UV Laser Marking Machine for Efficient Mass Production and Easy Use

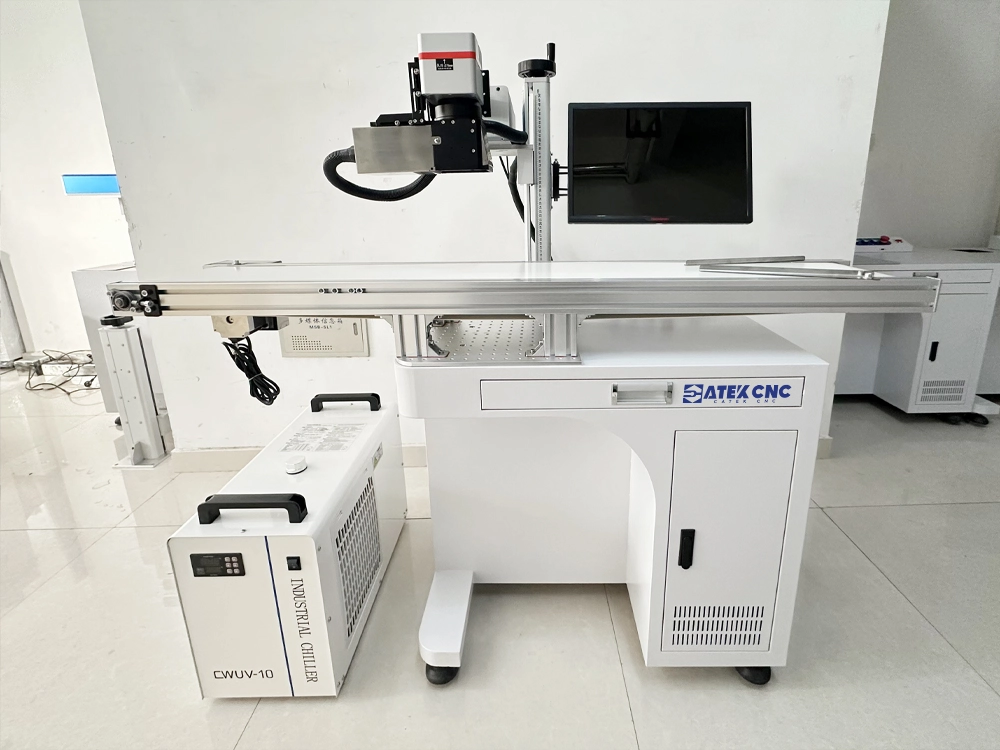

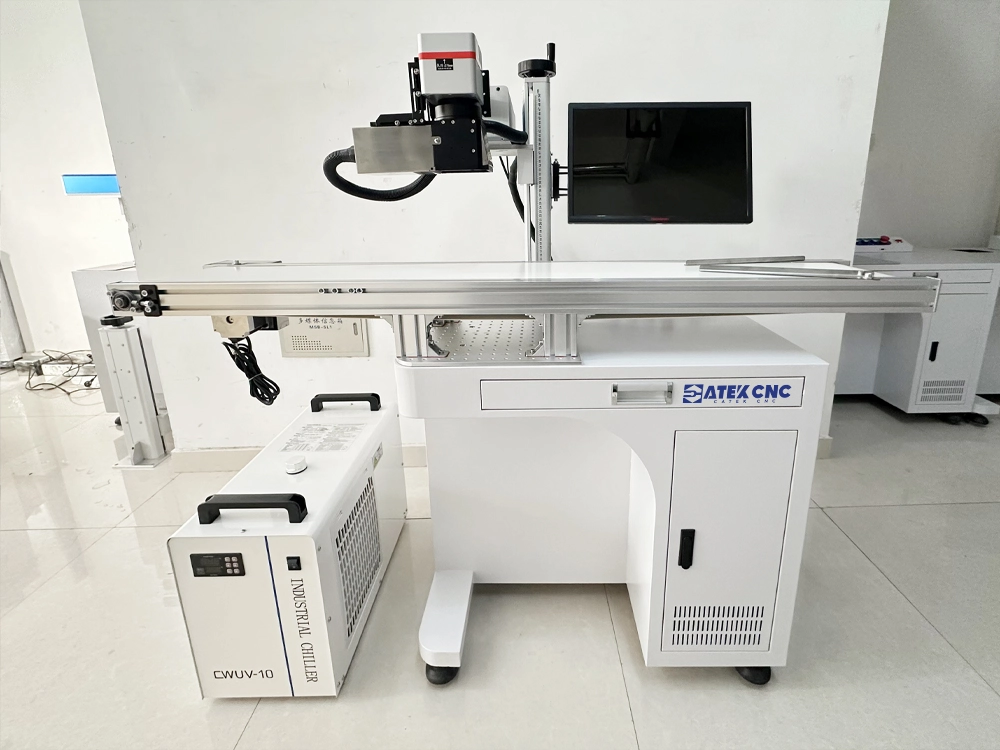

UV Laser Marking Machine with CCD Vision System and Conveyor Belt

[Function Description]

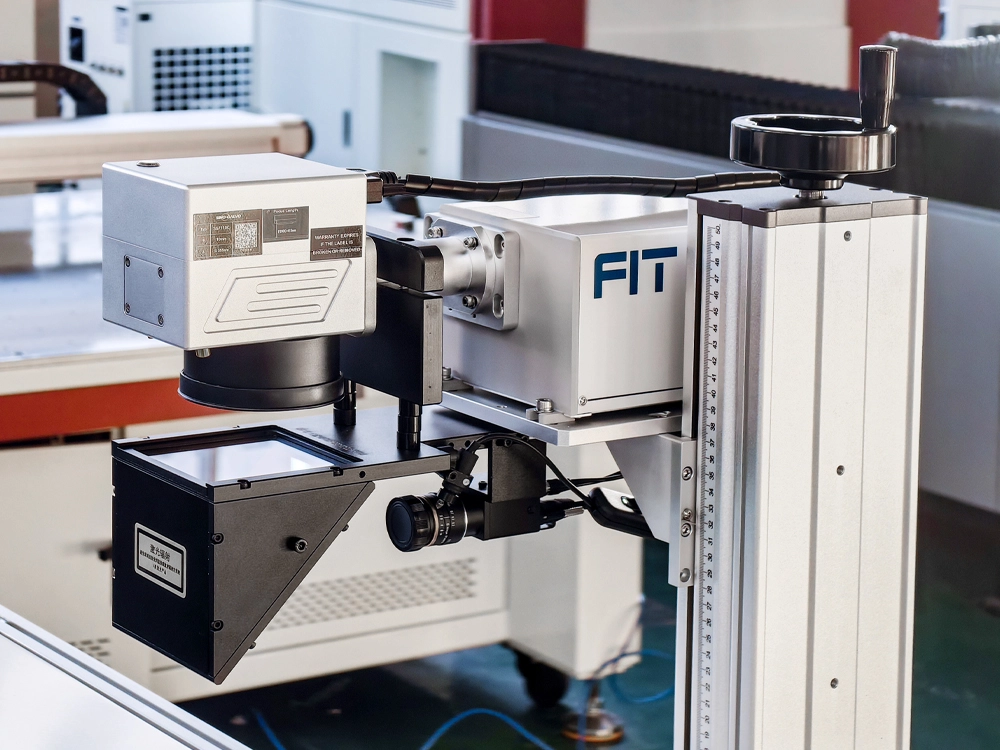

What is a CCD Vision Positioning System?

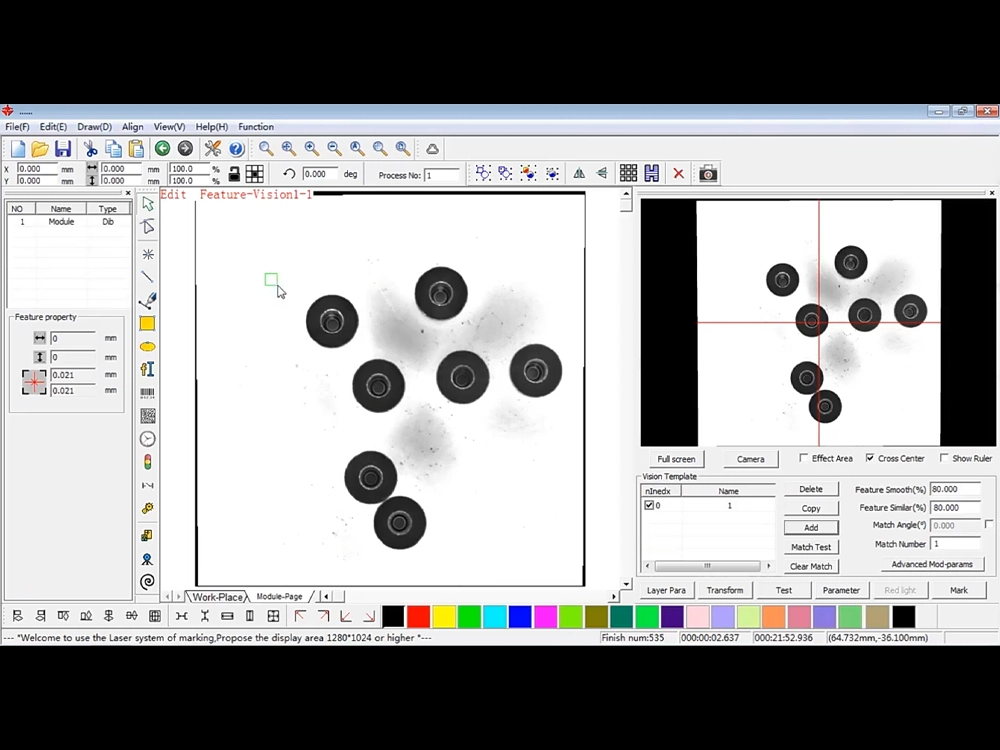

A CCD vision positioning system is an advanced technology that utilizes industrial cameras (CCD cameras) for image capture and processing. It employs CCD cameras to capture real-time images of product surfaces, identifying feature points or contour information to achieve automatic positioning and feature point analysis of workpieces.

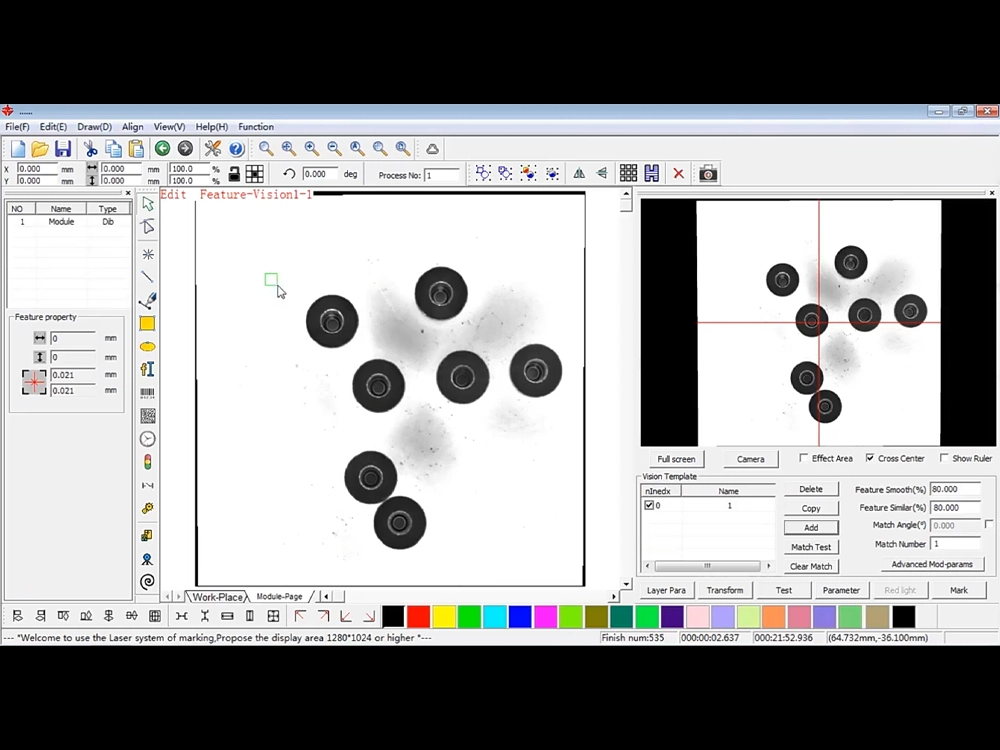

CCD vision positioning technology can be integrated with laser marking machines. By adding a high-precision CCD camera, it captures product images, and the real-time image data of one or more products is transmitted to the control system via a computer. The control system analyzes the image data to guide the laser for precise marking, enabling accurate marking without manual intervention or the need for fixtures. This system is suitable for batch processing of parts with various complex shapes and sizes.

CCD vision positioning technology is not only applicable to UV laser marking machines but also to CO2 laser marking machines and fiber laser marking machines. The vision positioning laser marking system can quickly achieve product positioning and mark multiple identical products simultaneously. It can be integrated with an automated conveyor system, where products are precisely positioned first. After positioning, the conveyor pauses for vision-based marking. Once marking is completed, the control system moves the conveyor to mark the next product, saving labor and improving production efficiency. By combining vision systems and laser marking technology, a fully automated production process can be achieved, reducing manual intervention, enhancing production efficiency, and ensuring product consistency.

The CCD vision positioning system supports one-click automatic calibration and automatic distortion correction, adapting to different product shapes and orientations. The visual recognition speed of a CCD vision positioning laser marking machine is extremely fast, capable of processing hundreds of parts per minute with low error rates. This effectively ensures marking quality, reduces errors caused by manual operations, saves manual loading time, meets the demands of mass production, and significantly improves production efficiency while lowering labor and production costs.

Working Principle of the CCD Vision Positioning System

The CCD vision positioning system uses a CCD camera to capture images of target objects, extracts feature points through image processing algorithms, and determines the position and orientation of the target object by combining matching algorithms. It can directly acquire a large amount of image information (up to 12 million pixels), overcoming the limitations of ultrasonic or infrared sensors and achieving higher precision in target positioning.

After real-time image capture by the CCD camera, the system automatically preprocesses the images (including noise removal, contrast enhancement, binarization, edge detection, etc.) to improve image quality and highlight feature points. Key feature points are then extracted using methods such as edge contour detection, and finally, the extracted feature points are matched with the preset marking positions in the system.

To eliminate the effects of lens distortion and improve positioning accuracy, the CCD vision positioning system requires camera calibration. Common calibration methods include: Faugeras calibration, Tsai's two-step method, Weng's iterative method, and self-calibration methods.

Features of Laser Marking Machines with CCD and Conveyor

- High-precision positioning: Uses a CCD vision system to capture product feature points in real-time, achieving millimeter or even micrometer-level positioning accuracy, ensuring accurate marking positions.

- Simple operation, no need for professional operators; even beginners can easily master the machine. Only manual placement of parts is required (no specific angle needed), supporting marking at any angle, any quantity, and any position.

- High level of automation, capable of processing multiple products at once, equipped with anti-missed processing functionality to ensure every product is correctly marked, improving production efficiency.

- Equipped with a non-slip conveyor belt for continuous product feeding and marking, can be integrated with factory production lines, and allows flexible adjustment of conveyor speed for convenient use.

- Strong product adaptability, capable of processing products of various materials and shapes without manual positioning, making processing simple.

- Non-contact processing of products, causing no damage to the product surface, suitable for high-speed and high-precision processing requirements.

- Supports multiple programming languages and file formats, including various image formats and vector file formats.

- Operated using the Ruida control system, with a simple software interface; easy setup allows for immediate recognition and processing.

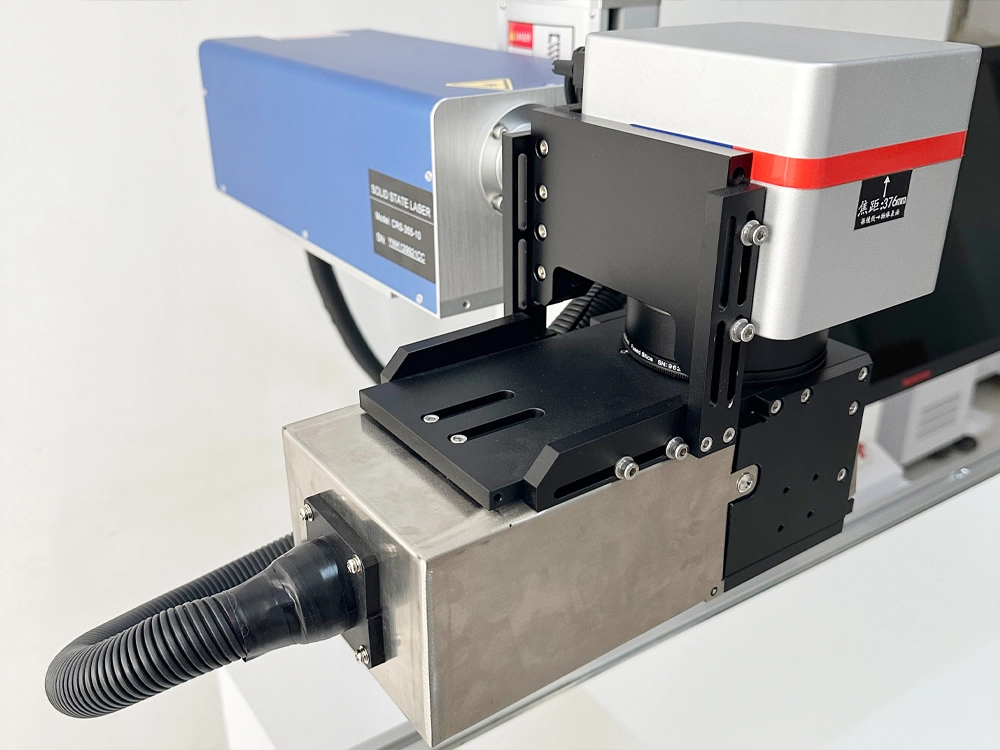

Details of UV Laser Marking Machine with CCD and Conveyor

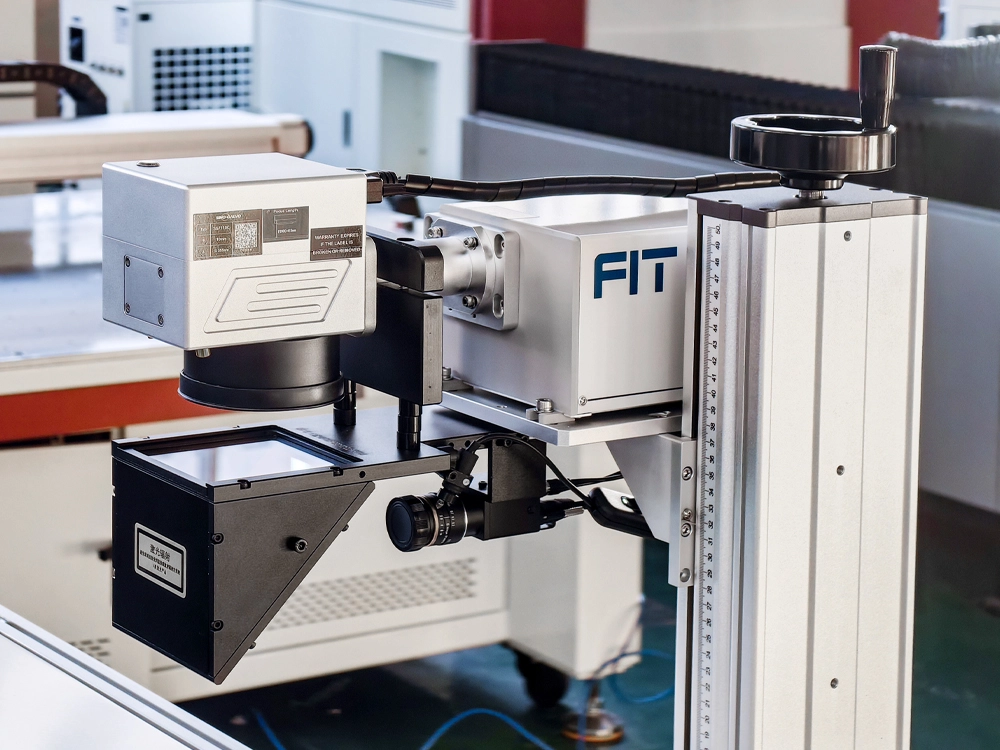

- UV laser source

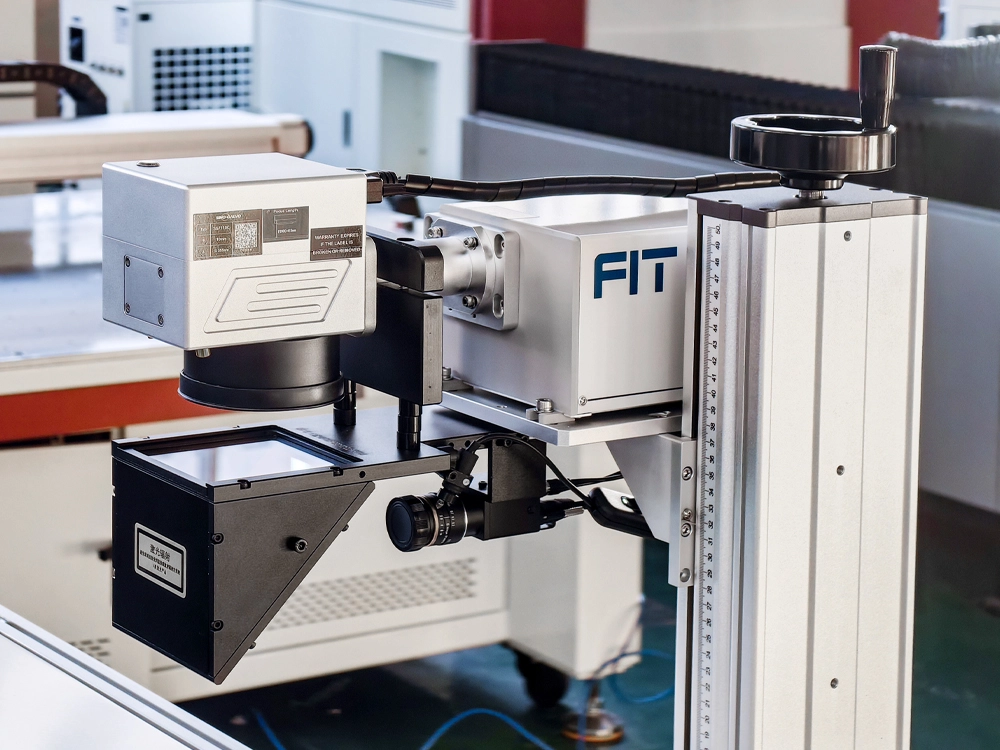

INNO-LASER's "FIT" series UV laser source, The body features a compact and lightweight design, weighing only 4 kg, with an auto-start function and low dependency on water cooling. It delivers pulse energy up to 200 μJ with an average power margin exceeding 30%.

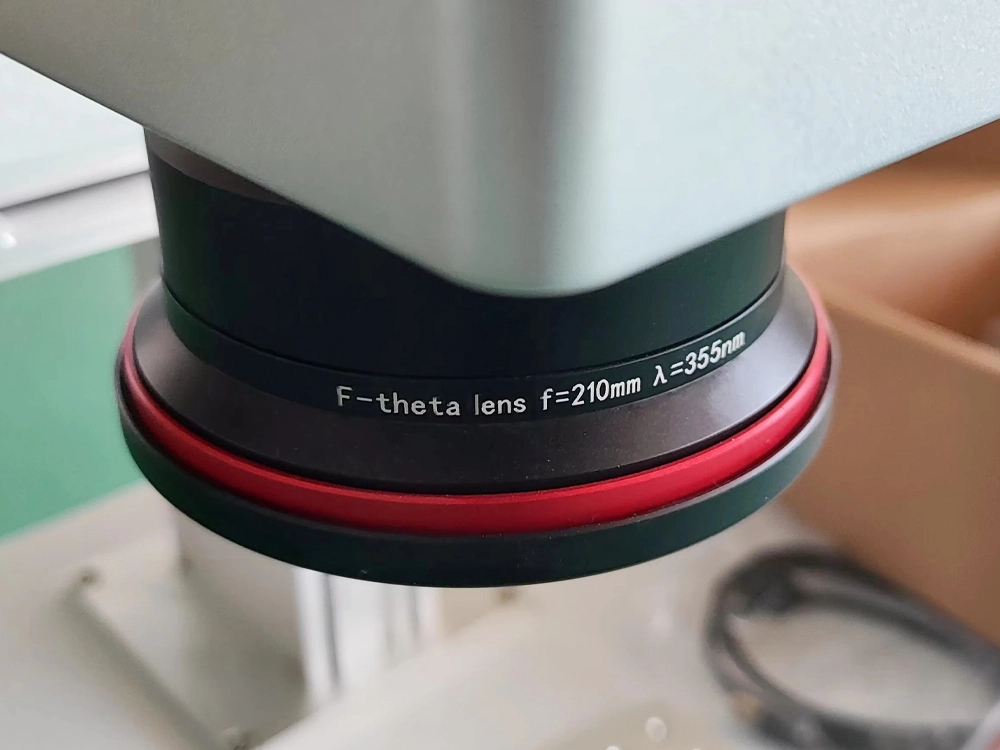

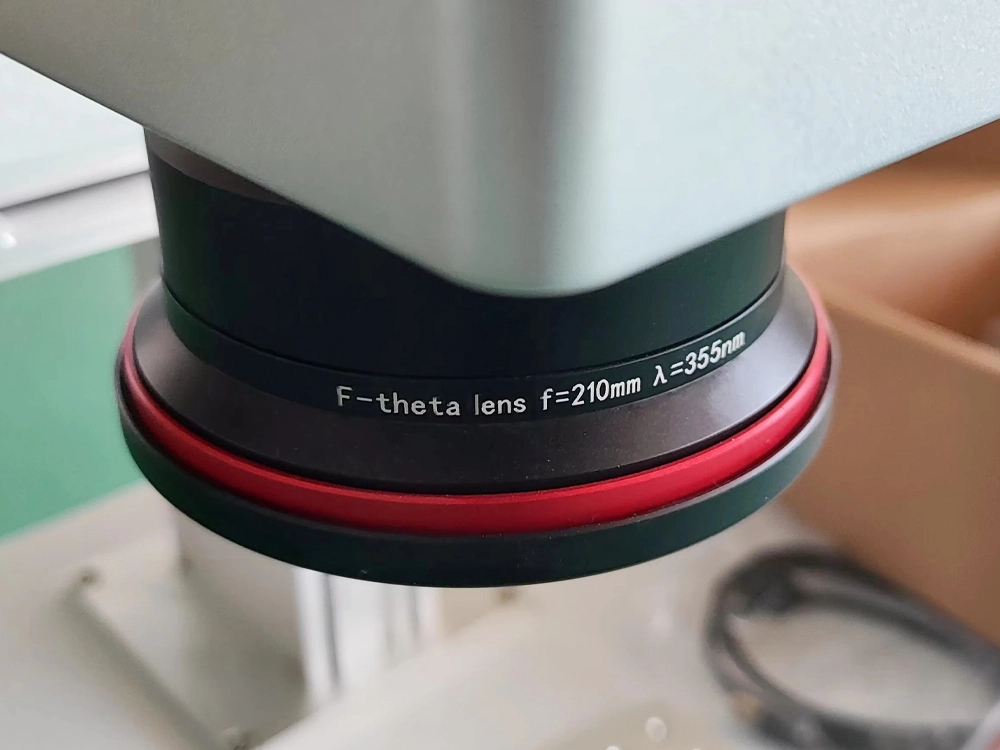

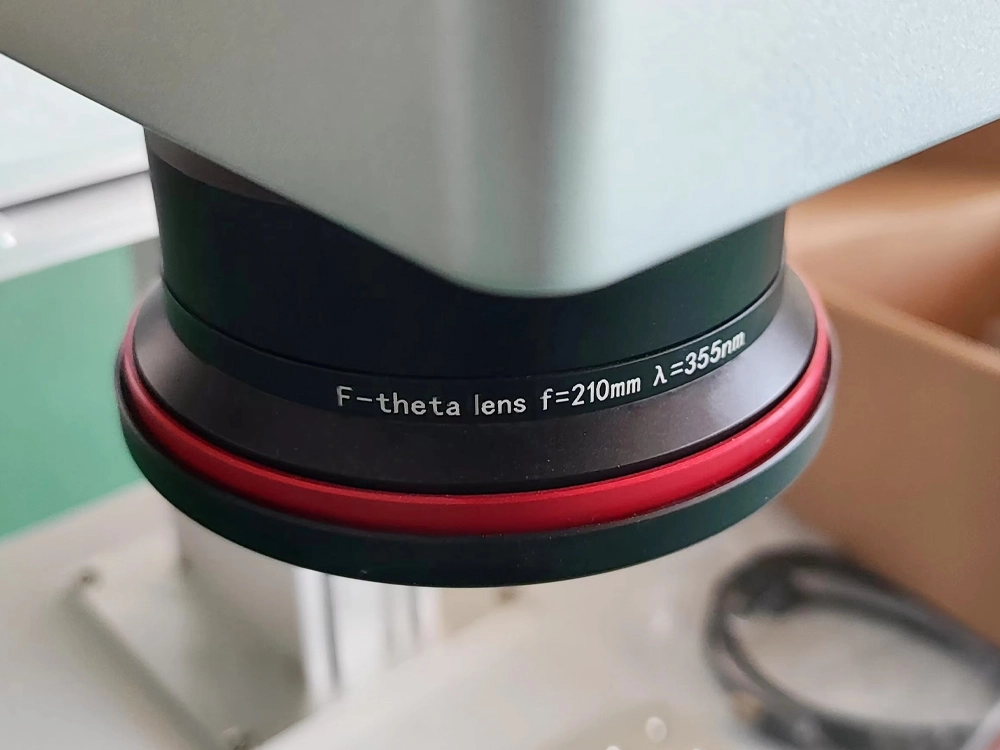

- Galvanometer scanner and field lens

High-quality laser galvanometer and quartz high-transmittance coated field lens greatly improve the ability of edge beams to enter the detector, the beam expansion can reach more than 10 times, the adjustable focal length range is wider, and the marking is more precise.

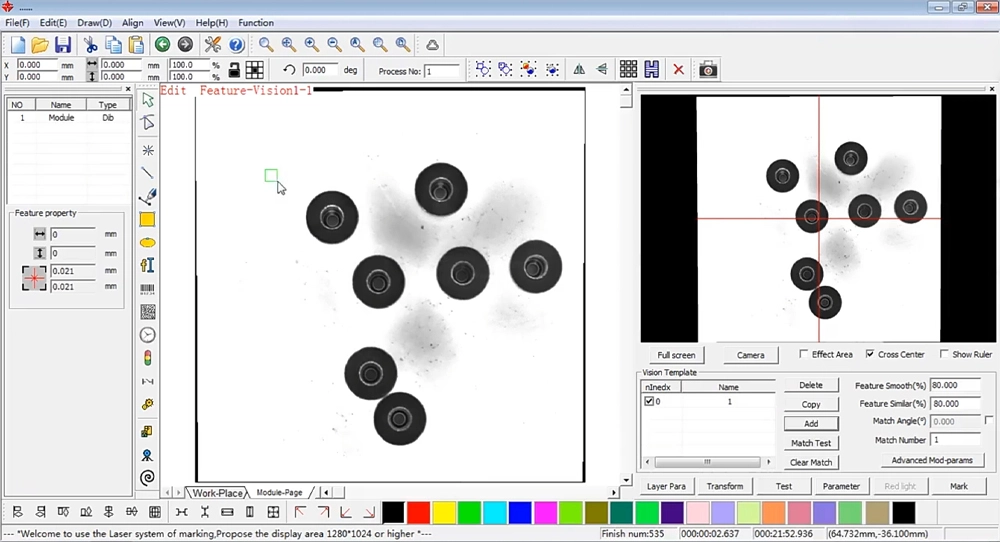

- Visual system

No need for manual positioning, no need to use fixtures, just place the parts flat at will. Fast recognition speed, positioning accuracy is 3-5 times that of ordinary marking machines, multiple parts in the image can be positioned all at once, accurate marking of various types of products, and mixed marking of different contents such as text images.

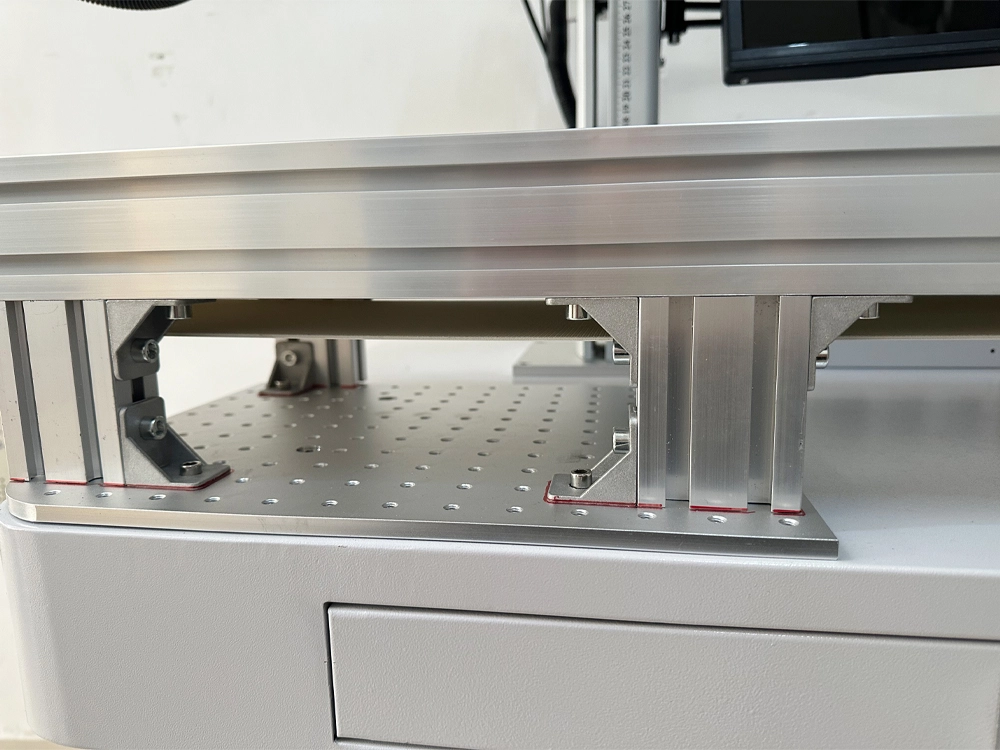

- Conveyor belt

Fully automatic assembly line conveyor belt, can be docked with the assembly line, stable work, and the transmission speed can be freely adjusted.

The conveyor belt is fixed to the standard perforated worktable with bolts. After removing the conveyor belt, this worktable can be also used for marking.

- Scale

The scale on the bracket can indicate the current lens height.

- Control software

Use Ruida's RDMarkVision control software to support visual positioning marking.

Technical Parameters of UV Laser Marking Machine with CCD and Conveyor

| Model | CK-11-UC-CCD |

|---|---|

| Maximum Marking Range | 110*110mm / 175*175mm / 200*200mm / 300*300mm |

| Laser Type | UV laser (Optional Fiber Laser / CO2 Laser) |

| Marking Speed | ≤ 7000 mm/s |

| Minimum Line Width | ≤ 0.005mm |

| Laser Wavelength | 355nm |

| Feeding Method | Conveyor Belt |

| Camera | 7MP / 12MP |

| Control System | Ruida |

| Repositioning Accuracy | ±0.001mm |

| Operating Temperature | 0-50℃ |

| Storage Temperature | -15-50℃ |

| Voltage Requirement | 110/220V 50/60Hz |

| Laser Working Medium | Ultraviolet |

| Laser Transmission Method | Galvanometer (SINO-Galvo) |

| Power Supply | Mean Well |

| Cooling Method | Water Cooling (S&A Chiller), Air Cooling Optional |

| Compatible File Formats | PLT / DXF / JPG / PNG / BMP / AI / JPEG / TIFF, etc. |

| Weight | 120kg |

| Dimensions | 750*750*1500mm |

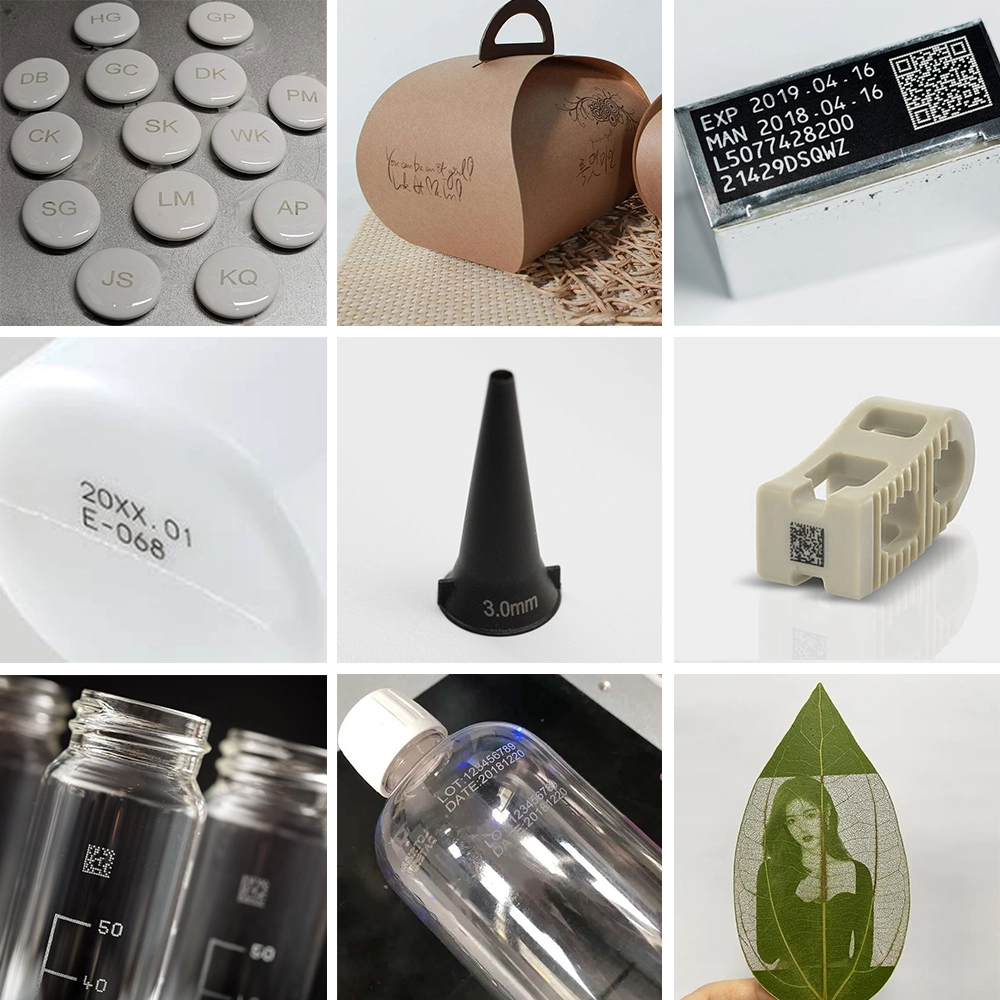

What Products Can a UV Laser Marking Machine with CCD and Conveyor Process?

Applicable Materials:

Iron, stainless steel, carbon steel, aluminum oxide, aluminum alloy, aluminum, copper, gold, silver, hard alloy, plastic, hard plastic, PVC, PCB, wood, bamboo, cork, paper, PE, ABS, PVC, leather, rubber, acrylic, fabric, glass, ceramic, crystal, polypropylene (PP), polystyrene (PS), polylactic acid (PLA), polycarbonate (PC), acrylic (PMMA), polyoxymethylene (POM), polyphenylene oxide (PPO), polycarbonate (PC), polyamide (PA), high-density polyethylene (HDPE), etc.

Applicable Products:

Electronic components, translucent buttons, bottle caps, signs, chips, charging heads, phone cases, USB drives, watch cases, jewelry, accessories, metal parts, cups, bottles, handles, batteries, buttons, chess pieces, etc.

| Model | CK-11-UC-CCD |

|---|---|

| Maximum Marking Range | 110*110mm / 175*175mm / 200*200mm / 300*300mm |

| Laser Type | UV laser (Optional Fiber Laser / CO2 Laser) |

| Marking Speed | ≤ 7000 mm/s |

| Minimum Line Width | ≤ 0.005mm |

| Laser Wavelength | 355nm |

| Feeding Method | Conveyor Belt |

| Camera | 7MP / 12MP |

| Control System | Ruida |

| Repositioning Accuracy | ±0.001mm |

| Operating Temperature | 0-50℃ |

| Storage Temperature | -15-50℃ |

| Voltage Requirement | 110/220V 50/60Hz |

| Laser Working Medium | Ultraviolet |

| Laser Transmission Method | Galvanometer (SINO-Galvo) |

| Power Supply | Mean Well |

| Cooling Method | Water Cooling (S&A Chiller), Air Cooling Optional |

| Compatible File Formats | PLT / DXF / JPG / PNG / BMP / AI / JPEG / TIFF, etc. |

| Weight | 120kg |

| Dimensions | 750*750*1500mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.