Cradle-Type 5-Axis Metal Milling Machine

Trunnion-Type 5-Axis Metal Milling Machine

[Function Description]

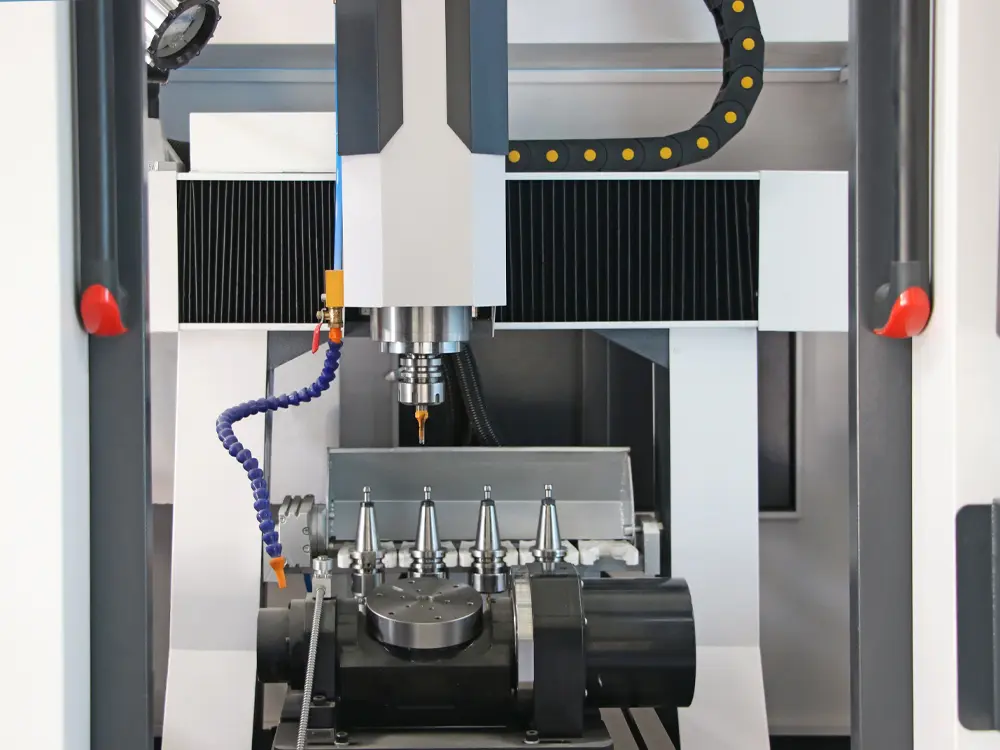

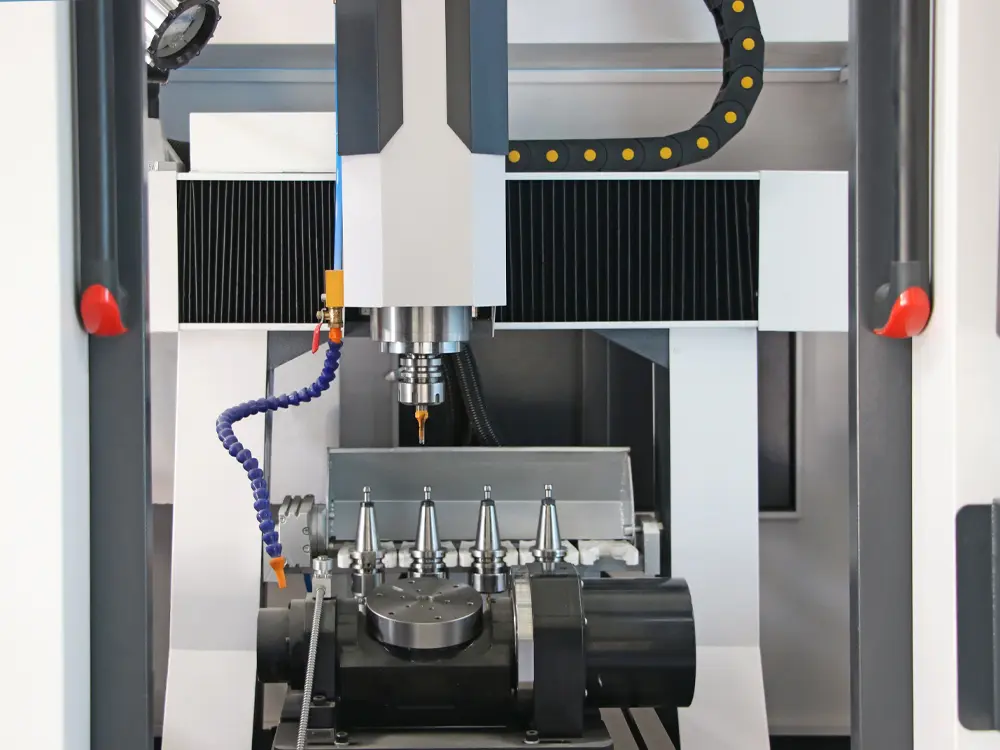

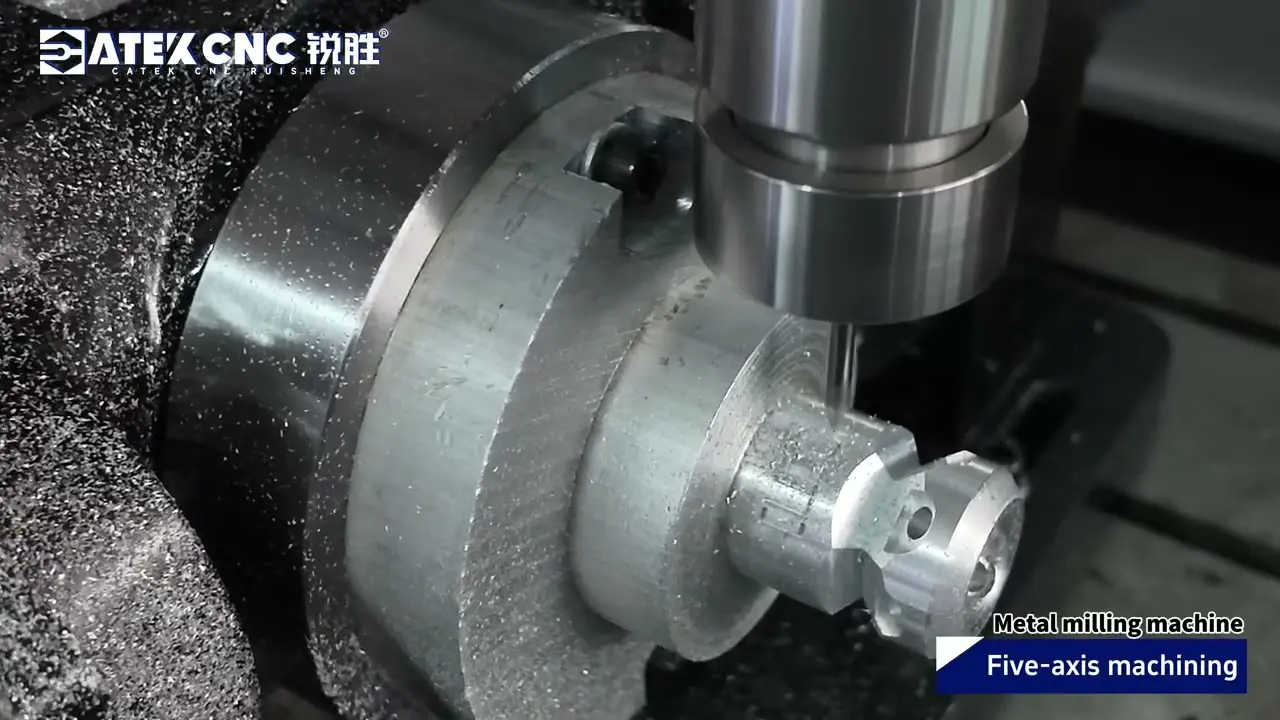

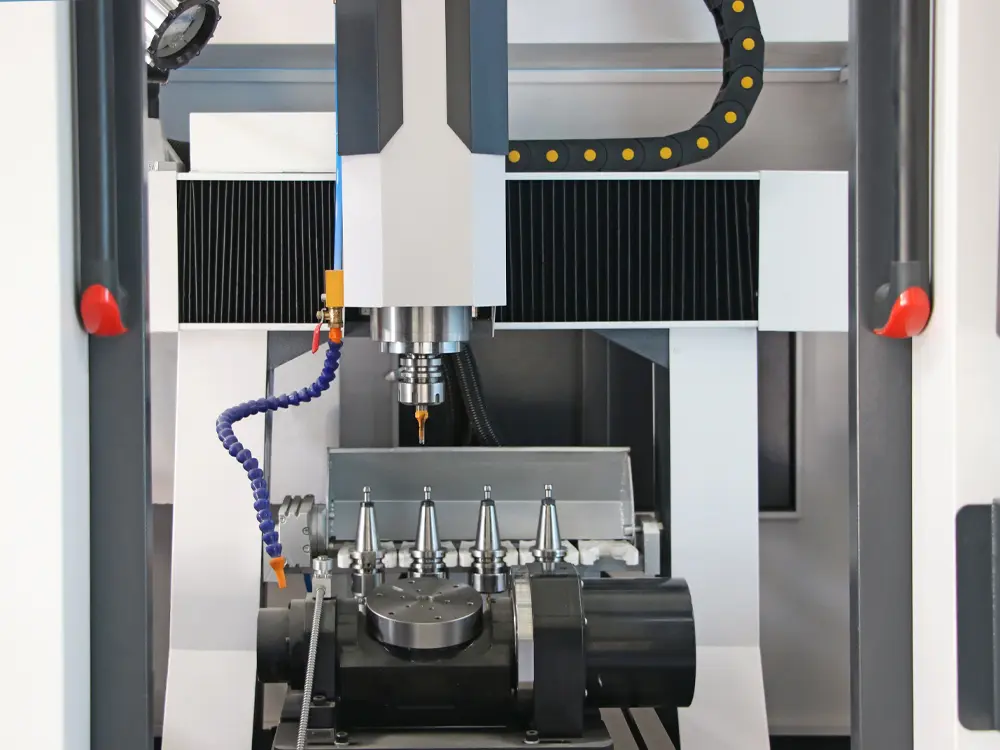

This equipment is a fully enclosed CNC metal milling machine that integrates a trunnion-type (cradle-type) 5-axis rotary table, an automatic tool changing system, and a touch probe. It features high rigidity, high precision, and the capability to process heavy and complex parts, representing the top technical level in this field.

The machine is equipped with a robust fully enclosed protective housing, which not only ensures machining safety but also effectively isolates external interference, reduces machining noise, and prevents the splashing of chips and coolant, safeguarding the operator.

The trunnion-type 5-axis rotary table can clamp the workpiece to perform multi-angle complex movements. Combined with the linear automatic tool changing system, it enables high-precision machining of heavy workpieces with complex surfaces in a single setup. The automatic tool changing spindle is integrated with an intelligent touch probe measurement system, capable of automatic workpiece fast zero-point acquisitions and datum positioning, elevating traditional metal machining to automated intelligent manufacturing. The 5-axis trunnion-type rotary unit features a detachable design. During complex surface machining, it can be secured to the worktable using screws; for conventional planar machining, removing the rotary unit converts the machine into a 3-axis milling machine with a larger work envelope and greater rigidity, thus meeting the processing needs for both complex precision parts and large conventional workpieces. With the investment and floor space of just one machine, various machining tasks can be accomplished, maximizing return on investment.

This CNC metal milling machine integrates a trunnion-type 5-axis worktable, an ATC spindle, a linear tool magazine, a touch probe, and a fully enclosed protective housing. It is suitable for a wide range of machining tasks, from complex surface precision parts to multi-feature assemblies. The trunnion-type 5-axis worktable offers excellent rigidity and high precision, supporting continuous 5-axis simultaneous machining and multi-angle positional machining of complex spatial surfaces. Combined with the touch probe system, the machine can automatically perform workpiece centering and measurement, significantly improving machining accuracy and consistency while greatly reducing the scrap rate and simplifying the positioning of complex-shaped workpieces. The linear tool magazine and ATC spindle enable automatic tool changes, and the touch probe facilitates automatic centering and measurement. Together with the 5-axis multi-face machining capability, this makes long-duration, multi-process unattended automated production possible, thereby effectively increasing equipment utilization and saving labor costs.

Features of Enclosed ATC CNC Metal Milling Machine with 5-Axis Trunnion-Type Rotary Axis and Touch Probe

1. High-Strength Heavy-Duty Cast Iron Bed and Integrated Gantry Structure

- Machine Bed: Made of high-strength gray cast iron, the coolant recovery channels and the platform for installing guide rails and ball screws are directly cast. Optimized structural design enables the cast iron bed to achieve extremely high static and dynamic rigidity under heavy loads, resisting deformation caused by cutting forces. The bed undergoes aging treatment to completely eliminate internal stress, and then the installation datums for key components such as guide rails, worktable and ball screws are machined by large 5-axis machining centers, ensuring extremely high flatness, straightness and perpendicularity. Compared with welded structures, the cast iron bed has a higher damping coefficient, which can significantly suppress vibration during machining, especially in finish machining, resulting in better surface finish and longer tool life.

- Integrated Gantry: Adopting an integrated gantry, the columns on both sides of the machine and the beam on the top are integrally cast. The integrated gantry has stronger overall rigidity and torsion resistance, effectively reducing vibration during machining and avoiding the connection loosening problem of split structures. When bearing complex composite loads during heavy-duty cutting and 5-axis linkage machining, the deformation is minimal, ensuring extreme stability of cutting and improving machining accuracy and surface quality.

2. Core of Multi-Process Machining: Water-Cooled ATC Spindle and Linear Tool Magazine

- Automatic Tool Change Spindle: Equipped with a 3.5KW high-speed water-cooled variable-frequency ATC spindle, the built-in circulating water cooling system directly cools the rotor, bearings and housing, effectively controlling temperature rise and ensuring the spindle maintains high precision and stable output during long-time heavy-load machining. The spindle is equipped with an NBT30 automatic tool change interface, which can quickly dock with the linear tool magazine to achieve second-level precise tool change.

- Linear Tool Magazine: The linear tool magazine is equipped with a dust cover and can hold up to five tools. It is in a closed state during machining, which can effectively prevent cutting fluid, metal chips, dust, etc. from entering and protect the taper surface and pull stud of the tool holder. The linear tool magazine has a more compact structure, occupies less overall space of the metal milling machine, and has a faster tool change speed, effectively reducing tool change time.

3. Heavy-Duty T-Slot Worktable, Trunnion-Type 5-Axis Rotary Axis, High-Precision Touch Probe

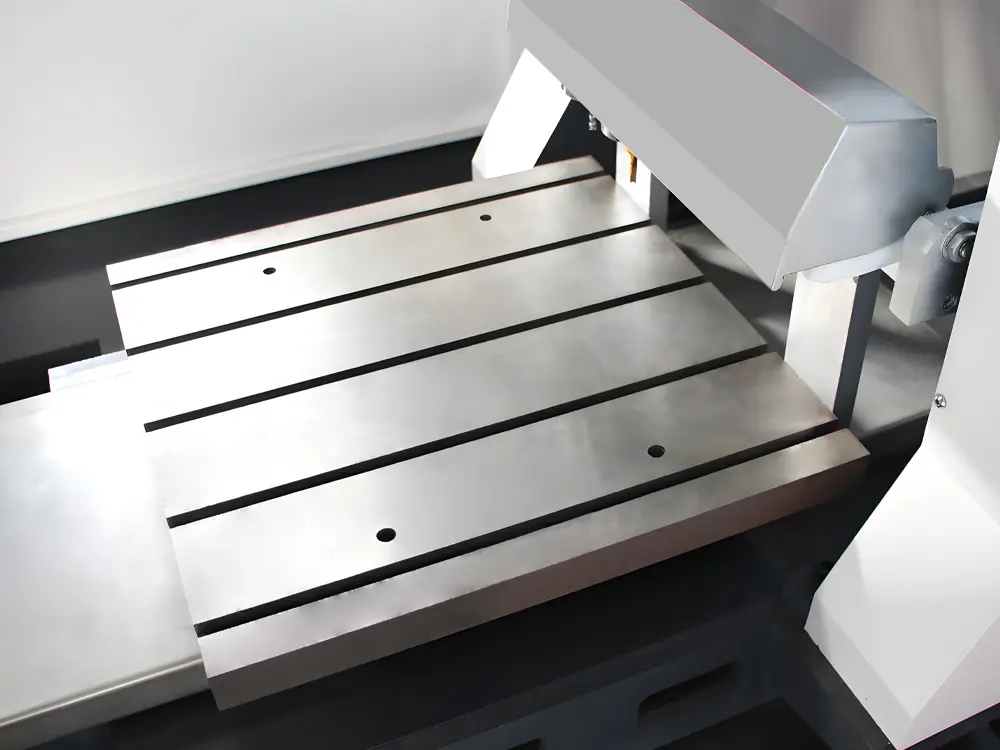

- Heavy-Duty T-Slot Worktable: The worktable is made of high-strength cast iron, featuring high rigidity, high quality and excellent damping characteristics, providing superior bending and torsion resistance. Its high self-weight design brings excellent vibration reduction effect, ensuring machining stability. Workpieces are fixed by pressing plate fixtures, supporting multi-angle clamping to meet different workpiece and process requirements.

- Rotary Axis: Adopting a detachable 100mm cradle structure, it can be fixed on the T-slot worktable with screws. The device consists of an A-axis roller and a C-axis turntable: the A-axis can rotate in the Y-Z plane of the machine, and the C-axis turntable is installed on the A-axis. The cooperation of the two realizes multi-angle machining, with strong structural rigidity and fast dynamic response, providing high positional accuracy and contour accuracy in 5-axis linkage, and effectively suppressing cutting vibration. This structure allows arbitrary adjustment of the workpiece's machining position and the tool in 3D space, thereby enabling the use of the tool's side edge for cutting, improving surface quality and machining efficiency, and is especially suitable for the machining of engine impellers, complex curved surface parts, auto parts, etc.

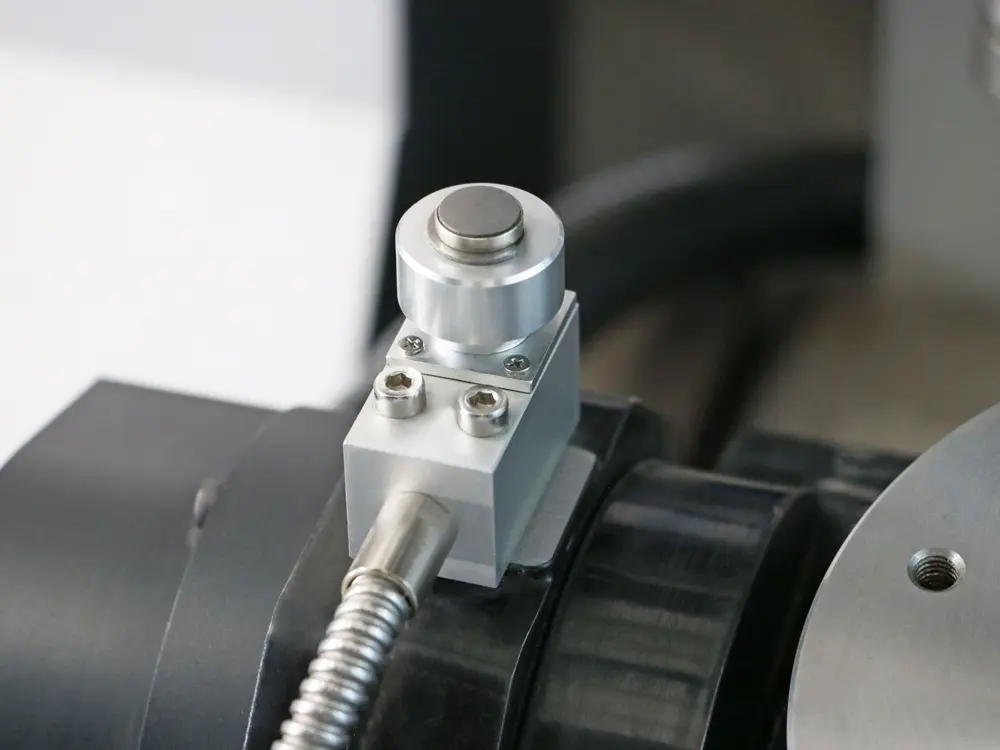

- Touch Probe: Equipped with a high-precision infrared touch probe, it has functions such as zero-point acquisition and measurement. During zero-point acquisitions, the probe's ball head contacts the workpiece, which can automatically measure reference features such as the workpiece edge and circular holes, replacing traditional manual alignment and reducing positioning time by more than 70%. At the same time, it can complete basic measurements such as step height and spacing, perfectly adapting to the multi-process and multi-angle machining needs of the 5-axis trunnion-type CNC milling machine.

4. Fully Enclosed Surrounding Shield and Fully Enclosed Sheet Metal Shields for XYZ Axes

- Fully Enclosed Surrounding Shield: Adopting a steel plate frame structure with side sliding doors with observation windows, it can completely block metal chips and cutting fluid splashing during machining, effectively reducing noise and ensuring operational safety. The bottom of the shield integrates a chip collection port and a coolant recovery and filtration device, which cooperates with the filtration system to achieve efficient recovery and recycling of coolant.

- Fully Enclosed Shields for XYZ Axes: The X-axis is equipped with a bellows shield, the Y-axis is a steel plate telescopic shield, and the Z-axis adopts a sheet metal shield, which effectively prevents chips, dust, cutting fluid, etc. from invading the guide rails and ball screws, ensuring long-term operation accuracy, extending service life and reducing failure rate.

5. High-Precision Bus Servo Drive System and High-Speed Transmission System

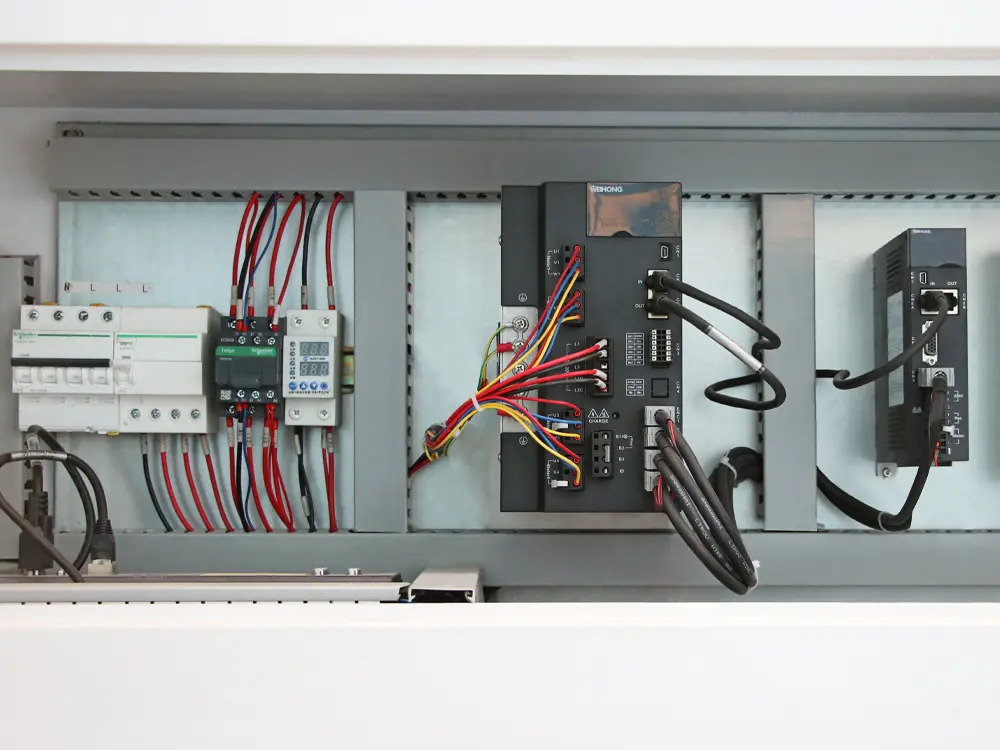

- Weihong Bus Servo Drive System: Adopting Weihong bus absolute value servo multi-axis driver, the compact integrated design can drive multiple servo motors, saving electrical cabinet space and simplifying wiring. It supports EtherCAT bus communication, with STO/DB braking safety functions and common DC bus technology, realizing complex movements and ultra-high synchronization accuracy, ensuring the coordination between the trunnion rotary axis and linear axes in 5-axis linkage, and improving the machining quality of complex curved surfaces.

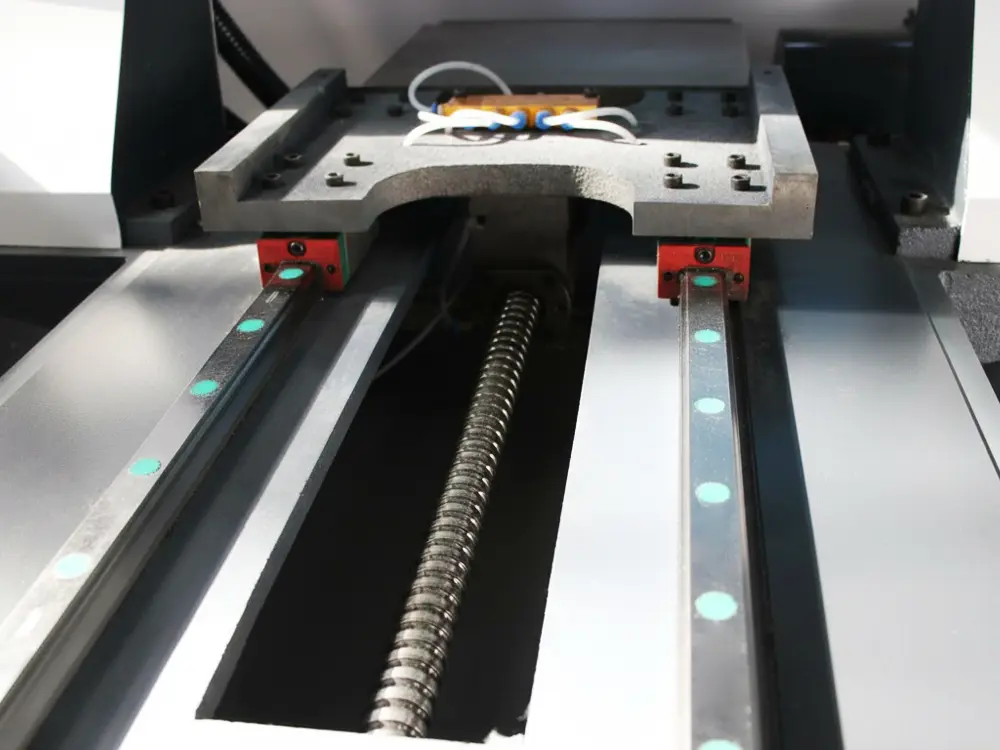

- Taiwan HIWIN Guideways: Adopting high-precision and heavy-load HIWIN 25 linear guide rails and linear bearings, the friction coefficient is only 1/50 of that of traditional sliding guide rails. The four-row ball structure and optimized track design realize micron-level positioning, which can bear multi-directional loads and lay the foundation for heavy-load and high-precision cutting.

- TBI Ball Screws: The XYZ axes all adopt high-load TBI ball screws, with special groove design and preload adjustment technology, eliminating axial clearance, realizing backlash-free transmission, and the transmission efficiency reaches 98%. It helps reduce the load of the servo motor, improve dynamic response and positioning accuracy, and ensure operational stability under heavy cutting.

6. Various Auxiliary Systems to Assist Efficient Operation of the Machine

- Water Chiller: The spindle cooling adopts a constant temperature water chiller, which provides precise constant temperature cooling for the spindle through refrigeration cycle, ensuring the spindle temperature is stable under high-speed, heavy-load and long-time operation, extending the spindle life and supporting 24-hour continuous machining.

- Automatic Tool Setter: Equipped with a high-precision contact-type automatic tool setter. When changing tools, the spindle slowly contacts the tool setter's probe, and the system records the coordinates after triggering the signal, automatically calculating the tool length and tool tip position, eliminating manual tool setting errors and improving calibration efficiency.

- Automatic Lubricater: Equipped with an electric automatic lubricater,the lubrication cycle and duration can be set through the controller. The lubricating oil is accurately delivered to each lubrication point through the oil divider, extending the service life of the transmission system.

- High-Quality Electrical Components: Adopting Schneider series electrical components, including circuit breakers, surge protectors, AC contactors, undervoltage protectors, etc., integrating multiple protections such as overload, short circuit and leakage, ensuring the electrical safety and stable operation of the equipment.

7. High-Precision Weihong 5-Axis Control System

Equipped with Weihong NK300CX 5-axis control system, it has functions such as HST high-speed trapezoidal algorithm, intelligent error compensation, friction compensation and one-key debugging, supporting 5-axis linkage. During machining, it provides two modes: "precision priority" and "speed priority": the former is suitable for mold and high-precision part machining, and the latter is suitable for semi-finish machining or roughing. The system is compatible with various CAD/CAM software and G-code files, and is equipped with a 5-axis control pulse handwheel, facilitating fine operations such as workpiece alignment and tool calibration.

Details of Enclosed ATC CNC Metal Milling Machine with 5-Axis Cradle-Type Rotary Axis and Touch Probe

- Machine bed

Cast machine bed undergoes stress relief treatment after casting. Key component mounting positions are milled by large gantry milling machines. Compared with welded beds, it offers higher rigidity and vibration resistance.

- Water-cooled ATC spindle

3.5KW water-cooled variable-frequency automatic tool change spindle with a maximum speed of 24,000r/min, equipped with NBT30 tool holders. The water-cooled spindle operates more stably—whether for high-speed finish machining or heavy-duty milling, it maintains rated power output continuously, achieving true efficient cutting and reducing machining time.

- Linear tool magazine with protective cover

A linear tool magazine with a protective cover is installed on the worktable. It features a closed box structure when not changing tools. Upon receiving a tool change command, the protective cover automatically flips upward; after tool change completion, it closes automatically to resume the closed state. This effectively prevents cutting fluid, metal chips, etc., from entering, protecting the tool holder and spindle.

- Trunnion-type 5-axis rotary axis

Detachable trunnion-type 5-axis rotary axis fixed on the T-slot worktable via bolts. It integrates two precision rotary axes, enabling multi-angle and multi-posture machining of workpieces.

- Heavy-duty T-slot worktable

High-strength T-slot worktable fixed with press plate fixtures. Its surface undergoes precision milling, featuring extremely high flatness, providing a solid and stable machining foundation for the machine.

- Automatic tool setter

Cooperates with the control system to realize automatic compensation of tool tip position after tool change, ensuring easy use.

- Touch probe

Transmits via infrared optical signals. It has functions such as automatic zero-point acquisitions and workpiece measurement, accurately matching the positioning and measurement needs of precision metal processing. Suitable for manufacturers of various precision parts, it effectively guarantees machining accuracy.

- Pulse handwheel

5-axis pulse handwheel allows precise and direct control of spindle or tool movement to the target position. It also offers advanced functions like handwheel simulation for easy operation.

- Fully enclosed protection for XYZ axes

Both XYZ axes are equipped with fully enclosed dust shields, effectively preventing chips, cutting fluid, etc., from invading the guide rails, ball screws and other transmission systems during machining, extending the machine's service life.

- Transmission system

Adopts Taiwan HIWIN linear guideways and TBI ball screws, fundamentally guaranteeing the positioning accuracy and service life of each linear axis.

- Water chiller

Equipped with a constant-temperature water chiller that can stabilize the coolant temperature at a fixed value with a control accuracy of ±1℃. It effectively reduces the spindle operating temperature, supporting 24/7 continuous operation.

- Drawer-type sewage tank

Integrated with the fully enclosed shield, the drawer-type sewage tank uniformly handles chips and cutting fluid generated during machining, reducing workshop pollution.

- Automatic lubricater

Automatically lubricates and maintains the machine's transmission system without manual lubrication. It ensures long-term machining accuracy of the machine and reduces failure rates.

- Bus servo system

Weihong bus multi-axis servo drive system uses the EtherCAT industrial bus protocol, offering higher real-time performance and high response bandwidth. It effectively guarantees contour accuracy in complex surface machining. The compact multi-axis integrated design simplifies wiring, commissioning and maintenance.

- Weihong control system

Weihong NK300CX control system supports 5-axis operation, multi-language interface display, and is compatible with various CAD/CAM software, featuring simple operation.

Technical Parameters of The Trunnion-Type 5-Axis Metal Milling Machine

| Model | CK-6060-5S |

|---|---|

| Travel | X: 600mm Y: 600mm Z: 400mm A: 0-130° C: 360° |

| Bed | Heavy-duty thickened cast iron bed |

| Gantry | Heavy-duty integrated gantry |

| Spindle | 3.5KW high-speed water-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000rpm |

| Tool Magazine | Flip-top linear tool magazine |

| Tool Holder Type | NBT30 ER32 φ20 |

| Rotary Axis | 5-axis trunnion-type rotary axis (100mm diameter) |

| Drive Mode | Weihong 750W bus absolute value servo motors *3 + multi-axis servo driver |

| Transmission Mode | High-precision tbi ball screw |

| Guideways | Taiwan Hiwin 25 high-precision linear square rails / flange sliders |

| Cables | Pure copper high-flexibility cables |

| Frequency Converter | Fuling inverter |

| Worktable | Heavy-duty T-slot worktable |

| Electrical Components | Schneider circuit breakers, surge protectors, AC contactors, etc. |

| Lubrication System | Fully automatic lubrication and oil maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Air Pressure | ≥0.6Mpa |

| Compatible Software | Artcam, Type3, AutoCAD, CDR, SolidWorks, UG, PowerMill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Rapid Traverse Speed | 18000mm/min |

| Max. Working Speed | 35000mm/min |

| Dimensions | 1400*1800*2100mm |

| Weight | 1450kg |

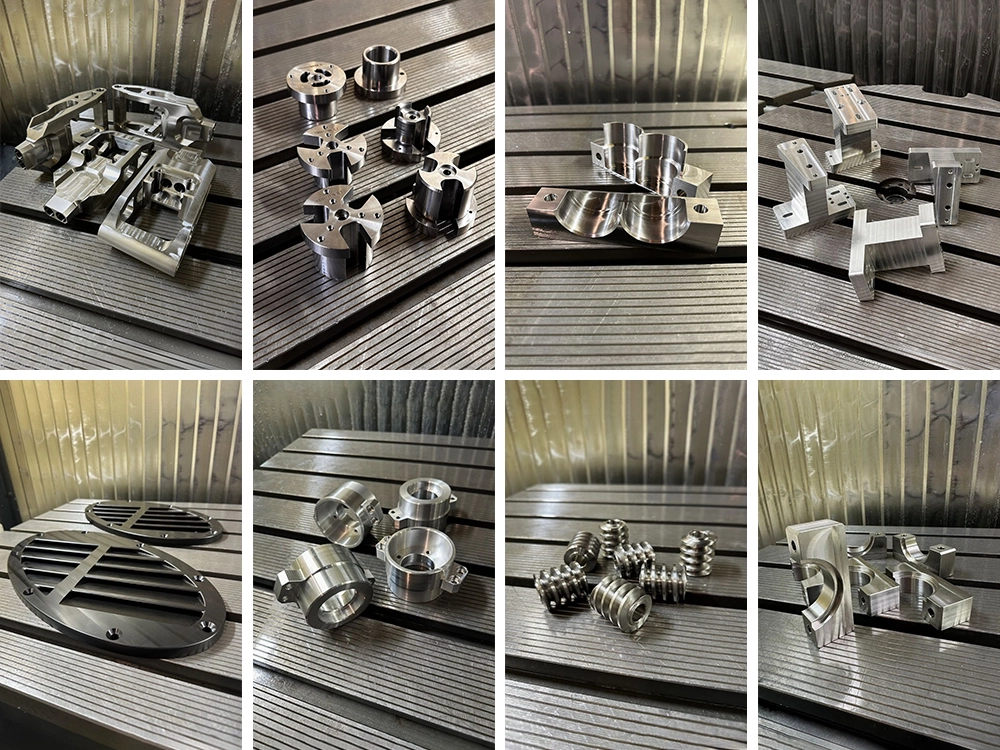

Application of The Trunnion-Type 5-Axis Metal Milling Machine

Aerospace: Impellers, engine casings, wing-body structural components, landing gear structures, aircraft parts, panel structural members, skins, slides/rails, etc.

Automotive: Engine blocks/housings, transmission cases, battery trays, motor housings, automotive wheels/hubs, motor end covers, brake discs/rotors, steering knuckles, control arms, gears, ratchets, spline shafts, etc.

Mold: Injection molds, stamping dies, die-casting dies, biscuit/cookie molds, chocolate molds, food molds, copper electrodes (for EDM), etc.

Hardware Industry: High-end door locks, hinges, gearbox/reducer housings, valve bodies, valves, connectors, fasteners, etc.

Medical Devices: Implants, surgical instruments, brackets/supports for imaging equipment, collimators, metal lens barrels, metal stents, etc.

Precision Components: Watch cases, watch parts, speaker enclosures, mobile phone cases/housings, mobile phone mid-frames, eyeglass frames, etc.

Advantages of the Trunnion-Type 5-Axis Rotary Table

The trunnion-type 5-axis rotary table integrates workpiece rotation with the machine's foundational structure through a unique design philosophy, offering the following prominent advantages:

Exceptional Rigidity and Stability: The two rotary axes (A-axis and C-axis) form a trunnion (cradle) structure, providing more stable support at the rotation center. This results in superior resistance to vibration and deformation during heavy-duty cutting or 5-axis simultaneous machining. Consequently, it achieves better workpiece surface finish and higher cutting efficiency.

Outstanding Machining Accuracy: The trunnion-type 5-axis rotary table features a simple and rigid structure with extremely high precision in the rotation center positioning. This allows the machine to maintain excellent long-term positional accuracy and contouring accuracy, making it ideal for machining precision parts with stringent tolerance requirements.

Wide Machining Range: Through the coordinated movement of the A-axis (±130° indexing range) and C-axis (360° indexing), the cradle structure enables the cutting tool to access the workpiece from virtually any angle. Complex surfaces and profiles, which are impossible to machine on traditional 3-axis equipment, can be completed in a single setup.

Enhanced Tool Accessibility: By adjusting the workpiece position via the rotary axes, the tool can always engage the workpiece at the optimal cutting angle. This avoids the need for machining with long-reach tools at extreme angles. This not only reduces tool chatter and wear, extending tool life, but also improves cutting efficiency.

Faster Machining Speed: Compared to gantry-type 5-axis structures, the trunnion-type design rotates the workpiece instead of requiring long-travel movements of the heavy spindle head. The workpiece is fixed directly on the trunnion table, allowing multi-face, multi-angle machining in one setup. This significantly reduces the positioning and calibration time associated with multiple setups, thereby boosting overall machining efficiency.

| Model | CK-6060-5S |

|---|---|

| Travel | X: 600mm Y: 600mm Z: 400mm A: 0-130° C: 360° |

| Bed | Heavy-duty thickened cast iron bed |

| Gantry | Heavy-duty integrated gantry |

| Spindle | 3.5KW high-speed water-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000rpm |

| Tool Magazine | Flip-top linear tool magazine |

| Tool Holder Type | NBT30 ER32 φ20 |

| Rotary Axis | 5-axis trunnion-type rotary axis (100mm diameter) |

| Drive Mode | Weihong 750W bus absolute value servo motors *3 + multi-axis servo driver |

| Transmission Mode | High-precision tbi ball screw |

| Guideways | Taiwan Hiwin 25 high-precision linear square rails / flange sliders |

| Cables | Pure copper high-flexibility cables |

| Frequency Converter | Fuling Inverter |

| Worktable | Heavy-duty T-slot worktable |

| Electrical Components | Schneider circuit breakers, surge protectors, AC contactors, etc. |

| Lubrication System | Fully automatic lubrication and oil maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Air Pressure | ≥0.6Mpa |

| Compatible Software | Artcam, Type3, AutoCAD, CDR, SolidWorks, UG, PowerMill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Rapid Traverse Speed | 18000mm/min |

| Max. Working Speed | 35000mm/min |

| Dimensions | 1400*1800*2100mm |

| Weight | 1450kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.