Best Multi-Station Atc Five-Axis Wood Machining Center of 2026

2026 The Best Five-Axis CNC Wood Milling Machine for Sale

[Function Description]

The five-axis drilling and milling woodworking machining center is a new type of five-axis machining center specially developed for the fields of European, American, and new Chinese furniture. It has five independent motion axes, including three linear axes (X, Y, and Z) and two rotary axes (A and B). This unique structure enables the five-axis machining center to achieve precise machining of various processes of each surfaces-of-revolution of the workpiece through the linkage control of five axes in one clamping.

The bed is welded with an all-steel structure and is treated with high-temperature annealing to ensure that it will not deform after long-term use. It uses a heavy-duty machine table and a gantry structure with a stable structure. Four different types of tools can be installed at each station at a time. It is mainly aimed at the mass production of special-shaped parts of solid wood furniture. Traditional processing methods are inefficient, product quality is unstable, and processing dimensions are difficult to control. Using a five-axis drilling and milling machining center, the workbench adopts a 360-degree indexing rotating fixture with both ends clamping each other. It has 360-degree drilling and milling functions at any angle. It can process 4 to 12 identical parts at a time. The processing efficiency is extremely high, which can effectively reduce production costs, expand production output, and is more suitable for mass production.

The five-axis drilling and milling machining center is equipped with a four-sided rotating tool changing device and an intelligent CNC system. It runs using G code and can import machining programs with one click. It is equipped with a convenient loading device, is easy to use, and has self-diagnosis and self-repair functions to ensure the stability and safety of the system.

Details of Five-Axis Wood Processing Center

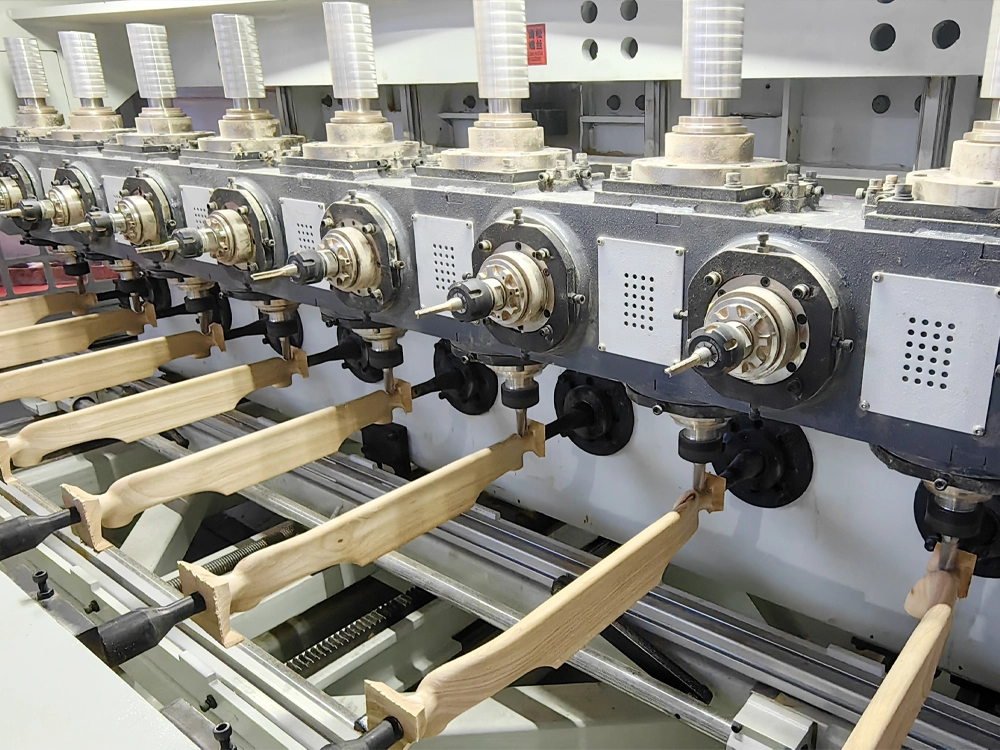

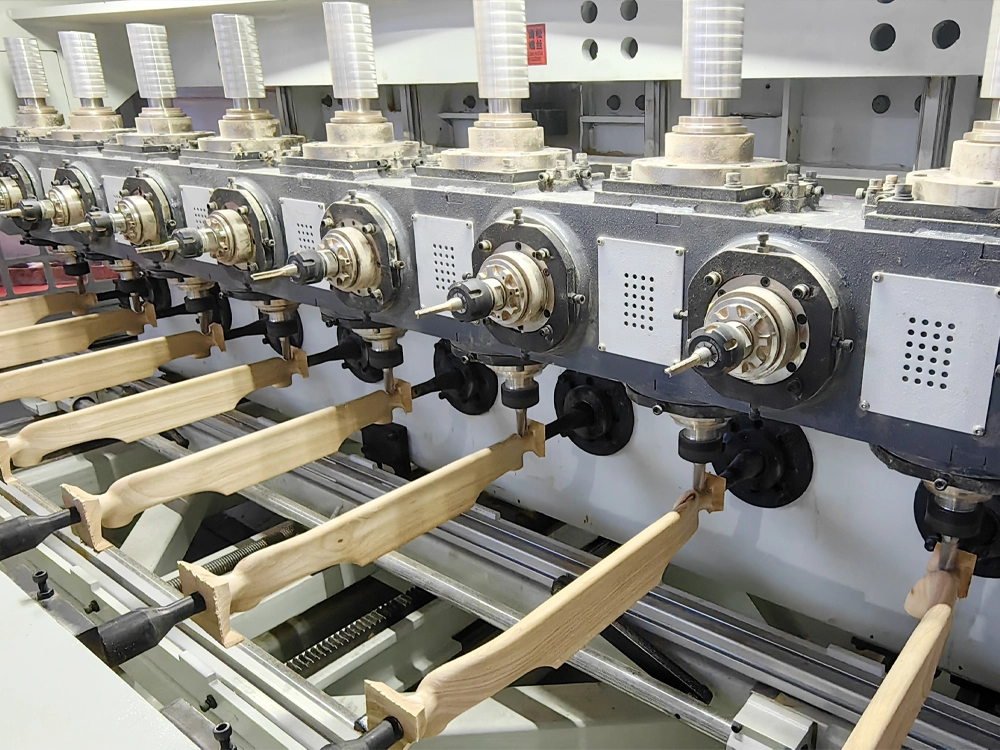

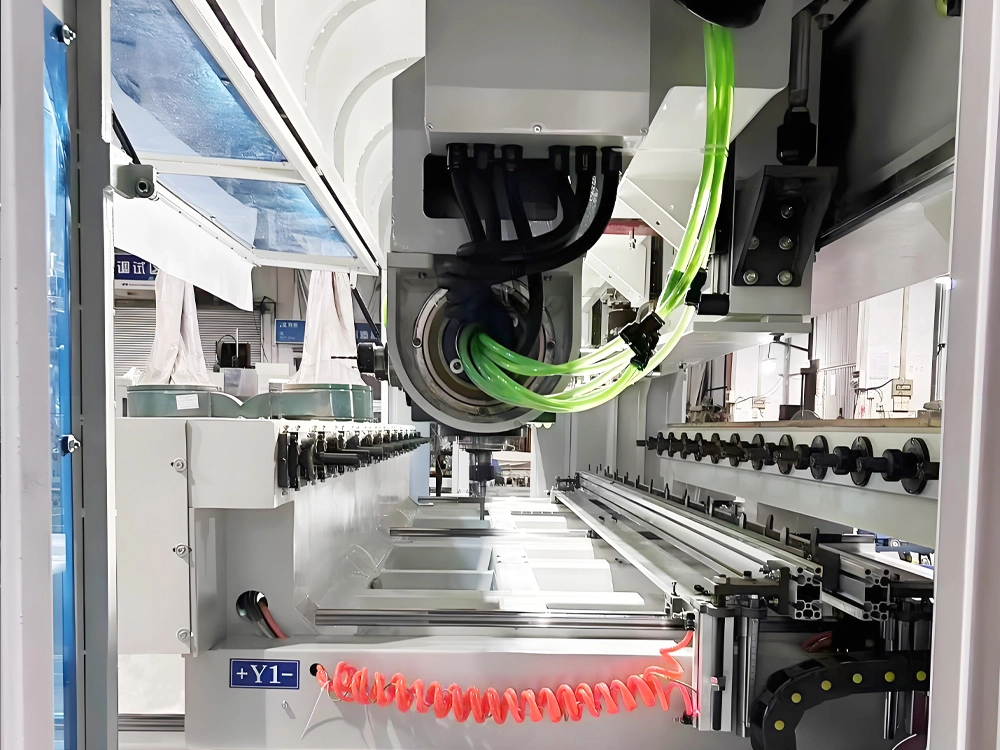

- Rotary axis for tool

-

The rotary tool-changing mechanism utilizes an imported RV reducer, offering high positioning accuracy and enabling multi-axis linkage machining. The spindle employed is a dual-end high-speed rotating spindle, which is fixed through the spindle housing, exposing the tools at both ends. Each station can simultaneously and vertically accommodate two such dual-end spindles in an interleaved arrangement, providing four different types of tools per station. During machining, the spindle housing rotates to switch between the corresponding tools, significantly improving processing efficiency.

Additionally, this tool turret can perform indexing rotation. Beyond tool changing, it can tilt the spindle at a specific angle by rotating, thereby enabling the machining of workpieces that conventional rotary engraving machines cannot handle.

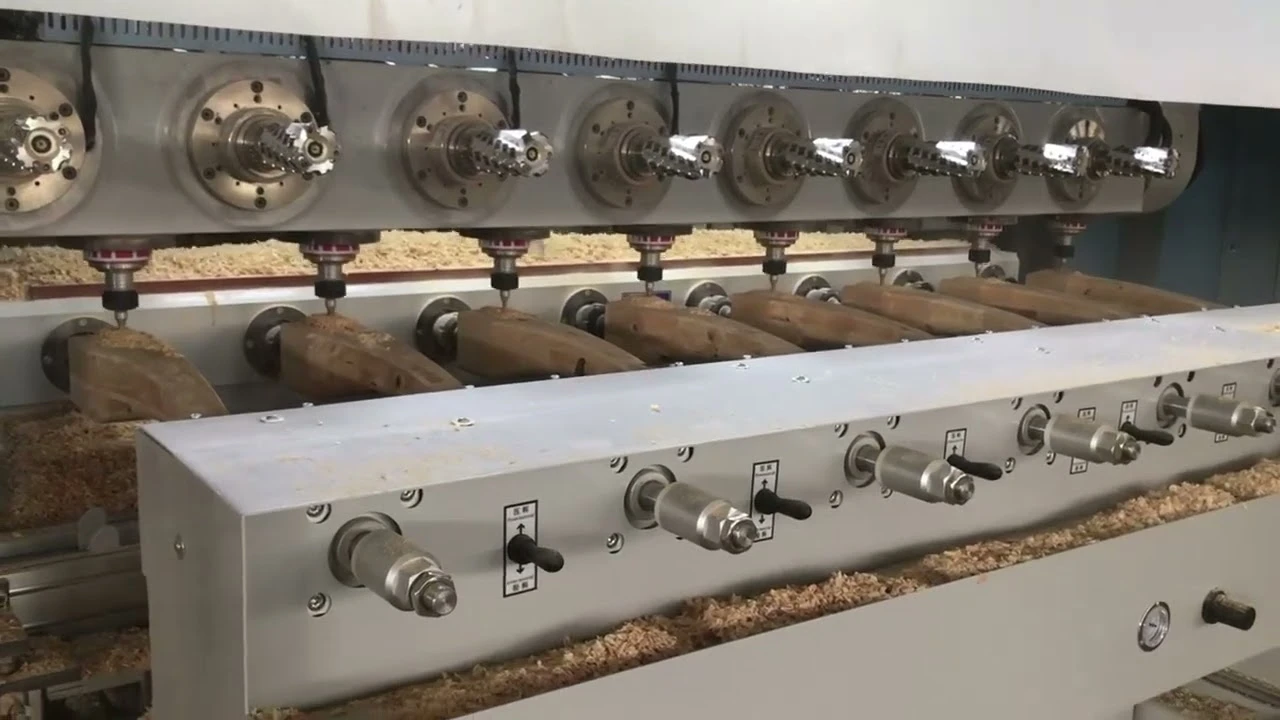

- Rotary axis for workpiece

-

After the wood is installed, the servo motor drives the reducer to rotate, and then drives the wood to rotate to start processing; multiple products can be processed at one time, improving production efficiency and reducing production costs.

- Material support device

-

When the machine tool stops, the material support positioning device rises. The lifting height can be adjusted according to the specifications of the wood, and the support point position can also be adjusted according to the shape of the wood; it can fix wood of various shapes, making it easier to fix wood.

- Fully enclosed safety enclosure

-

The fully enclosed safety enclosure is equipped with 4 large-diameter dust suction ports. By connecting the dust suction device, it can reduce the dust generated during processing and achieve fully automatic dust-free processing.

- Control electrical box

-

The main electrical parts are all imported electrical components; the drive motor is a Delta high-torque servo motor, and the main circuit is equipped with a filter to eliminate interference and ensure the stability of the control system.

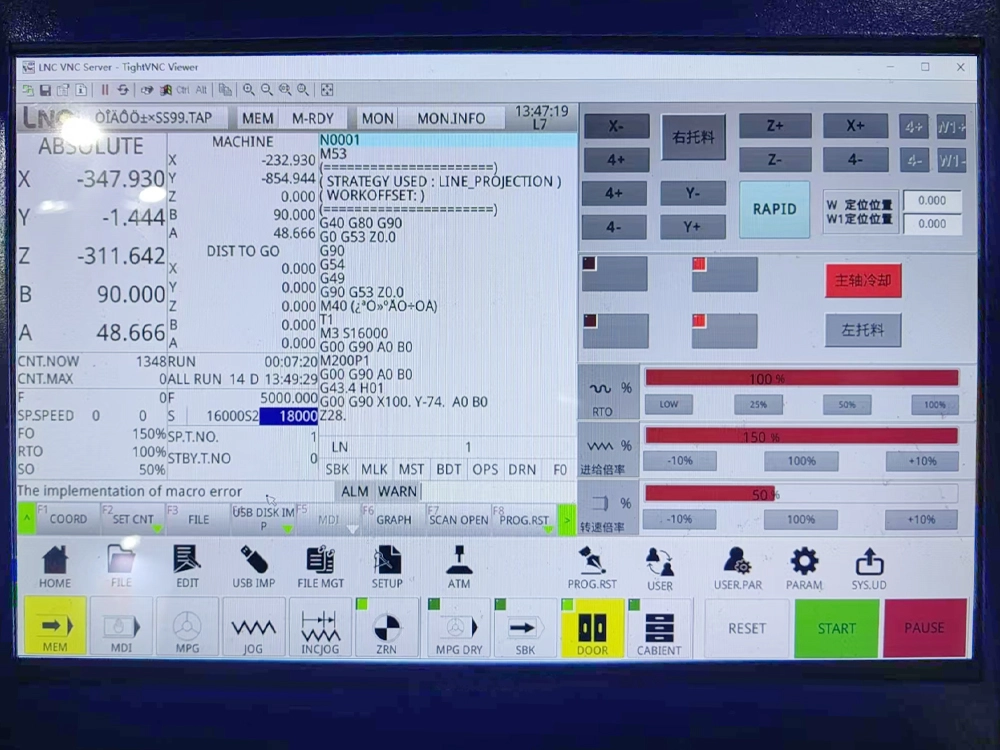

- Control system

-

Using Taiwan LNC bus control system, it is simple to operate and easy to use.

- Lubrication system

-

The machine is equipped with a fully automatic timed lubrication and oiling device. The distal part of the oil circuit and the proximal part of the oil circuit are separately controlled for lubrication to avoid the oil circuit being too far away and causing insufficient lubrication, effectively extending the service life of the machine.

- Automatic chip removal

-

The machine is equipped with an automatic chip removal device. The wood chips and dust generated during the processing can be automatically sent out through the chip removal groove, which is convenient for cleaning and maintenance of the equipment.

- Four-head five-axis wood processing center (CK-1219-4)

-

Four-station design, can process four workpieces at a time.

- Double-machining-zone four-head five-axis wood processing center (CK-1219-4B)

-

The double machining zone design is equipped with total four machining stations and eight workpiece clamping devices. While machining is performed in one zone, the other zone can handle loading operations, eliminating spindle idle time.

- Twelve-head five-axis wood processing center (CK-1219-12)

-

Twelve-station design, can process 12 workpieces at a time.

Technical Parameters of Five-Axis Wood Processing Center

| Model | CK-1219-4 | CK-1219-4B | CK-1219-8 | CK-1219-12 |

|---|---|---|---|---|

| Processing Dimensions | 1200mm long * 190mm diameter(customizable according to processing requirements) | |||

| Spindle Power | 5.5KW * 4 + 3.7KW * 4 | 5.5KW * 4 + 5.5KW * 4 | 5.5KW * 8 + 3.7KW * 8 | 5.5KW * 12 + 3.7KW * 12 |

| Spindle Speed | 12000-18000r/min | |||

| Spindle Spacing | 280mm | |||

| Electrical Parts | Schneider | |||

| Frequency Converter | BEST heavy-duty inverter | |||

| Pneumatic Components | AirTac | |||

| Screw | Taiwan TBI ball screw | |||

| Guideway | German Roster dustproof steel belt | |||

| RV Reducer | Taiwan TSUNTIEN | |||

| X-Axis Servo Motor | 4.5KW | 1.5KW | 4.5KW | 4.5KW |

| Y-Axis Servo Motor | 1.5KW * 2 | |||

| Z-Axis Servo Motor | 5.5KW | 2.3KW | 4.5KW | 5.5KW |

| A-Axis Servo Motor | 1.8KW * 2 | 1.0KW * 2 | 1.8KW | 1.8KW * 2 |

| B-Axis Servo Motor | 2.6kW | 1.0KW | 1.5KW | 2.6KW |

| W-Axis Servo Motor | 0.4kW * 4 | - | 0.44KW * 4 | 0.4kW * 4 |

| Control System | Taiwan LNC | |||

| Operating Voltage | 380V 60Hz | |||

| Total Power | About 46.6KW | About 46.6KW | About 89KW | About 89KW |

| Maximum No-Load Running Speed | 25m/min | |||

| Weight | 5100kg | 5600kg | 7800kg | 9500kg |

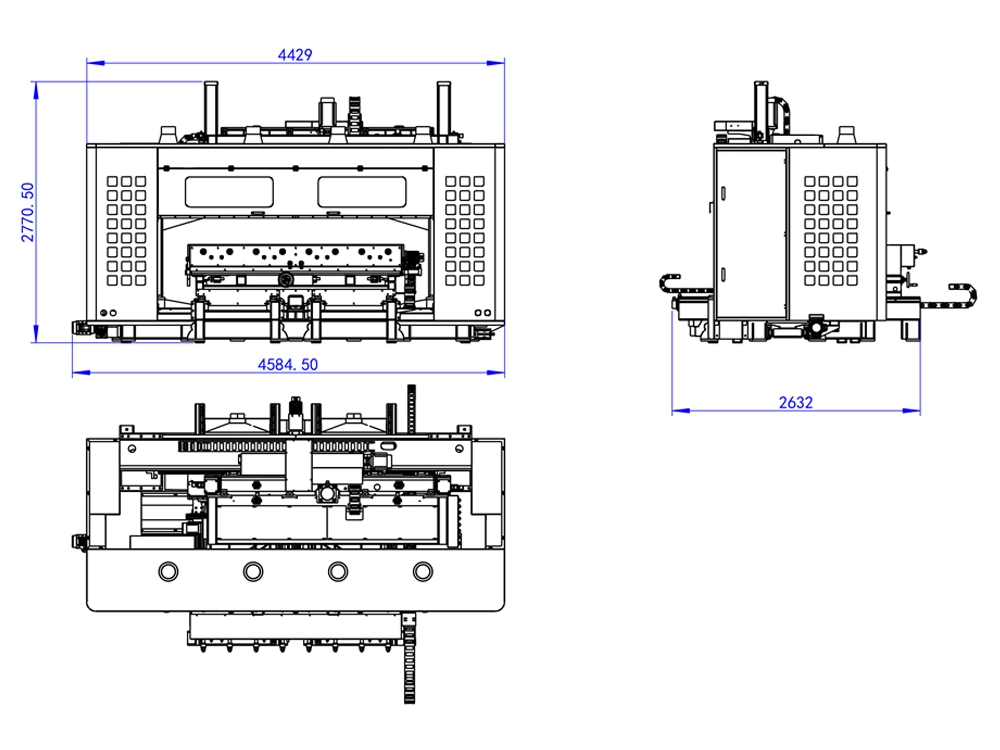

| Dimensions | 4100*2100*2720mm | 4100*3200*2720mm | 4800*3200*2900mm | 5180*3800*2900mm |

Application Scope of Five-Axis Wood Processing Center

The application range of the five-axis drilling and milling wood processing center is very wide, covering multiple industries and fields. It can process complex solid wood furniture parts, such as mortise and tenon products, sofa legs, solid wood furniture curved surface milling, grooving and drilling, etc. In addition, it is also widely used in various fields such as architectural woodworking, craft creation, prototyping, model making, sign making and engraving.

- Woodworking engraving industry;

- Mold processing industry;

- Home appliance trimming and milling;

- Bathroom and luggage industry;

- Aviation, motor vehicle, wind power, RV, yacht, wooden house, handicraft and other modeling processing;

- PVC/PP/PE, polylong, anti-bite, glass fiber, carbon fiber, resin, wood substitute and other new material processing;

- Copper, aluminum and other non-ferrous metal cutting and milling processing;

-

Musical instruments, coffin materials, shoe molds and other industries.

The Following Are the Processable Products of Five-Axis Wood Processing Center

| Model | CK-1219-4 | CK-1219-4B | CK-1219-8 | CK-1219-12 |

|---|---|---|---|---|

| Processing Dimensions | 1200mm long * 190mm diameter(customizable according to processing requirements) | |||

| Spindle Power | 5.5KW * 4 + 3.7KW * 4 | 5.5KW * 4 + 5.5KW * 4 | 5.5KW * 8 + 3.7KW * 8 | 5.5KW * 12 + 3.7KW * 12 |

| Spindle Speed | 12000-18000r/min | |||

| Spindle Spacing | 280mm | |||

| Electrical Components | Schneider | |||

| Frequency Converter | BEST heavy-duty inverter | |||

| Pneumatic Components | AirTac | |||

| Screw | Taiwan TBI ball screw | |||

| Guideway | German Roster dustproof steel belt | |||

| RV Reducer | Taiwan TSUNTIEN | |||

| X-Axis Servo Motor | 4.5KW | 1.5KW | 4.5KW | 4.5KW |

| Y-Axis Servo Motor | 1.5KW * 2 | |||

| Z-Axis Servo Motor | 5.5KW | 2.3KW | 4.5KW | 5.5KW |

| A-Axis Servo Motor | 1.8KW * 2 | 1.0KW * 2 | 1.8KW | 1.8KW * 2 |

| B-Axis Servo Motor | 2.6kW | 1.0KW | 1.5KW | 2.6KW |

| W-Axis Servo Motor | 0.4kW * 4 | - | 0.44KW * 4 | 0.4kW * 4 |

| Control System | Taiwan LNC | |||

| Operating Voltage | 380V 60Hz | |||

| Total Power | About 46.6KW | About 46.6KW | About 89KW | About 89KW |

| Maximum No-Load Running Speed | 25m/min | |||

| Weight | 5100kg | 5600kg | 7800kg | 9500kg |

| Dimensions | 4100*2100*2720mm | 4100*3200*2720mm | 4800*3200*2900mm | 5180*3200*2900mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.