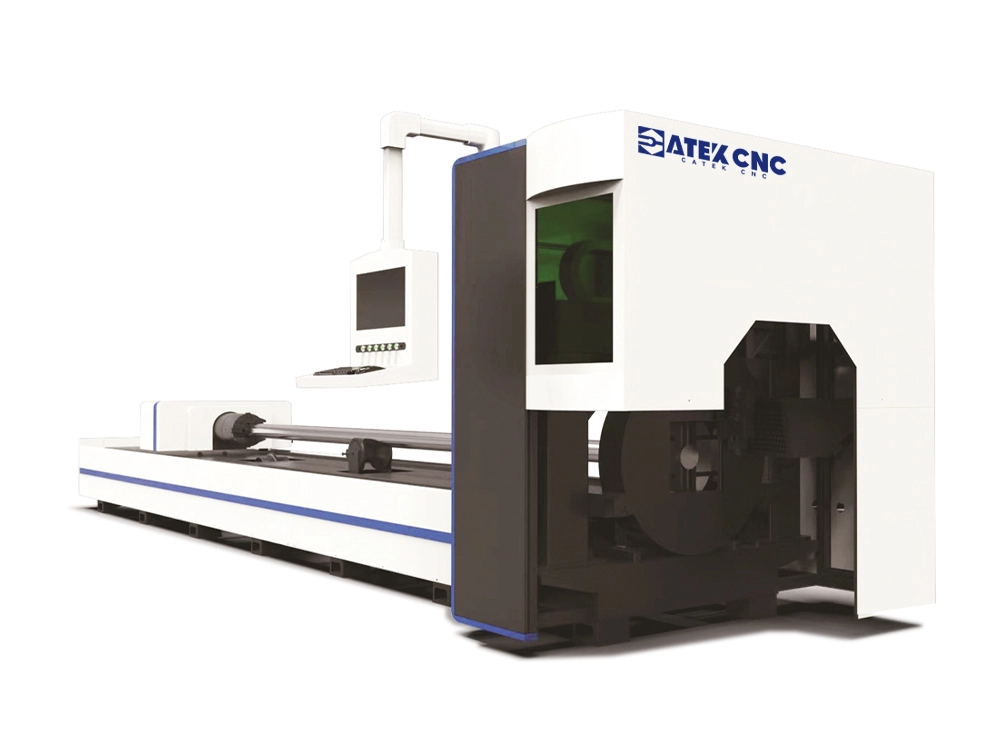

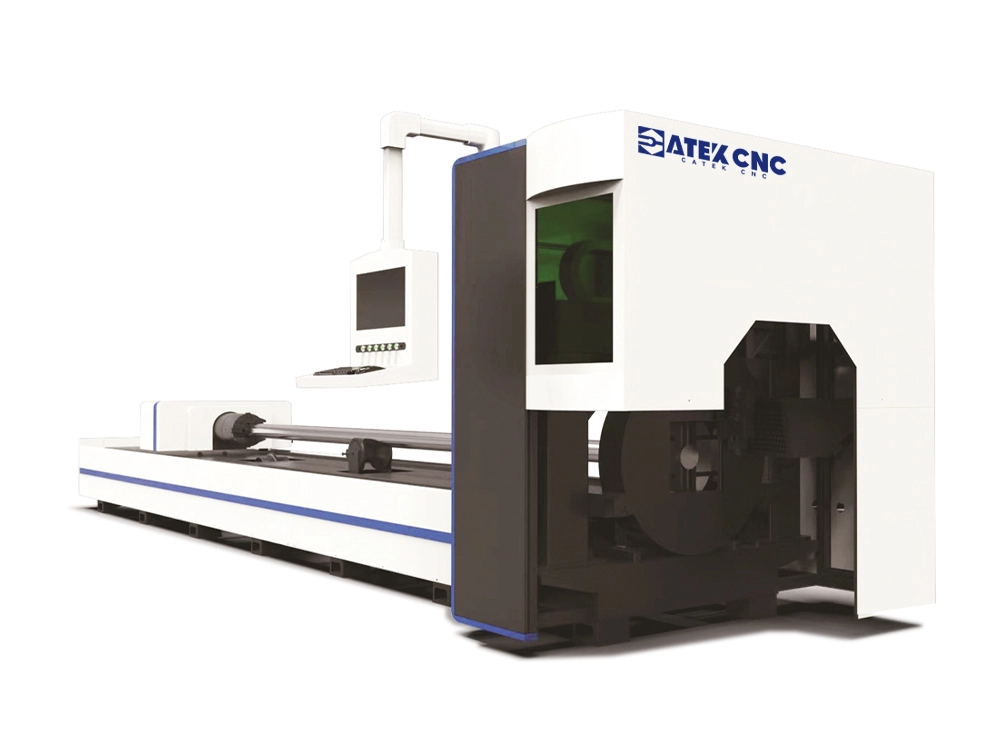

Best-Selling Heavy Duty Fiber Laser Machines for Tube, Profile Cutting

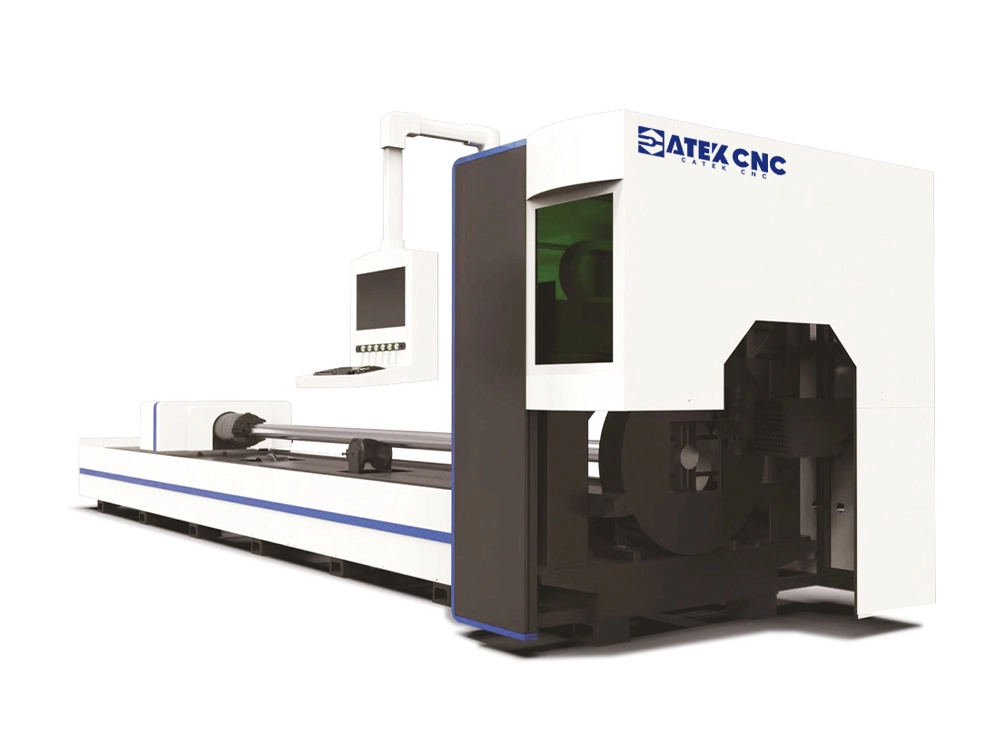

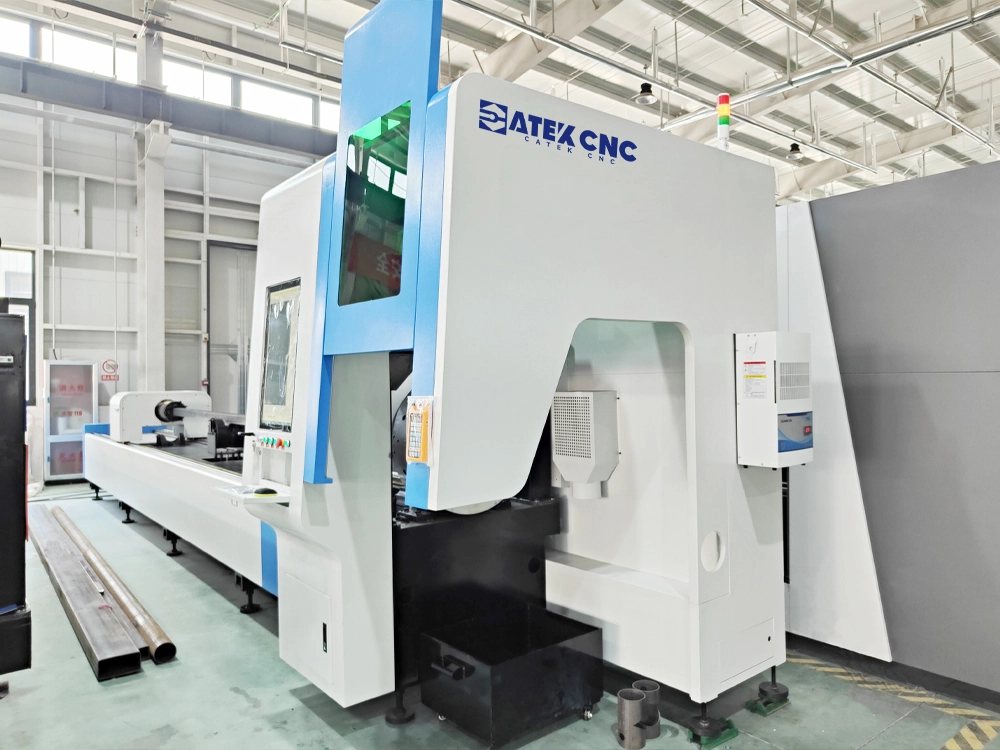

Industrial-Grade Professional Fiber Laser Tube Cutting Machine

[Function Description]

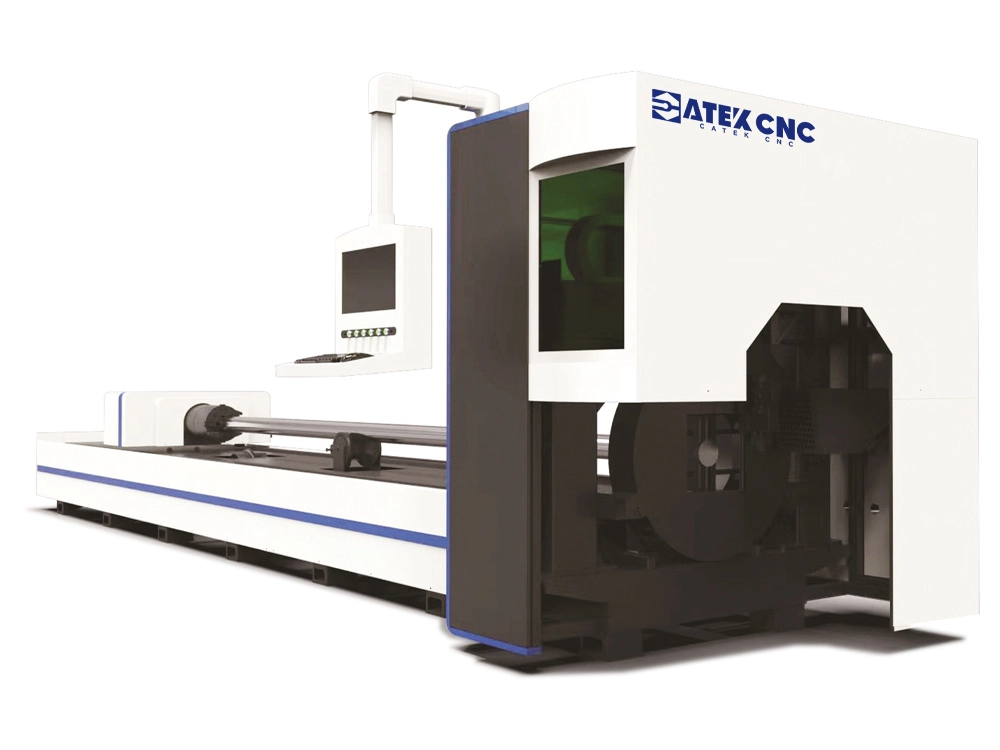

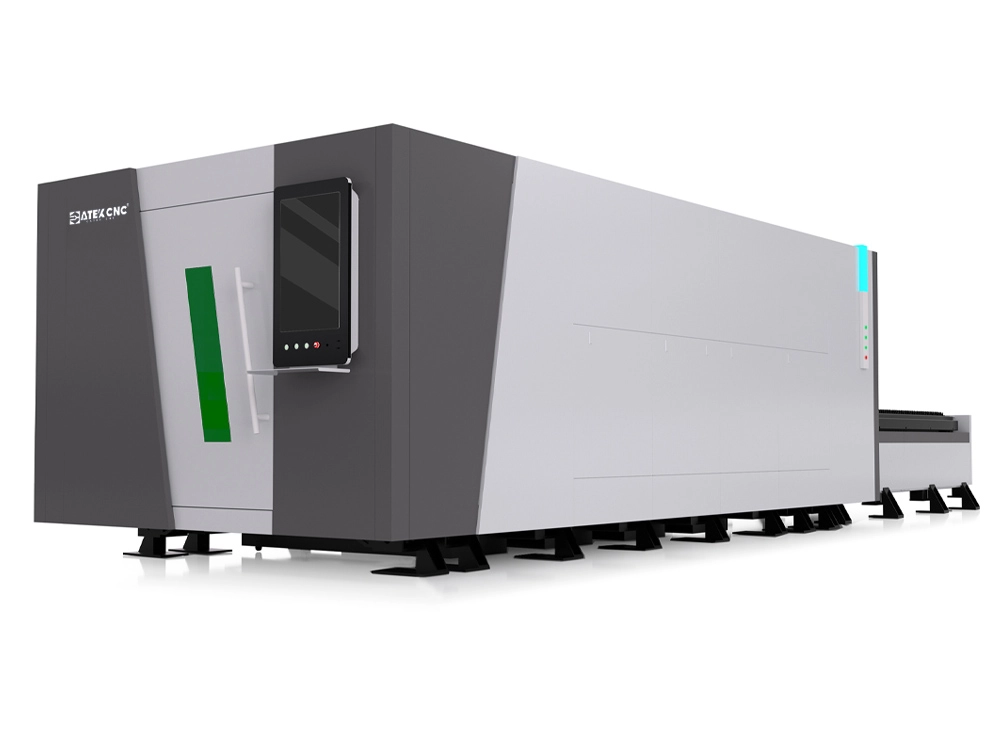

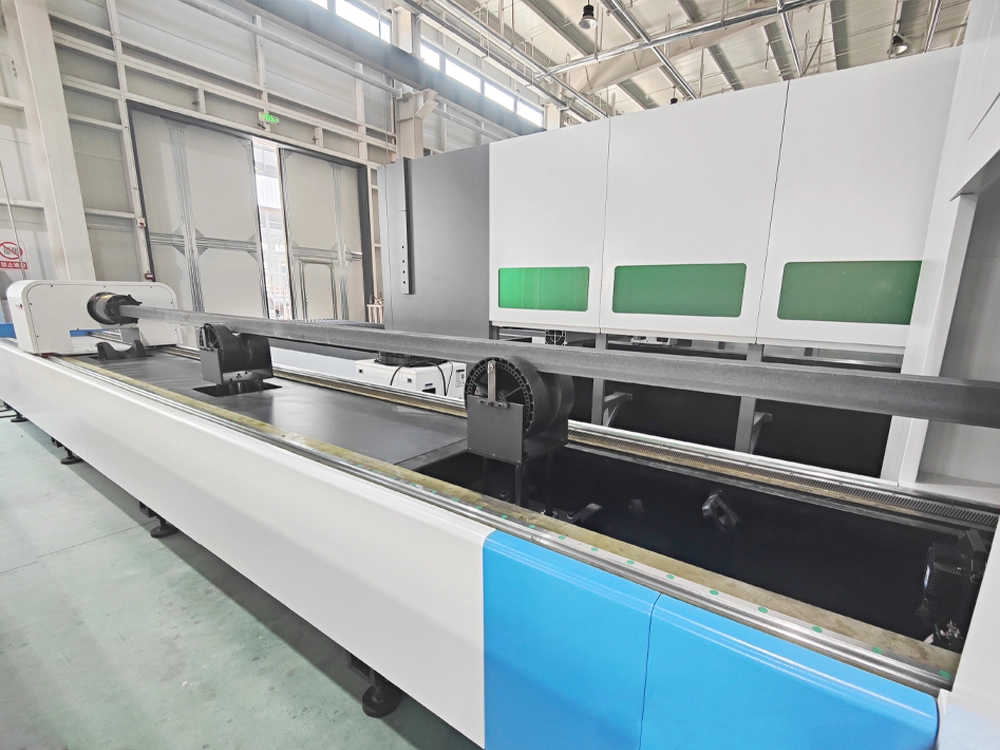

The industrial-grade fiber laser tube cutting machine utilizes a fiber laser as the laser source, employing high-energy-density laser beams to achieve precise and efficient cutting of metal tubes. It is a high-precision laser cutting machine primarily composed of a bed base, front chuck, rear chuck, beam, X-axis drive, Z-axis drive, laser cutting head, variable-diameter wheel support device, constant-temperature cooling system, control system, and laser generator. The design features a movable rear chuck, eliminating the need for additional manual adjustment of the chuck jaws and reducing machine setup costs. The system offers a simple and user-friendly automatic tube cutting interface with a built-in extensive tube processing database, allowing processing to begin with just one click without frequent adjustments.

The fiber laser tube cutting machine uses high-density laser beams for cutting, achieving a cutting precision of 0.1mm, ensuring accurate and consistent dimensions of the cut parts. Its cutting speed is extremely fast, with straight-line cutting speeds exceeding 10,000 mm/min. The automatic chuck can clamp square tubes, round tubes, rectangular tubes, and other types of tubes, enabling the cutting of any pattern or shape on metal tubes and performing cuts at various angles. Compared to traditional cutting methods such as flame cutting, plasma cutting, and waterjet cutting, laser cutting offers higher precision, faster speeds, no need for molds, simple operation, and high automation, making it more flexible for processing applications.

Fiber laser tube cutting machines are widely used in various industries, including construction engineering, construction machinery, agricultural machinery, home appliances and kitchenware, energy and power, elevator manufacturing, aerospace, vehicle manufacturing, and pipeline cutting. Although the initial cost of a fiber laser tube cutting machine is relatively high, its advantages of high processing efficiency, high precision, and low maintenance costs make it highly cost-effective in the long term and for batch processing.

Advantages of Fiber Laser Cutting Machines Dedicated to Metal Pipe Cutting

- The high-rigidity thickened bed and base, with a structurally tested internal design, are constructed from multiple rectangular square steel welds. Additional internal reinforcement welding enhances the bed's rigidity and tensile strength, preventing deformation.

- Equipped with various processing and auxiliary function commands, allowing free editing of complex graphics through commands.

- Features self-inspection alarms and automatic protection functions. A user-friendly display interface shows operational information, and the control panel includes functional keys for machine operations.

- Simulated graphic display and dynamic graphic tracking functions make the processing process more intuitive and easier to monitor and control.

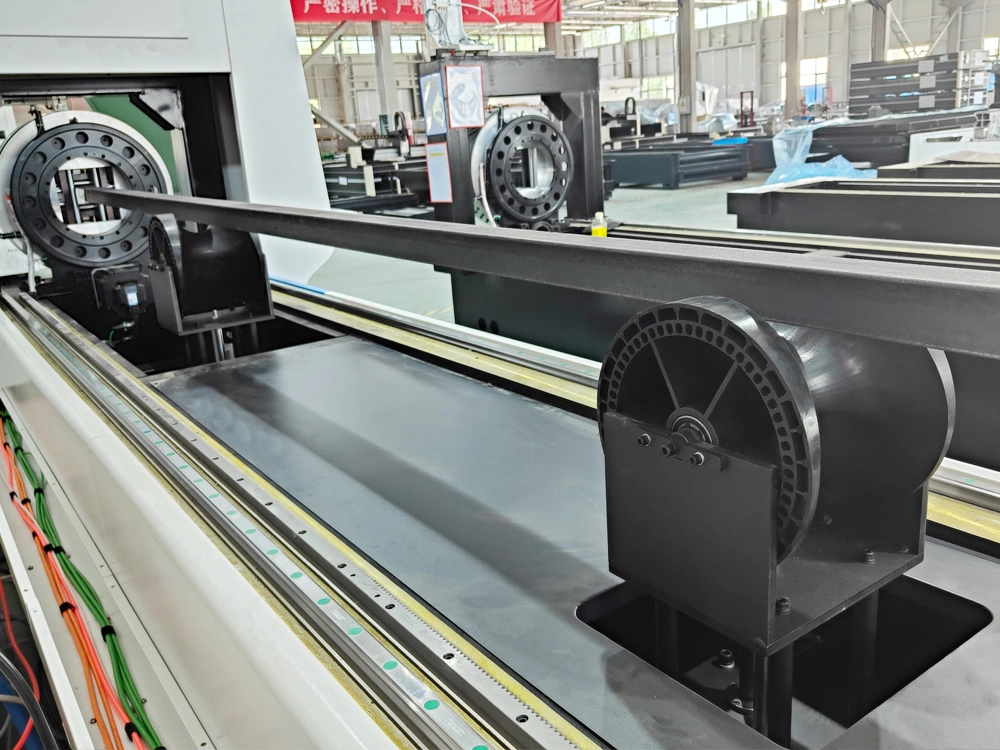

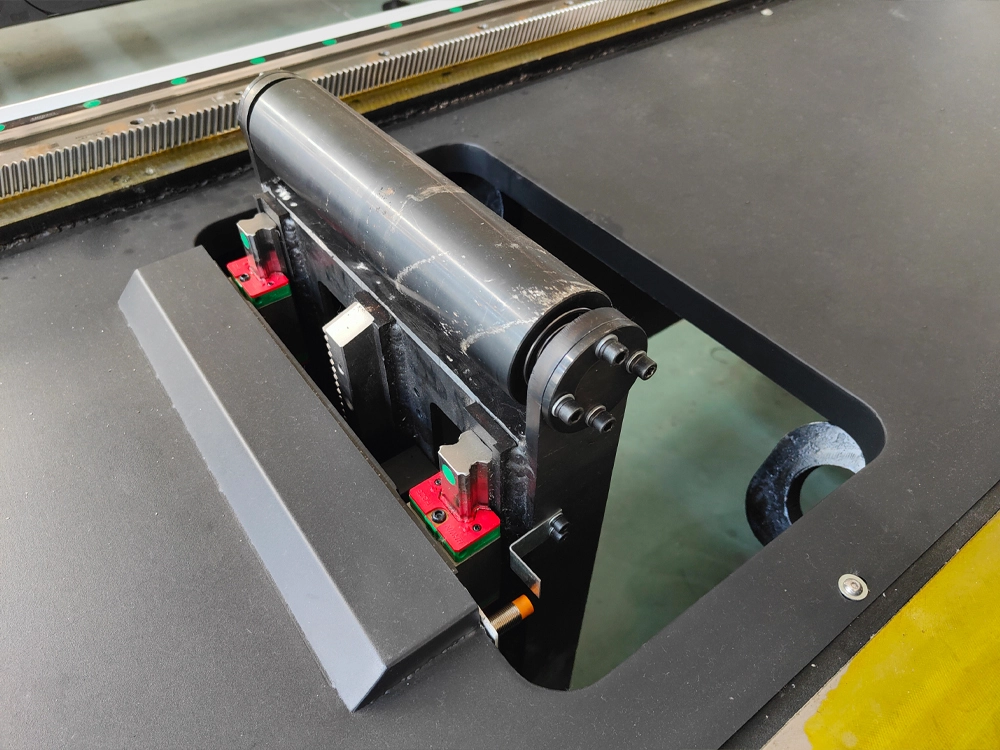

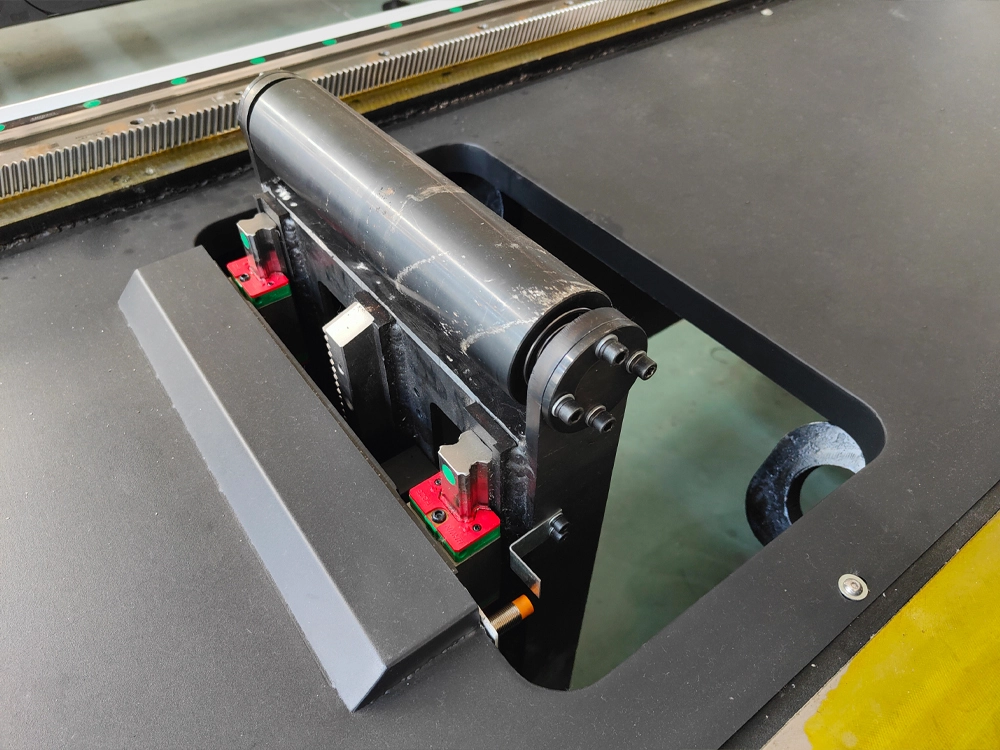

- Includes a pneumatic variable-diameter wheel support device to ensure the levelness of long tube cutting. It works in conjunction with the rear chuck for automatic lifting, preventing deformation of thin-walled tubes.

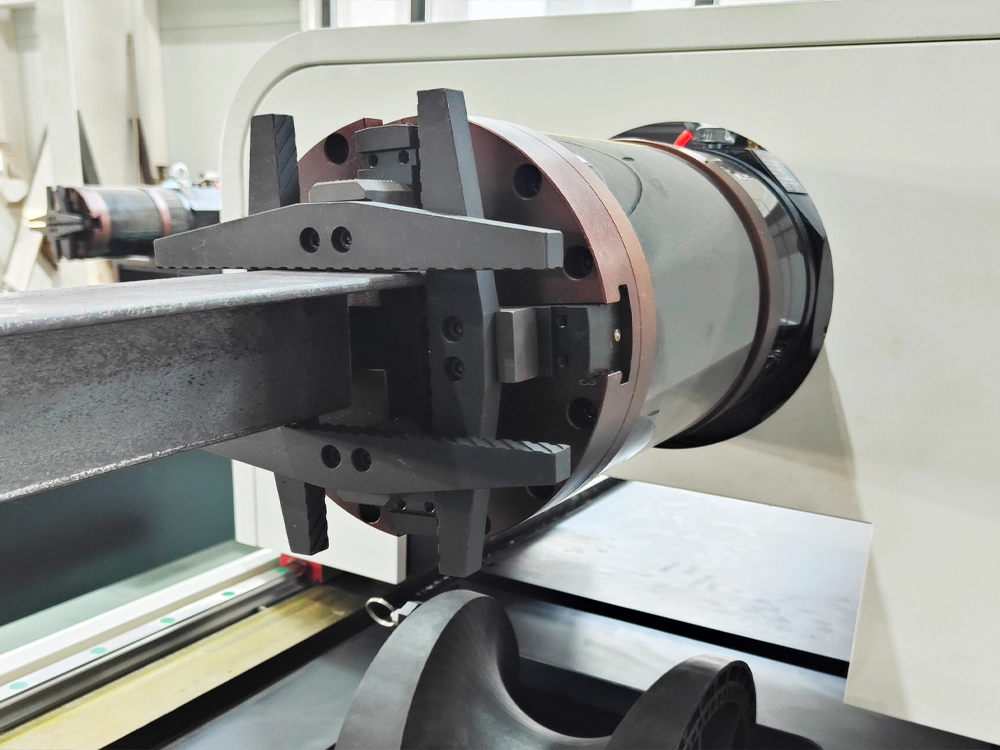

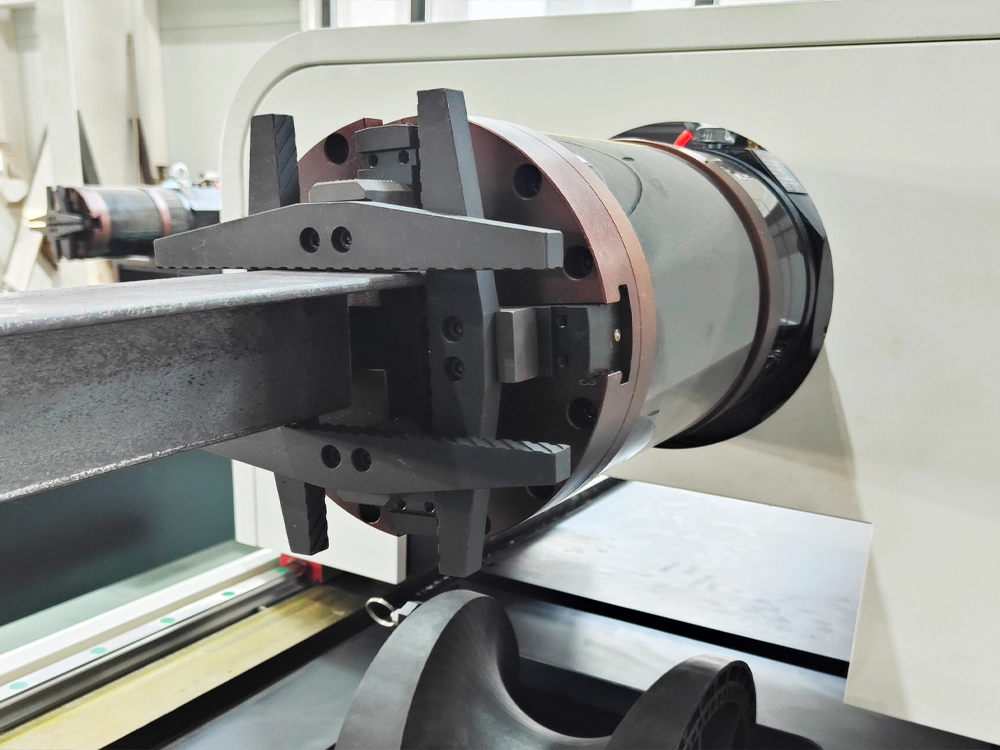

- A bidirectional pneumatic chuck automatically centers and clamps the tube during operation, improving operational stability.

- An intelligent tube cutting system detects tube errors, automatically corrects the center to ensure cutting precision, and features shared-edge cutting to reduce waste and save production costs.

- An automatic lubrication and oiling maintenance device lubricates the machine's transmission parts, simplifying maintenance.

- Both oxygen and nitrogen systems are equipped with pressure-reducing valves, oxygen gauges, and nitrogen gauges, allowing easy monitoring of system conditions.

- A constant-temperature water-cooling system ensures the laser operates within a temperature range of 20-30°C, maintaining laser quality and extending the machine's service life.

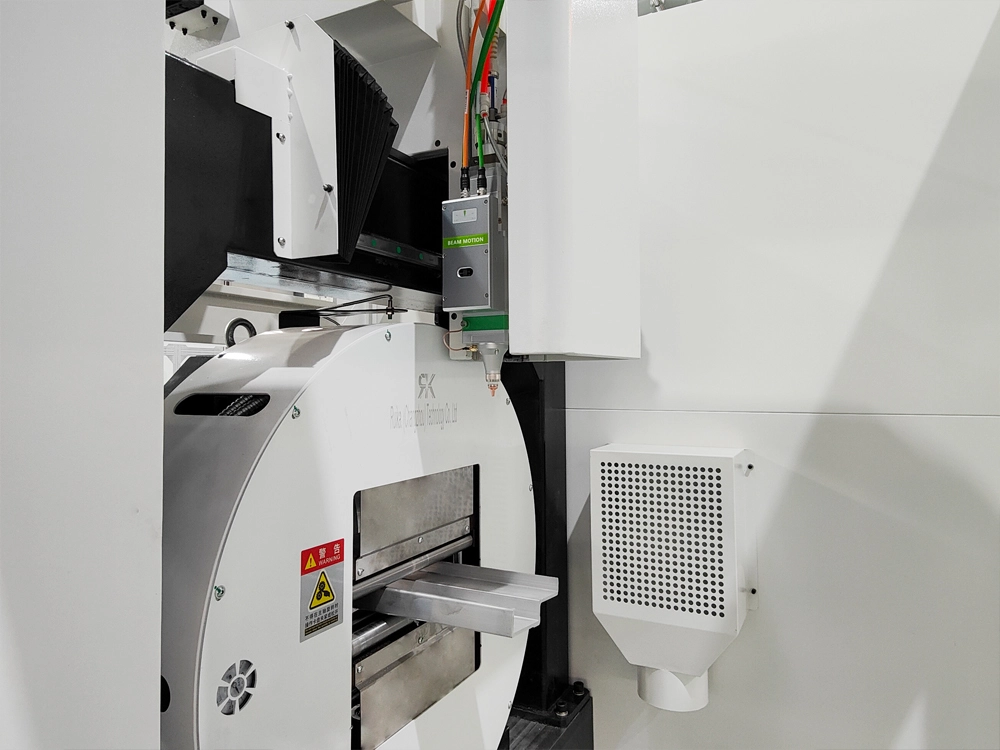

- An auto-focusing laser cutting head is equipped with double-layer dust and collision protection, full optical temperature detection, and air leakage detection. It includes a quick-change focusing protective lens device for convenient replacement.

Details of Industrial Fiber Laser Tube Cutting Machine

- Fiber laser generator

Using RAYCUS laser source, the electro-optical conversion efficiency is high, the single-module continuous fiber laser can achieve sustainable high-power output, and the second-generation fiber transmission system is used for cutting. The cutting is more stable and precise, and the cutting seam of the cut plate is narrower, with obvious advantages. The modular design is easier to maintain and can be operated maintenance-free.

Optional max, JPT, IPG laser generator.

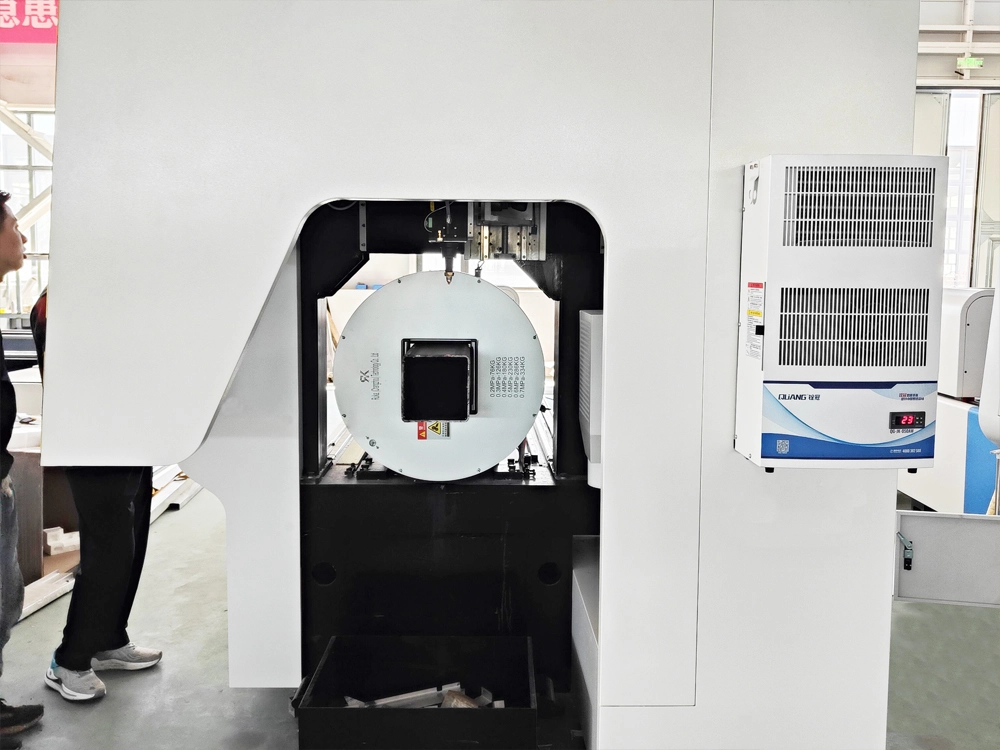

- Raytools auto-focusing laser head

RAYTOOLS laser cutting head can flexibly adjust the scale to unify the zero focus position, and no longer worry about adjusting process parameters. The efficient water-cooled focusing lens and collimating lens nozzle have built-in cooling function, which perfectly solves the problem of cutting heat.

- S&A water chiller

Use S&A water chiller, multiple alarm functions, all-round protection of laser, equipped with water pressure gauge: convenient to observe the water pressure of the water pump; add drain valve: convenient for drainage; high-precision temperature control system, dual temperature control circulation refrigeration function, two independent temperature control systems cooling at the same time, better effect.

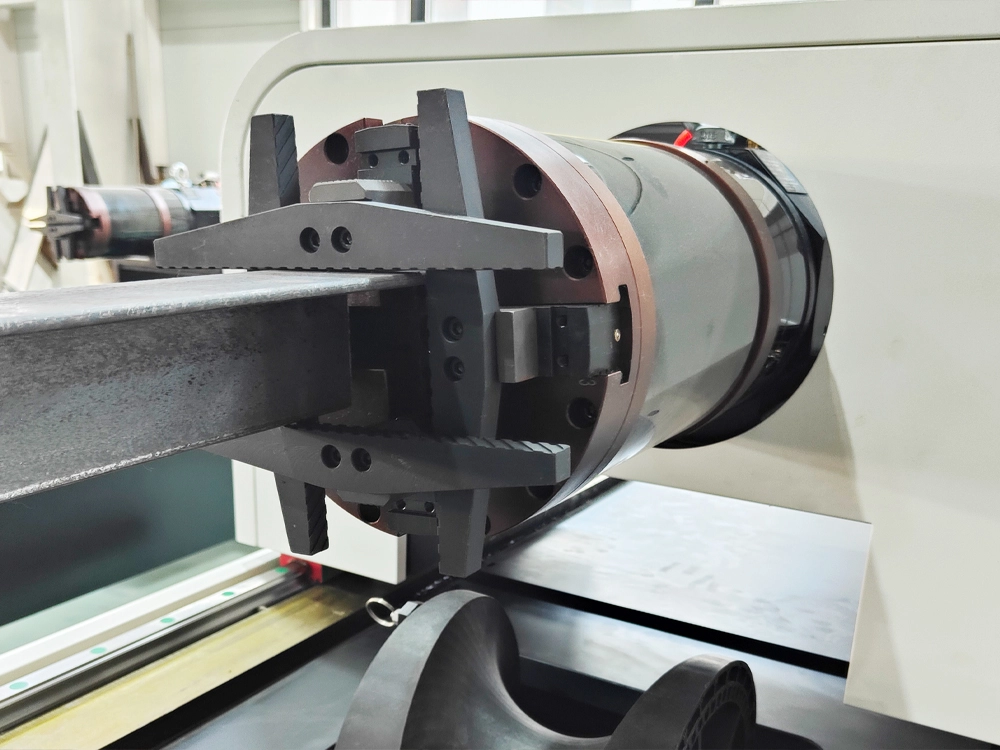

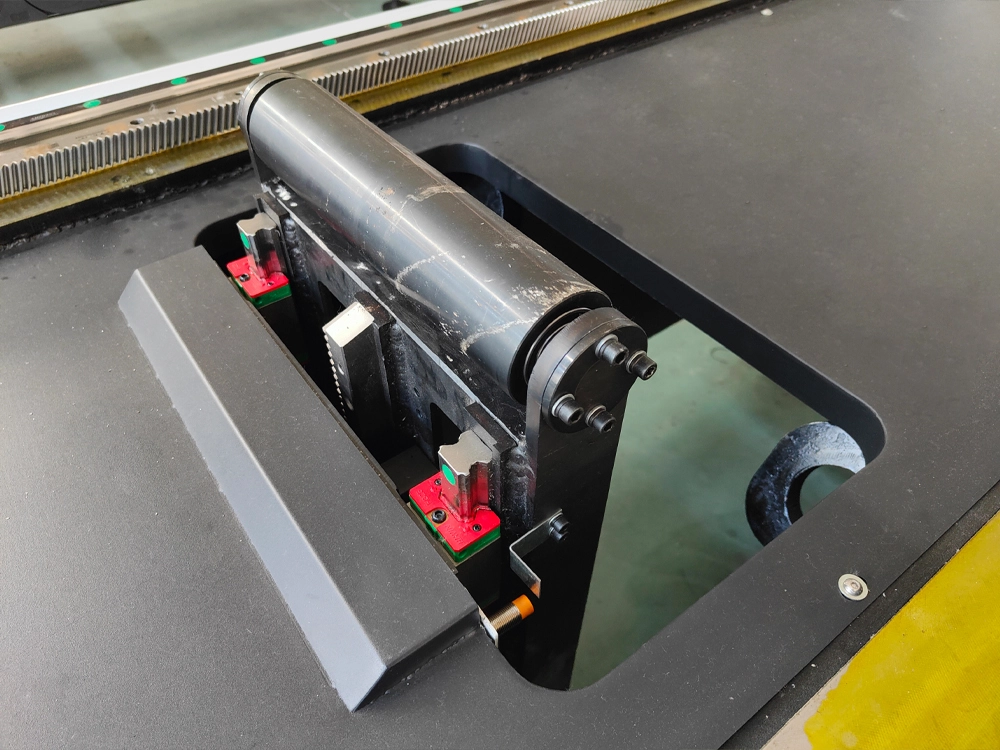

- Main pneumatic chucks

It features a fully automatic rotating shaft designed for large-diameter metal pipes, capable of clamp round and square tubes with diameters ranging from 20-300mm. Additionally, it can perform indexed rotational to cuts patterns.

It supports avoidance cutting function. When the cutting is about to end, the front chuck can open automatically, and the rear chuck can pass through the front chuck to reach the front end. The laser head can cut the tail material to avoid waste.

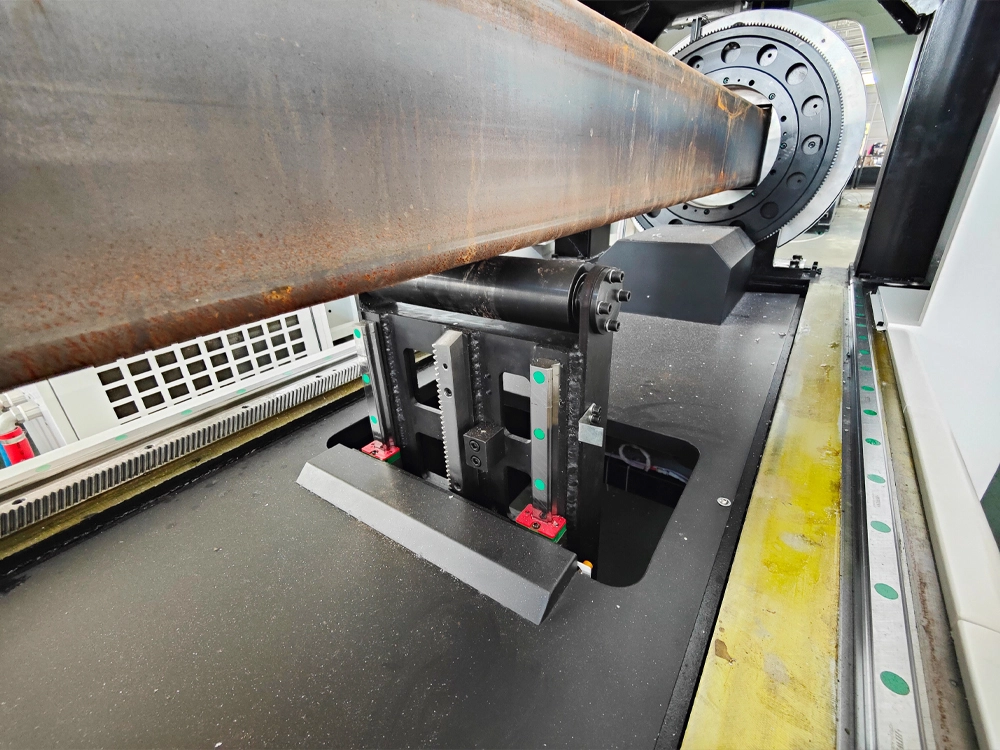

- Tail pneumatic chuck

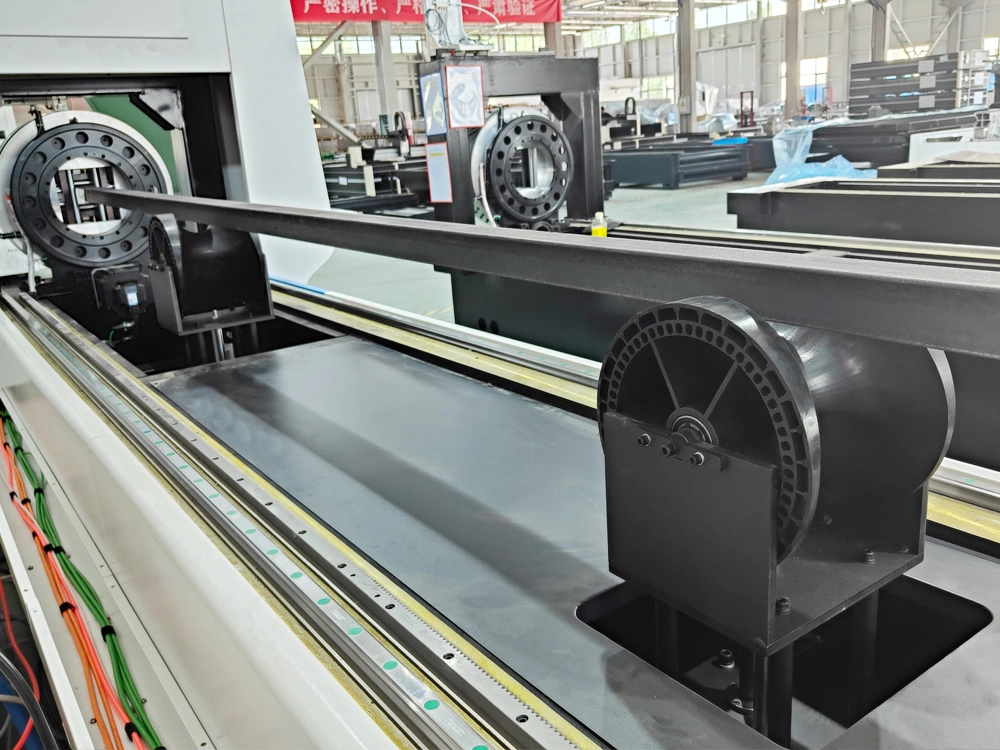

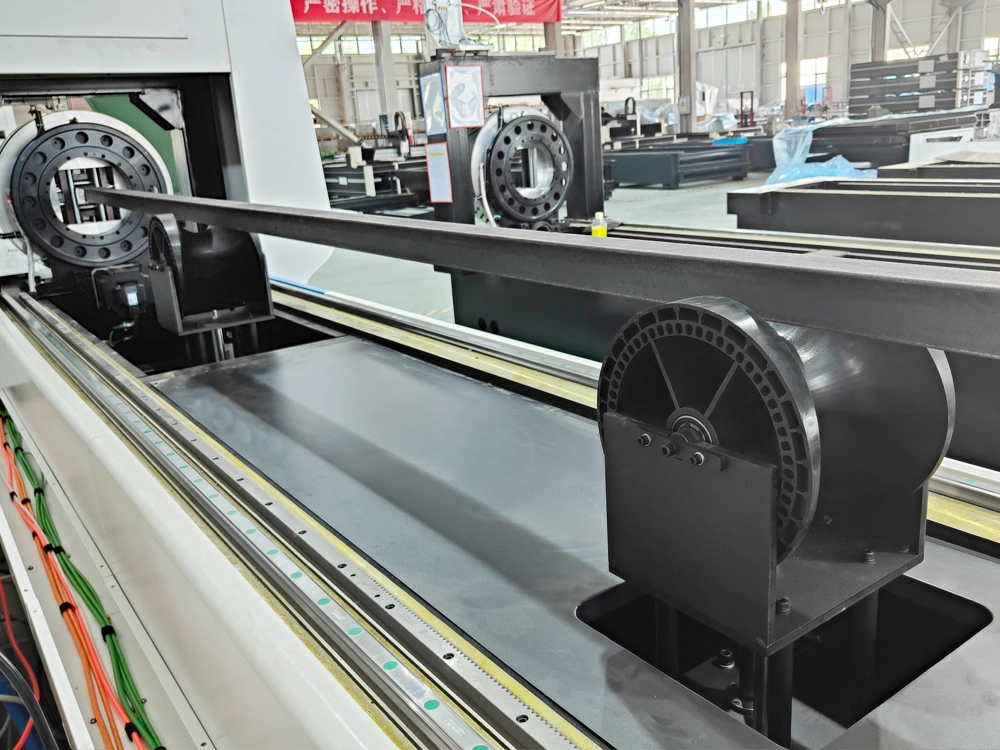

Securely grips most pipe diameters and shapes and can be moved back and forth to feed pipe.

- Pipe floating supporter

It can support pipes of different diameters, ensure the stability of the pipes during cutting, reduce vibration, and improve cutting accuracy and quality.

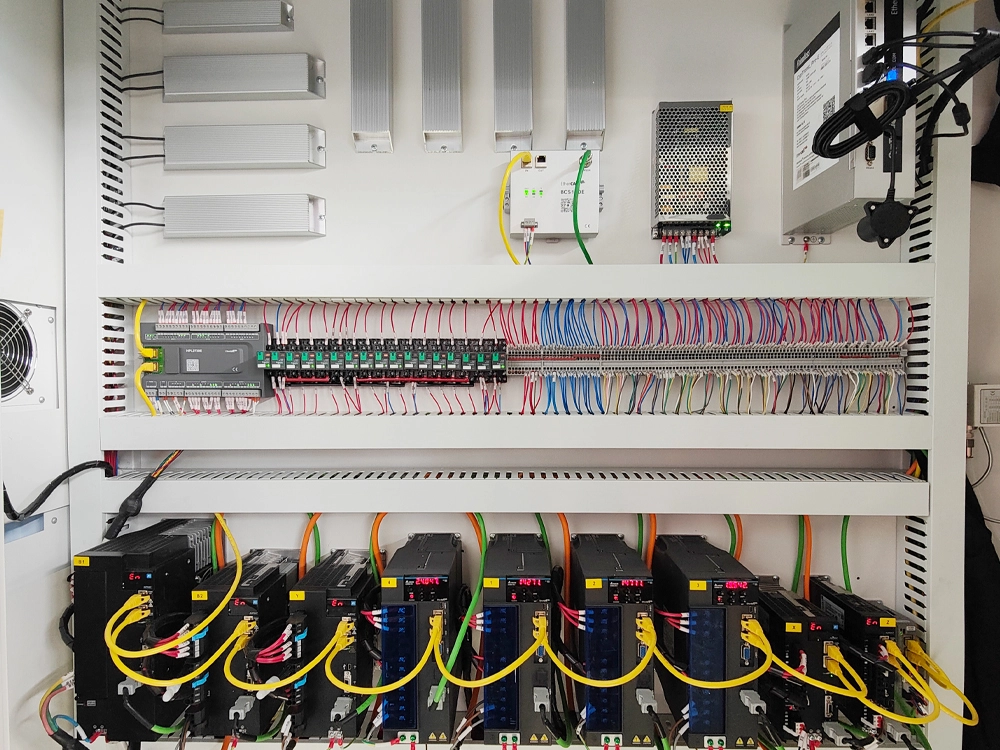

- Controller

The bus servo controller is adopted, which has the advantages of high real-time performance, strong anti-interference and good scalability.

- Special control system for laser tube cutting

Using the Cypcut laser control system and an external wireless handle, it supports advanced functions such as finding the edge of the workpiece, auto-focus control, double shuttle, breakpoint positioning, QR code generation, and residual material segmentation.It is easy to operate and stable in operation. It can provide fine cutting technology and highlight high-quality cutting effects.

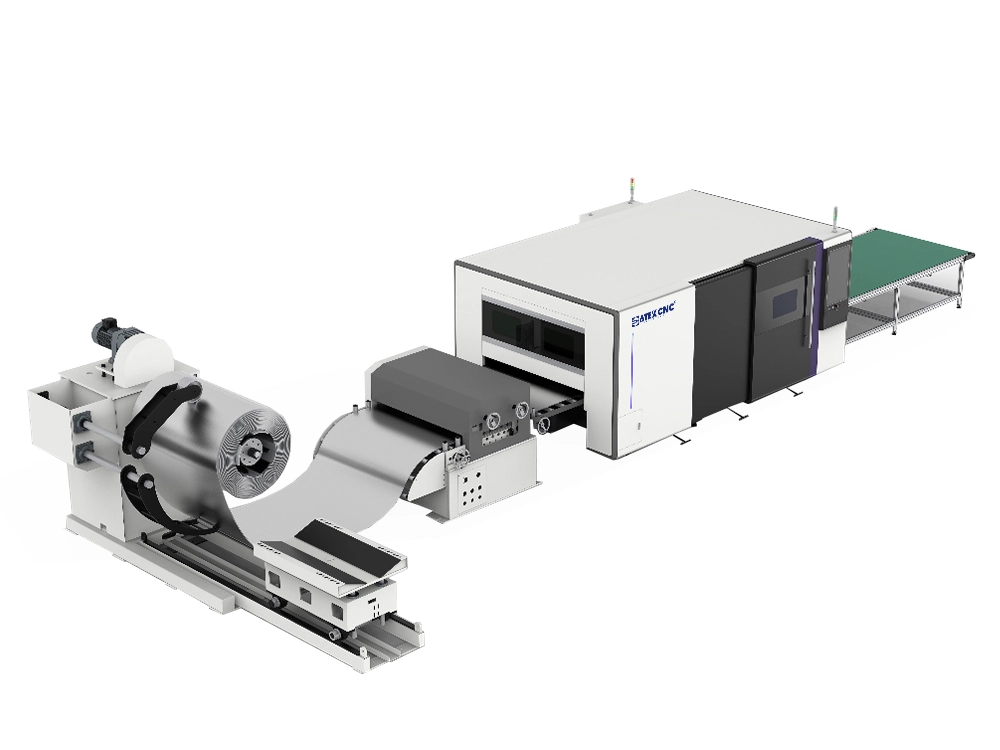

- Optional unloading platform

This platform can be raised, lowered, and tilted. When the pipe processing is completed, the platform will rise to catch the falling pipe, then descend. Once it reaches the lowest point, the platform tilts, causing the pipe to fall into the adjacent material collection device.

Technical Parameters of Fiber Laser Tube Cutting Machine

| Model | CK-2260-T |

| Cutting Area | 200mm * 6000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | servo motor * 4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | France Motoreducer reducer |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Fan | 1.5KW high power fan |

| Proportional Valve | SMC |

| Electrical Components | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser tube cutting machine dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 5500kg |

| Dimensions | 9400*1850*2150mm |

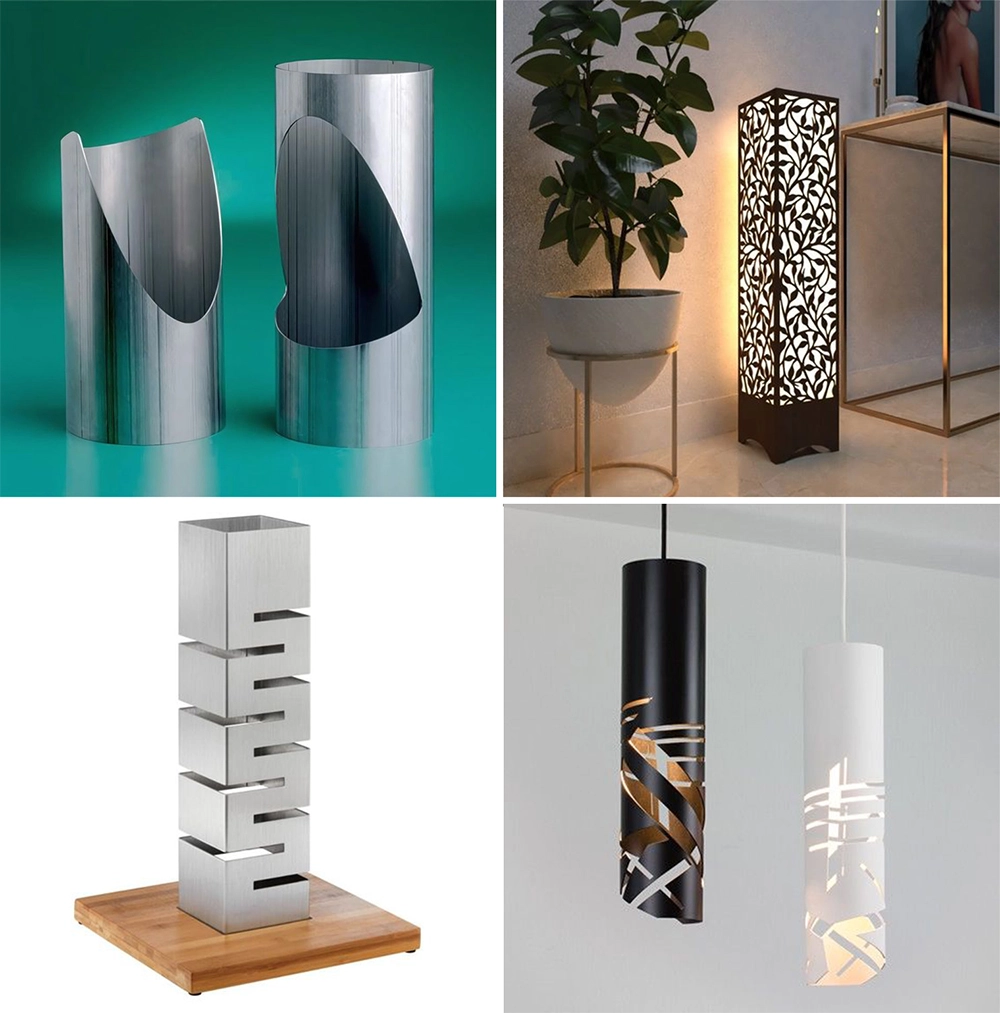

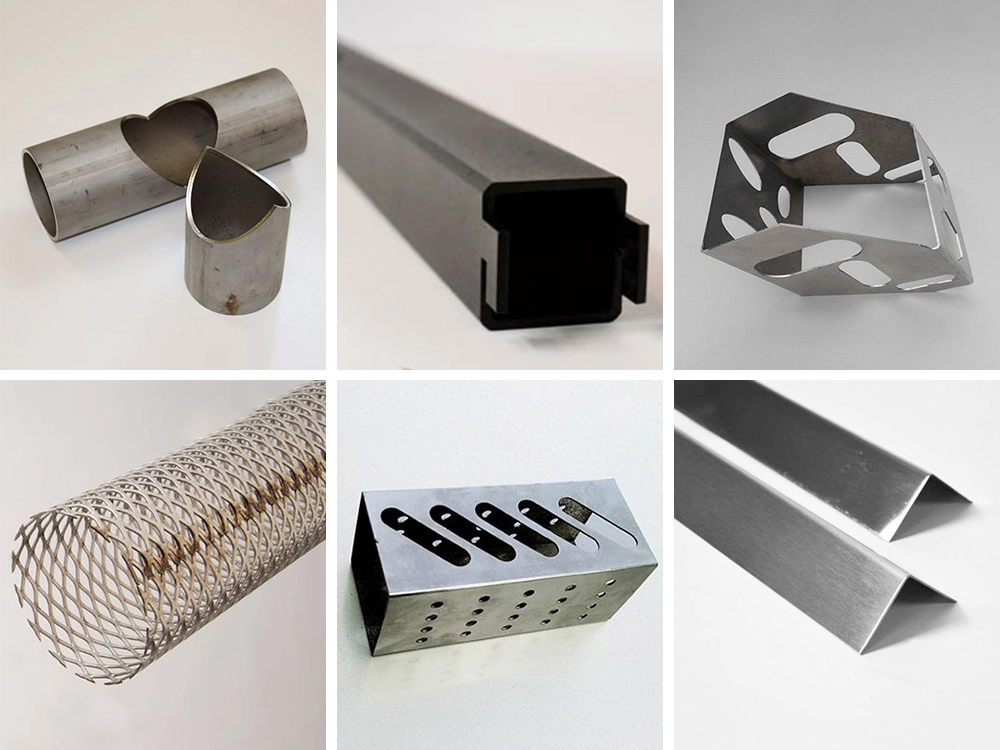

Application Scope of Fiber Laser Tube Cutting Machine

Materials

Metal pipes such as stainless steel, carbon steel, alloy steel, silicon steel, aluminum alloy, titanium, copper, manganese steel, galvanized sheet, etc.

Shapes

square tubes, round tubes, rectangular tubes, elliptical tubes, flat tubes, polygonal tubes, channel steel, angle steel, I-beams, and various other types of tubes.

The Following Are the Processable Products of Fiber Laser Tube Cutting Machine

How to Choose the Nozzle for a Fiber Laser Cutting Machine?

The nozzle is a critical component of a fiber laser cutting machine, primarily used to guide the laser beam and assist gas, enabling efficient and precise cutting processes.

- Material Selection: Nozzles are typically made of copper due to its excellent electrical and thermal conductivity, ensuring the transmission of capacitive signals and stable laser beam delivery. Copper nozzles are also considered the preferred type for fiber lasers because of their high durability and long lifespan.

- Nozzle Types: Common nozzle types include single-layer and double-layer nozzles. Single-layer nozzles are suitable for basic cutting needs, while double-layer nozzles offer higher precision and stability, making them ideal for more complex cutting tasks.

- Design Considerations: To improve cutting quality, factors such as nozzle concentricity and manufacturing precision must be considered to ensure the laser beam and assist gas are accurately focused on the workpiece.

- Application and Selection: The choice of nozzle depends on specific cutting requirements. For example, smaller aperture nozzles are suitable for cutting thin sheets, while larger apertures and higher gas pressure are needed for thick sheets. Additionally, the material being cut also influences nozzle selection.

- Maintenance and Replacement: Laser nozzles require regular inspection and replacement. Keeping the nozzle clean and ensuring proper installation are also crucial factors in maintaining cutting quality.

| Model | CK-2260-T |

|---|---|

| Cutting Area | 200mm * 6000mm (processing size can be customized) |

| Bed Frame/Gantry | High-strength heavy-duty bed support, aviation-grade aluminum alloy gantry |

| Driving Mode | servo motor * 4 |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Reducer | France Motoreducer reducer |

| Fan | 1.5KW high power fan |

| Proportional Valve | SMC |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Electrical Components | Schneider |

| Laser Generator | Raycus CE |

| Laser Head | Raytools |

| Fiber Laser Power | 1500W/2000W/3000W etc. |

| Cooling | S&A Special water chiller for fiber laser generator |

| Control System | FSCUT laser tube cutting machine dedicated system |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V |

| Compatible Software | Artcam, type3, CAD, CDR,AI etc. |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm/1000mm |

| X.Y Axis Max Moving Speed | 100m/min |

| Maximum Acceleration | 1.0G |

| Weight | 5500kg |

| Dimensions | 9400*1850*2150mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.