What Is the Transmission System of CNC Machine?

What Is the Transmission System of CNC Machine?

- Oct 14, 2025

In CNC machines, the transmission system refers to the collective term for a series of mechanical components and devices that convert the power from the transmission system into precise and stable linear or rotary motion required by the machine's execution parts. Its primary function is to transmit power and transform the nature, direction, and speed of the motion. Specifically, in CNC router machines and CNC lathes, the transmission system mainly converts the rotational motion of various motors into precise linear motion of linear axes (such as the X, Y, and Z axes) or drives the spindle to achieve high-speed or precise rotational motion. The performance of this system—including its accuracy, rigidity, response speed, and stability—directly determines the machining precision, operational efficiency, dynamic stiffness, and long-term machining consistency of the entire machine, making it one of the core factors influencing the overall performance of CNC equipment.

Transmission devices can be classified into several major categories based on various dimensions. Among these, classification according to the function and task of each component is the most commonly used and intuitive method.

Power Transmission and Conversion Device

In the narrow sense, the "transmission system" refers precisely to this category of devices. Their core task is to transmit and convert the power and motion forms generated by the motor, serving as the "muscles and joints" of the transmission system.

Depending on the transmission method, they can be categorized as belt transmissions, chain transmissions, screw transmissions, gear transmissions, worm transmissions, and so on.

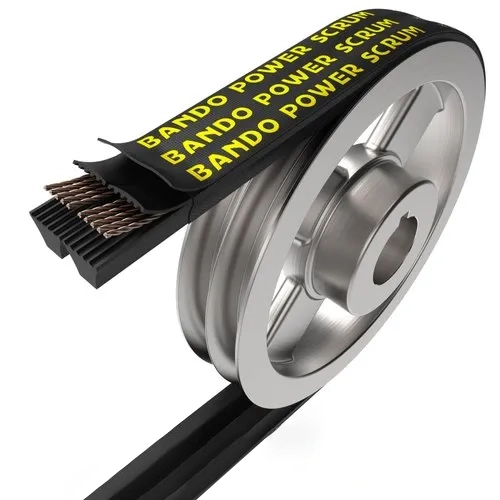

- Belt Transmission

Type Main or Feed Transmission.

Motion Conversion:

- Rotary→Rotary

- Rotary→Linear

Characteristics Transmits power from the motor to the spindle via a flexible belt. Mechanism V-Belt/Poly-V Belt: Friction-based transmission, can cushion and absorb vibrations, but may slip.

Timing Belt: Meshes with pulleys via teeth, provides accurate transmission ratio, no slippage, high transmission efficiency.

Applications Widely used in main spindle transmissions for small/medium machining centers and CNC lathes.

Linear axis movement in CO₂ engraving machines.

Advantages Smooth Operation: Belts are elastic and flexible, providing cushioning, vibration damping, and very low noise.

Low Cost: Simple structure, relatively low manufacturing, installation, and maintenance costs.

Overload Protection: Under sudden load increase, belts may slip (except timing belts), protecting critical components like motors and spindles.

High Adaptability: Suitable for large center distances, requires relatively low manufacturing and installation precision.

Disadvantages Inaccurate Ratio: Except for timing belts, V-belts experience elastic slip, preventing a guaranteed precise ratio.

Lower Efficiency: Slightly lower efficiency than gear or chain transmissions due to elastic friction.

Shorter Lifespan: Belts wear out and age, requiring periodic replacement.

High Bearing Load: The necessary belt tension imposes significant radial pressure on shafts and bearings.

- Chain Transmission

Type Auxiliary Transmission.

Motion Conversion:

- Rotary→Rotary

- Rotary→Linear

Characteristics Similar to belt transmissions but relies on meshing between chain links and sprockets for power transmission. Mechanism Metal Roller Chain: Consists of chain, sprockets, tensioners, etc.; transmits power via meshing.

Applications Tool magazine chains in Automatic Tool Changers (ATC).

Auxiliary power transmission in old heavy-duty machine tools.

Advantages Accurate Average Ratio: Maintains a precise average transmission ratio.

Relatively High Efficiency: Slightly higher transmission efficiency than belt transmissions.

High Load Capacity: Higher load capacity than belt transmissions, suitable for heavy-duty, low-speed applications.

Environmental Resilience: Can operate in harsh conditions (high temp, dust, humidity).

High Adaptability: Suitable for large center distances, requires relatively low manufacturing and installation precision.

Disadvantages Unsteady Instantaneous Ratio: The "polygon effect" causes varying instantaneous ratios, leading to poor smoothness, vibration, and impact loads.

High Noise: Significant noise from meshing impacts and friction between chain and sprockets.

- Screw Transmission

Type Feed Transmission.

Motion Conversion:

- Rotary→Linear

Characteristics Converts servo motor rotation into linear axis movement via recirculating balls rolling between the screw and nut threads. Mechanism Ball Screw Transmission: Comprises ball screw, nut, and balls. Balls roll within helical grooves, enabling highly efficient and precise transmission.

Applications Widely used for driving linear axes (X, Y, Z) in CNC machines, such as in CNC wood lathes.

Advantages High Precision: Preloading eliminates axial backlash, enabling micron-level positioning accuracy.

High Efficiency: Rolling friction provides efficiency over 90%.

Smooth Operation: Low friction, high sensitivity, small starting torque, ensures smooth high-speed operation.

Long Lifespan: Minimal rolling wear, high reliability, and long service life.

Disadvantages Complex & Costly: Complex structure, high manufacturing requirements, higher cost. Demanding installation needs regarding screw support and parallelism to guides.

Non-Self-Locking: Low friction prevents self-locking (requires brake for vertical axes).

Limited Speed: Linear speed relates to lead. High precision often requires small lead, limiting speed.

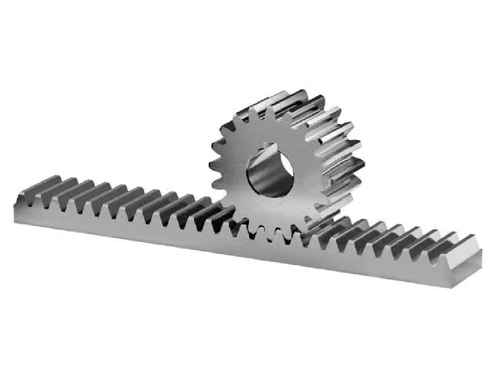

- Gear Transmission

Type Main or Feed Transmission.

Motion Conversion:

- Rotary→Rotary

- Rotary→Linear

Characteristics Transmits power between shafts via meshing gear teeth. Mechanism Rack and Pinion: Converts servo motor rotation into long-stroke precise linear motion via a pinion meshing with a straight/helical rack.

Planetary Gear Reducer: Gearbox modifies motor output speed/torque for different machining needs.

Applications High-speed, long-stroke linear motion in CNC machines (e.g., Z-axis in wood lathes, Y-axis gantry in engravers).

Gear reducers increase torque, rigidity, match inertia, enhancing stability, control accuracy, and load capacity.

Advantages High Efficiency: 98%–99.5% efficiency, minimal energy loss.

Stable Ratio: Constant instantaneous ratio ensures smooth, accurate, reliable transmission.

Long Lifespan: Highly reliable with proper design, manufacture, and maintenance.

High Speed: Much faster linear speed than screw transmissions, limited only by pitch line velocity.

Disadvantages High Manufacturing Demands: Requires high precision for rack alignment/joining and backlash elimination mechanisms.

Vulnerability to Overload: Potential for catastrophic tooth breakage under sudden overload.

Complex Backlash Control: Often uses dual motors with backlash elimination, requiring two servos.

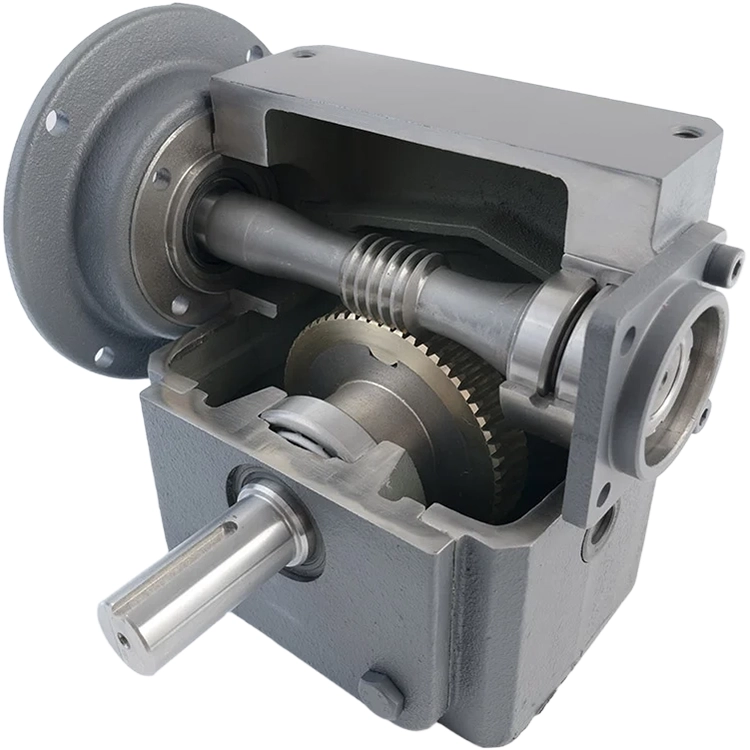

- Worm Transmission

Type Auxiliary Transmission.

Motion Conversion:

- Rotary→Rotary

Characteristics A special gear form. The worm (screw-like driver) meshes with the worm wheel (gear). Shafts are typically at 90°. Mechanism Worm Reducer: A speed converter/reducer that decreases motor RPM and increases torque.

Applications Used in 4th/5th axes for torque multiplication, speed matching, and precision enhancement. Self-locking can maintain angle in indexing applications.

Advantages High Reduction Ratio: Single stage achieves large ratios (5:1 to 100:1+), maintaining compactness.

Self-Locking: Possible when worm lead angle is small, preventing back-driving.

Smooth Operation: Continuous line contact meshing provides smoother, quieter operation than gears.

Disadvantages Low Efficiency: Significant sliding friction causes heat generation and low efficiency (typically 50%-90%).

Wear & Heat: High sliding friction leads to wear, requiring expensive materials (e.g., bronze wheel) and good lubrication/cooling.

Belt transmission is a mechanical transmission method that utilizes flexible belts and pulleys to transmit power and motion. It mainly consists of a driving pulley, a driven pulley, and an annular belt tightly fitted around the two pulleys, relying on the friction or engagement between the belt and the pulleys to achieve power transmission.

V-Belt

Timing Belt

Chain transmission is a mechanical transmission method that transmits power and motion through the meshing of a chain with specially toothed sprockets. It mainly consists of a driving sprocket, a driven sprocket, and a chain that encircles them.

A lead screw transmission is a mechanical transmission method that precisely converts rotational motion into linear motion. Its core components are a screw with a helical groove and a matching nut. When either the screw or the nut rotates, the other component moves in a precise linear motion along its axis.

Gear transmission is a mechanical transmission method that uses the meshing of gears to transmit power and motion. It primarily consists of two or more gears with specially shaped teeth that engage with each other.

Gear and Pinion

Gear Reducer

Worm transmission is a special type of gear transmission mechanism, consisting of a meshing worm (resembling a screw) and a worm wheel. Its most distinctive feature is that the two shafts are spatially crossed at a 90-degree angle.

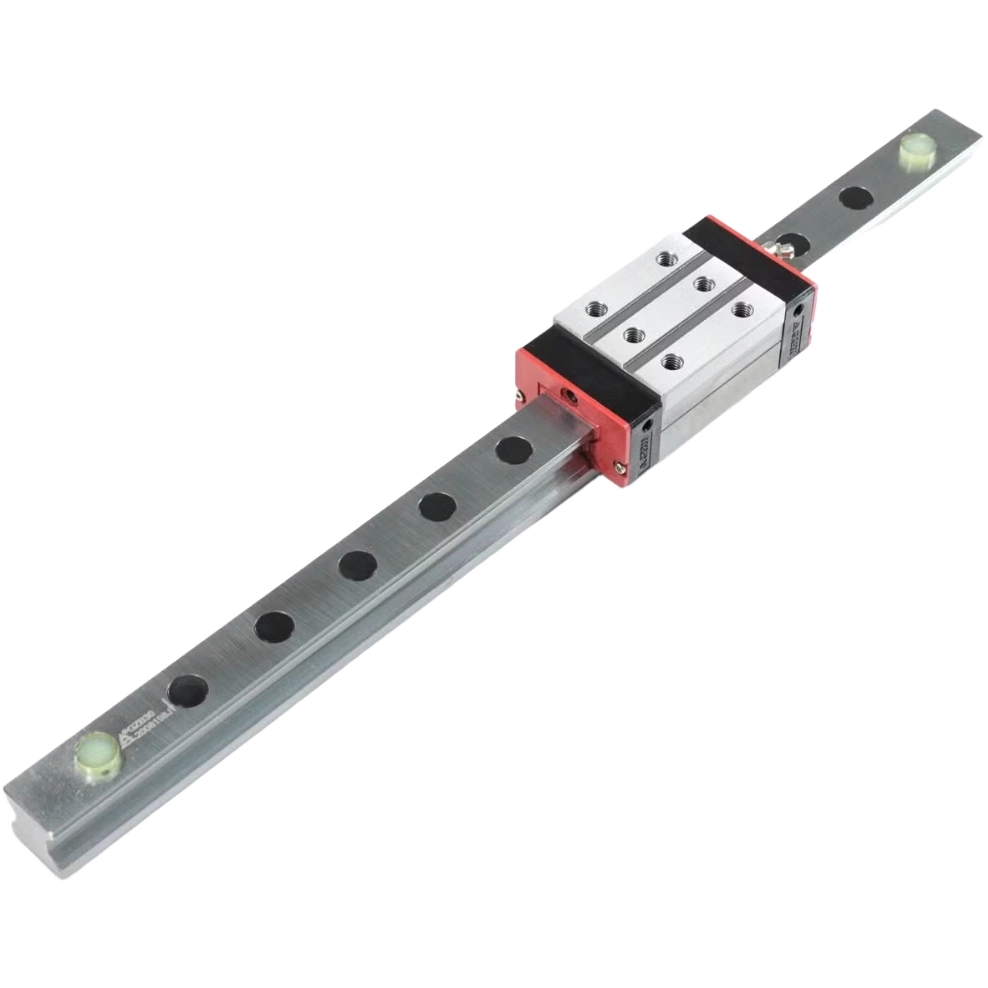

Guidance and Support Systems

The core function of these systems is to constrain the degrees of freedom of moving components, ensuring they follow precise preset trajectories while withstanding various forces and moments. They serve as the "skeleton" of the transmission system.

In CNC machine tools, guidance and support systems can be categorized into linear guidance systems (such as linear guides) and rotary guidance systems (such as bearings used to support rotating shafts).

Linear Guideway

Angular Contact Ball Bearings

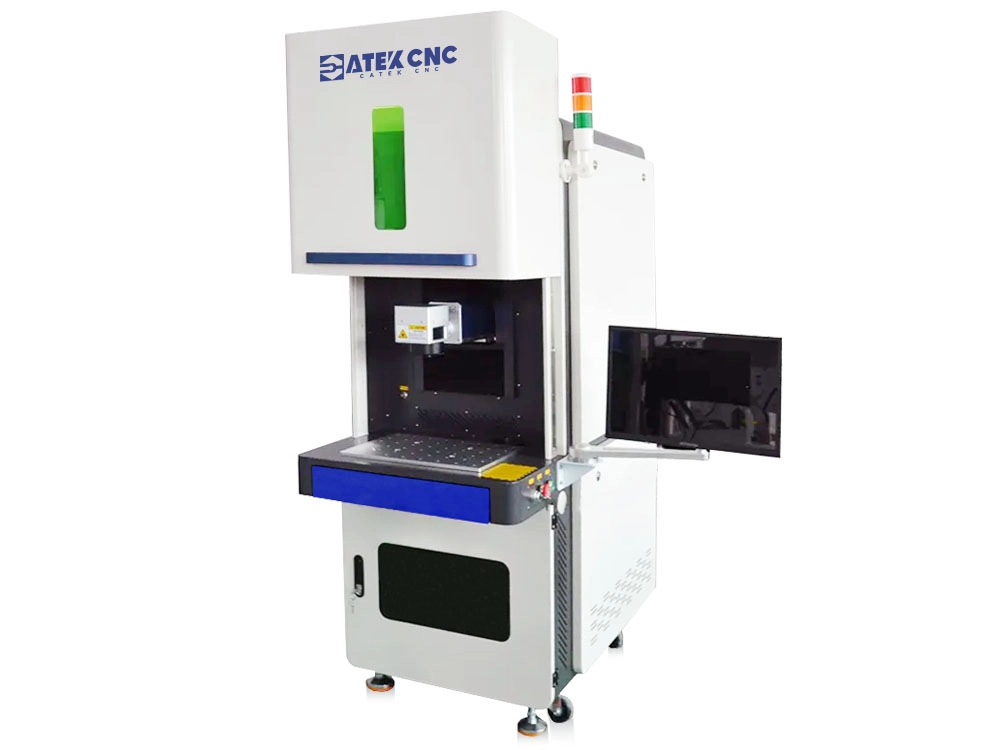

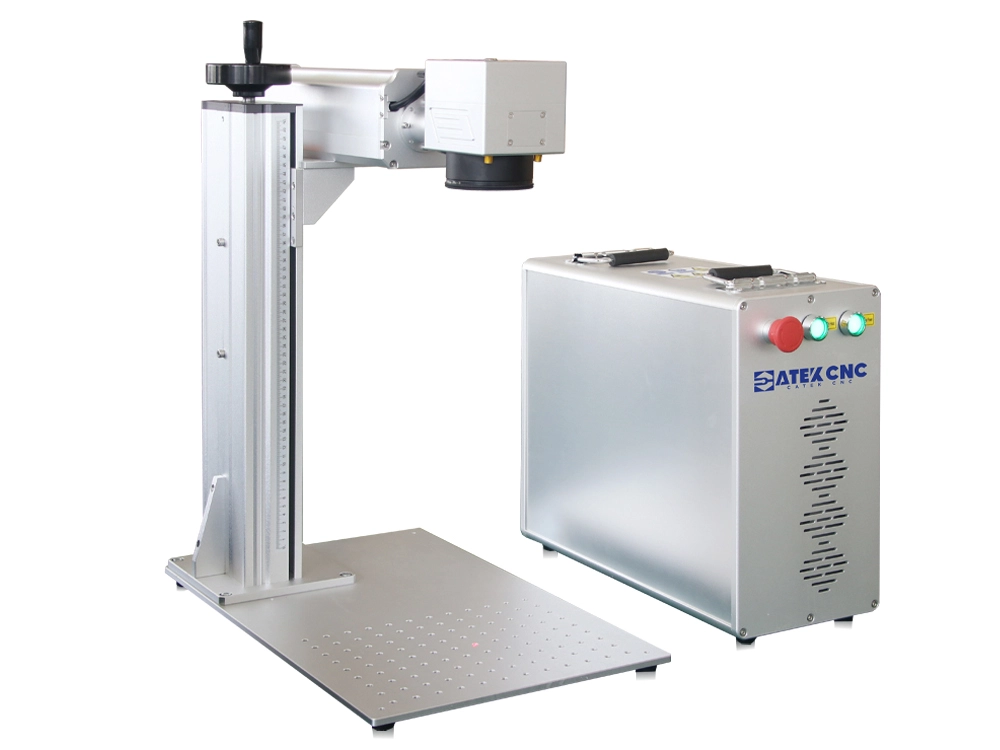

RELATED MODELS

We recommend some related models for you...