CO2 RF Laser Marker for Fine Marking

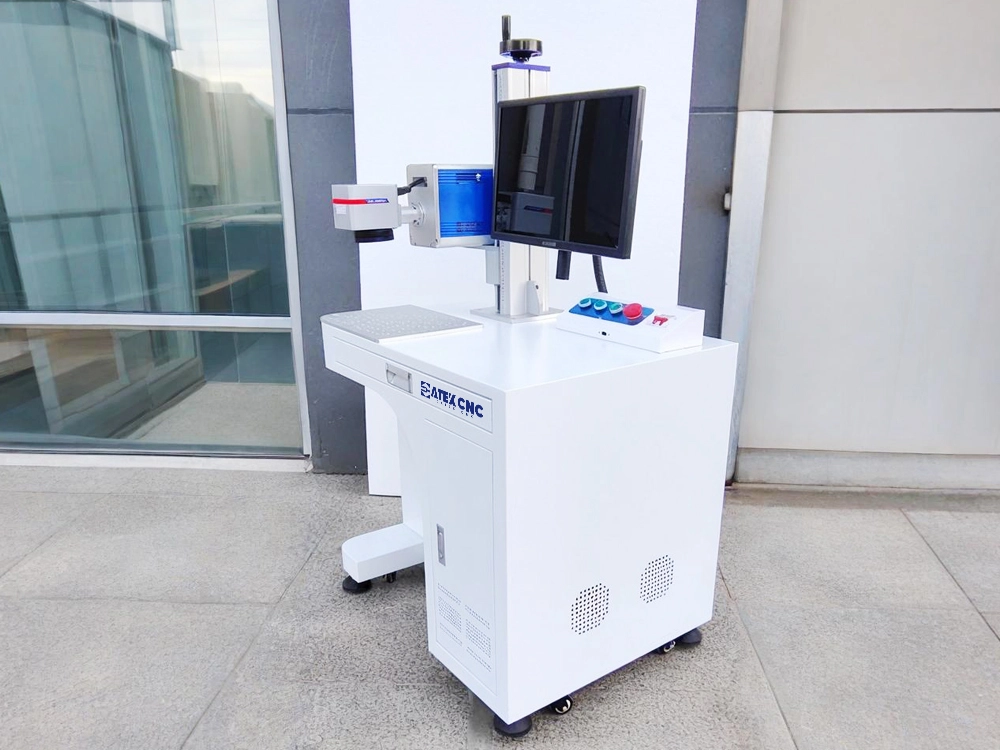

Cabinet-Type RF CO2 Laser Marking Machine

[Function Description]

What is a RF CO2 Laser?

A RF (Radio frequency) CO2 laser is a laser generator that uses an RF power supply to excite carbon dioxide gas to produce laser light. Its working principle is based on stimulated emission, where the RF power supply excites the gas to achieve population inversion. When population inversion occurs, the recombination of electrons and holes releases photons. These photons are reflected within the resonant cavity to form coherent laser light. The RF electric field controls the laser gain, gradually increasing the light intensity, and ultimately outputs a high-quality laser beam through the resonant cavity.

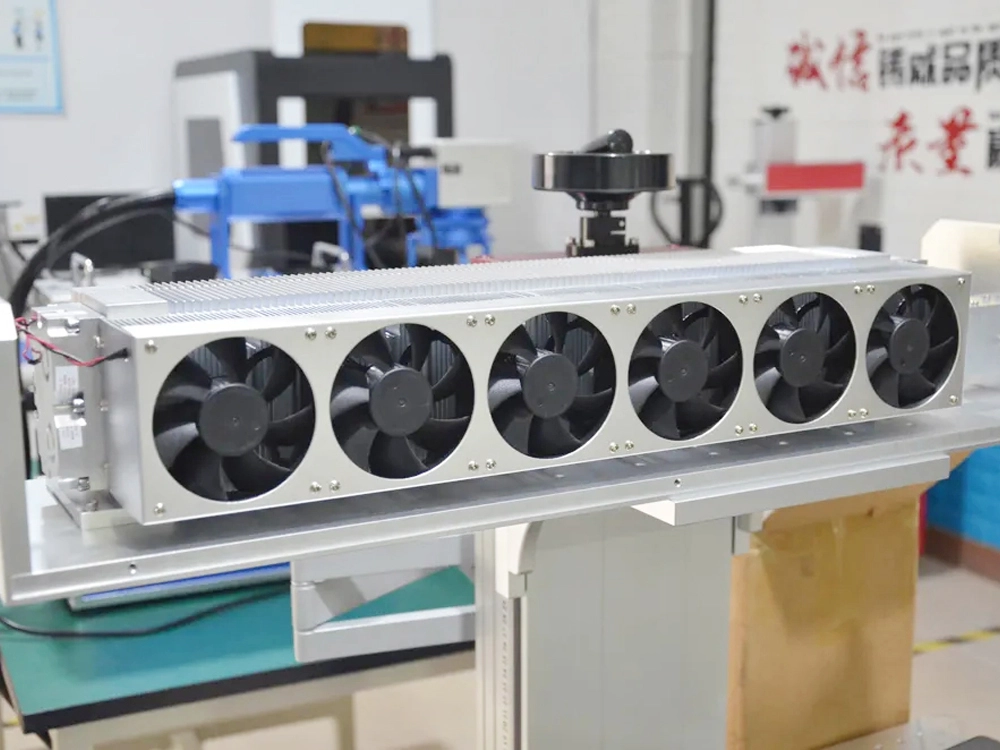

The RF laser requires maintaining a vacuum environment within the chamber and uses a cooling system to control the operating temperature, preventing performance degradation due to temperature rise, which could affect the normal operation of the equipment.

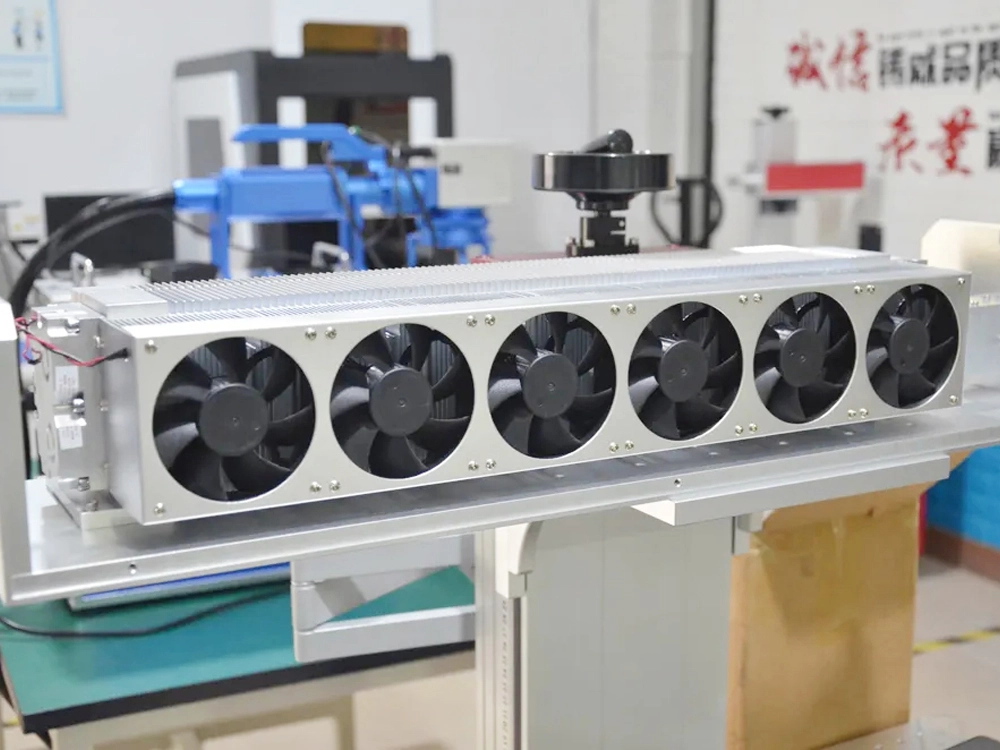

Key components include the resonant cavity, RF power supply, and cooling system. The RF laser uses a fully enclosed metal tube as the resonant cavity, which offers better thermal stability, strength, and dust resistance compared to ordinary materials, enabling it to withstand higher power output. The fully sealed design prevents performance instability caused by gas consumption, effectively enhancing lifespan and reliability.

Advantages of RF CO2 Lasers

- Higher Electro-Optical Conversion Efficiency: Enables efficient energy utilization with a discharge efficiency of over 25%.

- Stable Continuous Output Power: More suitable for large-area marking and processing.

- High-Frequency Laser Generation: High-frequency discharge produces lasers with higher repeatability and stability, making it ideal for precision processing.

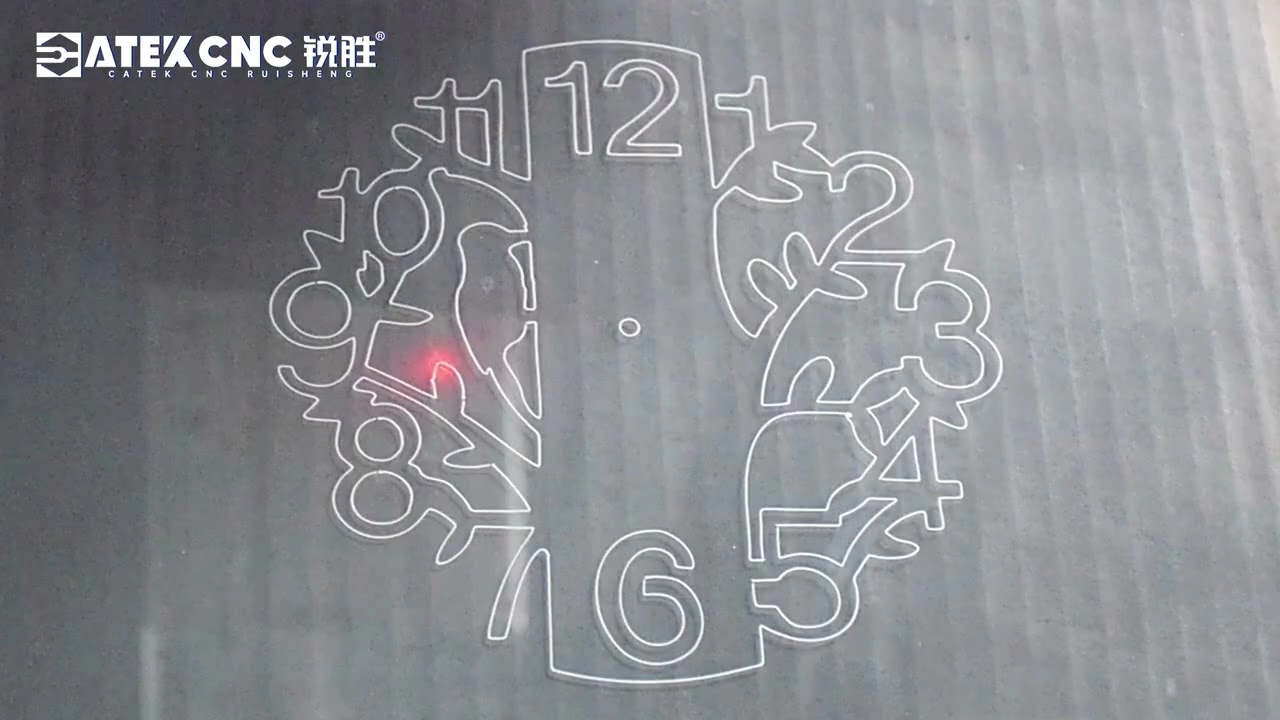

- Small Laser Spot Diameter: Superior beam quality, making it more suitable for high-precision fine engraving and marking.

- Compact Design: The RF laser is small in size and has a compact structure, allowing integration into various machinery and small devices, saving space.

- Higher Reliability and Stability: Offers longer service life and can be used in various working environments.

- Faster Marking and Engraving Speed: Higher precision with a smaller heat-affected area, achieving speeds of up to 15,000 mm/s.

- Constant Temperature Cooling System: Eliminates the need for frequent gas replacement, resulting in lower operating costs.

Details of RF CO2 laser marking machine

- CRD RF CO2 laser source

Compared to DC glass tube lasers, RF laser sources can operate at high repetition rates. Additionally, they offer superior beam quality—the RF beam is smaller and more uniformly dense than the DC-excited beam, and they maintain consistent characteristics and density across the entire power scale.

- Galvanometer scanner

Capable of 24-hour continuous operation with excellent stability, high positioning accuracy, faster marking speed, and strong anti-interference capabilities.

- F=160mm field lens

Features strong focusing performance, multi-layer coating, and a long service life.

- Multi-hole worktable

Made of aluminum alloy for enhanced durability. The multi-hole design facilitates quick positioning and can be used in combination with side backing plates, offering adjustable positions for versatile configurations.

- Push-pull keyboard drawer

The push-pull keyboard drawer allows you to store the keyboard when not in use, saving space and effectively preventing dust from entering.

- Hand crank

Using this device in conjunction with a scale allows for precise adjustment of the distance between the laser head and the workpiece.

- Control panel

The control panel is located below the display screen and is equipped with separate control buttons for each functional component for easy operation.

Technical Parameters of RF CO2 Laser Marking Machine

| Model | CK-11-CC-RF |

|---|---|

| Marking Area | 110*110mm / 175*175mm / 200*200mm |

| Laser Wavelength | 10.6μm |

| Laser Power | 30W / 40W / 50W / 60W |

| Marking Line Speed | < 15,000mm/s |

| Marking Speed | < 12,000mm/s |

| Minimum Character Size | 0.4mm |

| Repositioning Accuracy | 0.01mm |

| Cooling Method | Air Cooling / Water Cooling |

| Power Stability | ±5% |

| Beam Quality | M2 < 1.2 |

| Beam Diameter | 1.8±0.2mm |

| Beam Divergence Angle | 7.5±0.5mrad |

| Operating Frequency | 0-25kHz |

| Duty Cycle | 0-100% |

| Polarization | > >100:1 |

| Control System | BJJCZ |

| Control Software | EZCAD |

| Compatible Formats | BMP, JPG, PNG, DXF, AI, GIF, etc. |

| Operating Voltage | 110V/220V, 50/60Hz |

| Weight | 120kg |

| Dimensions | 850*650*1450mm |

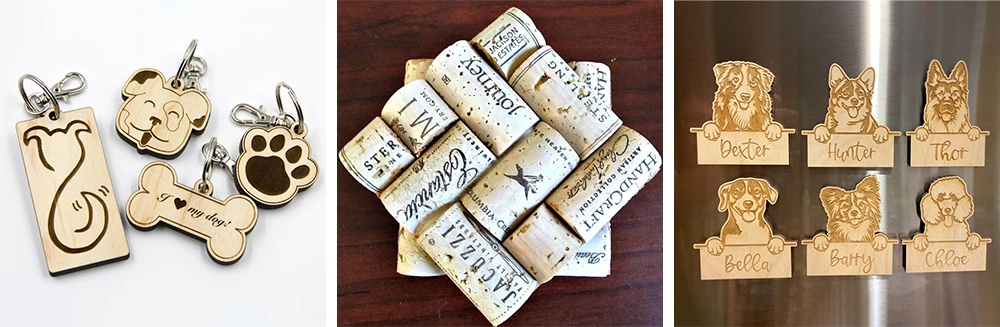

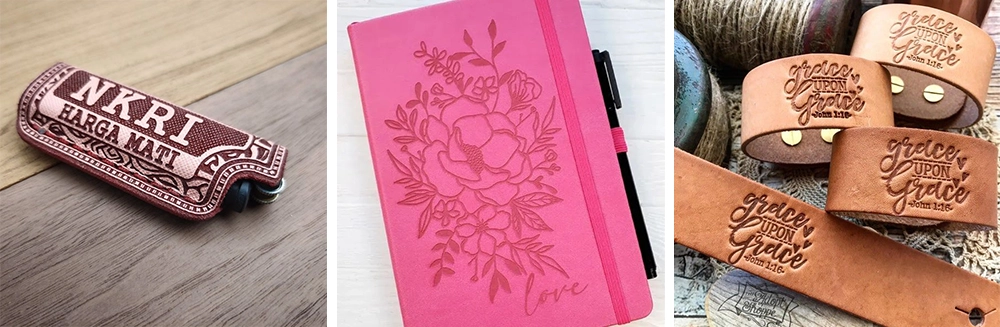

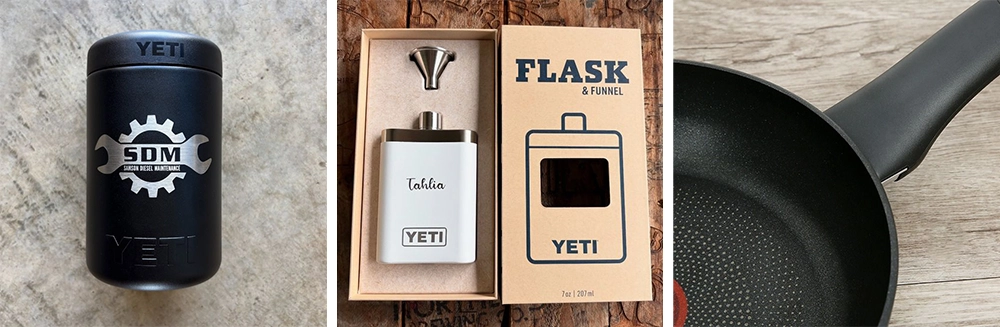

What Products Can a CO2 Laser Marking Machine with RF Laser Be Applied To?

CO2 laser marking machines are suitable for various non-metallic materials and coated or painted metal surfaces, including the following materials:

Bamboo and Wood: Bamboo products, wooden products, wooden lids, wooden handles, chess pieces, wood carvings, wooden signs, wooden boxes, MDF, artificial wood boards, etc.

Leather: Apparel leather, shoe leather, leather accessories, artificial leather, etc.

Textiles: Fabrics, garment accessories, woven materials, towels, etc.

Plastics: ABS, PVC, acrylic, plastic, rubber, soft glass, dual-color boards, rubber, PVB boards, circuit boards, buttons, etc.

Paper: Packaging boxes, labels, corrugated paper, thick cardboard, etc.

Ceramics: Building ceramics, ceramic cups, ceramic bowls, ceramic signs, tiles, etc.

Glass: Glass bottles, glass signs, glass bowls, glass cups, glassware, laboratory glass containers, etc.

Stone: Marble, granite, quartz stone, artificial stone, etc.

Metals: Various metal coatings, etc.

How Does a CO2 Marking Machine with an RF Laser Conduct Quality Management and Ensure Service Quality?

- Production Assembly Inspection: Each machine is inspected by a professional technical team during the production and assembly process to ensure assembly precision.

- Continuous Testing: After production, each machine undergoes 24 hours of uninterrupted testing to ensure continuous and normal operation.

- Three-Year Warranty: All models come with a three-year (36 months) free warranty.

- Lifetime Maintenance: Machines receive lifetime free maintenance and software upgrades.

- Pre-Shipment Confirmation: Before shipping, we confirm the machine's configuration and functions with you through photos, video chats, etc.

- Packing Confirmation: Photos of the packing process and accessories are sent to you for confirmation to ensure nothing is missing.

- Secure Packaging: All machines are packed with anti-collision foam and stretch film, with waterproof and moisture-proof treatments.

- User Manuals and Videos: Each machine comes with operation manuals and videos for maintenance and care.

- 24/7 Technical Support: We provide 24-hour technical support via video calls, email, and online customer service.

- On-Site Installation and Training: If needed, we can send engineers to your company for installation and training.

| Model | CK-11-CC-RF |

|---|---|

| Marking Area | 110*110mm / 175*175mm / 200*200mm |

| Laser Wavelength | 10.6μm |

| Laser Power | 30W / 40W / 50W / 60W |

| Marking Line Speed | < 15,000mm/s |

| Marking Speed | < 12,000mm/s |

| Minimum Character Size | 0.4mm |

| Repositioning Accuracy | 0.01mm |

| Cooling Method | Air Cooling / Water Cooling |

| Power Stability | ±5% |

| Beam Quality | M2 < 1.2 |

| Beam Diameter | 1.8±0.2mm |

| Beam Divergence Angle | 7.5±0.5mrad |

| Operating Frequency | 0-25kHz |

| Duty Cycle | 0-100% |

| Polarization | > >100:1 |

| Control System | BJJCZ |

| Control Software | EZCAD |

| Compatible Formats | BMP, JPG, PNG, DXF, AI, GIF, etc. |

| Operating Voltage | 110V/220V, 50/60Hz |

| Weight | 120kg |

| Dimensions | 850*650*1450mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.