Small Dual-Process CNC Router With Two Spindles That Can Be Automatically Switched

Small Dual-Process CNC Wood Router With Two Switchable Spindles

[Function Description]

The small dual-process CNC router is a compact CNC machine designed for products that require two types of tools. It is equipped with a 600*900mm workbench and two high-speed air-cooled spindles. The two spindles can automatically switch, which is very suitable for small studios, hobbyists and places with limited space. During processing, the two spindles are equipped with different tools at the same time. The spindles are controlled and switched using cylinders. For example, when a workpiece needs to be engraved and cut at the same time, the two spindles can be equipped with engraving and cutting tools at the same time. During engraving, the control system automatically controls the engraving spindle to perform the engraving task. After the engraving task is completed, the engraving spindle is automatically retracted, and the control system drives the cutting spindle to work automatically. The switching of the two spindles takes only 1 second. The processing task that originally required two processes to complete can be completed at one time using the dual-process CNC router, and there is no need to stop the machine in the middle, change the tool, calibrate the tool, and no manual intervention is required, which improves efficiency and saves time.

Due to the dual-process automatic switching design of the dual-process CNC router, the tool change time can be effectively reduced, and the processing efficiency can be improved by 30%-50%. It can replace 2-3 small ordinary CNC routers and is very suitable for batch processing of various small handicrafts, wood carvings, badges, badges, signs, pendants, PCBs, etc.

Advantages of Small CNC Routers That Can Switch Between Two Processes

- Equipped with a 600*900mm (2*3ft) worktable, suitable for processing various small products.

- Two 3.5KW high-speed air-cooled spindle motors, four-bearing design, speed 18000r/m, using ER20 tool holder, can clamp any tool handle within 12.7mm.

- Aluminum alloy T-slot worktable, using a pressure plate to fix the material, can flexibly fix raw materials of various sizes, easy to use.

- Consumable-free processing: No tools, ink, or other consumables required, resulting in minimal operating costs.

- Automatic tool setting instrument. Even if the tool lengths installed on the two spindles are different, the automatic tool setting instrument can automatically calibrate the Z-axis height without manual calibration, saving time and improving efficiency.

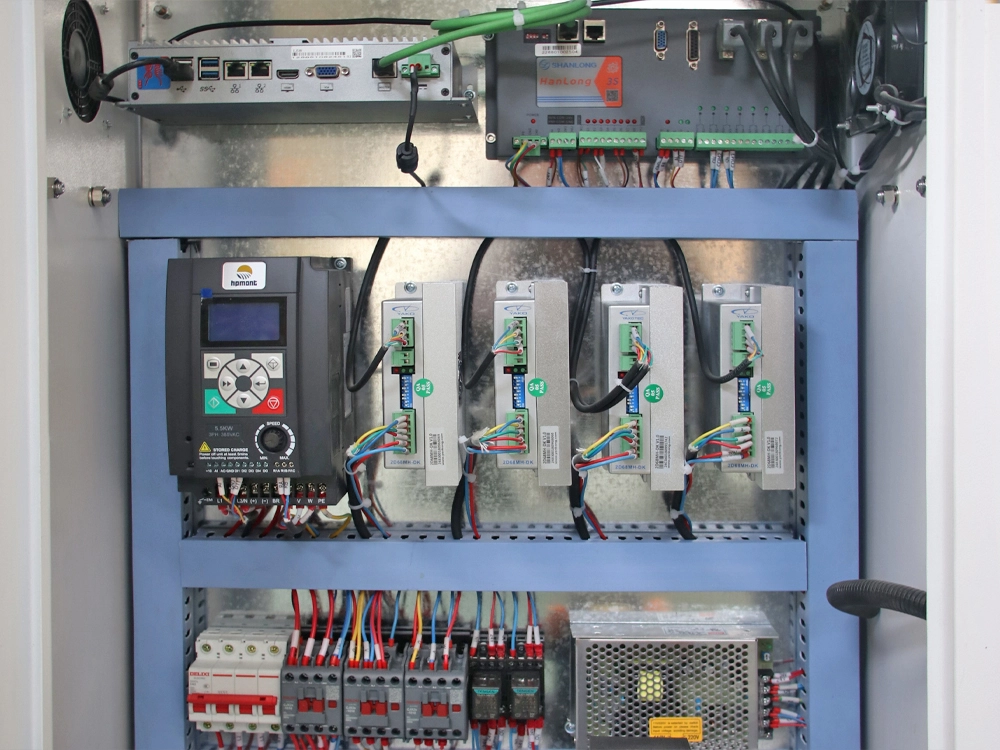

- Independent control chassis, inverter, driver, transformer, and control system are all placed inside the chassis to prevent dust generated by machine processing from entering the chassis and affecting the life of the machine.

- Using a large torque drive motor, the maximum idle speed of the machine can reach 18000mm/min, effectively improving work efficiency.

- XYZ axes all use Taiwan Hiwin linear guides/linear bearings, XY axis transmission uses high-precision helical racks, and Z axis uses Taiwan TBI ball screw.

- Even small machines use thickened square steel welded bed, heavy-duty gantry bracket and support columns, which can ensure the service life of the machine is longer and can work 24 hours a day.

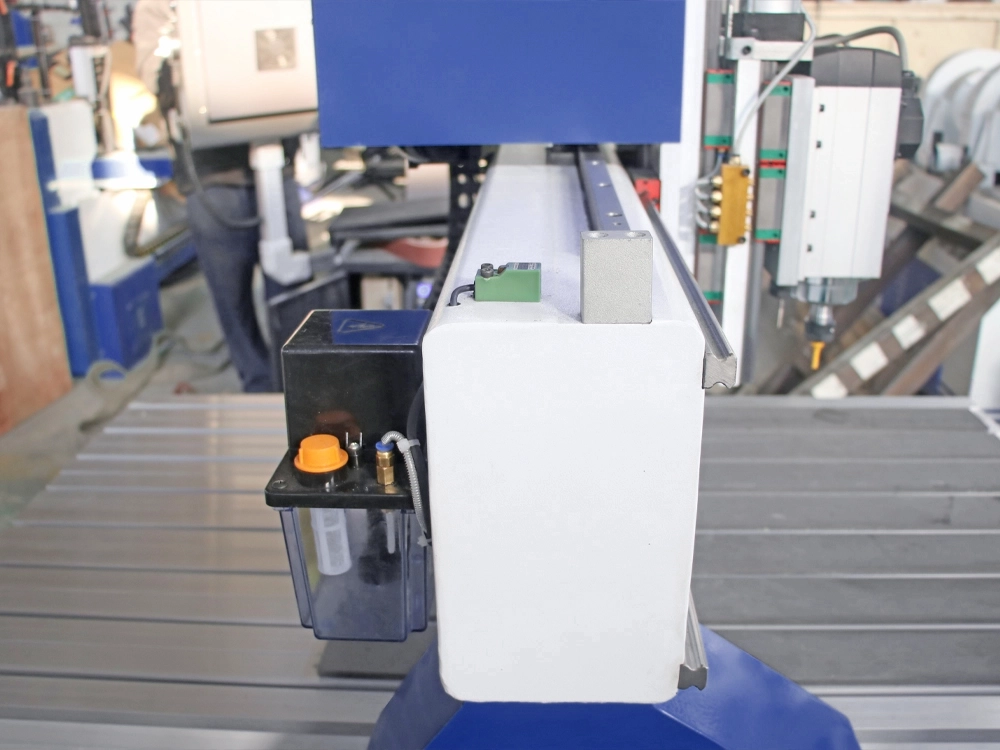

- Equipped with a fully automatic electric lubricating oil pot, the machine can be automatically maintained without manual intervention, which is more convenient.

- Using Shanlong CNC system, compatible with various CAD/CAM type software, it automatically controls the switching of the two spindles during the processing, without manual operation, simple to use, and very easy to get started.

Details of a Small CNC Router With Dual-Process Switching

- Two spindles

Equipped with two air-cooled spindles, which can be equipped with different tools and automatically switch according to needs during processing.

- Automatic tool setting instrument

Automatically calibrate the error between tools during processing, without manual calibration, easy to use and time saving.

- Automatic lubricating oil pot

Fully automatic lubrication and maintenance of the machine transmission position, without manual lubrication.

- Strengthened flame-retardant drag chain

Built-in machine control cable to protect the cable from damage.

- Independent control cabinet

Used to place key components such as inverters, drives, transformers, control systems, etc., to isolate external environmental pollution.

- Heavy duty thickened gantry

The x-axis uses two Taiwan Hiwin guide rails and high-precision helical gear dimensions, which have fast running speed and higher precision.

Technical Parameters of a Small CNC Router Capable of Automatically Switching Between Two Spindles

| Model | CK-6090-2T |

|---|---|

| Processing Size | 600*900*200mm (processing size can be customized) |

| Gantry | Thickened aged steel gantry, steel beam |

| Bed Base | Machining center bed processing (heavy duty bed) |

| Spindle Power | CATEKCNC dedicated 3.5KW high speed air-cooled spindle * 2 |

| Drive Mode | Stepping/servo motor |

| Spindle Speed | 0-18000r/min |

| Mesa | Aluminum alloy T-slot table (vacuum adsorption table optional) |

| Transmission Mode | The XY axis uses high-precision helical rack/gear, and the Z axis uses Taiwan TBI ball screw |

| Guideway | Taiwan Hiwin high precision linear square guide rails/linear bearings |

| Tool Shank Diameter That Can Be Clamped | 3.175mm,4mm,6mm,8mm,10mm,12.7mm etc. |

| Control System | Shanlong CNC system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam,type3,CAD,CDR,solidworks,UG,powermill etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt etc. |

| Security System | Photoelectric sensor limiter |

| Repeat Positioning | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Empty Line Speed | 18000mm/min |

| Maximum Processing Speed | 12000mm/min |

| Dimensions | 1300*1100*1350mm |

| Weight | 650kg |

What Products Can the Small CNC Router With Dual-Process Switching Be Used to Process

Materials Used:

Wood, MDF, plywood, multi-ply, composite wood, hardwood, engineered wood, PVC, PCB, graphite, gypsum, foam, acrylic, plexiglass, double-sided board, engineering plastics, bakelite, EVA, carbon fiber, fiberglass, aluminum, copper, and aluminum alloys etc.

Application Products:

Handicrafts, wooden combs, wooden decorative paintings, badges, signs, doorplates, advertising characters, molds, pendants, gift boxes, models, puzzles, PCB lettering, electronic product shells and other products.

FAQs of Small Dual-Process CNC Router

The surface of the engraved product is rough and deformed:

- The tool is severely worn and needs to be replaced with a sharp tool.

- The material is not fixed stably. The material needs to be firmly fixed to prevent the material from loosening during processing.

- The tool does not match the drawing. The tool that matches the drawing parameters needs to be replaced.

Limit alarm:

- The machine limit stroke is set too small. Adjust the software parameters.

- The zero return operation is not performed after the machine is turned on. The xyz axis needs to be returned to zero.

- Limit trigger, check whether there are foreign objects on the guide rail.

The software cannot be opened:

- The file is too large, optimize the file.

- Check whether the software connection line is loose.

- Check whether the driver is installed correctly.

The spindle is abnormal:

- Check whether the voltage is abnormal.

- Check whether the inverter has an alarm.

- Check whether the connection line is detached.

Regular Maintenance

- Regularly check the oil level in the lubricating oil pot and add lubricating oil regularly.

- Regularly clean the spindle motor exhaust fan to prevent blockage.

- Regularly check the control chassis, clean the internal dust, and check the circuit.

- Regularly replace the tool, select the appropriate tool according to the hardness of the material, and avoid wasting materials due to inappropriate tools.

| Model | CK-6090-2T |

|---|---|

| Processing Size | 600*900*200mm (processing size can be customized) |

| Gantry | Thickened aged steel gantry, steel beam |

| Bed Base | Machining center bed processing (heavy duty bed) |

| Spindle Power | CATEKCNC dedicated 3.5KW high speed air-cooled spindle * 2 |

| Drive Mode | Stepping/servo motor |

| Spindle Speed | 0-18000r/min |

| Mesa | Aluminum alloy T-slot table (vacuum adsorption table optional) |

| Transmission Mode | The XY axis uses high-precision helical rack/gear, and the Z axis uses Taiwan TBI ball screw |

| Guideway | Taiwan Hiwin high precision linear square guide rails/linear bearings |

| Tool Shank Diameter That Can Be Clamped | 3.175mm,4mm,6mm,8mm,10mm,12.7mm etc. |

| Control System | Shanlong CNC system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam,type3,CAD,CDR,solidworks,UG,powermill etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt etc. |

| Security System | Photoelectric sensor limiter |

| Repeat Positioning | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Empty Line Speed | 18000mm/min |

| Maximum Processing Speed | 12000mm/min |

| Dimensions | 1300*1100*1350mm |

| Weight | 650kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.