UV Marking Machine for Metal, Wood, Plastic, Glass, Crystal

Universal UV Laser Marking Machine for All Materials

[Function Description]

What is a UV Laser Marking Machine?

A UV laser marking machine employs a 355nm wavelength laser, which generates a laser beam with an extremely small focused spot through third-order intracavity frequency doubling technology, directly acting on the material surface to achieve fine engraving and marking. The core principle involves the ultraviolet laser beam directly breaking the molecular chains of the material, creating permanent marks or patterns on the material surface. Compared to ordinary fiber laser marking, UV laser marking boasts advantages such as high precision, high efficiency, and a low heat-affected zone. It is applicable to almost all materials, whether metal, plastic, glass, ceramic, paper, or even leaves, all of which can be marked using UV laser. Due to the short wavelength, concentrated energy, fine beam, and low thermal effect of the UV laser, the heat-affected area is minimal, avoiding issues like charring or high-temperature yellowing that can occur with fiber or CO2 lasers. This makes it particularly suitable for fine processing of heat-sensitive materials, enabling high-precision, non-destructive marking. It is especially well-suited for precision processing of materials such as precision electronic products, fine metal materials, jewelry, mobile phone casings, and silicon wafers.

How Does a UV Laser Marking Machine Work?

UV laser marking is an efficient, high-precision, and environmentally friendly processing technology. Its working principle involves incorporating erbium-doped materials inside the laser crystal, where the erbium ions are excited by a pump light source, causing them to transition to a higher energy level. Subsequently, through spontaneous radiation, they transition back to a lower energy level, releasing laser light. This laser is then focused by an optical system to form an extremely small spot. Utilizing the cold processing characteristics of UV laser, it achieves fine marking on various materials. The machine employs a UV laser generator as the light source, converting infrared laser into UV laser through THG technology. It processes in a non-contact manner, meaning the laser head does not directly touch the material surface, thereby avoiding physical damage to the material. Instead, it uses the energy of short-wavelength laser to directly break the molecular chains or induce chemical bond breakage in the material, causing the surface material to decompose and evaporate, thus forming clear and durable marks. The working process of the UV marking machine is called the photolithography effect. By adjusting parameters such as laser power, processing speed, and resolution through the control system, it is possible to achieve marking effects of varying depths and clarity.

Advantages of UV Laser Marking Machines for Glass, Plastic, Ceramic, and Metal

- Utilizes a 355nm UV laser generator with an extremely small focused spot, enabling precision marking effects up to 0.01mm, while also offering high marking speeds to enhance production efficiency.

- UV laser marking employs cold light technology, with almost no heat-affected zone, preventing material deformation, charring, or yellowing, making it more suitable for processing heat-sensitive materials.

- The lines produced by UV laser marking are fine and clear, resistant to wear and fading, ensuring more distinct and durable marks with superior quality.

- The control software features a user-friendly interface, supporting various image formats (e.g., jpg, png, dxf), allowing users to easily set parameters on a computer, making operation straightforward and quick to learn within 5-10 minutes.

- Equipped with a professional water-cooling system to lower the laser's operating temperature, enhancing the device's stability and lifespan, making it more suitable for prolonged processing.

- The laser adopts an integrated structural design, combining the optical path and external drive circuits into one, offering strong anti-interference capabilities. The entire machine is upgraded to a fully sealed structure, effectively preventing external dust ingress, ensuring efficient operation even in harsh production environments.

- Employs advanced high-speed galvanometer, field lens, and laser technology, ensuring fast and efficient marking without the need for consumables, resulting in almost zero usage and maintenance costs.

- The UV marking machine is compact in size, low in power consumption, and produces no smoke or pollution during processing, avoiding secondary environmental pollution, thus better meeting environmental protection requirements.

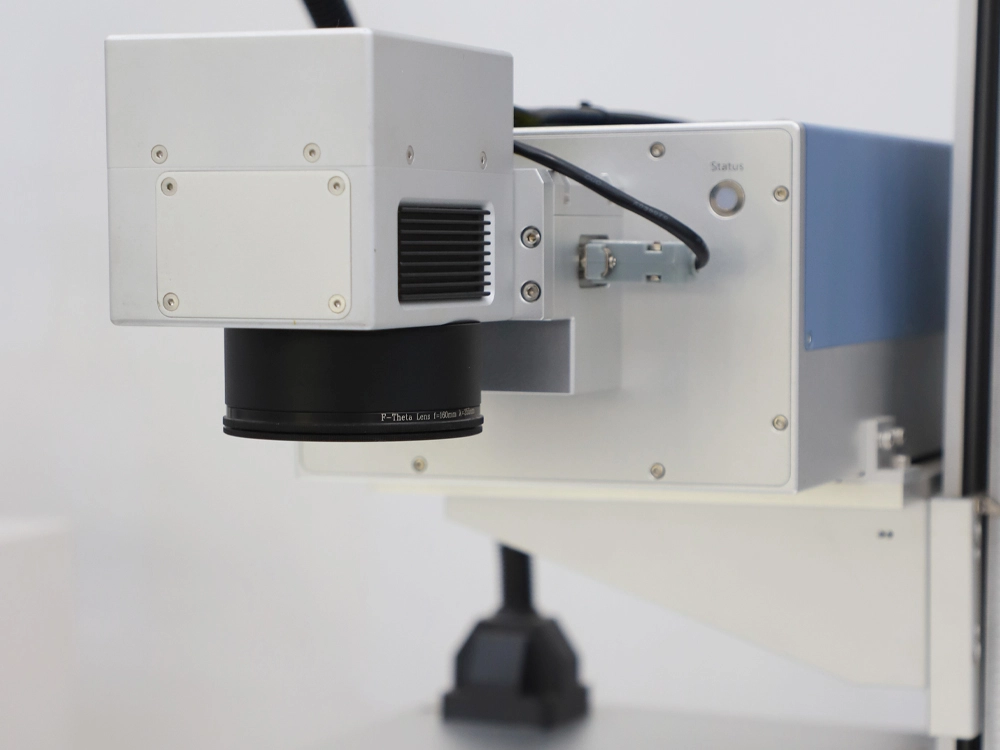

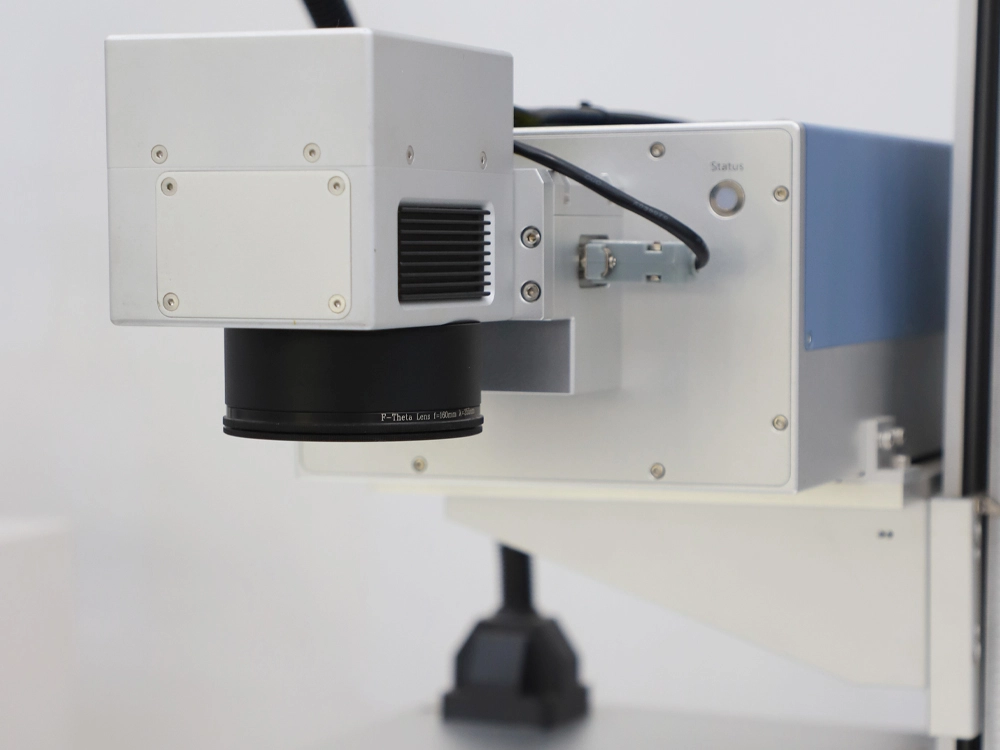

Details of UV Laser Cabinet-type Marking Machine

- UV laser source

RFH-LASER's "Expert" series UV laser source, The laser wavelength is 354.7 nm, with a wide repetition rate range (single pulse to 200kHz). It features excellent beam quality (M²<1.2) and a pulse width of <14ns@30kHz, resulting in minimal HAZ during processing.

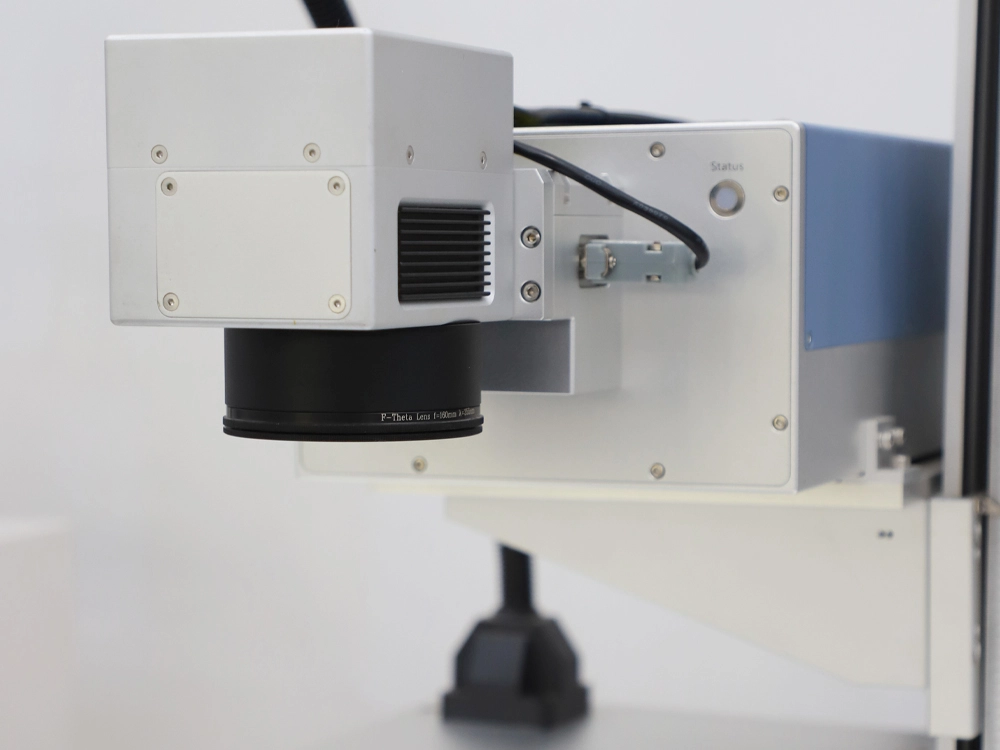

- Sino-Galvo galvanometer scanner

The machine employs a high-speed galvanometer, which controls the laser beam trajectory through high-speed oscillation, offering high scanning precision, sensitive response, accurate focusing, and good compatibility, resulting in more stable and agile marking, effectively improving marking precision and efficiency.

- Field lens

It is equipped with a high-quality field lens, featuring high resolution, excellent light sensitivity, uniform illumination, and high light transmittance, which better focuses the laser beam and optimizes beam quality.

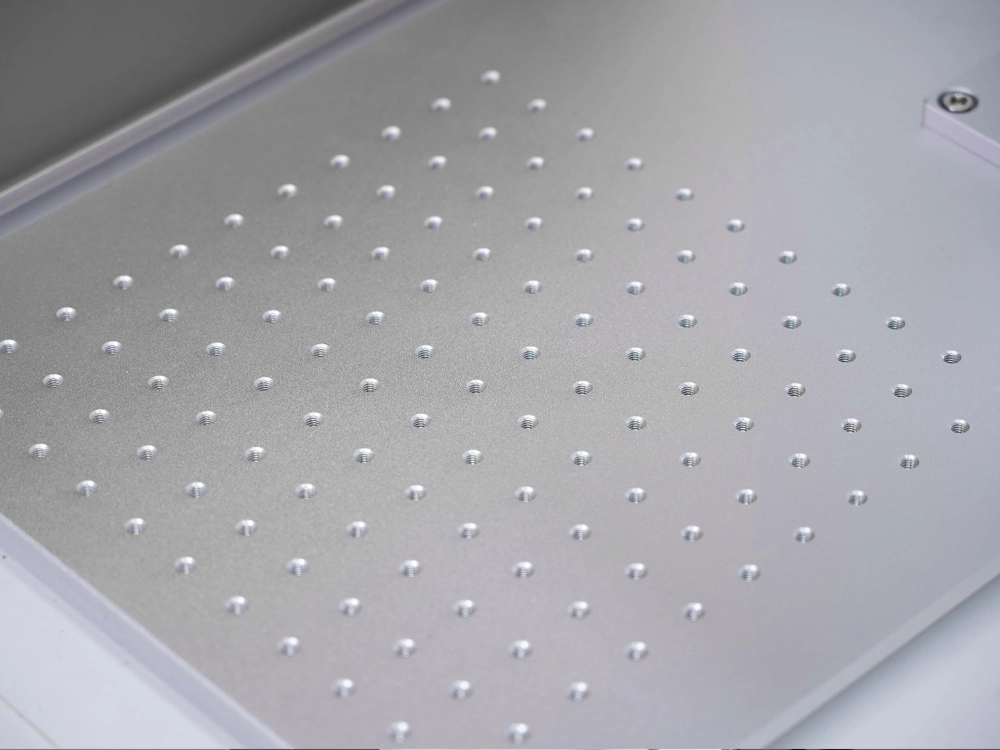

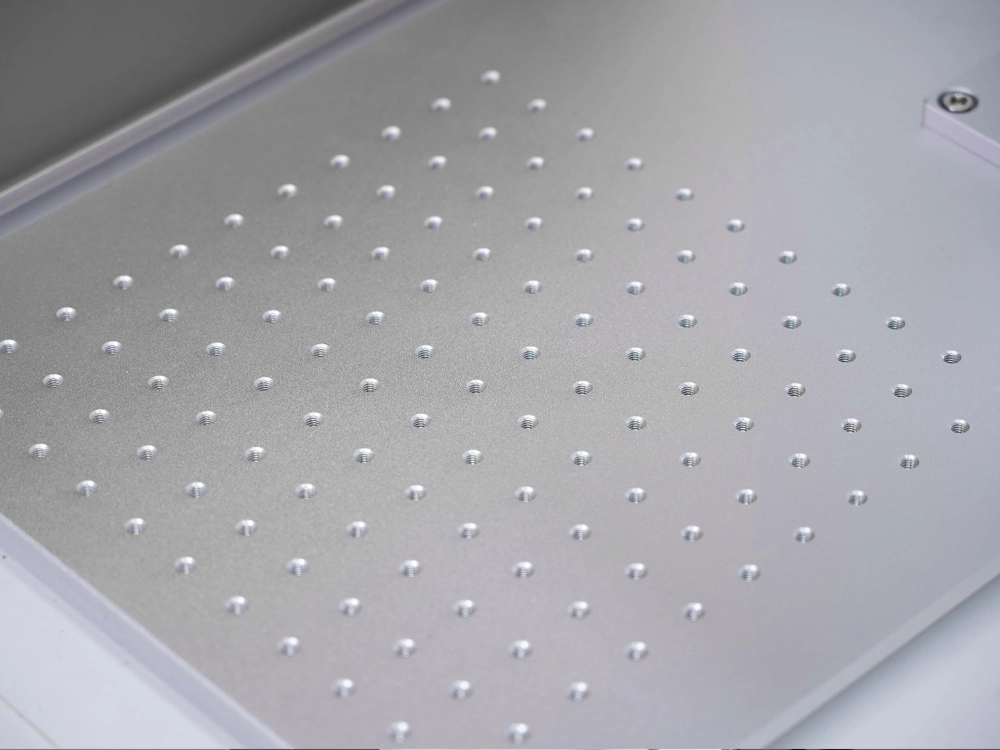

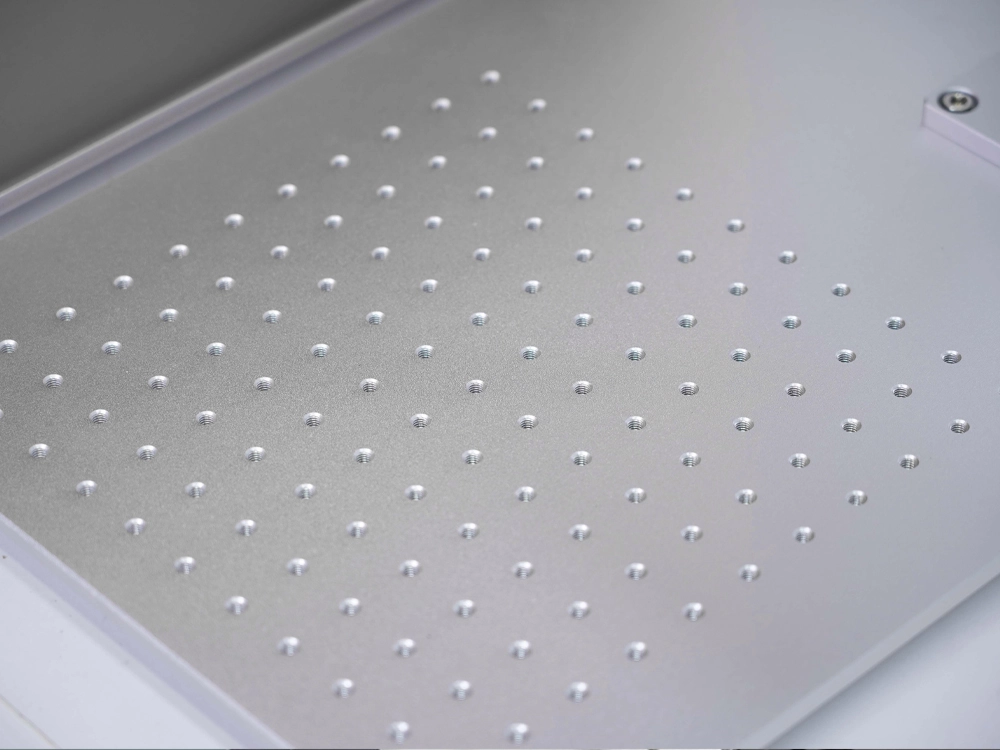

- Worktable

The machine features a large-area aluminum alloy fixed panel, equipped with positioning holes and a positioning backplate, ensuring convenient positioning, flexible adjustment, and more precise marking.

- Hand crank

The lens height can be flexibly adjusted according to different workpiece heights by turning the hand crank.

- Water chiller

It utilizes a UV-laser-marker-specific constant-temperature water chiller, capable of rapidly reducing the operating temperature of the laser, ensuring the device runs at a constant temperature. It can operate 24/7 without interruption. The water cooling method is more efficient compared to air cooling, significantly enhancing the stability and lifespan of the equipment, and preventing performance degradation or malfunctions due to excessive temperatures.

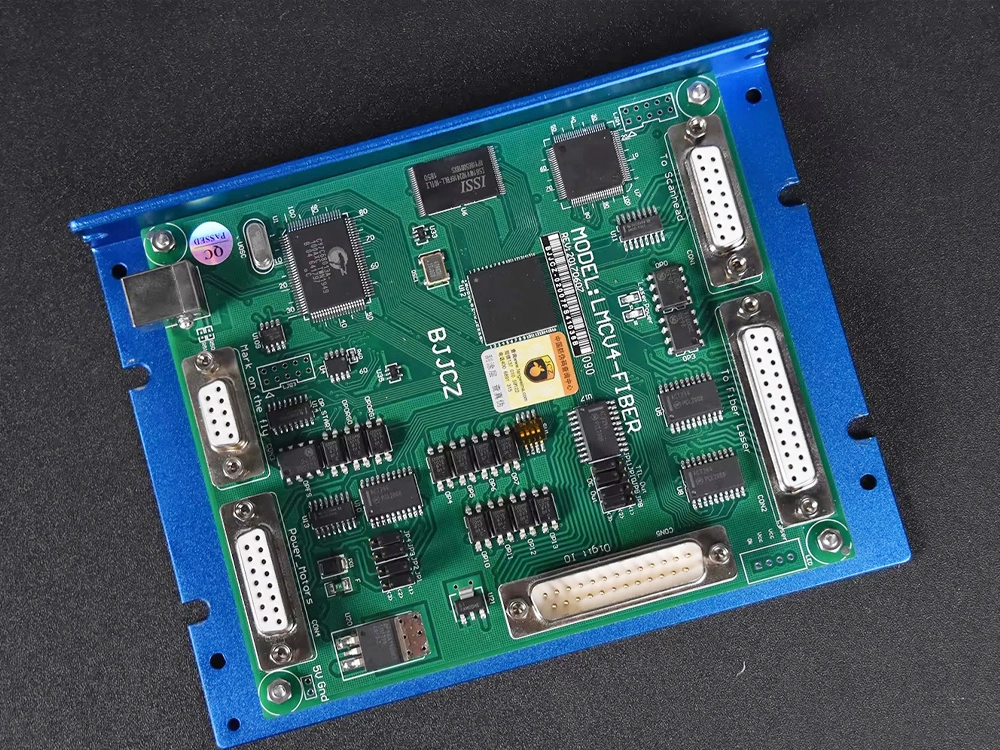

- Controller

It uses the controller from Beijing JCZ, which has the highest adoption rate in the industry. It has stable performance, rich functions, and is used with Ezcad software.

Technical Parameters of UV Laser Marking Machines for All Materials

| Model | CK-11-UC |

|---|---|

| Maximum Marking Area | 110*110mm / 175*175mm / 200*200mm / 300*300mm |

| Laser Power | 3W / 5W / 10W |

| Marking Speed | ≤ 12000 mm/s |

| Laser Central Wavelength | 355nm |

| Pulse Width | < 18ns@40kHz |

| Frequency Range | 20kHz - 150kHz |

| Spatial Mode | TEM00 |

| Beam Quality | M2 ≤ 1.2 |

| Spot Roundness | > 90% |

| Beam Divergence Angle | ≤ 2mrad |

| Polarization Ratio | >100:1 |

| Average Power Stability | RMS ≤ 3%@24hrs |

| Pulse Stability | RMS ≤ 3%@40kHz |

| Minimum Marking Character Size | 0.5mm |

| Laser Working Medium | Ultraviolet |

| Laser Transmission Method | Galvanometer (SINO-Galvo) |

| Power Supply | Mean Well |

| Cooling Method | Water Cooling (S&A Water Chiller) |

| Control System | BJJCZ (EZCAD) |

| Compatible File Formats | PLT / DXF / JPG / PNG / BMP / AI, etc. |

| Weight | 120kg |

| Dimensions | 750*750*1500mm |

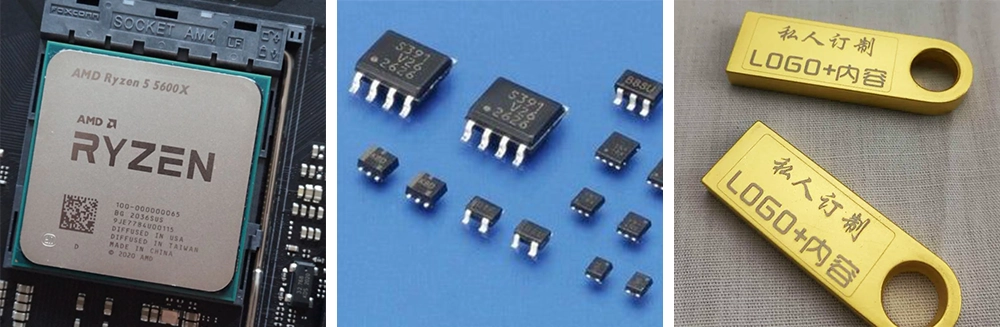

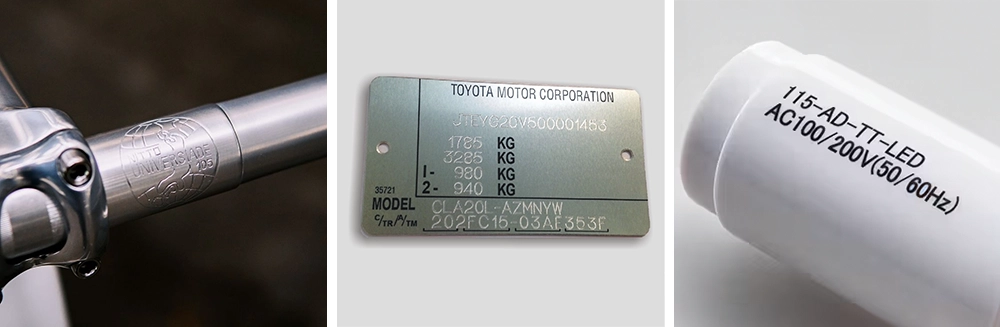

What Products Can a UV Laser Marking Machine Process?

Applicable Materials

Plastic, ceramic, glass, silicon wafers, polypropylene (PP),polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), polycarbonate (PC), polylactic acid (PLA), polyimide (PMMA), acetal (POM), ABS, nylon (PA), glass, crystal products, screens, solid wood, MDF, plywood, OSB boards, leather, fabric, silicone, acrylic, aluminum, gold, silver, platinum, titanium, copper, stainless steel, and various other materials.

Applicable Industries

Electronics Industry: Electronic components, integrated circuits (IC), chips, mobile phone accessories, earphones, charging heads, mobile phone casings, USB drives, etc.

Jewelry and Accessories Industry: Eyeglasses, watches, jewelry, rings, bracelets, wristbands, pendants, pens, etc.

Packaging and Food Industry: Food packaging materials (such as PVC, PP, PO, etc.), pharmaceutical packaging materials, beverage bottles, sterile containers, packaging boxes, plastic bottles, glass bottles, cosmetic casings, etc.

Industrial Manufacturing: Tool accessories, automotive parts, metal products, plastic products, marking on polymer materials (such as ABS, PC, PMMA, etc.).

Medical Industry: Medical device marking and engraving, surgical knives, scissors, syringes, etc.

Advertising and Decoration Industry: Signage, handicrafts, tiles, acrylic, glass, etc.

Leather and Textiles Industry: Leather products, fabric cutting, garment accessories, clothing labels, etc.

Other Industries: Plastic toys, ceramic products, toys, business cards, etc.

How to Use a UV Laser Marking Machine?

- Preparation Work

- Check the Equipment: Ensure the device is properly connected to the power supply and the cooling system is running stably.

- Connect to the Computer: Open the computer control software and ensure the machine is properly connected to the computer.

- Parameter Settings

- Laser Power Adjustment: Adjust the laser power according to the material type and thickness to avoid material damage caused by excessive power.

- Focus Height Adjustment: Adjust the focus height based on the distance between the material and the laser, as well as the material thickness, to prevent processing issues due to improper focus height.

- Marking Operation

- Positioning: Use the red light positioning system to align the laser marking area with the processing area.

- Start the Marking Program: Input the content to be marked and click the start button to begin the marking process.

- Complete Marking: After marking is completed, turn off the device and check if the marking effect meets the requirements.

How Is the UV Laser Marking Machine Packaged and Transported?

It employs a three-layer packaging system:

- First Layer: The galvanometer and field lens are securely wrapped with bubble wrap and anti-collision foam to ensure they are protected from any impact.

- Second Layer: The entire machine is then encased in PP stretch film, providing an additional layer of protection to prevent any movement or shaking during transit.

- Third Layer: Finally, the machine is placed in an export-grade plywood crate, which offers robust reinforcement to safeguard against any potential collisions during transportation.

| Model | CK-11-UC |

|---|---|

| Maximum Marking Area | 110*110mm / 175*175mm / 200*200mm / 300*300mm |

| Laser Power | 3W / 5W / 10W |

| Marking Speed | ≤ 12000 mm/s |

| Laser Central Wavelength | 355nm |

| Pulse Width | < 18ns@40kHz |

| Frequency Range | 20kHz - 150kHz |

| Spatial Mode | TEM00 |

| Beam Quality | M2 ≤ 1.2 |

| Spot Roundness | > 90% |

| Beam Divergence Angle | ≤ 2mrad |

| Polarization Ratio | >100:1 |

| Average Power Stability | RMS ≤ 3%@24hrs |

| Pulse Stability | RMS ≤ 3%@40kHz |

| Minimum Marking Character Size | 0.5mm |

| Laser Working Medium | Ultraviolet |

| Laser Transmission Method | Galvanometer (SINO-Galvo) |

| Power Supply | Mean Well |

| Cooling Method | Water Cooling (S&A Water Chiller) |

| Control System | BJJCZ (EZCAD) |

| Compatible File Formats | PLT / DXF / JPG / PNG / BMP / AI, etc. |

| Weight | 120kg |

| Dimensions | 750*750*1500mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.