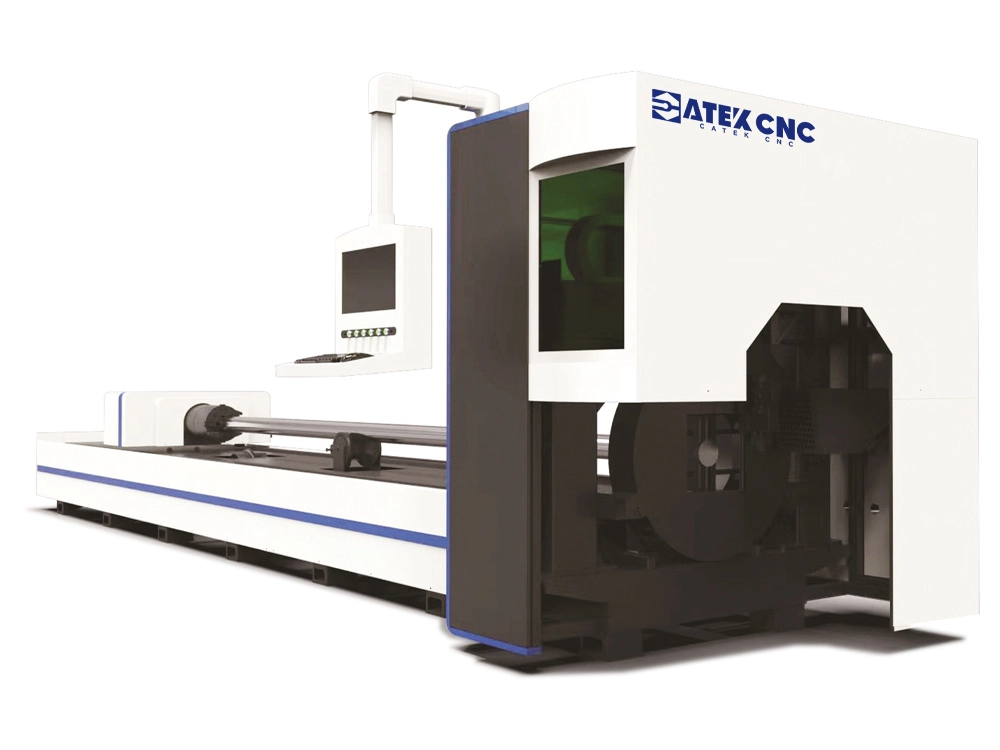

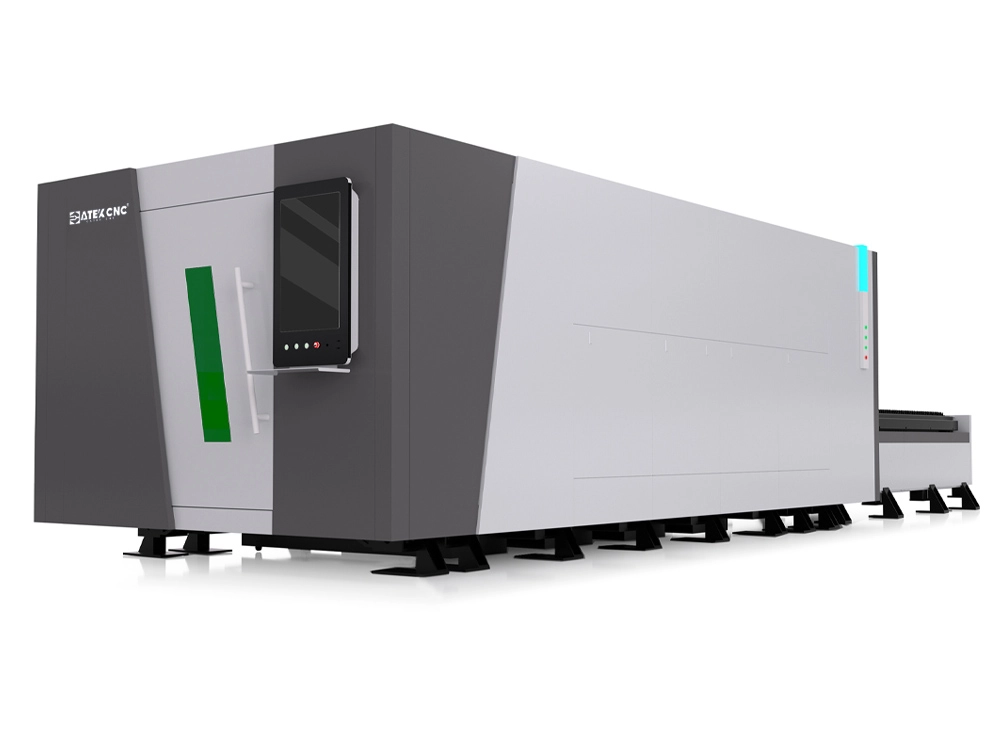

Enclosed Fiber Laser Cutting Machine With Coil Fed System

Laser Blanking Line for Cutting Steel Coils

[Function Description]

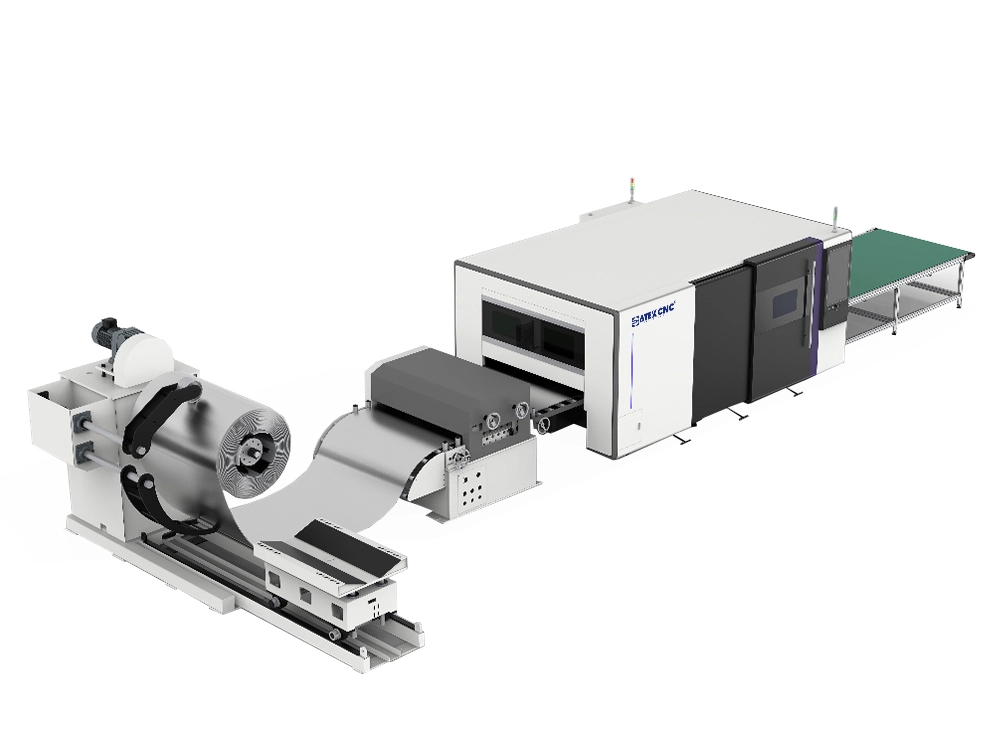

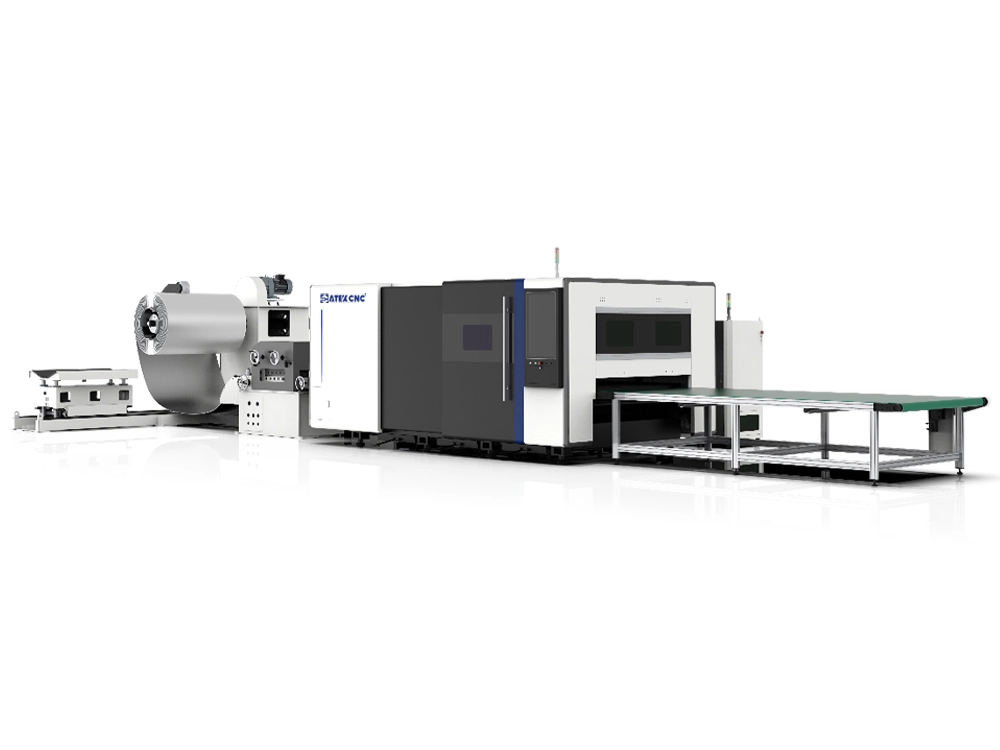

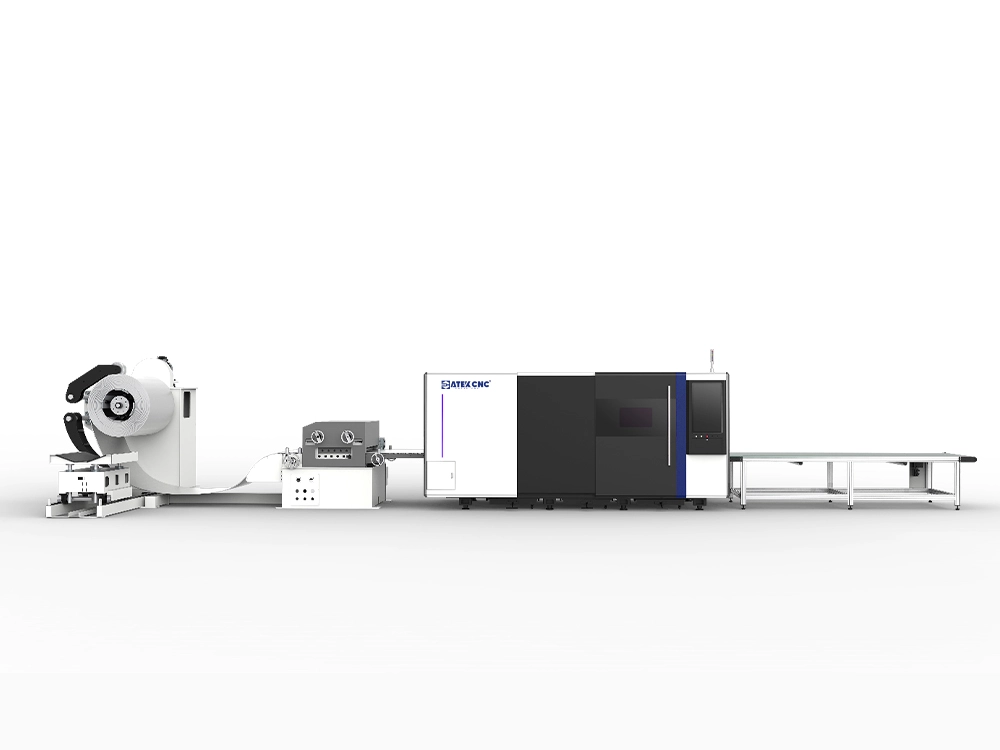

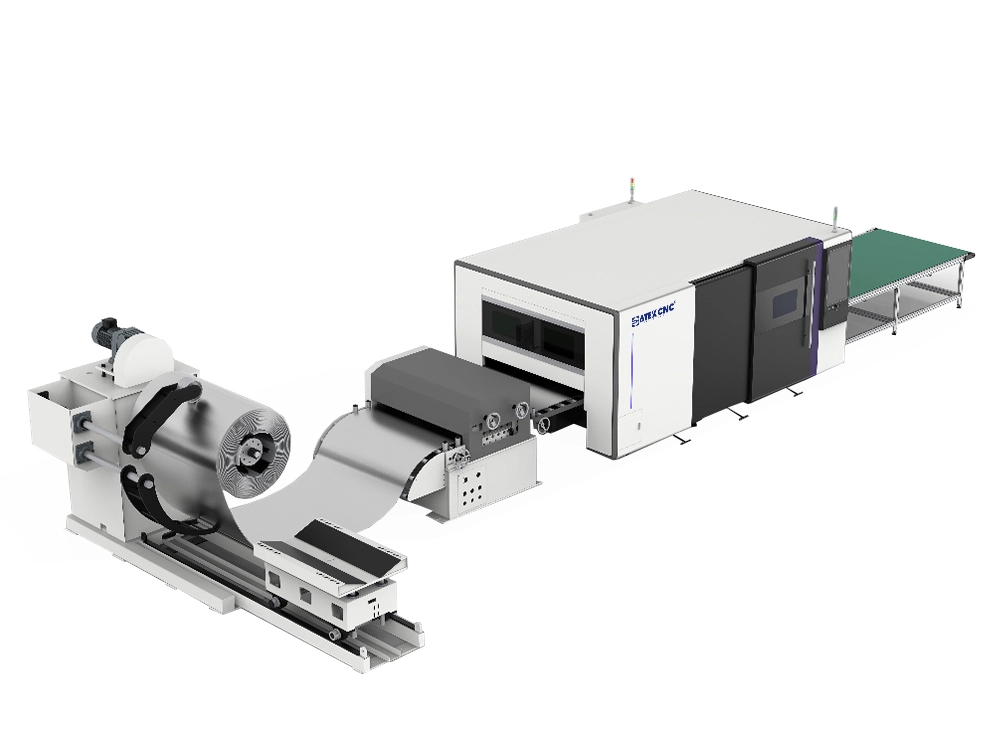

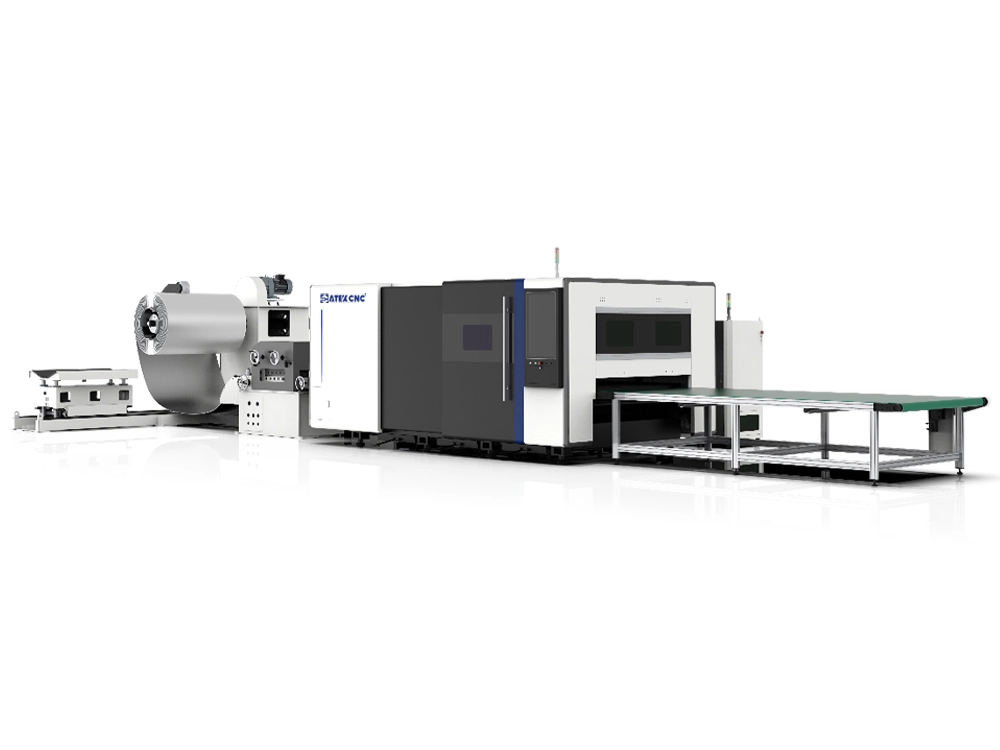

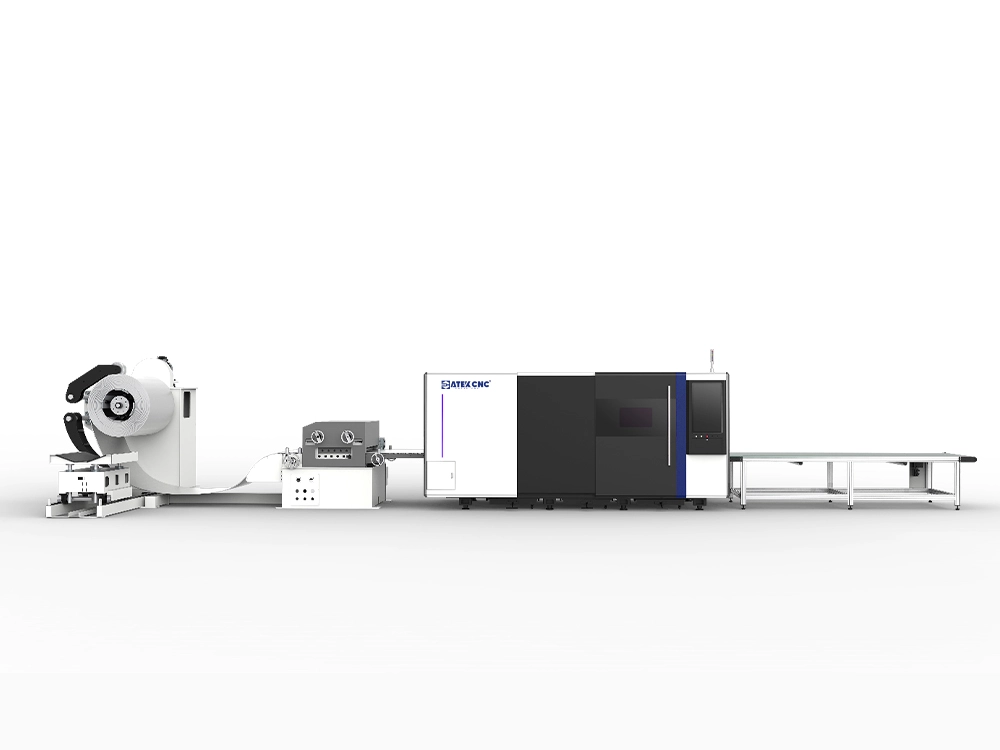

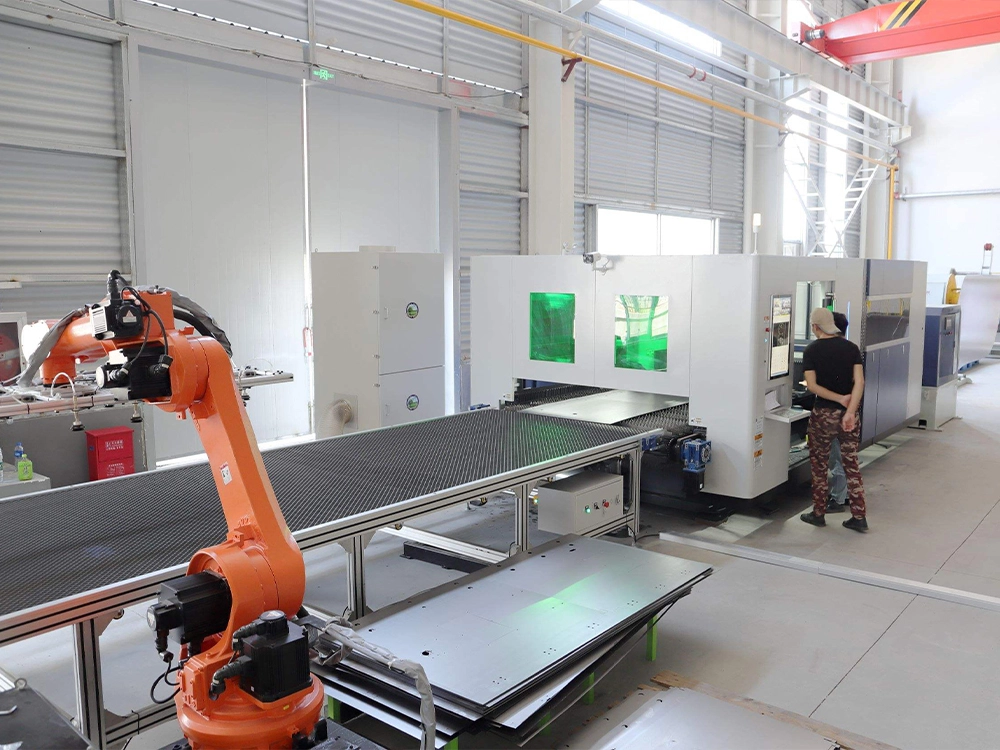

The CK-1530-ACF is an automated blanking line that integrates a coil automatic feeding system with fiber laser cutting technology. Controlled by a CNC system that coordinates all functional modules, it enables continuous cutting of carbon steel, stainless steel, and other coil materials. With advantages such as high cutting precision, high material utilization rate, and low labor costs, it supports 24/7 uninterrupted operation. It is suitable for high-volume, high-precision sheet metal production in industries including home appliances, automotive parts, hardware, and architectural decoration.

In traditional laser processing, large quantities of individual metal sheets require stacked storage and rely on manual feeding during operation, which not only consumes warehouse space but also increases labor costs. The fiber laser cutting machine equipped with a coil automatic feeding system effectively resolves these issues: a single steel coil can replace a large number of individual sheets, enabling a fully automated process from automatic uncoiling, leveling, and feeding to cutting and finished product sorting. This ensures cutting precision and speed while significantly improving processing efficiency and reducing manual labor input.

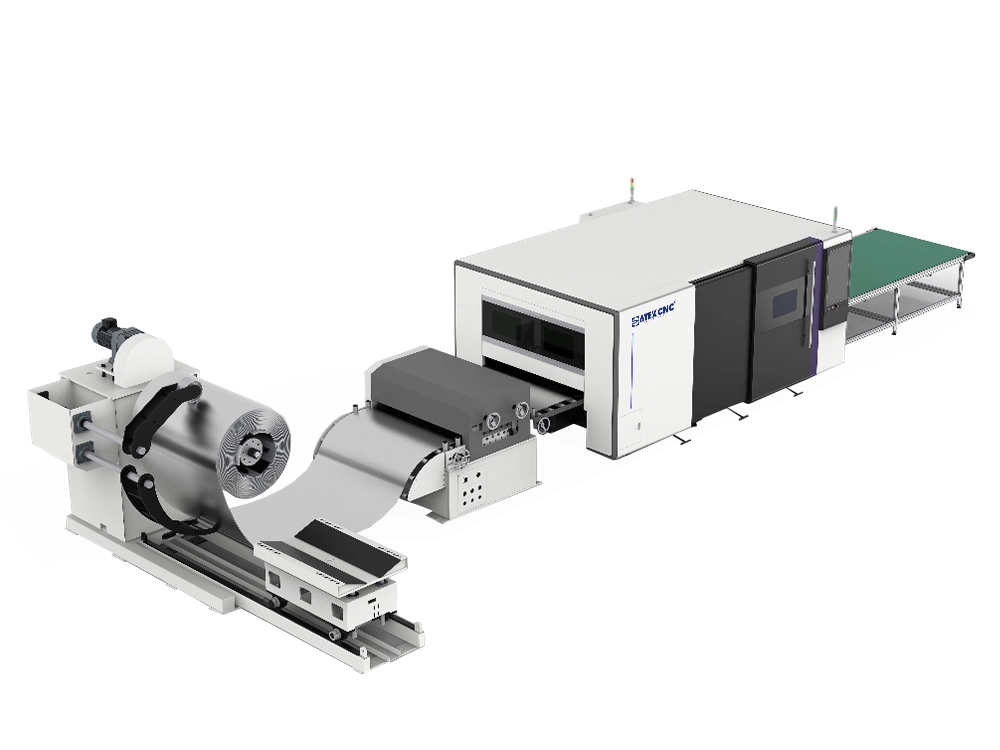

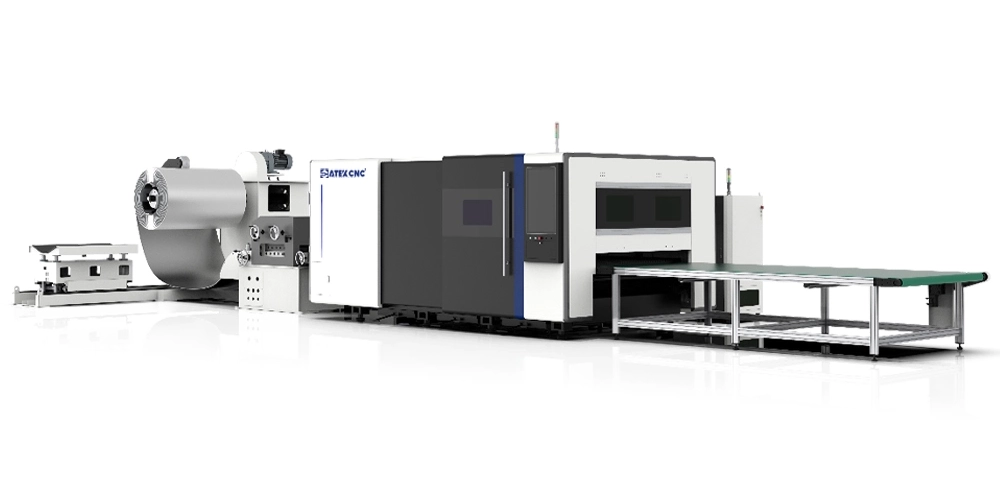

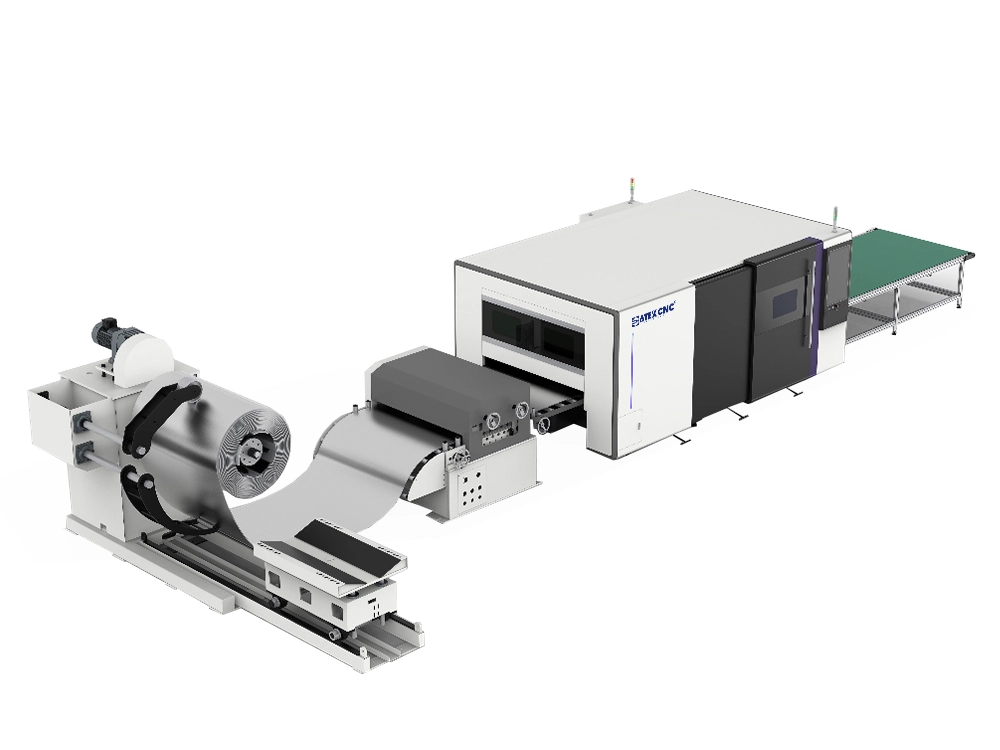

Structure of the Laser Blanking Line for Cutting Steel Coils

The laser blanking line machine primarily consists of a steel coil uncoiling and leveling system, an automatic feeding and positioning system, a fiber laser cutting system, and a finished product automatic unloading system. These systems work in coordination to achieve automated operation from coil to finished product.

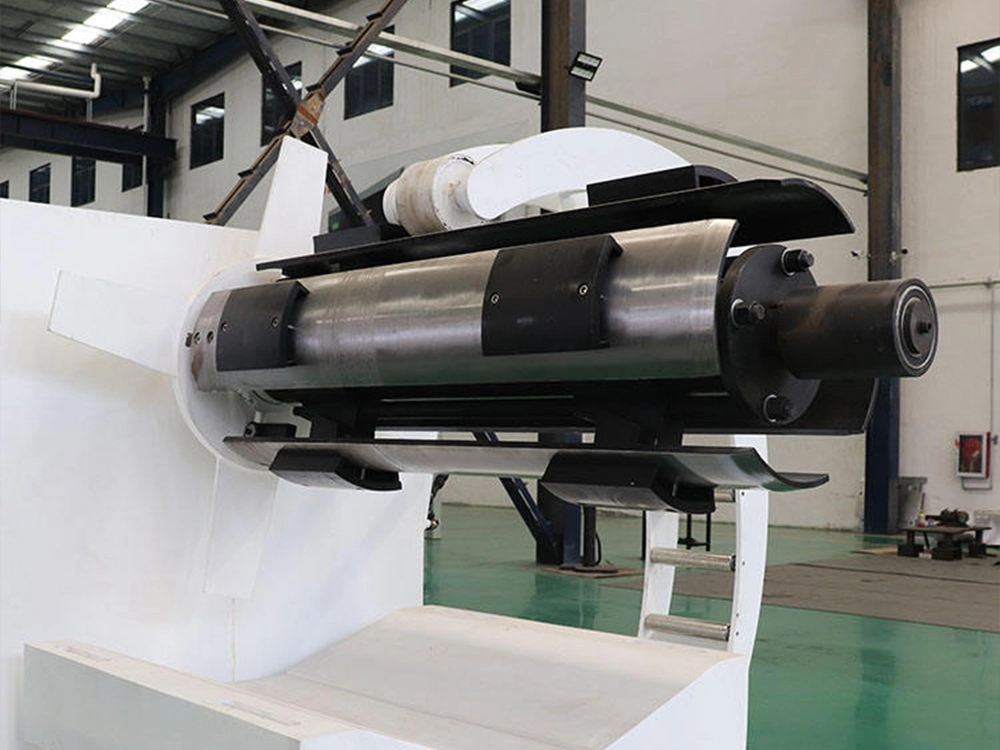

1. Steel Coil Uncoiling and Leveling System

- Heavy-Duty Hydraulic Uncoiling Unit: Equipped with a hydraulic expandable mandrel, compatible with steel coils having an inner diameter of 450–610mm, width of 600–1500mm, and thickness of 0.5–3mm. Utilizes frequency conversion control to adjust feeding speed in real-time, preventing material loosening or breaking. Maximum capacity: outer diameter 1500mm, weight 10,000kg.

- Coil Leveling Unit: Employs a multi-roller heavy-duty leveling machine. Upper and lower pressure rollers eliminate internal stresses and wave deformations caused by coiling, ensuring material flatness. This provides a foundation for precise feeding and smooth cutting.

2. Automatic Feeding and Positioning System

- Feeding System: Automatically transports the steel coil with a feeding speed of 0-20 m/min, adjustable according to the laser cutting speed, and prevents material displacement or slipping. Feeding accuracy is within ±1mm, supporting 24-hour continuous operation.

- Positioning Mechanism: A material pressing device at the front of the cutting area automatically clamps the material upon arrival, preventing displacement during processing.

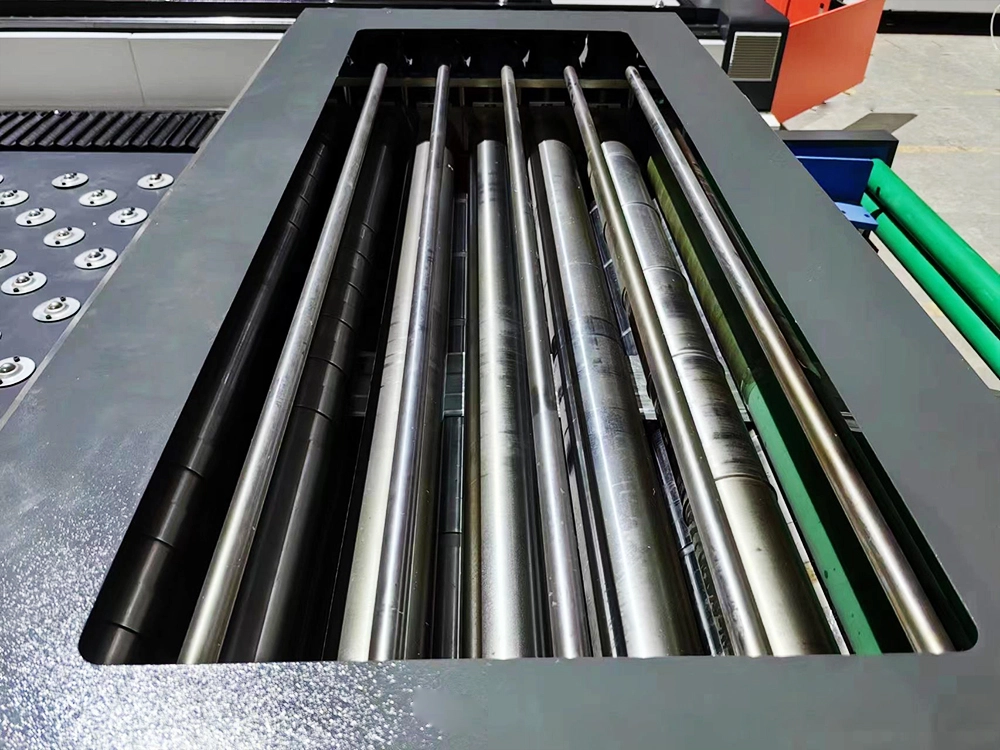

- Work Table: Features a conveyor-type tooth slats table. Driven by a motor and reducer via chain transmission, it works with the feeding system to achieve automatic feeding and cutting.

3. Finished Product Automatic Conveying System

- Conveyor Platform: Finished workpieces are automatically transported to a designated location via the conveyor platform. An automatic stacking robot is available as an option for automatic palletizing according to set layers, facilitating handling and subsequent processing.

4. Fiber Laser Cutting System

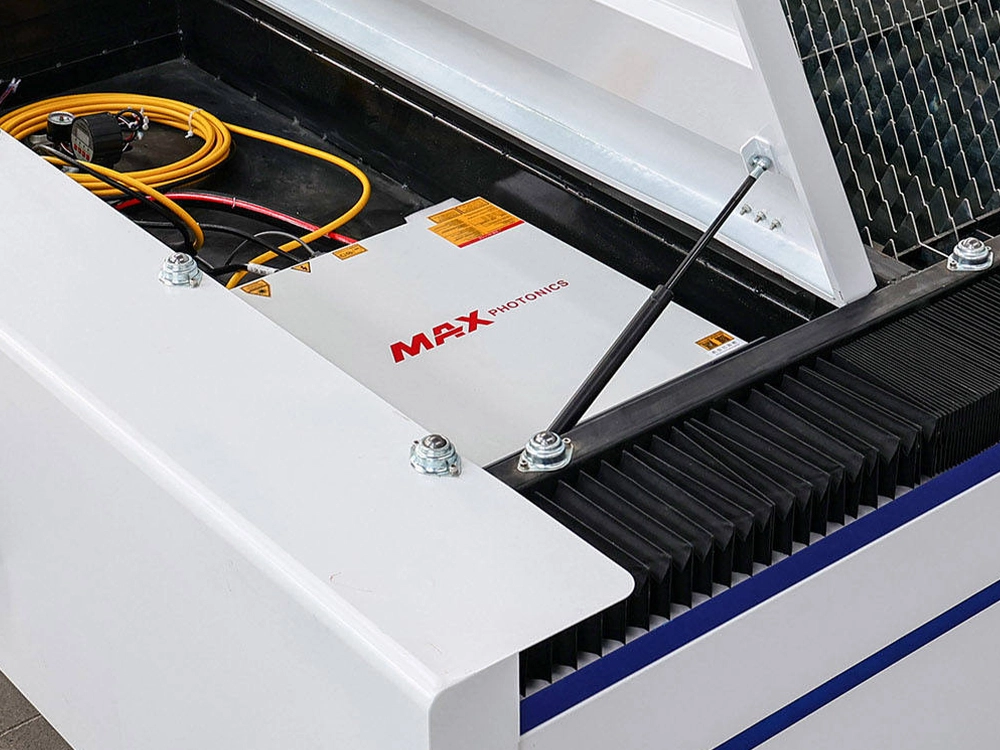

- Laser Generator: Equipped with a Maxphotonics 3000W high-power laser generator, featuring a compact structure and stable output. It offers excellent beam quality and high reflection resistance. Superior beam quality ensures precise processing, meaning more concentrated laser energy for finer cuts. The anti-high-reflection function effectively suppresses harmful reflected light when processing highly reflective materials like copper and aluminum, ensuring continuous and stable laser operation.

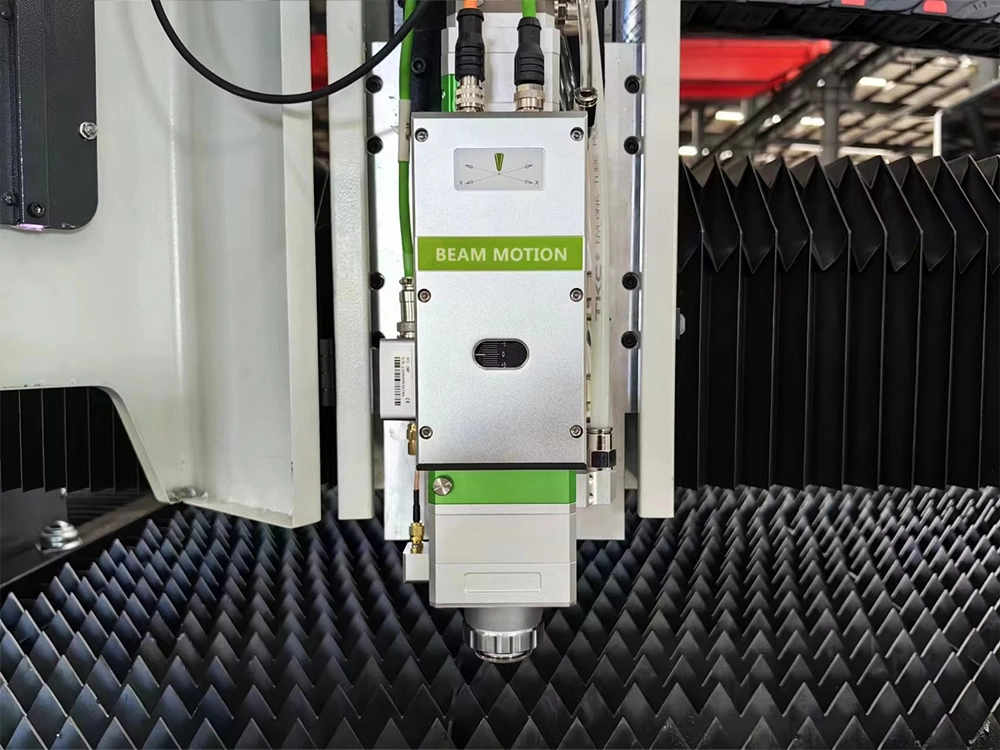

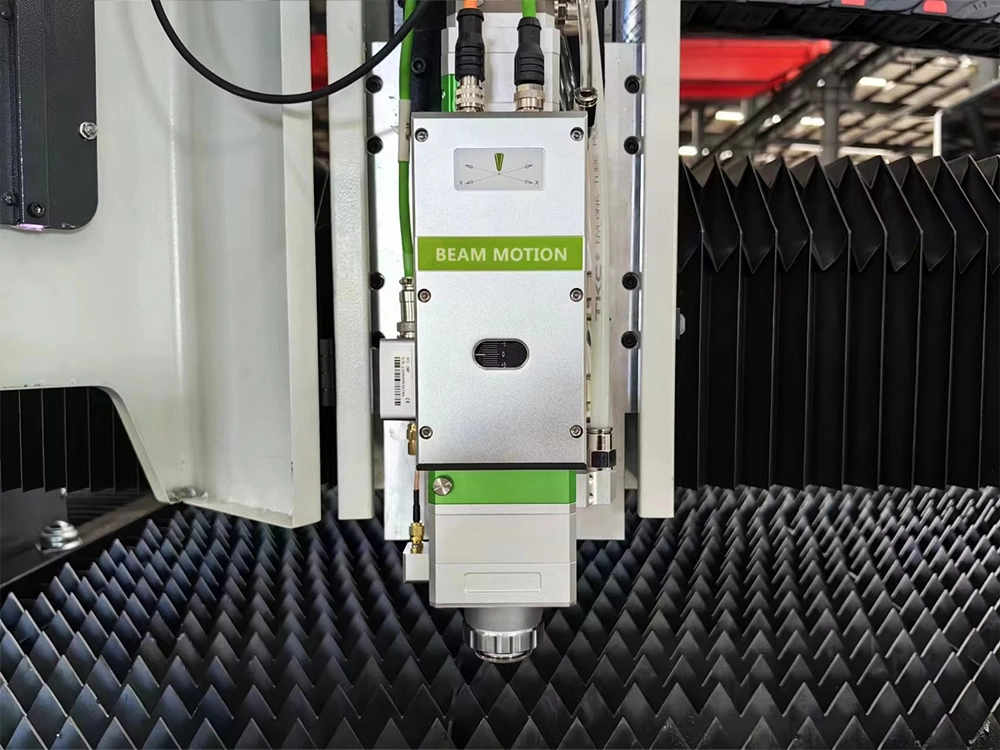

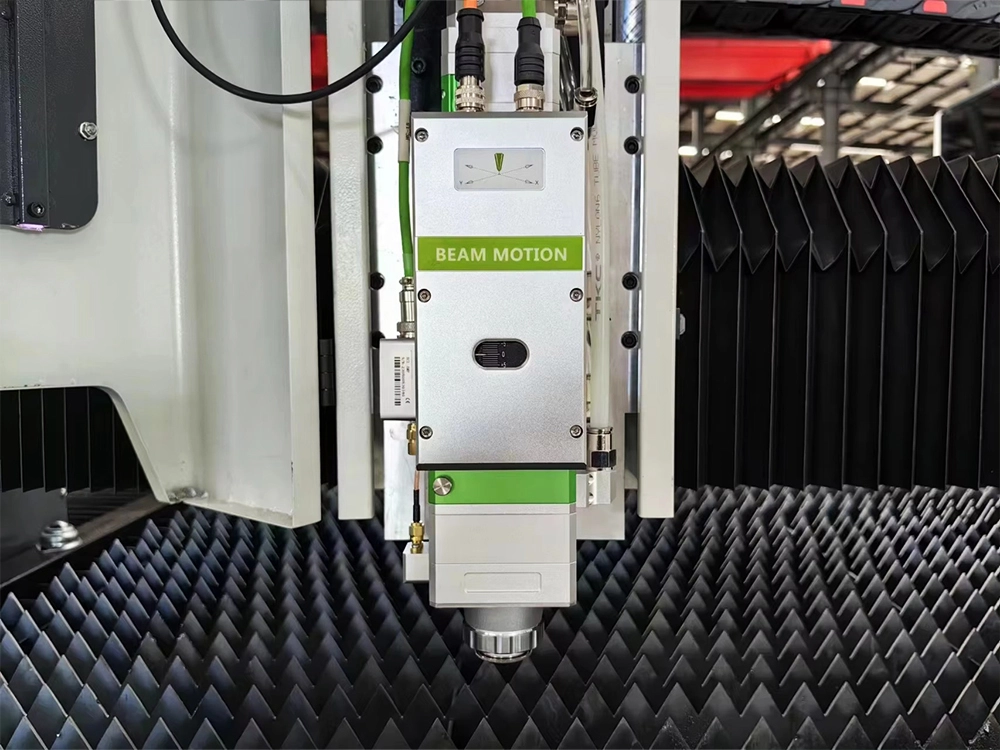

- Laser Cutting Head: Includes a Raytools BM110 high-performance auto-focus cutting head. It automatically adjusts the focal point based on material thickness, ensuring consistent cut quality across different thicknesses. Integrated anti-collision protection automatically powers off and retracts upon unexpected impact, safeguarding core components.

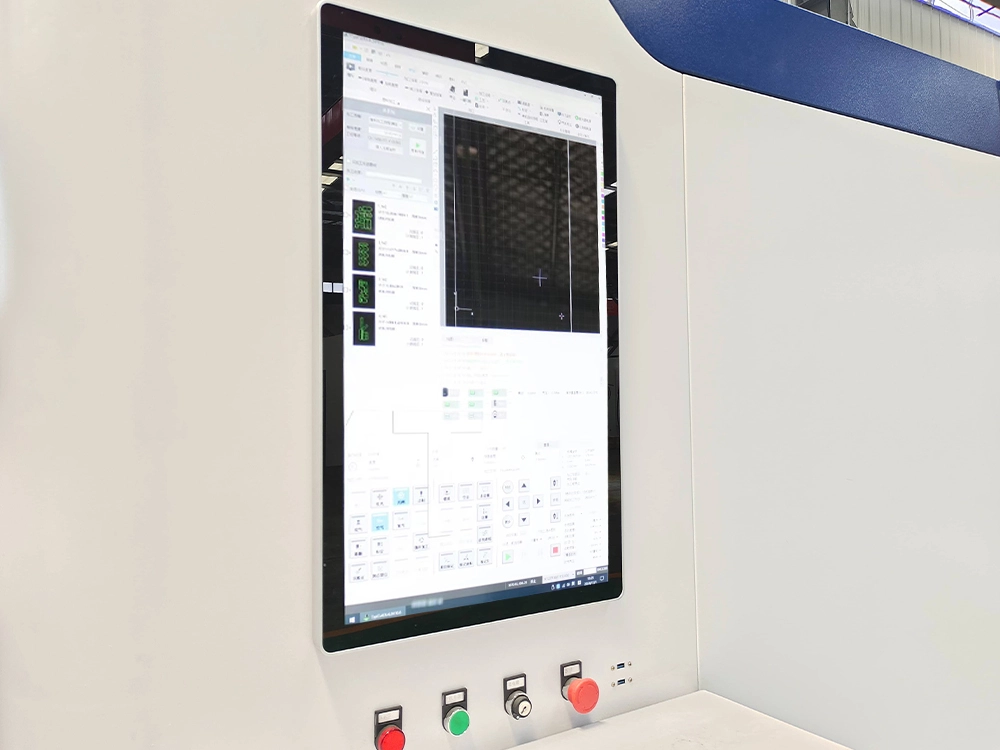

- Control System: Deep integration of a high-precision PLC automatic feeding system and the BOCHU laser cutting system automates the entire process from feeding and cutting to unloading. The BOCHU system supports automatic nesting, flying cutting, and automatic four-edge finding. It automatically adjusts optical and gas path parameters and includes preset parameters for different metal thicknesses, allowing direct selection based on processing needs, saving setup time and improving efficiency.

- Cooling System: Utilizes a S&A CWFL3000W dedicated laser chiller with dual temperature control circuits, providing independent and precise cooling for the laser generator and cutting head separately. It includes multiple alarm functions for water temperature, flow, and level, ensuring stable equipment operation.

5. Bed and Gantry

- High-Strength Square Steel Welded Bed: Constructed from thickened square steel with a finite element analyzed structure ensuring bed strength. After stress relief annealing, precision machining effectively resolves stresses from welding and machining, enhancing equipment rigidity and stability, and prolonging machine service life.

- Aerospace-Grade Aluminum Alloy Beam: Made from aerospace-grade aluminum alloy, optimized via finite element analysis for high rigidity and lightweight design. The lightweight beam reduces the load on the transmission system, improves dynamic response speed and acceleration/deceleration performance, significantly shortens idle travel time, and is particularly suitable for complex graphics and high-speed small-diameter hole cutting, markedly boosting overall efficiency.

6. Drive and Transmission System

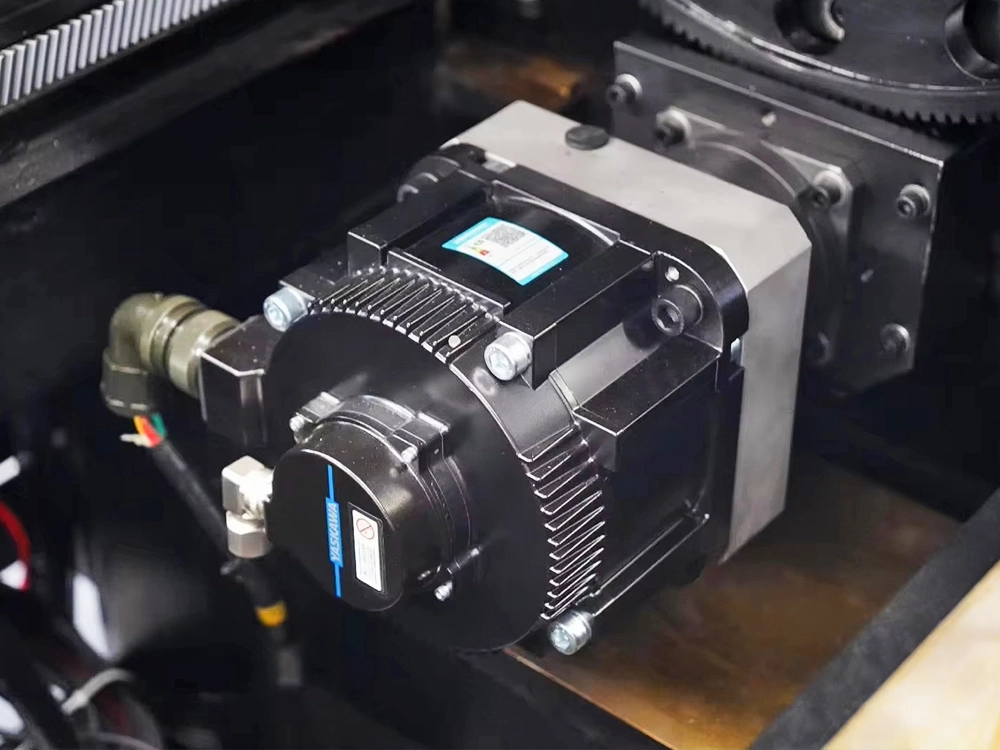

- Servo Motors: Fitted with Yaskawa (Japan) bus-type absolute servo motors, featuring high-precision current control technology with torque control accuracy within ±1%. They offer fast response and precise positioning, suitable for high-speed laser cutting, fully leveraging equipment performance.

- Reducer: Uses Motoreducer planetary gear reducers to effectively increase motor output torque, enhance machine rigidity and positioning accuracy, enabling faster and smoother driving of the laser machine's beam and cutting head at high speeds, ensuring workpiece cutting quality.

- Guideways: Employ Taiwan HIWIN square linear guide rails, known for high precision, high rigidity, high load capacity, and long service life. Low friction coefficient ensures smooth movement. Guide rails and linear bearings are interchangeable, simplifying maintenance and reducing costs.

- Rack and Gears: Uses Taiwan YYC high-precision ground helical racks/gears. Heat treatment and quenching processes provide high tooth toughness, enabling resistance to long-term high-frequency meshing wear and high-speed machine impacts, ensuring long-term machine service life.

7. Auxiliary Systems

- Assist Gas System: Different gases should be selected based on the material: oxygen is commonly used for cutting carbon steel (aids combustion, increases speed); nitrogen is typical for stainless steel (prevents oxidation, ensures burr-free, rust-free cuts); compressed air can be used for ordinary thin sheets (lower cost). Gas pressure is regulated via proportional valves controlled by the CNC system.

- Lubrication Maintenance System: Includes a fully automatic electric timed oil lubricator that automatically lubricates transmission parts without manual intervention, saving maintenance time and costs.

Details of the Laser Blanking Line for Cutting Steel Coils

- Thickened machine bed frame

The bed structure is welded from heavy-duty thickened square steel. It undergoes high-temperature annealing to eliminate internal stress, effectively ensuring long-term use accuracy and preventing structural deformation.

- Aluminum alloy beam

The lightweight aviation aluminum alloy beam has excellent anti-fatigue performance, capable of withstanding high-speed vibration for a long time without deformation. Its light self-weight reduces the load on the guide rail, enables sensitive dynamic acceleration and deceleration response, and helps improve processing accuracy and equipment service life.

- Steel coil uncoiling system

It is a hydraulic heavy-duty uncoiler equipped with an expandable mandrel, suitable for steel coils of various specifications. A hydraulic feeding cart is configured on the side to realize fully automatic feeding, ensuring convenient operation.

The expanding mandrel holds coils of different specifications by expanding.

- Steel plate leveling system

The multi-roller leveler eliminates internal stress of the plate through upper and lower pressure roller groups, ensuring the plate is flat and guaranteeing smooth cutting process and processing accuracy.

The hydraulic oil pump supplies hydraulic pressure to the entire system's hydraulic components.

- Conveyor belt type worktable

The chain-driven conveyor belt type tooth slat worktable is equipped with a positioning mechanism at the front end, which effectively suppresses material vibration during the cutting process.

A positioning device is provided at the front end of the cutting area, and the material is automatically fixed by pressing after it is in place.

- Conveyor belt type automatic unloading table

Processed workpieces are automatically transported to the designated position through the automatic unloading table. An optional automatic stacking robot is available to realize automatic palletizing of finished products.

- Raytools laser cutting head

Raytools BM110 automatic focusing laser cutting head adopts a dual optical protection design, integrating an air pressure sensor and a protective lens temperature monitoring module. It detects the cutting status in real time and automatically alarms when the lens is contaminated or the temperature is abnormal, effectively preventing equipment failures.

- Max laser generator

Max 3000W fiber laser generator adopts a single-module design, featuring compact structure and high integration. The simplified internal structure and connection points effectively improve photoelectric conversion efficiency and operational stability.

- S&A water chiller

S&A CWFL 3000W water chiller is equipped with a dual-circulation cooling system, which can independently cool the laser generator and the laser head respectively to maintain stable operating temperature of the equipment.

- Yaskawa servo

The XYZ three axes all adopt high-precision bus absolute value servo motors from Yaskawa (Japan), which have strong anti-interference ability and stable signal transmission performance, ensuring processing accuracy.

- Transmission system

It adopts Hiwin (Taiwan) linear square guideways and YYC (Taiwan) helical rack/gear. It is easy to maintain and effectively ensures the machine's operation accuracy and long-term operation stability.

- Lubrication system

The automatic timing lubricating oil pot realizes fully automatic lubrication and maintenance of the transmission system without manual intervention, avoiding equipment performance degradation due to inadequate maintenance.

- Auxiliary gas system

During laser cutting, assist gas is required, and the gas flow must be precisely controlled through a proportional valve.

- Control system

The automatic feeding PLC system and the BOCHU laser cutting system operate in coordination, combined with automatic nesting software. It realizes intelligent typesetting and cutting path optimization, significantly saving processing time and improving material utilization.

Technical Parameters of the Laser Blanking Line for Cutting Steel Coils

| Model | CK-1530-ACF |

|---|---|

| Sheet Cutting Size | 1500mm * 3000mm |

| Z-Axis Travel | 100mm |

| Bed Frame / Gantry | High-strength heavy-duty bed frame, aerospace-grade aluminum alloy gantry |

| Laser Wavelength | 1064nm |

| Laser Generator | Max / Raycus / IPG / Reci / BWT, etc. |

| Laser Head | Raytools BM110 |

| Fiber Laser Power | 3000W (Customizable power) |

| Cooling Method | S&A 3000W dedicated fiber laser chiller |

| Drive System | Yaskawa bus-type absolute servo motor * 4 |

| Guideways | Taiwan HIWIN high-precision square linear guide rails, HIWIN sliders |

| Rack | Taiwan YYC high-precision ground helical rack and gear |

| Reducer | Motoreducer planetary gear reducer |

| Cables | Pure copper highly flexible anti-bending cables |

| Proportional Valve | SMC |

| Electrical Components | Schneider Electric components |

| Control System | FSCUT 2000E dedicated laser cutting system |

| Unloading | Conveyor-type automatic unloading platform |

| Worktable Load Capacity | 200kg |

| Material Width | 600-1500mm |

| Feeding Length | 500-3000mm |

| Automatic Feeding Material Thickness | 0.8-3mm |

| Max. Coil Weight | 10T |

| Material Inner Diameter | 450-610mm |

| Material Outer Diameter | 1500mm |

| Feeding Speed | 0-20m/min (Adjustable) |

| Feeding Accuracy | ±1mm/m |

| Loading Cart Load Capacity | 10T |

| Lubrication System | Electric lubrication and oil maintenance system |

| Compatible Software | ArtCAM, Type3, CAD drawing, CDR, AI, etc. |

| Max. Acceleration | 1.2G |

| Operating Voltage | AC380V |

| Positioning Accuracy | ±0.03mm |

| Repeated Positioning Accuracy | ±0.02mm/1000mm |

| Maximum Moving Speed | 115,000mm/min |

| Machine Weight | 8500kg |

| Machine Dimensions | 12600 * 2500 * 2400mm |

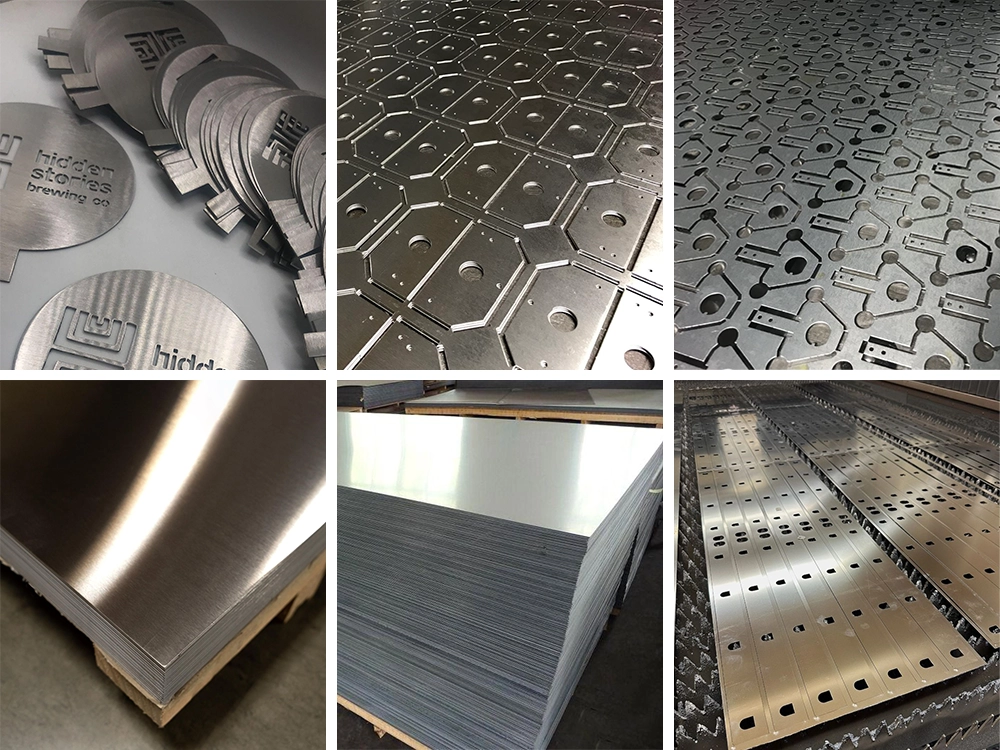

Application Scope of Fiber Laser Cutting Machine with Coil Automatic Feeding System

Hardware Manufacturing: Mass production of hardware accessories, brackets, fasteners, connectors, flange plates, gaskets, shelves, etc.

Home Appliance Industry: Cutting refrigerator side panels, washing machine back panels, appliance evaporator mounting plates, appliance casing shells, air conditioning sheet metal housings, air conditioning brackets, heat exchanger fins, internal structural components.

Automotive Components: Processing automotive chassis, body panels, brake pad backings, sunroof frames, new energy battery pack shells, side plates, cover plates, etc.

Building Materials: Color steel plates, steel structure connectors, wall panel fixings, decorative panels, curtain walls, etc.

Metal Products: Metal storage cabinets, filing cabinets, sheet metal enclosures and cabinets, metal doors and windows, door and window frames, stainless steel tables, stainless steel cabinets, etc.

| Model | CK-1530-ACF |

|---|---|

| Sheet Cutting Size | 1500mm * 3000mm |

| Z-Axis Travel | 100mm |

| Bed Frame / Gantry | High-strength heavy-duty bed frame, aerospace-grade aluminum alloy gantry |

| Laser Wavelength | 1064nm |

| Laser Generator | Max / Raycus / IPG / Reci / BWT, etc. |

| Laser Head | Raytools BM110 |

| Fiber Laser Power | 3000W (Customizable power) |

| Cooling Method | S&A 3000W dedicated fiber laser chiller |

| Drive System | Yaskawa bus-type absolute servo motor * 4 |

| Guideways | Taiwan HIWIN high-precision square linear guide rails, HIWIN sliders |

| Rack | Taiwan YYC high-precision ground helical rack and gear |

| Reducer | Motoreducer planetary gear reducer |

| Cables | Pure copper highly flexible anti-bending cables |

| Proportional Valve | SMC |

| Electrical Components | Schneider Electric components |

| Control System | FSCUT 2000E dedicated laser cutting system |

| Unloading | Conveyor-type automatic unloading platform |

| Worktable Load Capacity | 200kg |

| Material Width | 600-1500mm |

| Feeding Length | 500-3000mm |

| Automatic Feeding Material Thickness | 0.8-3mm |

| Max. Coil Weight | 10T |

| Material Inner Diameter | 450-610mm |

| Material Outer Diameter | 1500mm |

| Feeding Speed | 0-20m/min (Adjustable) |

| Feeding Accuracy | ±1mm/m |

| Loading Cart Load Capacity | 10T |

| Lubrication System | Electric lubrication and oil maintenance system |

| Compatible Software | ArtCAM, Type3, CAD drawing, CDR, AI, etc. |

| Max. Acceleration | 1.2G |

| Operating Voltage | AC380V |

| Positioning Accuracy | ±0.03mm |

| Repeated Positioning Accuracy | ±0.02mm/1000mm |

| Maximum Moving Speed | 115,000mm/min |

| Machine Weight | 8500kg |

| Machine Dimensions | 12600 * 2500 * 2400mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.