4x8 CNC Woodworking Router with Rotary Tool Magazine on Sale

CNC Wood Router with Carousel Automatic Tool Changer for Sale

[Function Description]

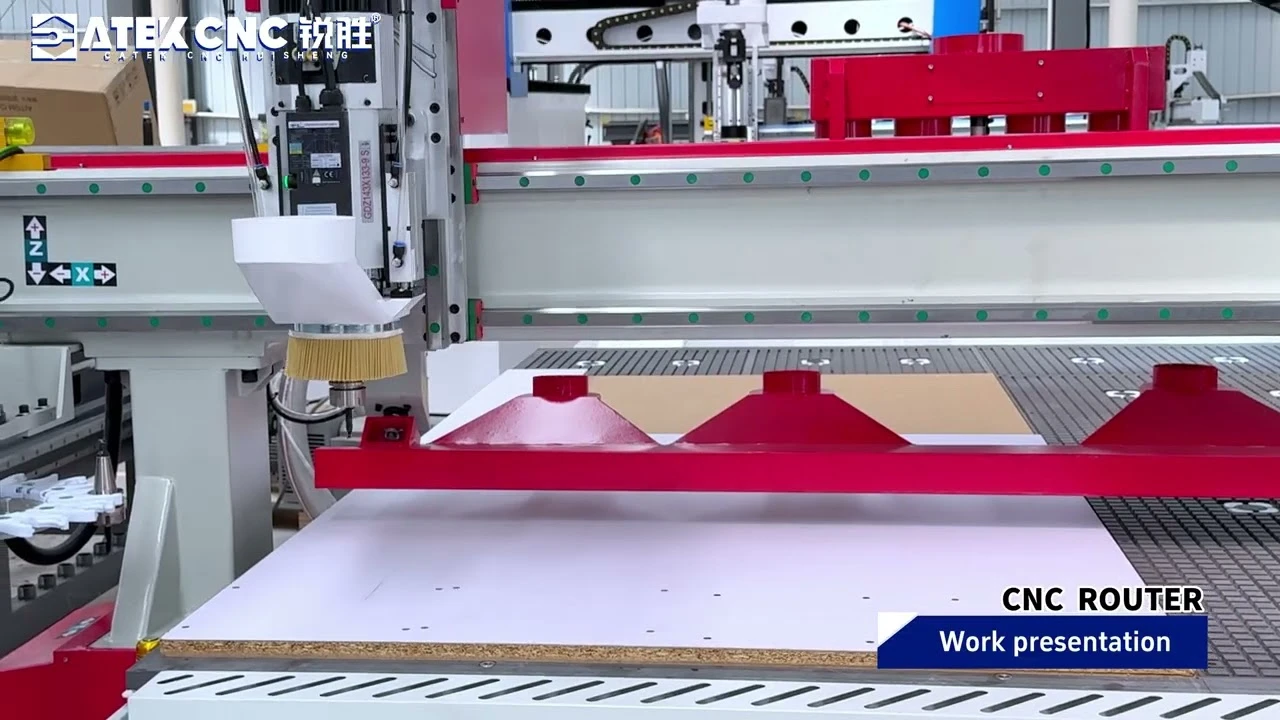

Overview of 4x8 CNC Router with Carousel Tool Changer

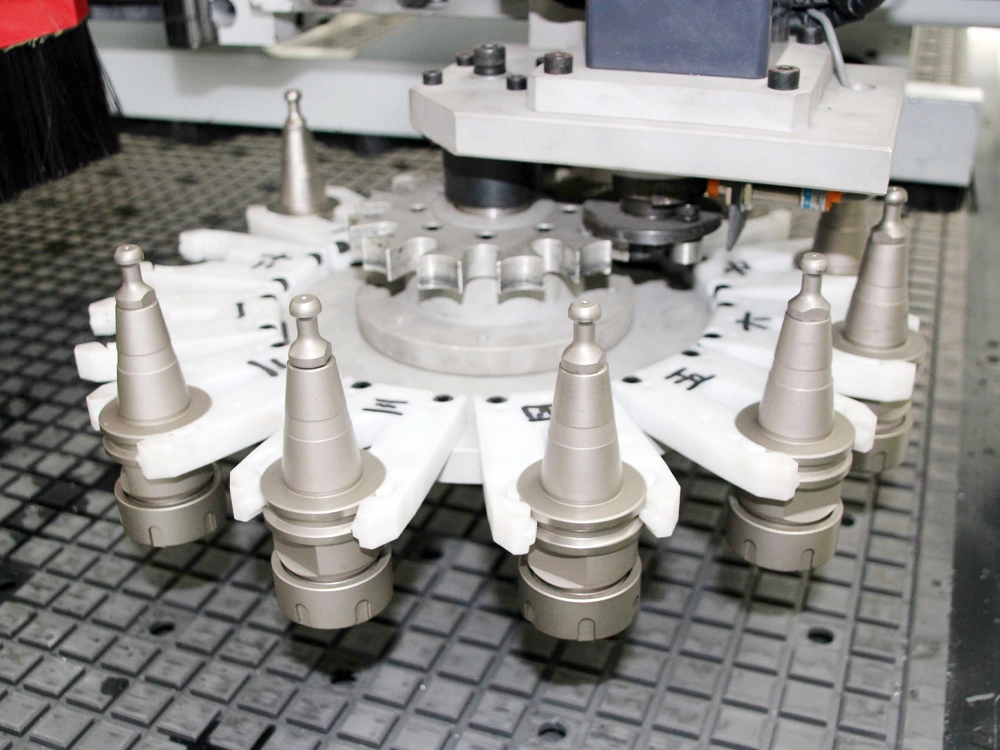

The CNC router with carousel-type tool change kit uses a 9KW automatic tool change spindle and a carousel tool change magazine with a maximum capacity of 12 tools. It can realize automatic tool change when processing products that require multiple processing techniques. Taking the complex cabinet door processing as an example, the surface of the board must first be milled, and some parts must be engraved. After the processing is completed, it must be cut with a cutting tool or drilled with a drilling tool. Traditional processing methods require frequent shutdowns and manual tool changes before continuing processing, while machines equipped with automatic tool change functions can effectively save the time wasted by manual tool changes. This CNC router can be used for processing various complex processes, and can cut, drill, slot, mill and other operations on the board. It is suitable for various factories and personal studios, can greatly improve production efficiency, make complex work easier to complete, and the processed products are more standardized and more refined in appearance, greatly improving product competitiveness.

The CNC router is easy to operate and the CNC program is highly integrated. Simply copy the drawing to the machine and install all the required tools, such as pre-milling cutters, carving knives, ball-end cutters, drill bits, cutting knives, milling cutters, etc., in the carousel-style tool magazine at once. The control system will switch different tools when performing different processing techniques to achieve automatic tool change processing. At the same time, the machine is equipped with an automatic tool setting instrument, which can automatically calibrate the tool zero point regardless of the length or diameter of the tool, without manual intervention, thereby reducing labor costs, improving production efficiency, and shortening production cycles.

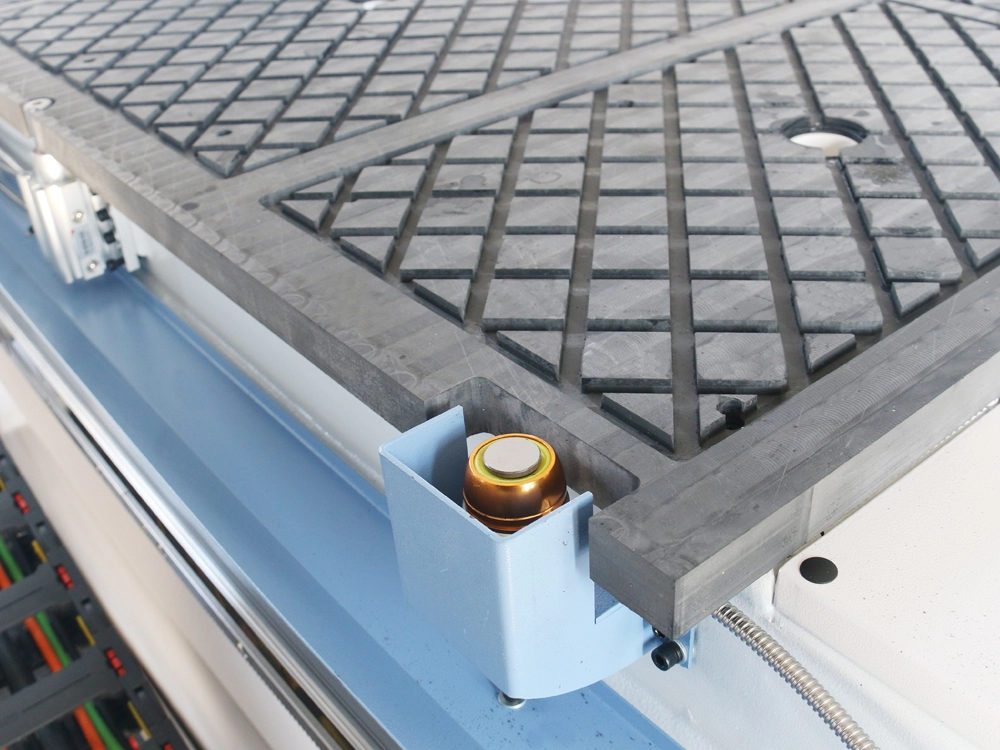

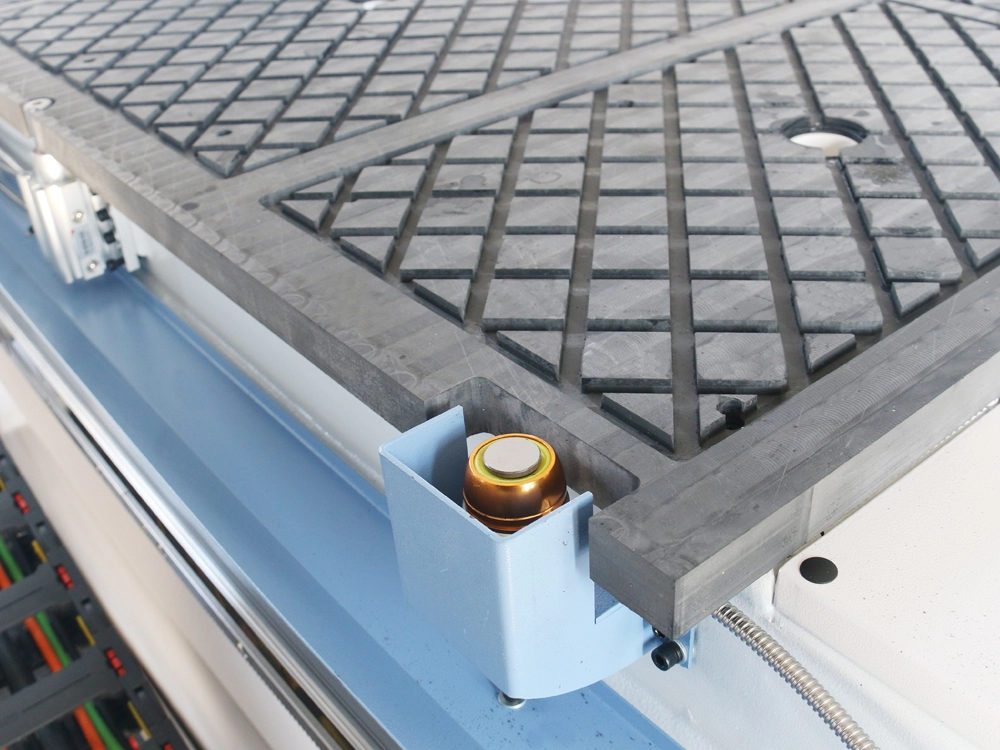

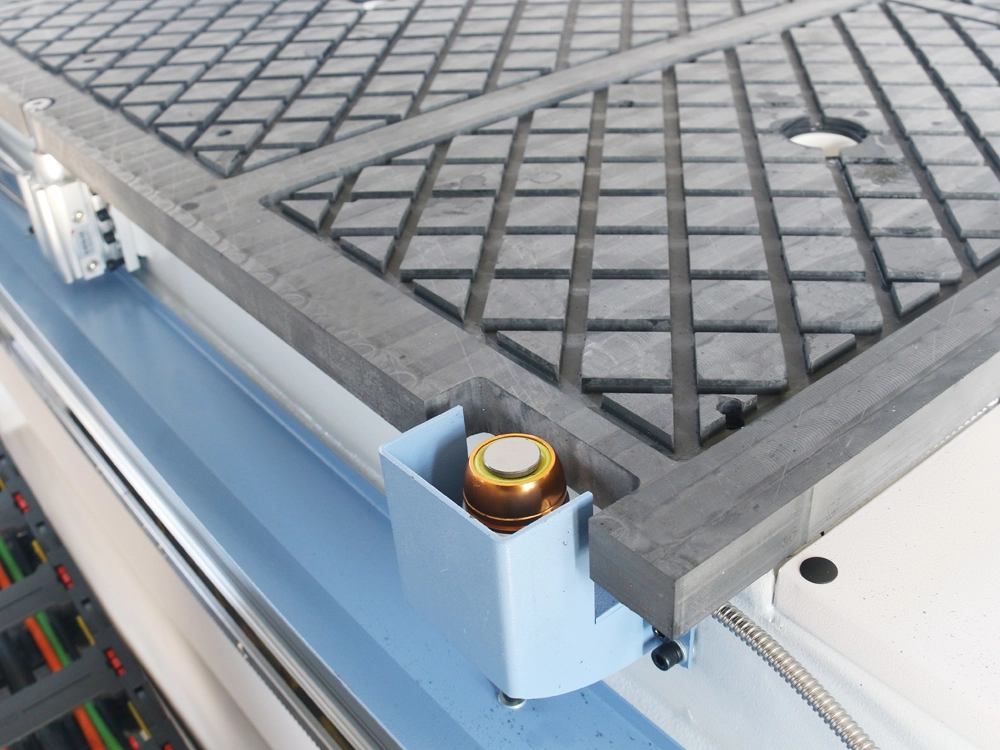

How Does an Automatic Tool Setting Device Work?

Before using the first tool for processing on a CNC router, the tool slowly moves toward the surface sensor of the tool setting device at a set speed. When the tool tip slightly touches the surface sensor, the high-precision switch sensor is triggered. At this moment, the automatic tool setting device immediately sends a sensing signal, and the CNC system automatically records the Z-axis coordinate value at the instant of triggering. After a tool change, the CNC system controls the newly replaced tool to touch the automatic tool setting device again. Upon sensing the dimensions of the second tool, the CNC system automatically updates the tool length compensation value, corrects and calculates the Z-axis program origin of the workpiece coordinate system for the second tool, thereby achieving automatic tool setting and zero-point calibration. Automatic tool setting can save over 95% of manual tool setting time, with errors controlled within 0.005 - 0.01mm, effectively improving processing efficiency and precision.

Advantages of 4*8 CNC Router with Carousel Tool Changer Kit

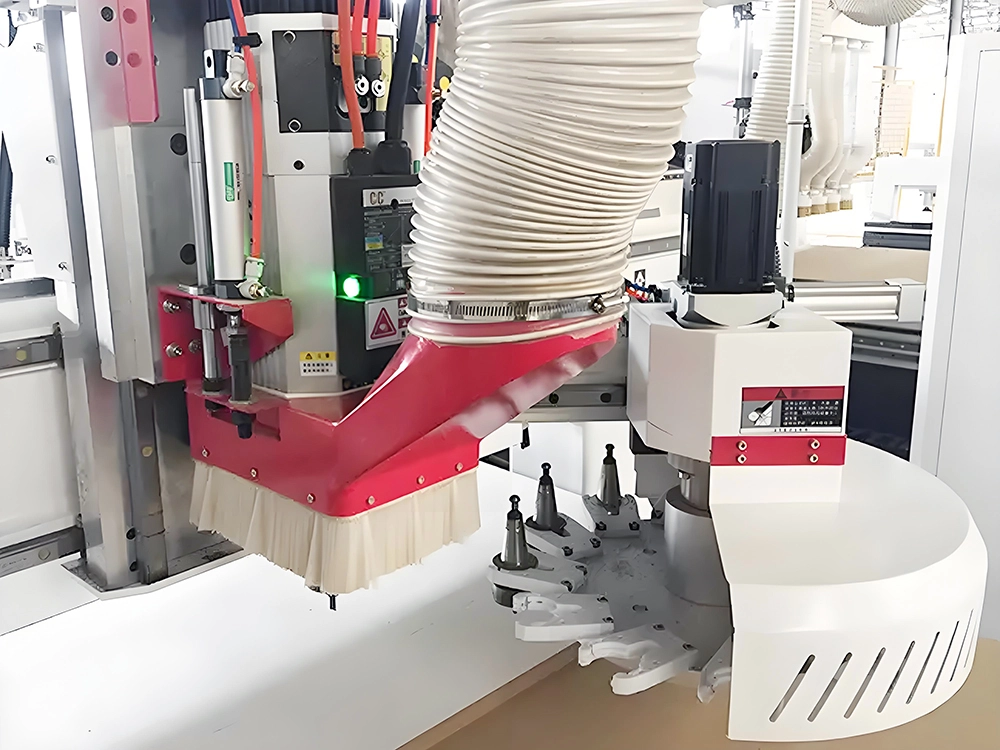

- The 9KW HQD automatic tool-changing spindle, air-cooled, uses an ISO30 tool holder and ER32 collet, enabling automatic switching of 8/12/16 tools. It can hold tool shanks up to 20mm, offering wide compatibility with various tools.

- The Taiwan LNC four-axis rotary tool-changing CNC nesting machine control system features an intuitive interface and supports power-off resumption. Optional expansion kits include automatic loading/unloading platforms, automatic labeling devices, cutting saw blades, pressure rollers, and 5+4 drilling packages.

- An 11KW high-power water-ring vacuum pump, paired with a 6-zone, 24-hole vacuum adsorption table and 4+2 positioning cylinders, ensures rapid positioning and processing of boards.

- The automatic tool setting device allows for one-click positioning and tool calibration, regardless of tool length or size, effectively saving time wasted on manual tool setting.

- A dual-barrel bag-type dust collector automatically collects dust during processing, ensuring environmentally friendly operation that complies with EU ROHS standards.

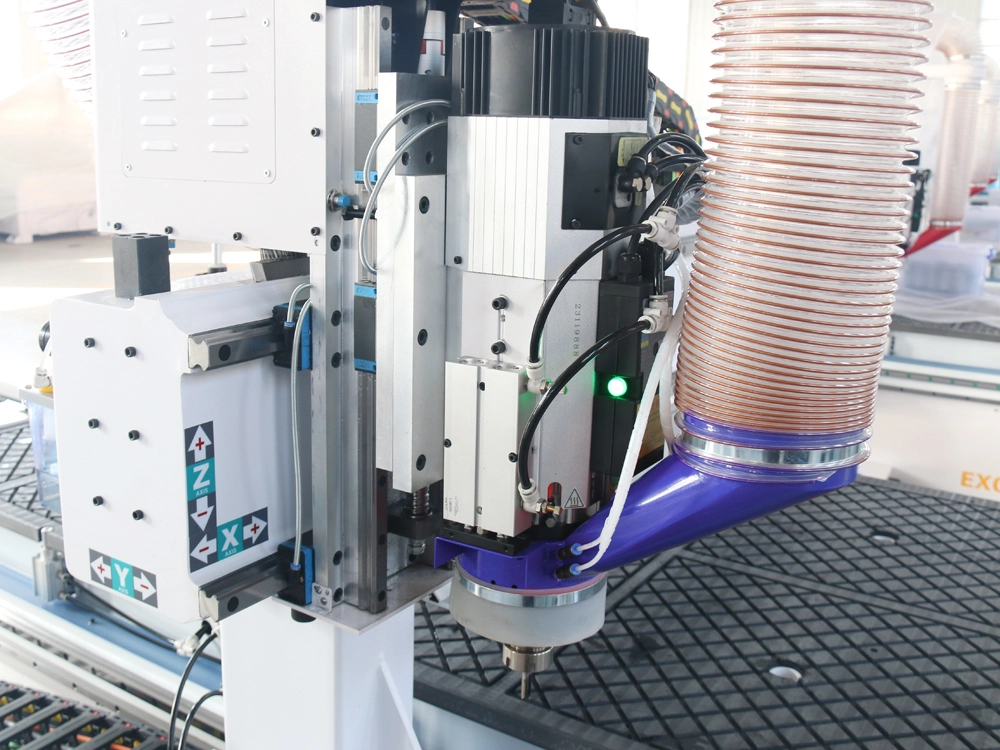

- Hiwin 30 linear guides and sliders provide greater stability and smoother operation compared to ordinary 25 linear guides.

- The 1.5KW high-power servo motor delivers high output torque, fast operation speed, and precise positioning.

- The heavy-duty, thickened square steel welded bed features a double-layer design, treated with annealing and vibration aging to reduce deformation, making it more suitable for long-term, high-intensity processing tasks.

- The machine supports various nesting and cabinet software, such as Cabinet Vision, TopSolid, CutList Plus, and ArtCAM.

Details of CNC Router with Vacuum Adsorption Table and Carousel Automatic Tool Changer

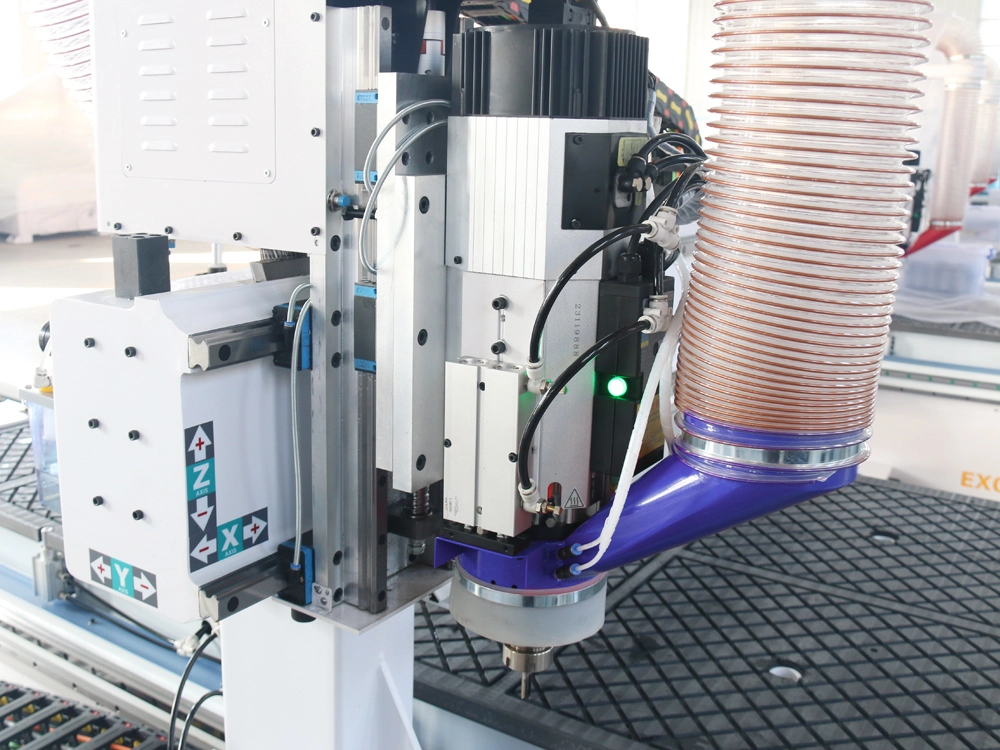

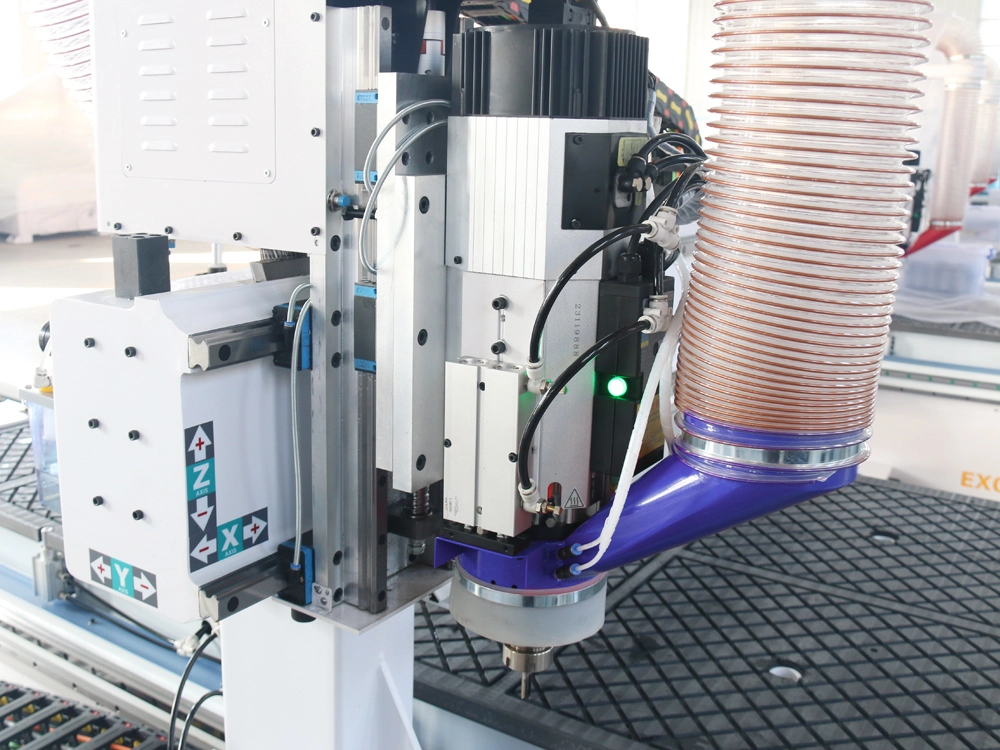

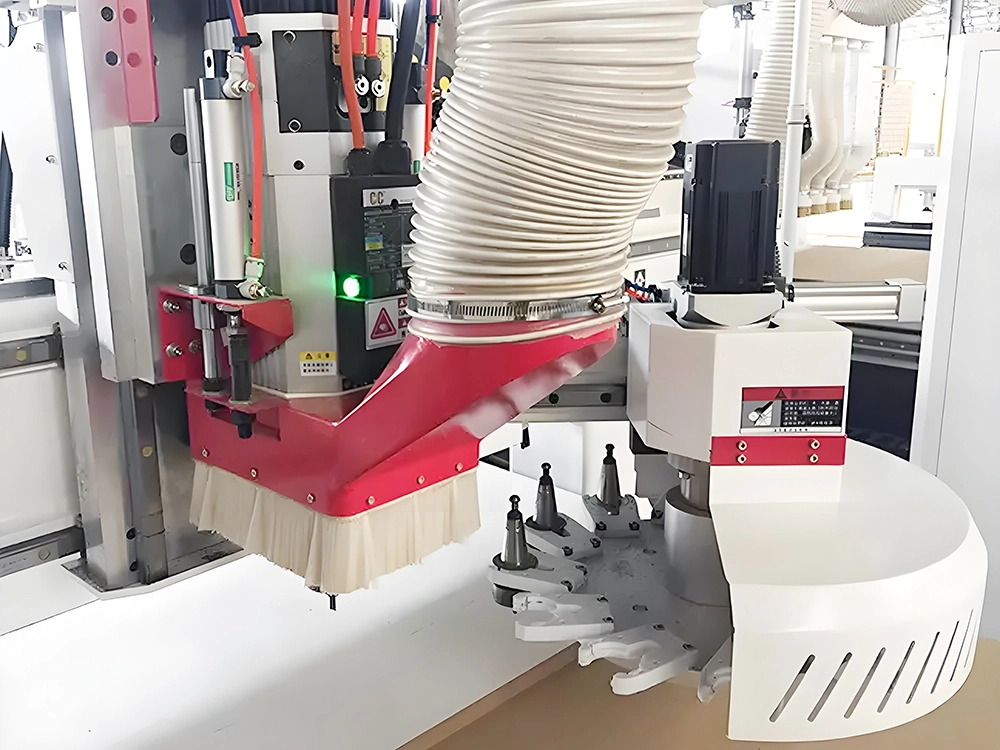

- Automatic tool change spindle

9KW automatic tool change spindle, air cooling, easy to use.

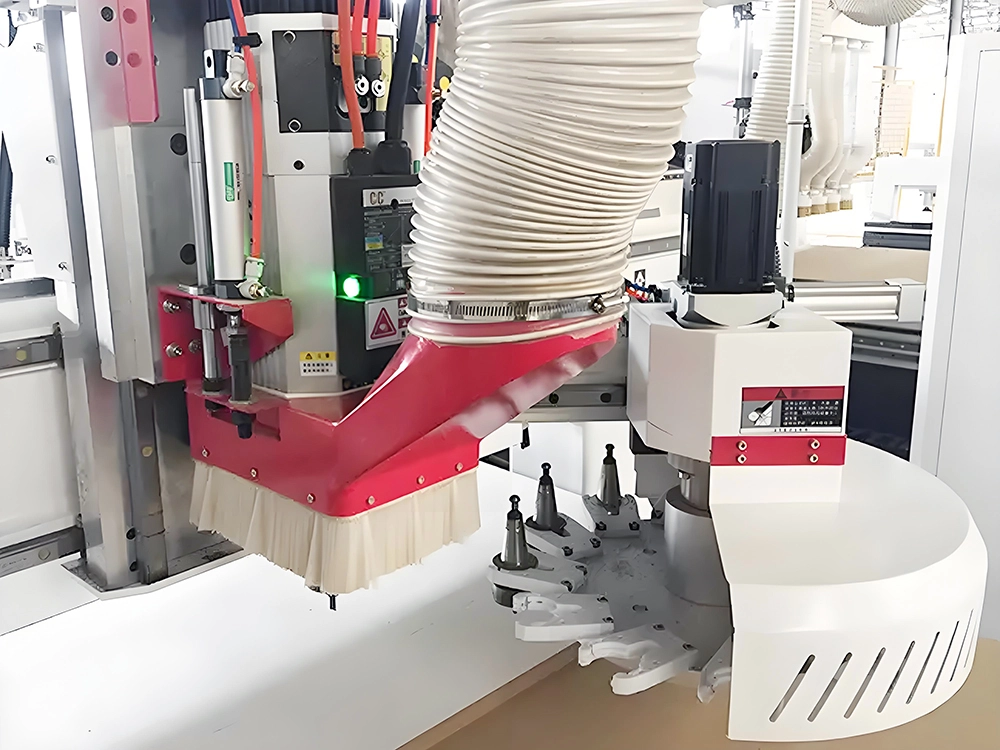

- Carousel type automatic tool changer

Large-capacity tool magazine, installed on the side of the machine, does not affect the maximum processing height.

- Vacuum adsorption workbench and automatic tool setting instrument

The vacuum adsorption workbench can quickly fix the plate, and the automatic tool setting instrument can instruct the control system to calculate the corresponding compensation amount according to the length and tool tip position of different tools.

- Tool blade removal fixture

Tool blade removal jig for easier tool replacement.

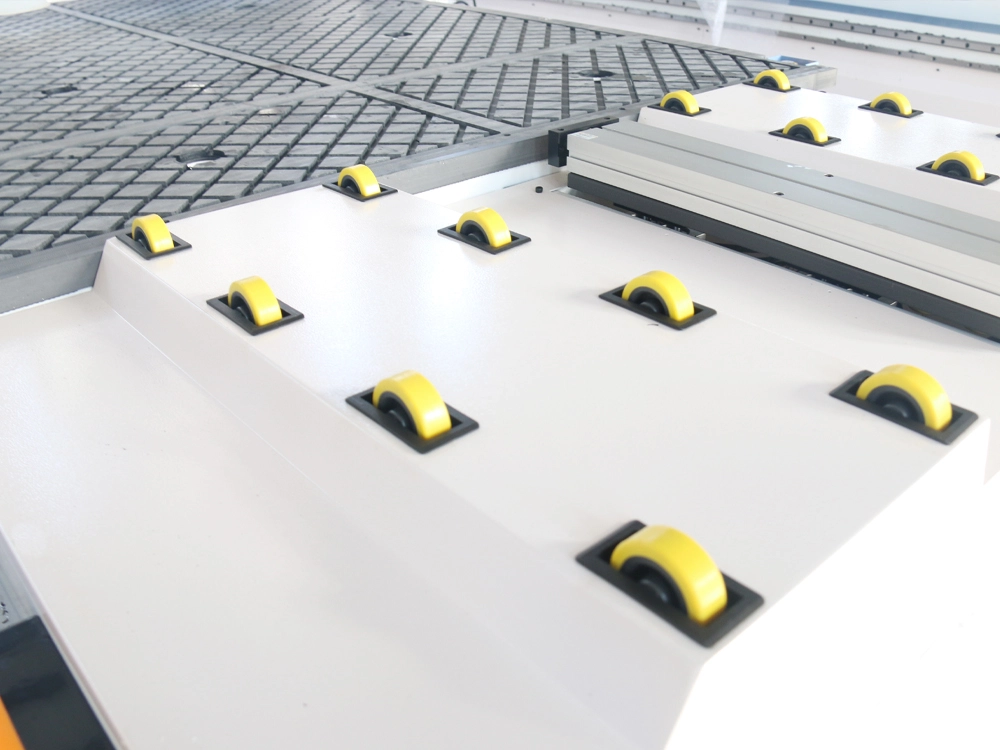

- Feeding roller

When loading, the plate is dragged on this device to reduce static friction with the table top, making loading more labor-saving and less likely to cause wear to the plate.

- Transmission system

High-precision helical racks and gears, low transmission noise and fast moving speed.

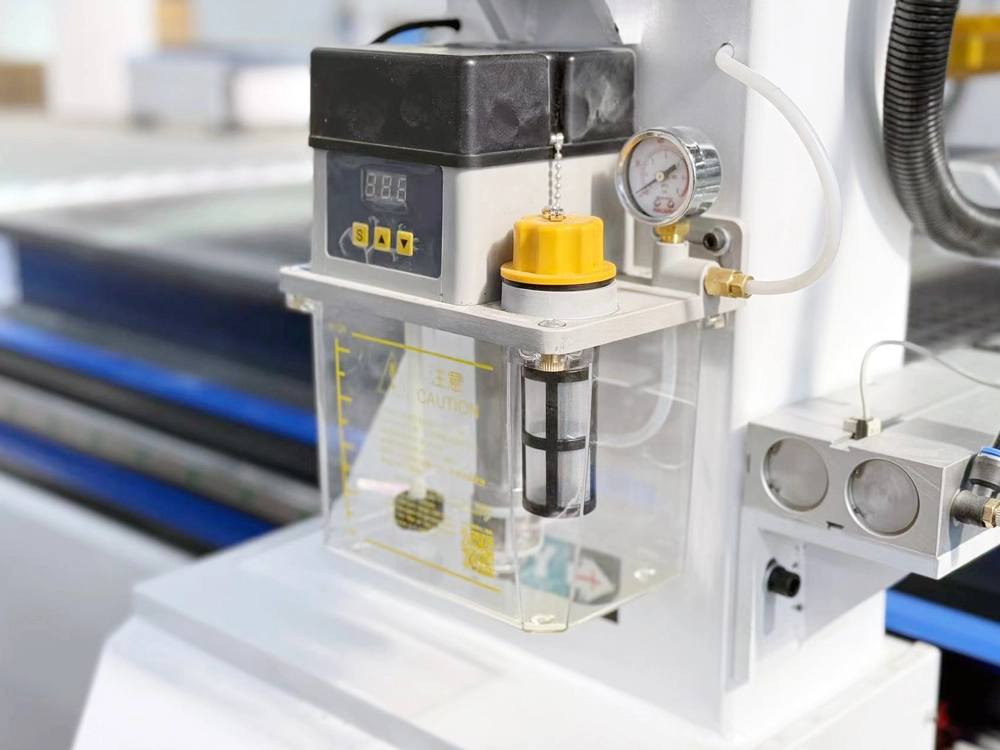

- Lubrication system

Automatic lubrication and maintenance system, maintenance is simpler and more convenient.

- Control button group

Button group for controlling processing start, vacuum adsorption start, and positioning start respectively

- Pulse handwheel

The position of each axis can be adjusted directly and easily.

Parameters of Carousel ATC CNC Router for Wood Processing

| Model | CK-1325-A |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 carousel tool magazine |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2900kg |

| Dimensions | 3900*2150*2100mm |

Optional Accessories for Carousel ATC CNC Router

| Spindle | Italian HSD spindle/Italian HITECO spindle |

| Servo Motor | Yaskawa servo motor/Delta servo motor |

| Control System | Syntec/NCStudio/Mach3 etc. |

| Vacuum Pump | Vortex air pump/rotary vane vacuum pump |

| Saw Blades | 6KW/7.5KW saw blade spindle |

| Pressure Roller | Double rod independent pneumatic pressure rollers can be individually controlled to fix the plate |

| Tool Changing Method | Linear tool changer (8/12/16) |

| Pneumatic Drill Bits | 5+4 drill bit magazine/CNC side milling angle head |

| Automatic Feeding | Automatic lifting loading platform |

| Automatic Unloading | Rolling automatic unloading platform |

| Rotation Axis | 3D carving fourth axis rotation axis |

| Oscillating Knife | Oscillating knife for cutting paper/leather/foam/cloth etc |

| Camera | CCD camera for scanning, printing and cutting |

Optional Configurations for Carousel ATC CNC Router

- 5+4 pneumatic drilling device for fast drilling.

- Side milling device for side drilling tasks.

- Saw blade cutting device for cutting multiple layers of plates at one time or for fast cutting of single layers of plates.

- Double-rod pneumatic rollers can fix the processed materials without using a vacuum adsorption workbench to prevent the materials from moving during processing.

- Lifting automatic loading platform, no manual handling required, the machine automatically transports the plates to be processed to the processing position.

- Rolling unloading platform, after processing, can automatically push the processed plates to the unloading platform through the pushing device, which can be connected to various production lines to save labor.

What Projects Can the Carousel ATC CNC Router Suitable for Woodworking Be Used to Process?

Cabinet door panels, indoor wooden doors, outdoor wooden doors, wardrobe door panels, cabinets, wooden furniture, office furniture, antique furniture, mahogany furniture, classical furniture, screens, doors and windows, lattices, corrugated boards, European furniture, computer desks, filing cabinets, wine cabinets, tatami, Lamino invisible connectors, three-in-one connectors, Lock & Lock connectors, etc. Processing wooden musical instruments, guitars, piano accessories, violins, cello accessories, etc. Processing advertising characters, crystal characters, outdoor billboards, advertising logos, etc.

The Following Are the Processable Products of Carousel ATC CNC Router

How to Use a CNC Router with Automatic Tool Changer?

- When the machine is shipped, we will provide you with a USB drive containing instructional videos and design software for the machine. You can refer to the tutorial videos for learning.

- We can also provide you with the machine's design software immediately after your purchase, allowing you to start learning how to create designs in advance.

- After receiving the machine, we can offer remote online guidance or conduct remote training via video chat.

- If needed, we can provide on-site training services.

- All models of CNC routers are pre-configured with all parameters before shipment. Upon receipt, you can start using the machine directly without needing to set up the parameters again.

| Model | CK-1325-A |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 carousel tool magazine |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Syntec / NCStudio / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2900kg |

| Dimensions | 3900*2150*2100mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.