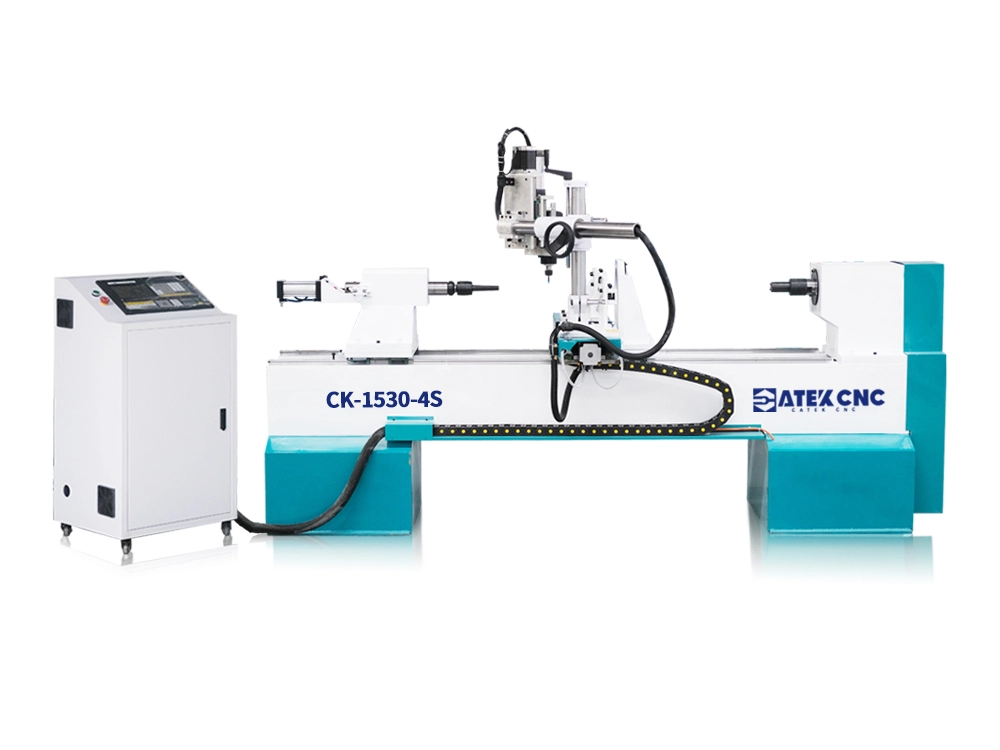

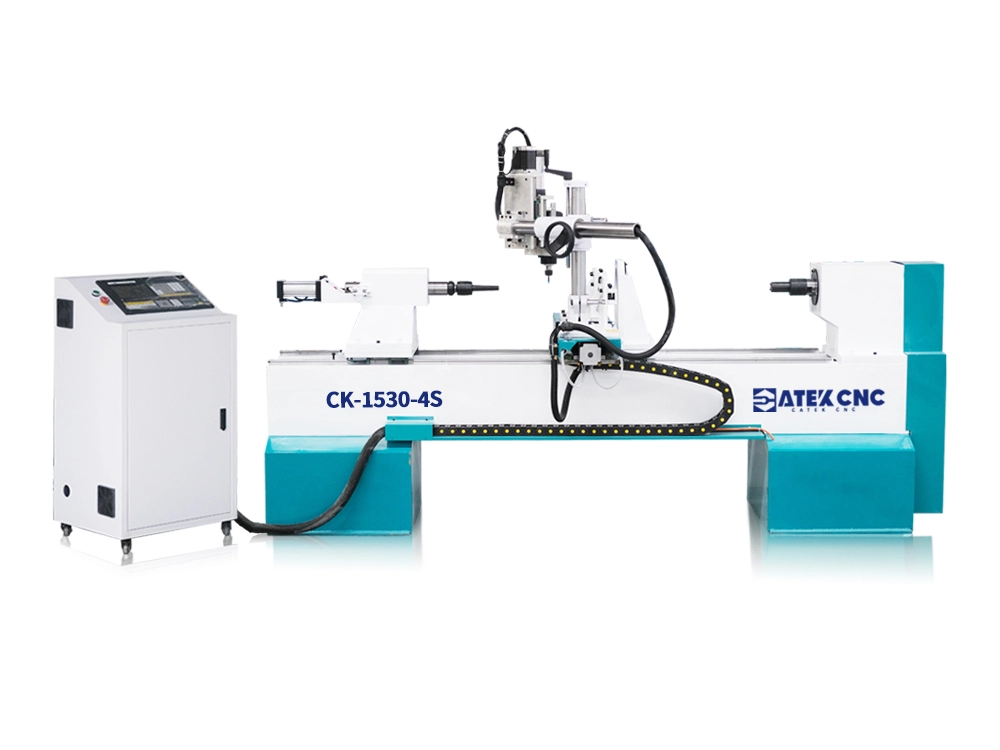

Four-Axis CNC Woodworking Lathe Machine for Wood Carving

CNC Wood Carving Lathe with Four-Axis Linkage for Sculptures

[Function Description]

What Is a Multifunctional Four-Axis CNC Woodworking Lathe?

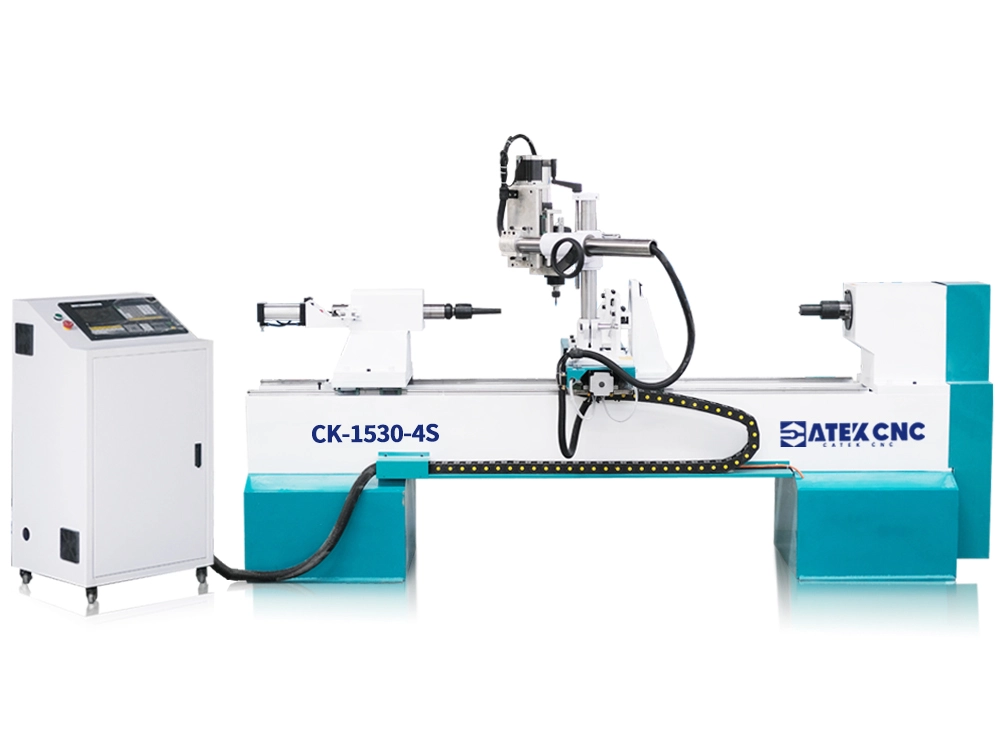

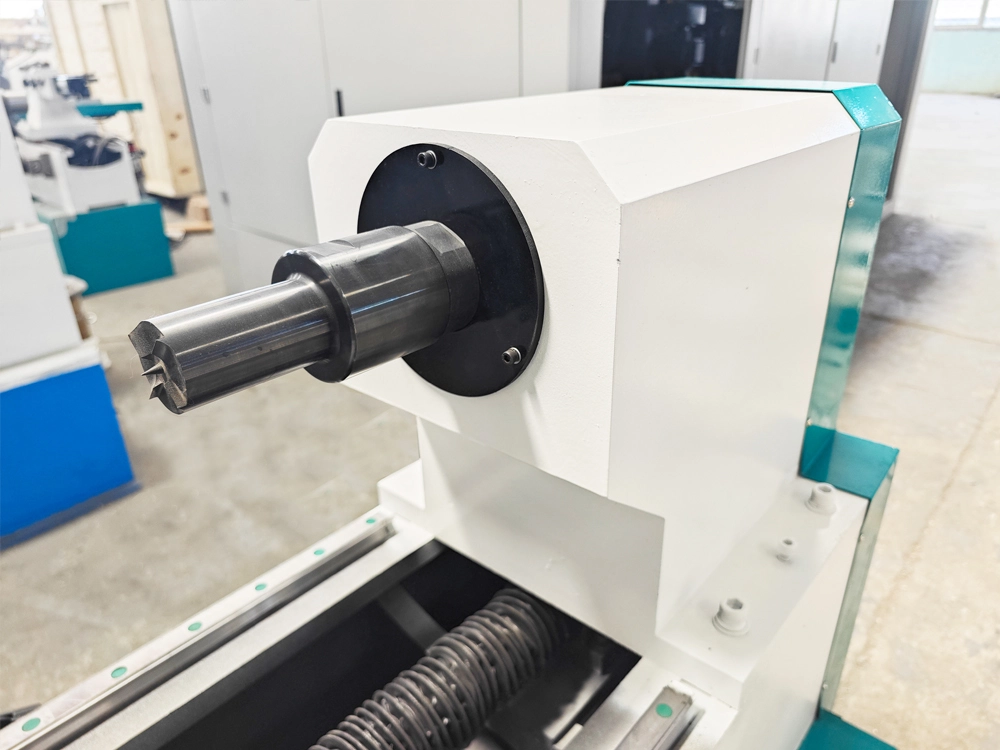

The four-axis CNC wood lathe is based on the ordinary CK-1530 model, replacing the drivce-spindle with an indexable A-axis, and adding a universal bracket and a multi-function spindle. The main motor of the A-axis has been replaced with a 4KW high-speed rotating servo motor, which can switch between speed mode and position mode. When turning wood, the speed mode is used. At this time, the machine drives the workpiece for turning through high-speed rotation; the position mode is used when milling and carving. The machine can rotate the workpiece by a specified angle to accurately control the engraving position of the workpiece.The milling and engraving function uses a high-speed air-cooled spindle with a speed of up to 18000rpm. It can quickly process wood and the surface smoother. Through the cooperation of the servo motor and the high-speed air-cooled spindle, it can realize slotting, drilling, milling, 3D engraving, four-axis linkage engraving and other functions, making the machine more widely used and suitable for a variety of processing scenarios. Whether it is amateurs, personal studios, or large factories, this CNC woodworking lathe can be used.

What Is the Four-Axis Four-Link Function?

The four-axis linkage function refers to the ability of the control system to simultaneously control the linear or rotational movements of four motion axes (X, Y, Z linear axes and one rotational axis, the A-axis), with each axis capable of coordinating with the others. It is important to note that the three linear axes can be specified through programming. During turning, the bilateral cutting tools are programmed as the X and Y axes, while the movement of the cross slide is programmed as the Z axis. When spindle engraving or milling is required, the turining tool's operation is paused. The left and right movements of the multifunctional spindle are programmed as the Z axis, the front and back movements as the X axis, the vertical up and down movements as the Y axis, and the indexing rotation of the workpiece as the A axis. The CNC system can simultaneously control the coordinated operation of these four axes. The indexing rotation of the workpiece means that the engraving spindle can always process any position on its surface-of-revolution at at the optimal angle, reducing the number of workpiece clamping operations and avoiding the time waste and error accumulation caused by multiple clampings. This achieves the integration of multiple processes and reduces reliance on other specialized equipment. The four-axis linkage function not only enables flat engraving but also three-dimensional carving and milling of irregular workpieces.

Advantages of a CNC Wood Lathe with a 4-Axis Carving Kit

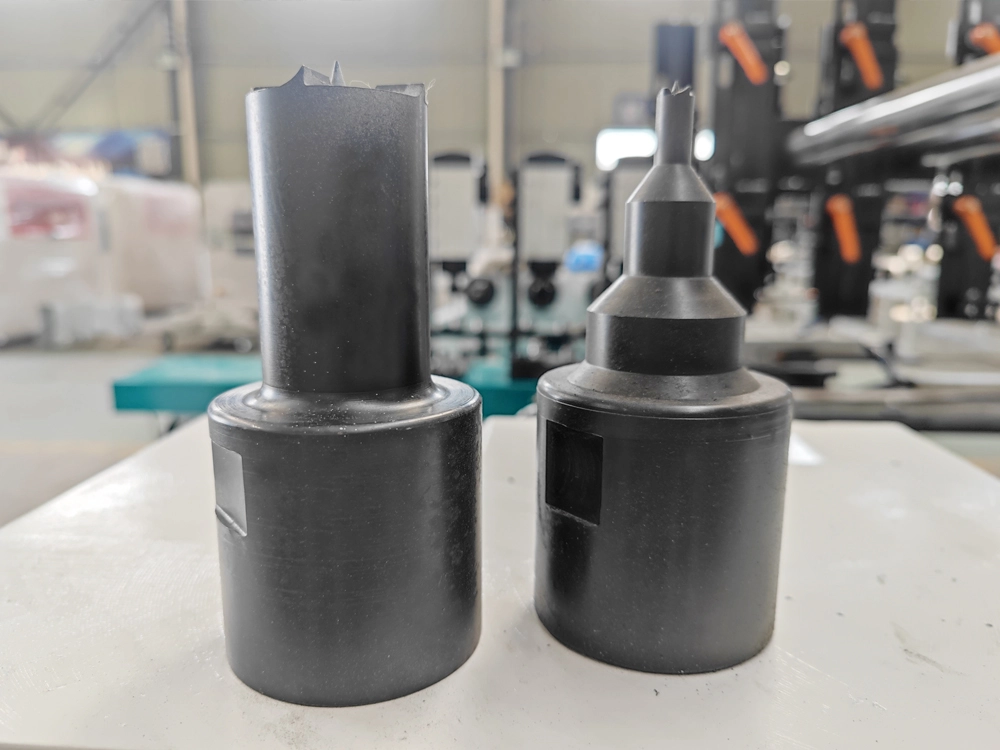

- Double-tool turning processing, can be equipped with various types of tools, and can be adapted to different processing products according to different tools, and can be replaced at will.

- Use Hiwin guide rails, Hiwin sliders, TBI high-precision ball screws, and fully automatic lubricating oil pots to automatically lubricate and maintain the transmission parts of the machine, and the service life is longer.

- The main motor uses a high-speed servo motor with a maximum speed of 6000r/min, which can support speed mode/position mode switching.

- Use 3.5KW high-speed air-cooled spindle, with four-axis four-linkage function, support multiple processing modes, such as milling, carving, drilling, etc., and can process various complex products.

- The machine uses a gray cast iron bed as a whole. After stress relief processing, the weight of a only bed reaches more than 1000kg, the processing is more stable, and there will be no jitter even at high speed.

- The CNC system uses G code to run, supports various CAD/CAM and other types of software, and is compatible with nc, txt, dxf and other format files.

- Only one clamping and tool setting are needed to complete the turning, engraving, drilling and other work of the workpiece.

- The operation interface is friendly and supports the full English interface. All key parameters have been set before delivery, and you can start processing with simple settings.

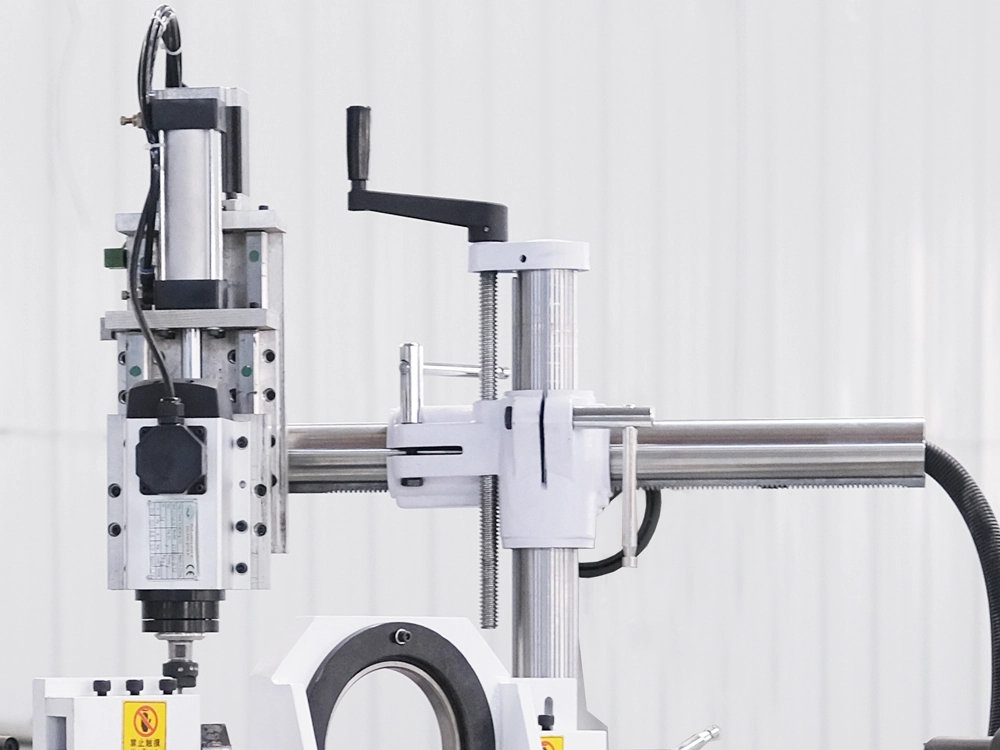

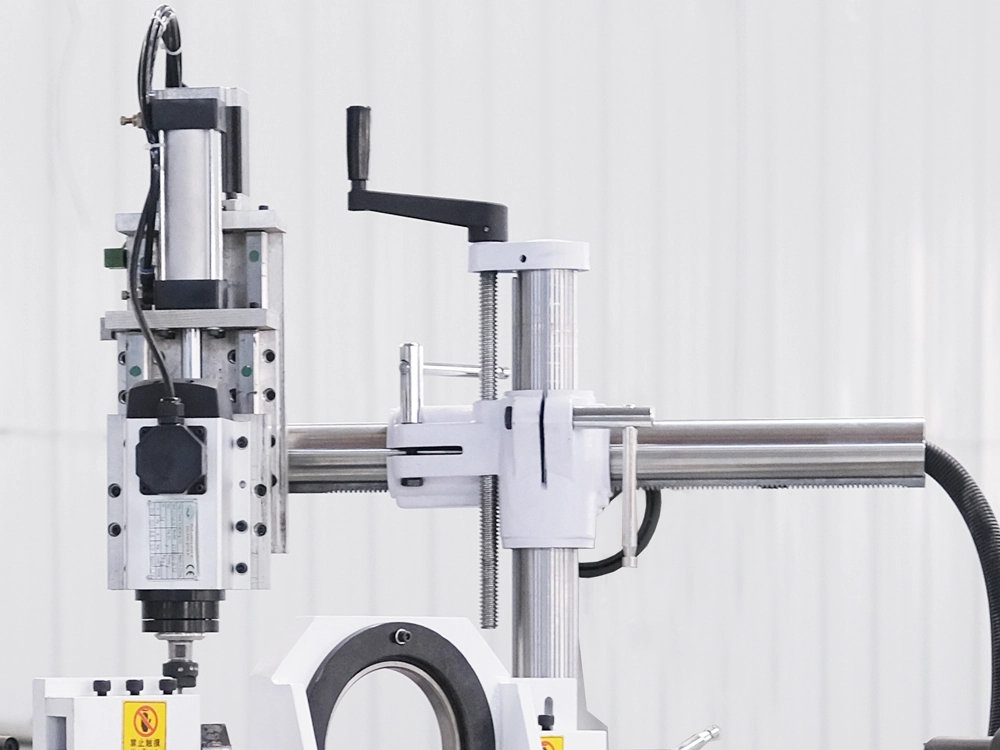

Details of Four-Axis Linkage CNC Wood Lathe

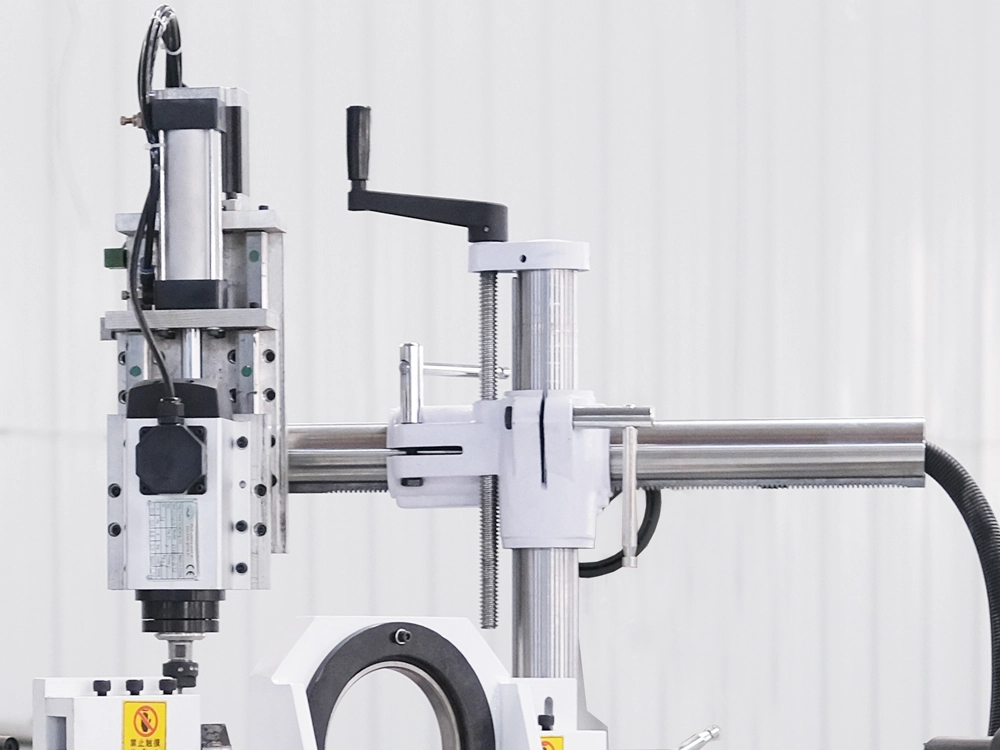

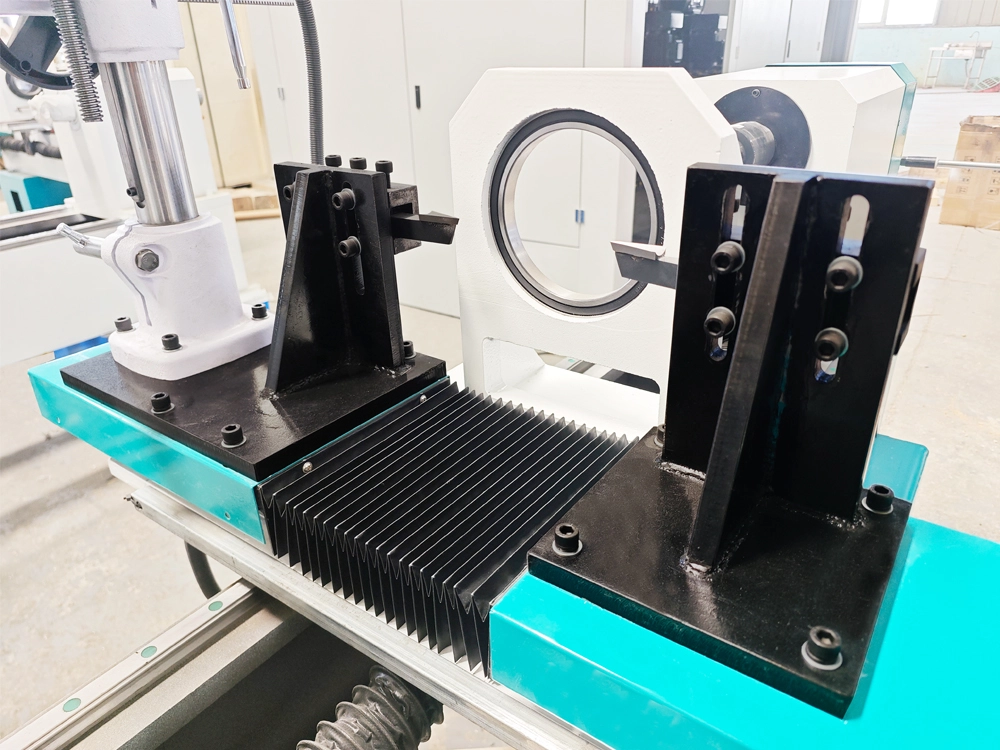

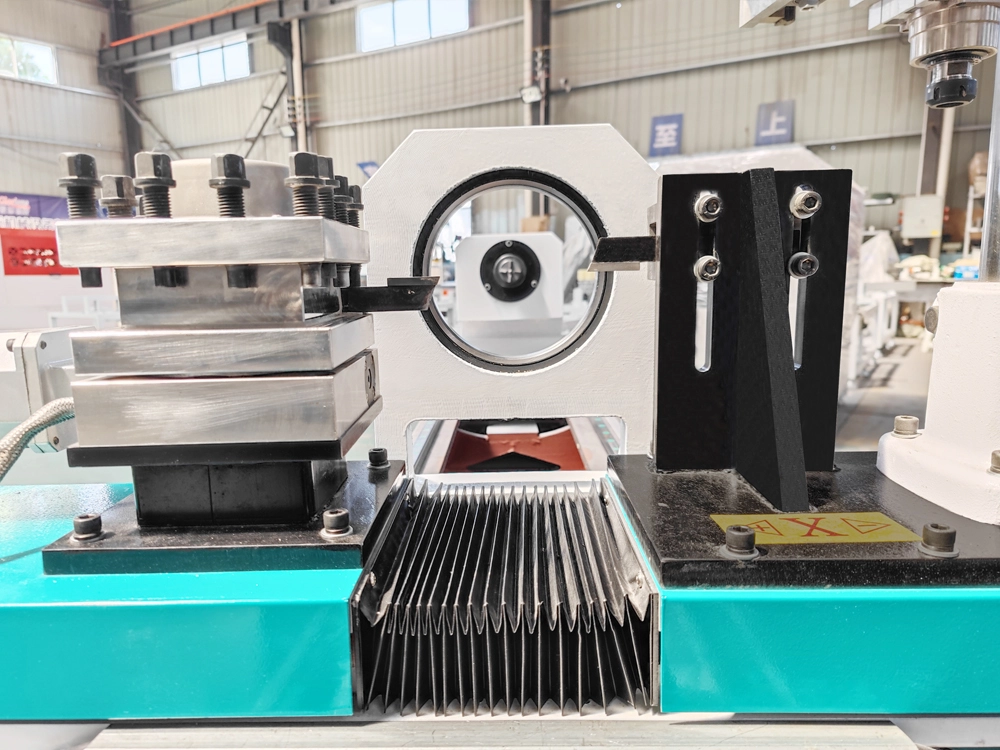

- Four-axis linkage

Four-axis linkage spindle kit,can be used for wood carving,milling shapes,milling lines,drilling,and other functions.

- Processing Tools

Two turning tools with steady rest to prevent wood vibration.

- Drive motor

4KW high-speed rotary servo motor supports switching between position mode and speed mode, and the angle control can be accurate to 0.01°.

- Electrical parts

Servo frequency converter, Hpmont inverter, Delixi electrical parts, more stable use.

- CK-1530-4S with sanding device

Optional sanding wheel or sanding belt.

- Electric tool holder

This device is optional and can hold up to four tools and can be rotated to switch tools.

- Headstock and tailstock

The headstock and tailstock are both made of grey cast iron, and the bearing hole is processed by a boring machine imported from Germany. The lathe-center adopts Morse No. 5, which is stable in clamping, smooth in rotation, and easy to disassemble and replace.

- Handwheel

Equipped with handwheel, the position of each axis can be adjusted quickly and easily.

- CK-2530-4S

Customized model, processing length is one meter longer than CK-1530-4S.

Technical Parameters of CNC Woodworking Lathe Supporting Four-Axis Linkage

| Model | CK-1530-4S |

| Processing Dimensions | 1500mm length * 300mm diameter (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle (supports four-axis four-linkage) |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1750mm |

Processing Uses of Four-Axis Multifunctional Woodworking CNC Lathe

- Applicable materials: pine, rubber wood, beech, oak, birch, teak, sapele, merbau, sandalwood, ash, boroge, walnut, cherry, mahogany, basswood and other wood. Plastic, PVC, acrylic, MDF, artificial wood, resin and other materials.

- Applicable products: wooden stair columns, stair railings, Roman columns, wooden furniture, sofas, tables, chairs, stools, vases, pen holders, wooden bowls, wooden basins, gourds, lamp poles, crutches, drumsticks, walking sticks, wooden beads, wooden pens, dining table legs, round legs, tapered legs, Queen Anne legs, square legs, tiger legs, curved legs, baseball bats, wooden hangers, rolling pins, etc., as well as some common sports and music supplies, with a very wide range of uses.

Some Processing Cases of Four-Axis CNC Woodworking Lathe

How to Choose the Most Suitable CNC Woodworking Lathe?

- Processing size: Choose the appropriate processing size according to the diameter and length of the product you need to process, which will affect the model selection of the machine.

- Product processing type: Clarify the type of processing you need, such as turning, engraving, grooving, drilling, cutting, etc., which will affect the function selection of the machine.

- Budget cost: Choose the right machine tool according to your budget. The price of CNC woodworking lathe ranges from US$4,000 to tens of thousands of dollars, depending on the function and configuration of the machine.

- Maintenance cost: Consider the maintenance cost of the machine, the cost of the tool, and the comprehensive benefits brought by the improvement of production efficiency.

- After-sales service: Choose a production factory that can provide good after-sales service and technical support to avoid trouble for the subsequent maintenance of the machine.

- Simple operation: Choose a CNC system with a friendly operation interface, which should have a wide range of software and file compatibility, facilitate the import of various design drawings and processing files, and be easy to learn and operate.

| Model | CK-1530-4S |

|---|---|

| Processing Dimensions | 1500mm length * 300mm diameter (customizable according to processing requirements) |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Motor | 4KW pure servo motor |

| Motor Speed | 0-6000rpm |

| Driving Mode | CATEKCNC dedicated high-torque servo motor |

| Frequency Converter | BEST inverter / servo frequency conversion drive |

| Spindle | CATEKCNC dedicated 3.5KW high-speed air-cooled variable frequency spindle (supports four-axis four-linkage) |

| Spindle Speed | 0-18000r/min |

| Transmission Mode | XY axis 25 TBI ball screw drive, Z axis uses high-precision helical rack / TBI 32 ball screw |

| Guideway | Taiwan Hiwin high precision 25 linear square rail / 25 slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Control System | CATEKCNC dedicated control system panel, CK1000TC |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, solidworks UG powermill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Weight | 1800kg |

| Dimensions | 3100*1400*1600mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.