluminum, brass, etc.

- Other materials: Such as bamboo, pearl cotton, EVA, etc.

Applicable Industries:

- Woodworking: Includes wooden doors, cabinet doors, beds, wardrobes, cabinets, tables, chairs, wooden furniture, classical furniture, office furniture, sofas, decorative crafts, etc.

- Decorative products: Wooden crafts, decorative picture frames, jewelry boxes, screens, advertising signs, plaques, relief patterns, etc.

- Music products: Guitars, violins, cellos, pianos, piano cases, etc.

- Mold products: Mooncake molds, biscuit molds, chocolate molds, candy molds, shoe last molds, architectural models, wooden ship models, aviation models, sand table models, etc.

- Advertising production: Advertising signs, advertising letters, signage, nameplates, outdoor billboards, advertising light boxes, advertising display boards, LED light boxes, neon light troughs, three-dimensional advertising letters, display boards, bulletin boards, directional signs, acrylic cutting, etc.

Sample Display of 7x10 CNC Router Pocessing

How Is The 7*10 Industrial-Grade CNC Router Packaged and Shipped?

All CATEKCNC CNC machines need to be packaged after being fully prepared before transportation.

- The whole machine needs to be rust-proofed and oiled to prevent rust due to the humid environment during sea transportation.

- Anti-collision foam protection, anti-collision foam packaging is used for the parts of the machine that are easily damaged and raised.

- Stretchable wrapping film packaging, the whole machine is wrapped with wrapping film.

- The outermost layer uses a fumigation-free plywood wooden box for export, an iron square tube bottom support, and the machine is completely packaged, and the shipping mark is affixed to the outside of the wooden box.

- Use iron strapping tape to tighten and fix the wooden box. If the machine size is too large, the machine needs to be disassembled and packaged for transportation.

The Best CNC Router To Use

CATEKCNC, as a leader in the field of CNC routers, has a rich and diverse product line covering all categories. Whether you are new to the CNC field, eager to start your CNC learning journey, looking for a cost-effective entry-level CNC router kit, or an expert who has been deeply involved in the CNC industry for many years, aiming to choose a commercial-grade CNC router that can meet the needs of high-intensity industrial production, CATEKCNC can accurately match your budget and needs, present you with the most suitable model, and help you go unimpeded on the road of CNC processing.

How to Maintain 7x10 Industrial CNC Router

The care and maintenance of CNC routers is an important part of ensuring their normal operation and extending their service life. Whether you are a novice or an expert, you should regularly care and maintain your CNC routers.

- The CNC router control cabinet should be placed in a well-ventilated area, avoiding direct sunlight and humid environments. Keep the surroundings free of clutter and away from high-temperature locations to prevent electrical components from failing due to heat.

- If the equipment is not used for an extended period, it is recommended to power it on periodically and let the machine run idle to lubricate bearings and other parts, ensuring all components remain in good condition.

- Before using the equipment each day, carefully check for loose wire connections, confirm that the voltage is stable, and conduct a machine test to ensure the equipment can start and operate normally.

- Before formal processing, make full use of the machine's simulation function for a simulated processing test to identify potential issues in advance.

- Regularly clean the cooling system of the control box, promptly remove accumulated dust inside the control box to maintain the machine's good cooling performance.

- After using the equipment, promptly clean the residual dust on the machine surface and worktable to prevent dust accumulation from affecting the equipment's performance or causing part wear.

- Closely monitor the oil level of the lubrication system, and promptly replenish oil if a shortage is detected.

- Regularly check if the screws of each component are loose, and it is recommended to tighten the screws periodically to ensure all parts of the equipment are securely connected and always in good working condition.

- For models that require a gas source during processing, always check the gas source status before processing to ensure stable gas pressure and no leaks in the pipeline.

- Ensure the machine is safely grounded to avoid electric leakage accidents.

Common Questions with CNC

- After I purchase the machine, will you provide a CNC operation manual?

- Yes. After you purchase our CNC equipment, we will provide you with comprehensive and detailed support. In addition to the complete machine operation manual, there will also be a complete operation video to help you master the equipment operation more intuitively. In addition, we will also provide machine-adapted drawing software and some free processing drawings. The operation manual is detailed, covering not only the basic operation steps of the machine, but also explaining the troubleshooting methods of various faults, as well as the key points of machine maintenance and some other frequently asked questions.

- Do you have free warranty service?

- Yes, of course. All our equipment comes with a three-year warranty (except for equipment consumables). During this period, if any non-human factors cause any failure when you use the machine, we will provide you with free replacement parts. At the same time, we will also arrange professional technicians to guide you to replace machine parts free of charge through telephone, video, etc., to ensure that you can quickly restore the normal use of the equipment, so that you have no worries.

- Do you have after-sales service?

- We provide permanent free full-service after-sales. From the moment you receive the machine, we will provide you with 7/24 hours of online engineer service. As long as you have needs, you can contact our engineers through WhatsApp, WeChat, email, phone, video call, etc. Whether you have CNC operation problems or software drawing confusions, our engineers are always ready to answer your questions.

- Can I customize my machine?

- Of course, we provide a full range of CNC customization services. Whether you have requirements for machine functions, machine processing dimensions, machine appearance, or machine color, we can provide you with your own CNC DIY customization service.

| Model | CK-2130-TA |

|---|---|

| XYZ Working Travel | 2100*3000*200mm |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | HSD 9KW air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Collet | ISO30 ER32 |

| Driving Mode | Yaskawa servo motor drive (Z-axis brake motor) |

| Frequency Converter | BEST/Hpmont inverter |

| Reducer | Japan Shimpo reducer |

| Table | Vacuum table 9 zones, 30 holes, and with two pneumatic pressure roller |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision 30 linear square rail/flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Vacuum Pump | 11KW (or two 5.5KW) water ring vacuum pumps |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Central lubrication oil filling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 30000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 4500kg |

| Dimensions | 9500*2100*2250mm |

| Optional Parts | Drilling bank |

| Rotary 4th axis | |

| Saw blade cutting spindle | |

| Side milling device | |

| Yaskawa/Delta Servo |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.