How to Choose a Fiber Laser Cutting Machine?

How to Choose a Fiber Laser Cutting Machine?

- Nov 16, 2024

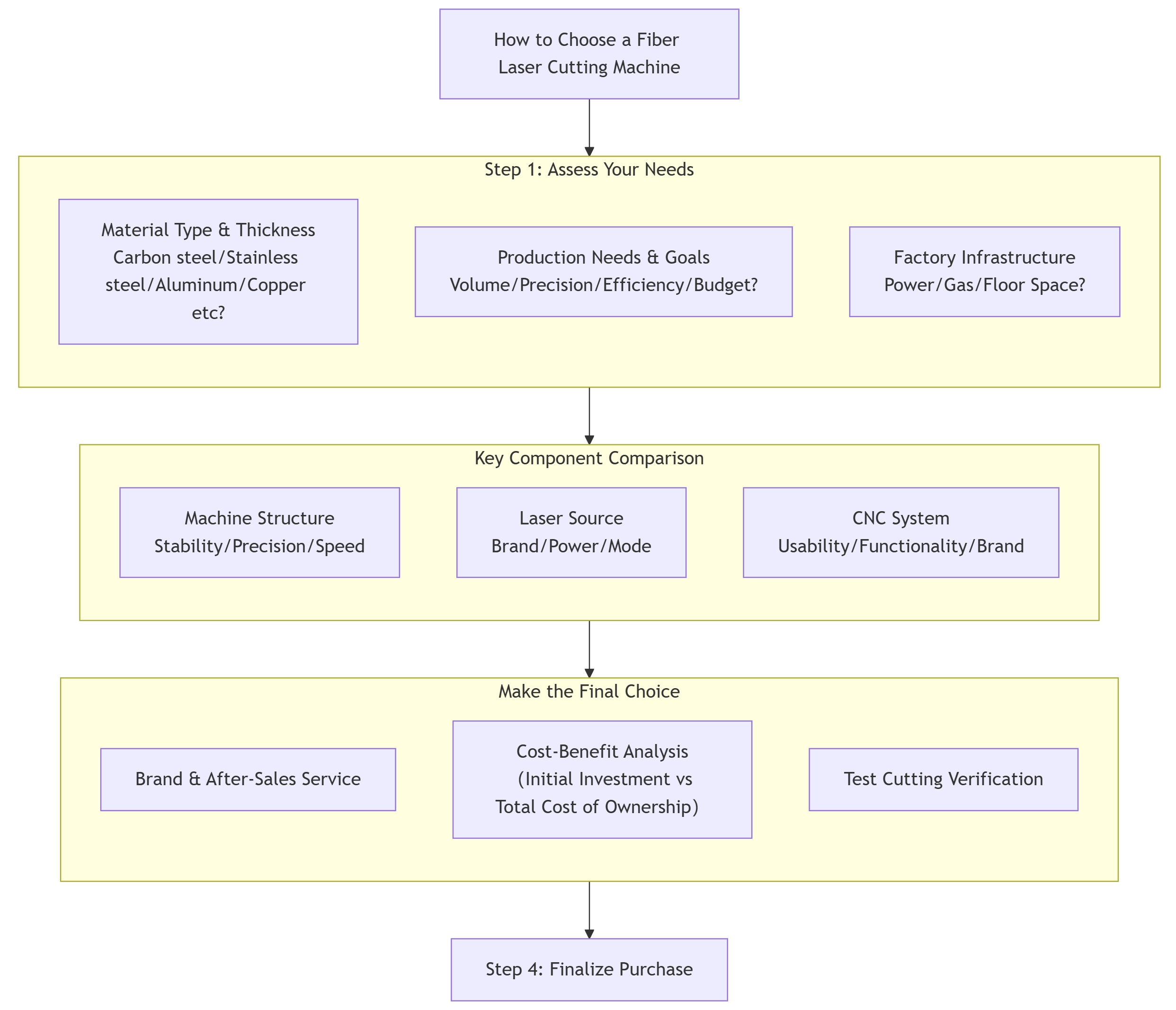

Step 1: Conduct an In-Depth Analysis of Your Requirements

This is the most critical step, determining the direction of all subsequent choices. Please answer the following questions:What materials will be cut?

- Carbon steel: This is the most common application, and all fiber laser machines excel at it.

- Stainless steel/aluminum/brass: Higher-pressure nitrogen is required as an assist gas to achieve an oxide-free cut surface. This places higher demands on laser stability and gas pressure.

- Highly reflective materials (e.g., copper, brass, aluminum): It is essential to choose a laser equipped with an "anti-reflection device." Otherwise, reflected light may damage the laser.

- Other materials: For non-metals such as acrylic and wood, fiber laser machines are not the best choice; CO2 laser machines are more suitable.

What is the maximum thickness of the materials?

Laser power directly determines cutting capacity. Here is a rough reference (using carbon steel as an example):

- 1000W-1500W: Suitable for thin sheets ≤10mm, cost-effective.

- 2000W-3000W: Suitable for plates ≤16mm, currently the mainstream market configuration, offering high cost-performance.

- 6000W-12000W: Suitable for medium-thick plates ≤25mm+, featuring high cutting speeds and strong capability.

- >12000W: Used for heavy industrial applications, cutting very thick plates.

Note: Higher power isn't always better. Using a 10kW+ machine to cut 1mm thin sheet will cause over-burning, low efficiency, and waste. Power selection should be based on the thickness you most frequently cut.

What types of workpieces need to be cut, and what are their maximum dimensions?

What type of workpieces do you need to cut? Do you need to cut metal sheets, tubes, or coils? Since the structures of the relevant machines differ significantly, you need to evaluate your current processing types and consider any additional processing types you may require in the future.

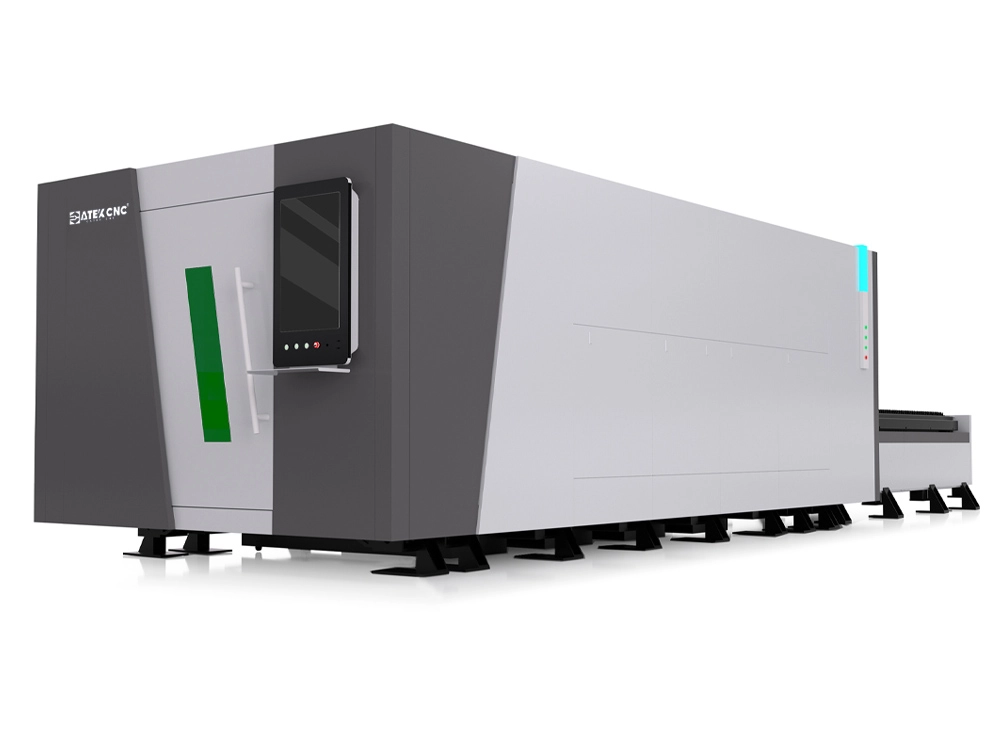

- Sheet cutting requires a fiber laser sheet cutting machine. These machines typically feature a gantry structure with a large horizontal table for placing sheets. The worktable is equipped with metal slats for heat dissipation and to prevent adhesion after metal melting. Common processing dimensions for such machines include 1300*900 mm (4x3 feet), 1300*2500 mm (4x8 feet), 1500*3000 mm (5x10 feet), and 1500*6000 mm (5x20 feet).

- Sheet cutting requires a fiber laser sheet cutting machine. These machines typically feature a gantry structure with a large horizontal table for placing sheets. The worktable is equipped with metal slats for heat dissipation and to prevent adhesion after metal melting. Common processing dimensions for such machines include 1300*900 mm (4x3 feet), 1300*2500 mm (4x8 feet), 1500*3000 mm (5x10 feet), and 1500*6000 mm (5x20 feet).

- Coil cutting requires a metal coil cutting machine. This is an automated laser device specifically designed for efficient, continuous processing of metal coils (e.g., steel, stainless steel, aluminum coils). It integrates multiple functions such as uncoiling, leveling, feeding, laser cutting, and collecting (or sorting). The processing size of such machines is generally measured by the maximum width of the material, with common specifications being 1.5 m, 2 m, and 2.5 m.

- There is also a type of machine called a multi-function fiber laser cutting machine (e.g., a combined sheet and tube cutting machine). These machines integrate the capabilities of the above types. For factories with diverse processing needs, such multi-function equipment can save floor space and reduce procurement costs.

What are your requirements for cutting precision?

- Standard Precision (±0.1mm ~ ±0.2mm): Meets the needs of most sheet metal fabrication.

- High Precision (±0.05mm or better): Requires selecting high-end brand laser sources, high-precision servo motors, precision reduction gears, and a high-rigidity machine tool structure.

What is your budget?

The budget range directly determines the tier of brands and level of configuration you can consider.

What are your factory conditions?

Power supply: Industrial fiber laser cutting machines generally require 380V industrial electricity.

Gas: Will you need to configure an air compressor and storage tank? Or will you use liquid nitrogen/liquid argon?

Floor space: The equipment dimensions, worktable movement distance, and maintenance space all need to be considered.

Step 2: Evaluate and Select the Core Components of the Machine

A laser cutting machine consists of several core components, each of which is crucial.

Machine structure and transmission system

- Structure: After years of development, the structures of various laser cutting machines have become standardized. Taking fiber laser sheet cutting machines as an example, the gantry structure is absolutely mainstream. Lightweight aluminum alloy is typically chosen for the gantry to ensure excellent movement speed and acceleration.

- Guideway and racks: High-precision, high-wear-resistant guide rails and rack and pinion are critical guarantees for long-term stability and accuracy. Priority should be given to components from well-known first-tier brands.

- Drive motors: The brand of servo motors and servo drivers affects the acceleration, speed, and precision of each axis. Carefully investigate the motor brands and models equipped by the manufacturer.

Laser source

- Brands: IPG (USA), JPT (China), Raycus (China), Max (China), Reci (China), etc., are mainstream brands.

- Power: Select based on the requirements determined in Step 1.

- Beam mode: Single-mode lasers are more suitable for high-speed cutting of thin sheets, while multi-mode lasers are more suitable for cutting thick plates. For related information on laser modes, please click here - [What Factors Affect Fiber Laser Cutting?]

Cutting head

- Brands: Common brands include Empower, WSX, Au3tech, BOCI, etc.

- Features: Consider whether the laser head includes functions such as "auto-focusing", "collision protection", and "piercing sensing".

CNC system

- Brands: Common brands include NCStudio, Raytools, Cypcut Plane, FL, Au3tech, etc. Understand the advantages and disadvantages of various control systems in advance and prioritize the one that best suits your needs.

- Features: Check whether it includes functions such as "automatic obstacle avoidance", "intelligent nesting", "common-edge cutting", and "remote monitoring".

Auxiliary systems

- Cooling system: The chiller must be stable and highly precise (temperature control within ±1°C). Otherwise, it will severely affect the laser's lifespan and beam output stability.

- Exhaust system: Higher laser power requires a fume extractor with greater air volume.

Step 3: Comprehensive Comparison and Decision Making

Brand and after-sales service

- Choose brands with a good market reputation and a long operational history.

- Laser machines are large-scale industrial equipment, and the importance of after-sales service and technical support is no less than that of the equipment itself.

Cost analysis

Don't just look at the purchase price. Calculate the total cost of ownership, including: machine cost, electricity consumption, gas consumption, consumable costs (like lenses), maintenance costs, and losses due to downtime.

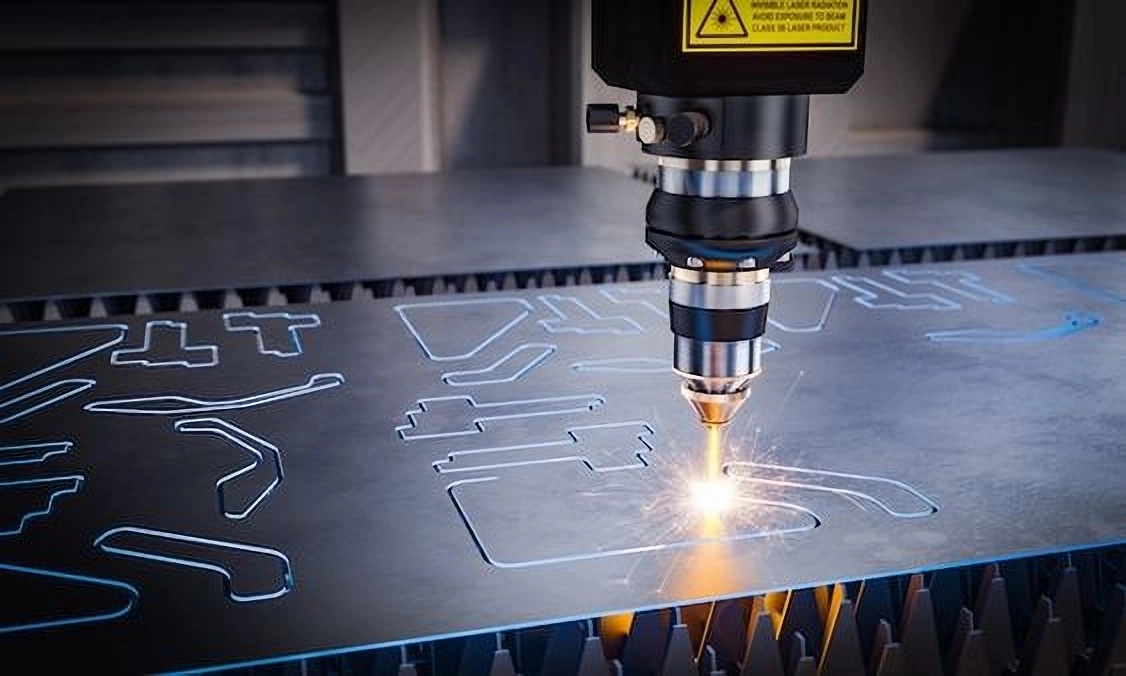

Test Cut

This is the most critical step. Require the supplier to perform on-site cutting tests on their machine using your actual materials (grade and thickness). Then, carefully evaluate the cutting speed, smoothness of the cut surface, perpendicularity, dross adhesion, and the accuracy of rounded corners and square holes.

RELATED MODELS

We recommend some related models for you...