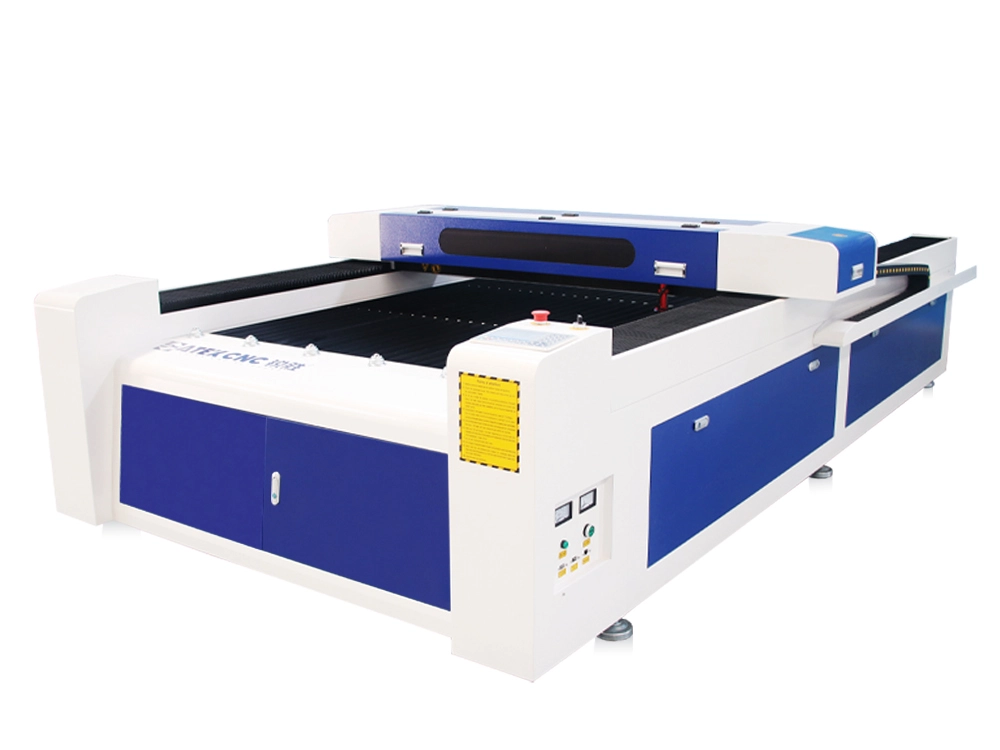

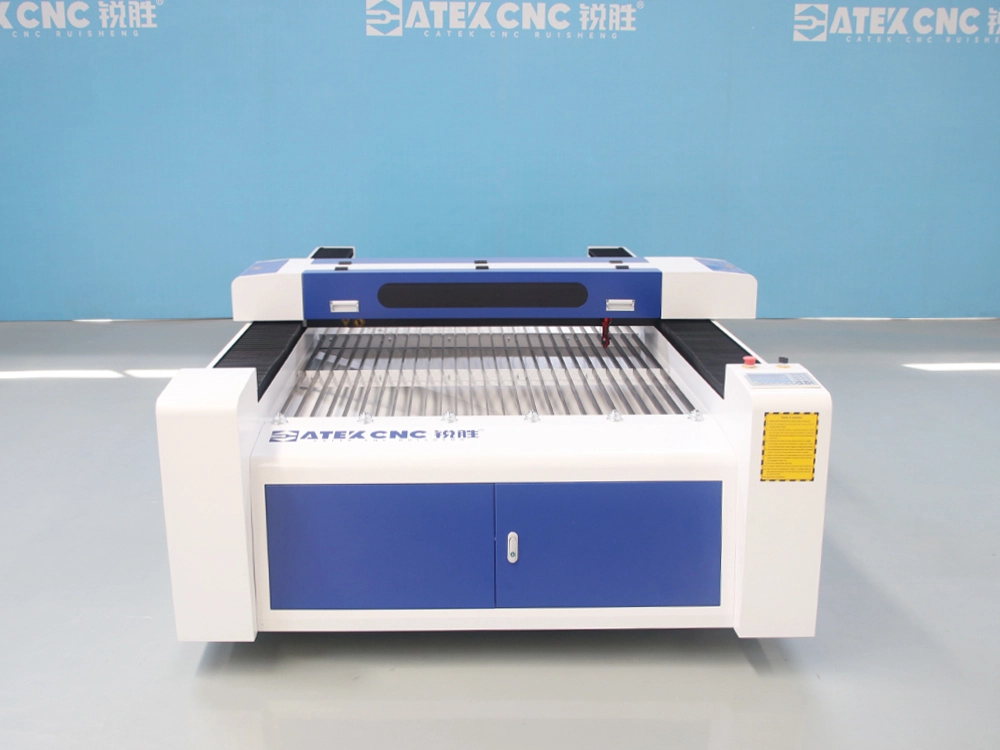

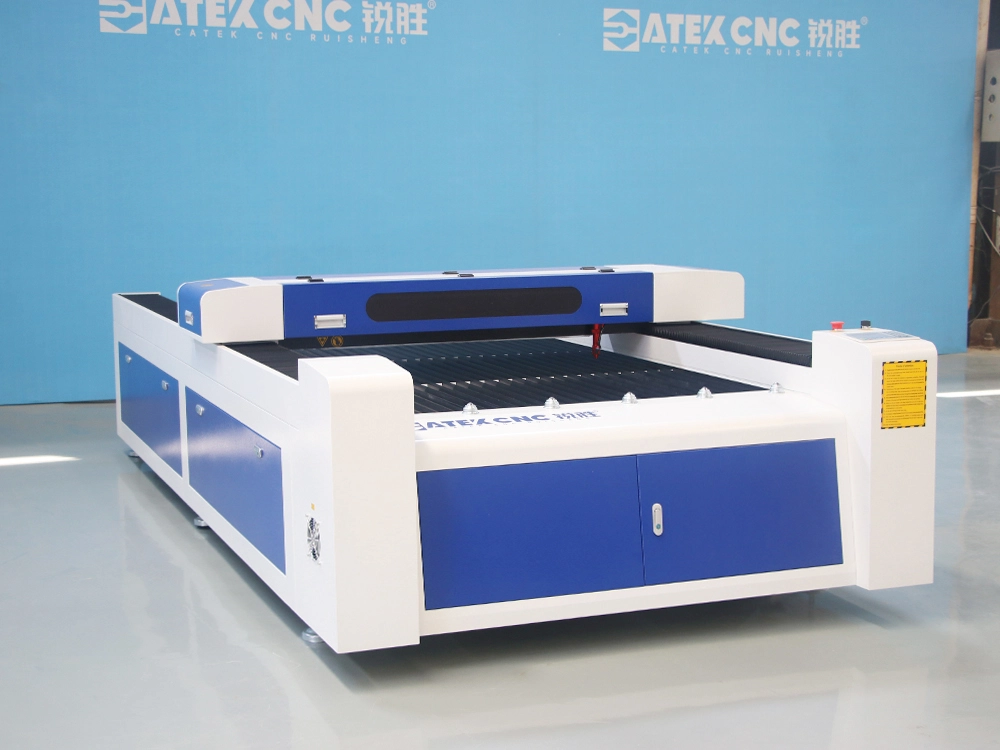

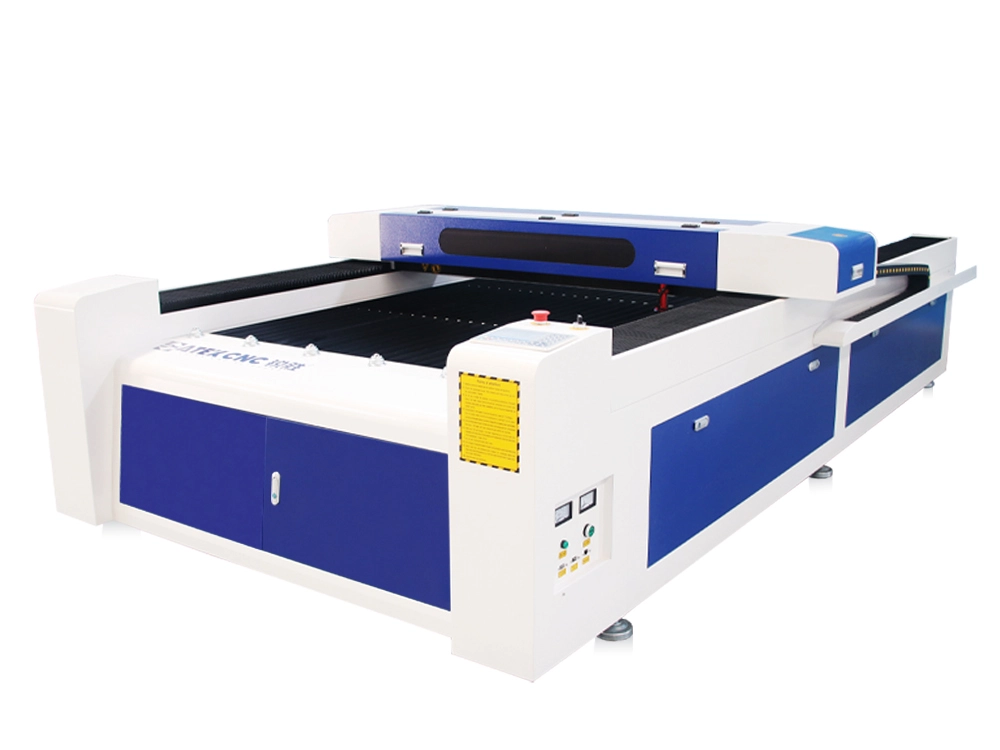

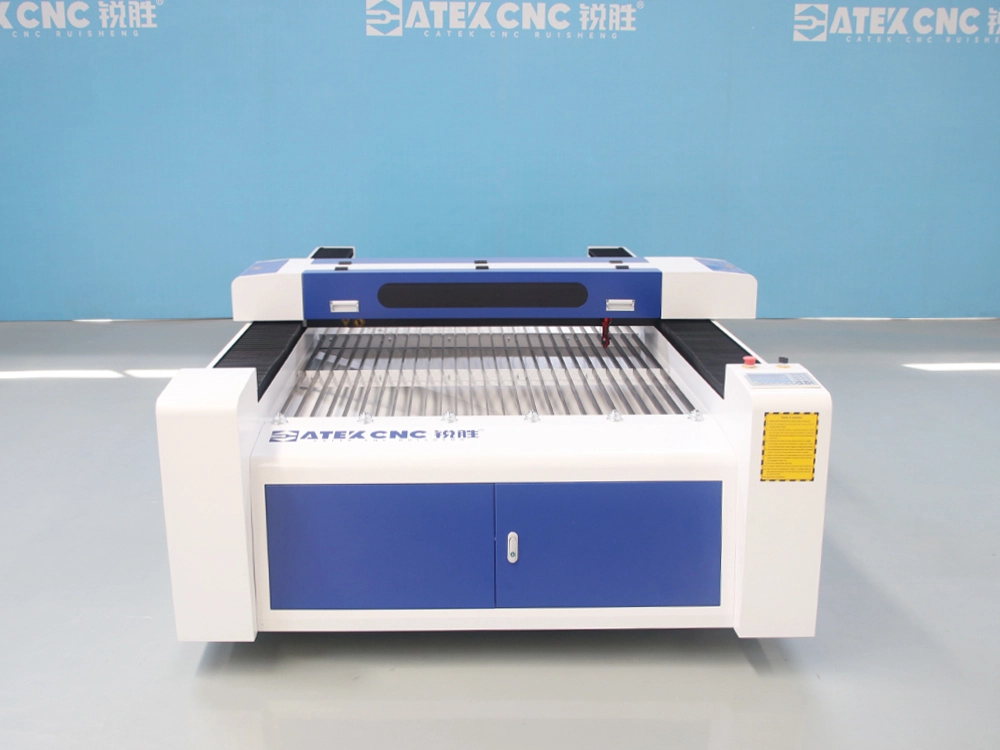

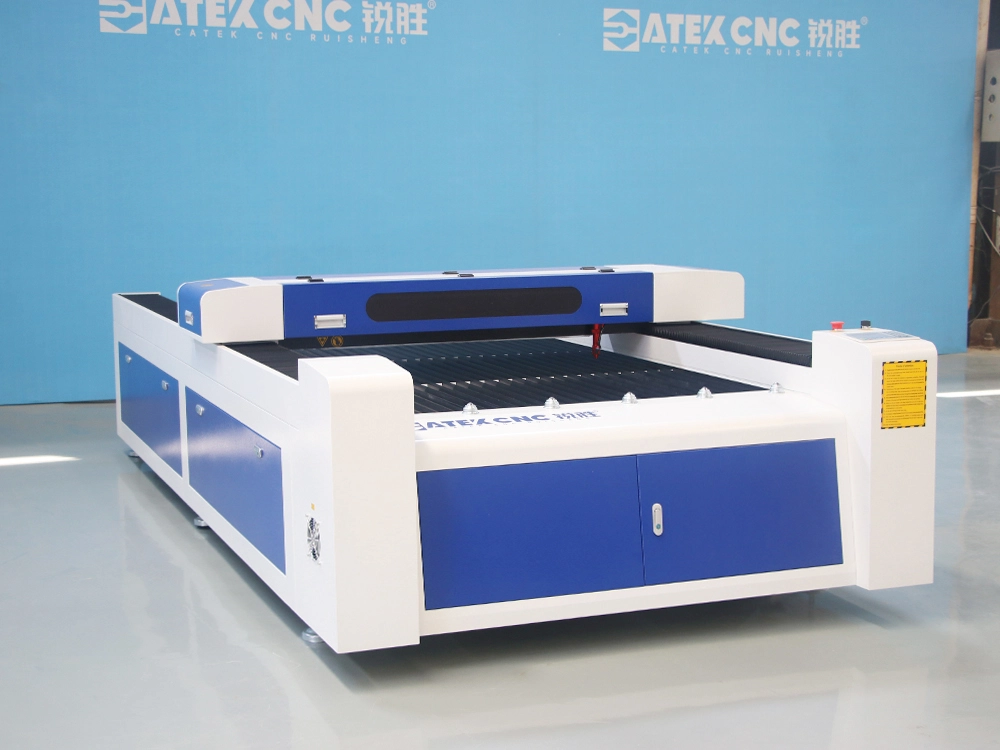

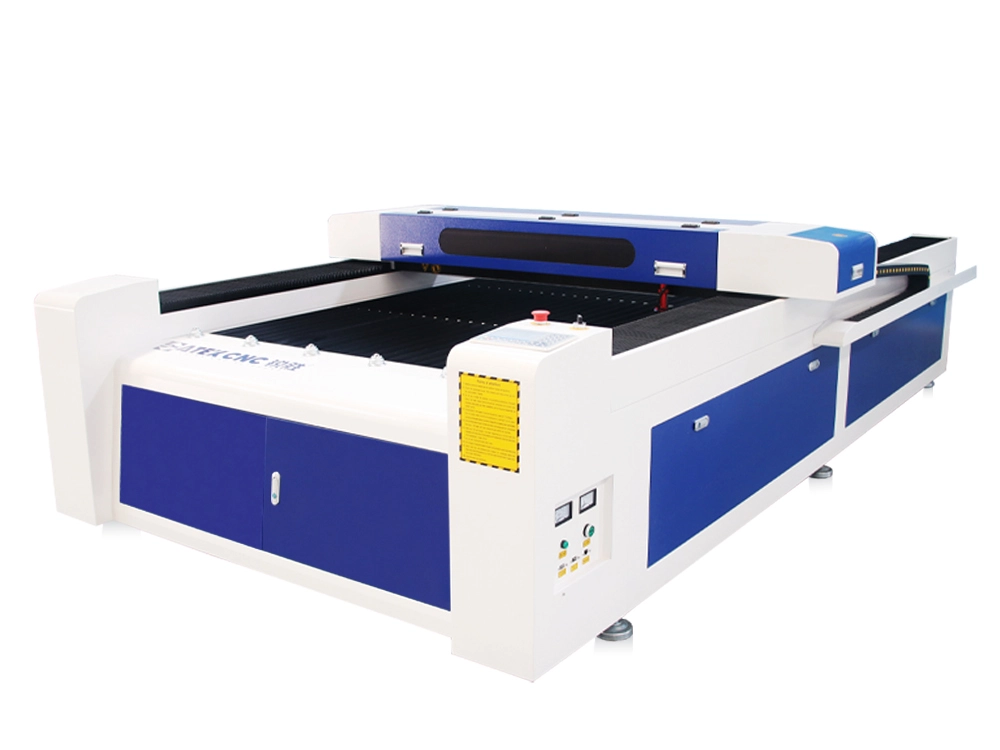

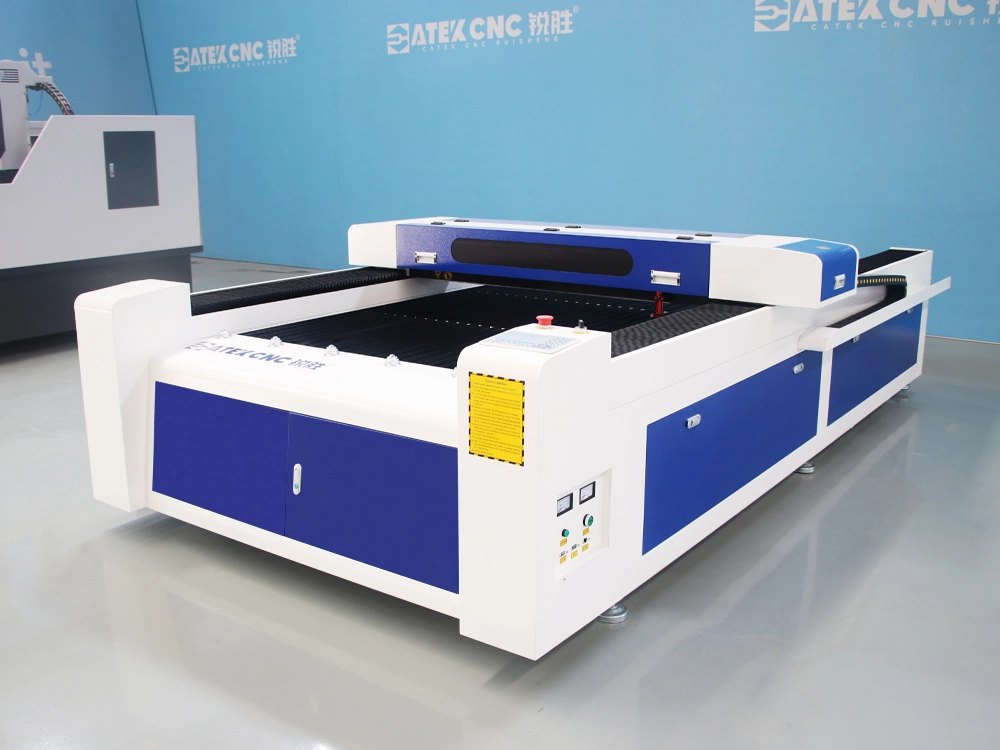

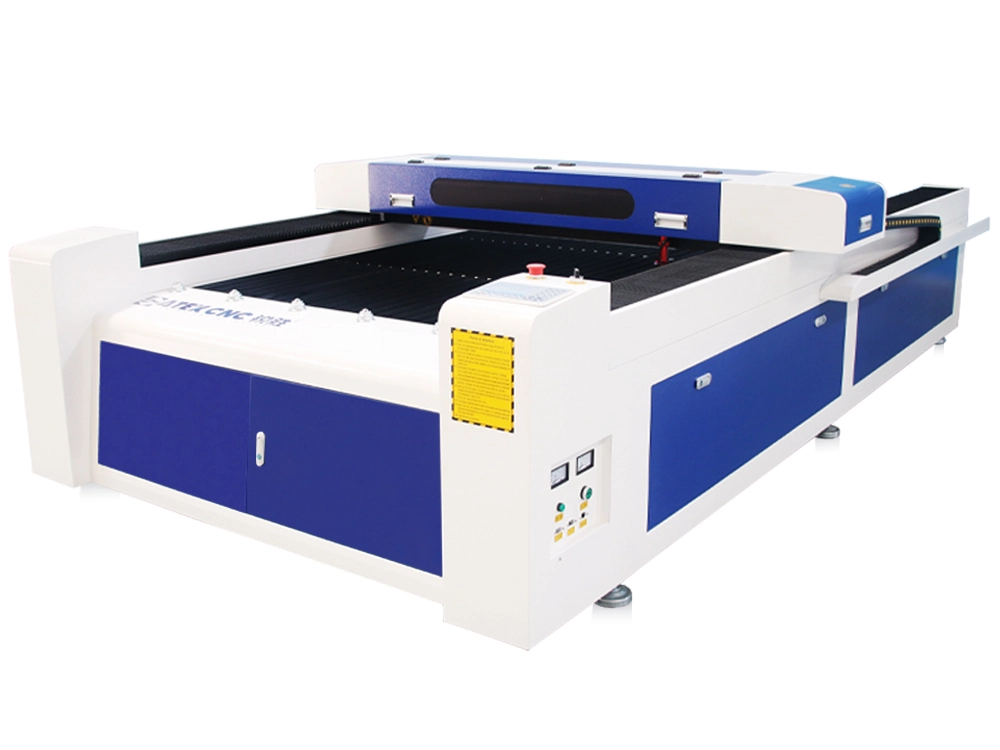

CO2 Laser Engraving and Cutting Machine Suitable for Processing Various Non-metallic

Best Selling 4x8 1325 CO2 Laser Engraving and Cutting Machine

[Function Description]

1325 CO2 laser cutting machine is a high-performance laser processing equipment, specifically designed for engraving and cutting non-metallic materials. Featuring a 1300 x 2500 mm worktable, it utilizes a CO2 laser to cut and engrave materials by vaporizing or melting them with a high-energy laser beam. Controlled by a CNC system, it enables rapid cutting and engraving of text, patterns, photos, numbers, signs, or logos onto surfaces of materials such as acrylic, glass, rubber, MDF board, wood, fabric, paper, stone, plastic, leather, and textiles.

1325 CO2 laser cutting machine can perform a combination of cutting and engraving on 4*8 feet of raw materials at one time. The CNC system can control different trajectories and shapes. You can use the cutting mode to cut the edge shape of the material, or switch the scanning mode to perform surface depth engraving. The 1325 CO2 laser engraving machine is easy to operate. You only need to use simple vector or bitmap files in formats such as DXF, AI, CDR, JPG, PNG, etc. You can start processing after selecting. It is equipped with a circulating water cooling system and can work continuously for 24 hours. It does not use any tools, has no wearing parts, and does not cause a lot of sawdust and dust during the processing process like the CNC router uses tools for processing. It is very environmentally friendly and is an ideal choice for today's wood crafts, advertising logos, model puzzles, textile packaging and other industries.

Advantages of 4*8ft 1325 CO2 Laser Engraving and Cutting Machine

- 1325 CO2 laser engraving and cutting machine with a 1300×2500mm worktable, supporting processing of full-size 4×8 ft sheet materials (e.g., MDF, acrylic sheets).

- Extensive software compatibility: Supports CorelDraw/AutoCAD/Photoshop, and directly imports DXF/AI/JPG files.

- Features a laser tube with extremely high photoelectric conversion efficiency and low overall power consumption for significant energy savings.

- Consumable-free processing: No tools, ink, or other consumables required, resulting in minimal operating costs.

- Non-contact laser processing prevents physical damage and material deformation.

- Laser tube lifespan exceeds 10,000 hours with zero maintenance required.

- Advanced features include power-off resumption, offline operation, and auto-focus for simplified use.

- Eco-friendly laser processing generates no waste chips, compliant with EU CE/ROHS certifications.

- Equipped with S&A water cooler, using efficient water cooling circulation system, it can effectively remove the heat generated by the laser tube during operation and can work continuously for 24 hours.

- Laser tubes are available in various brands such as Yongli/Reci/EFR, and the power can be selected at will.

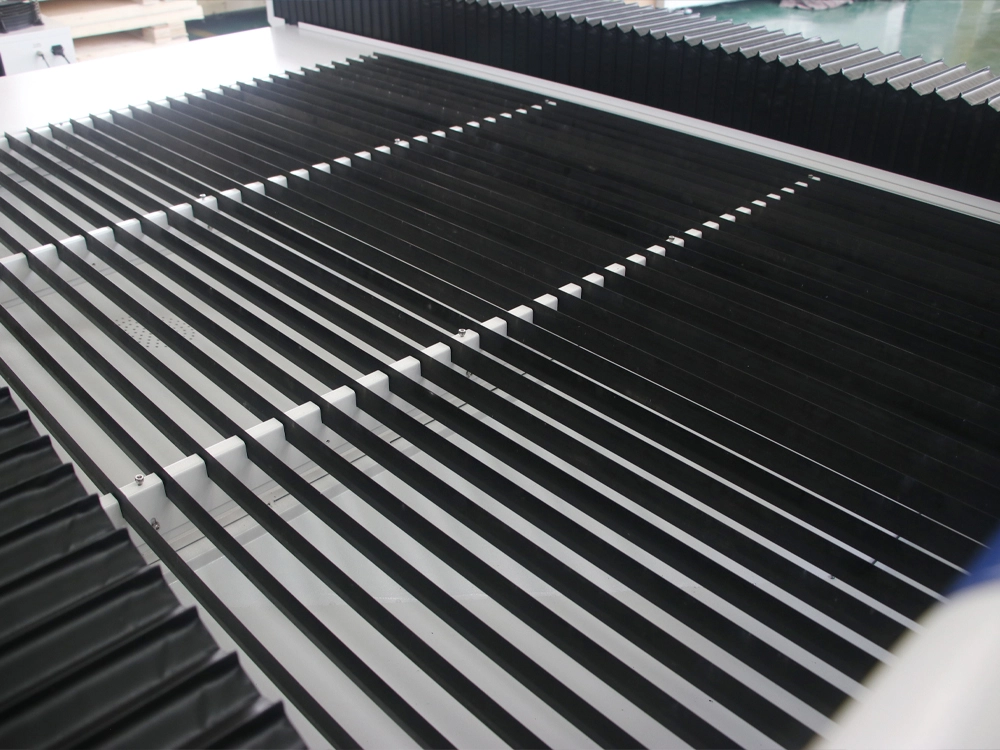

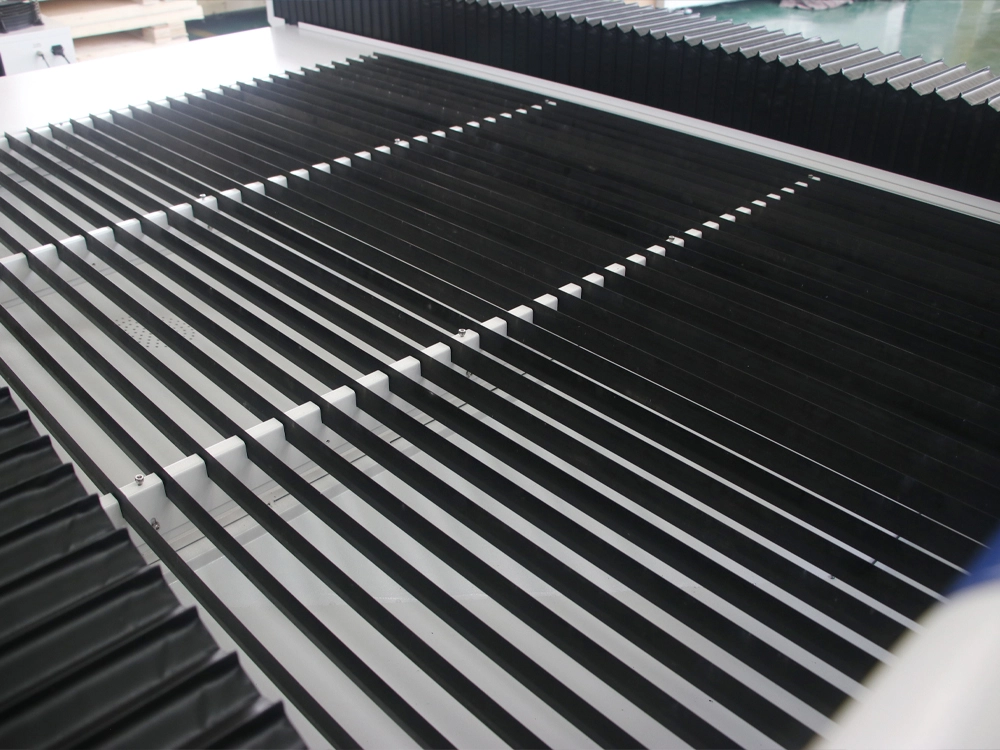

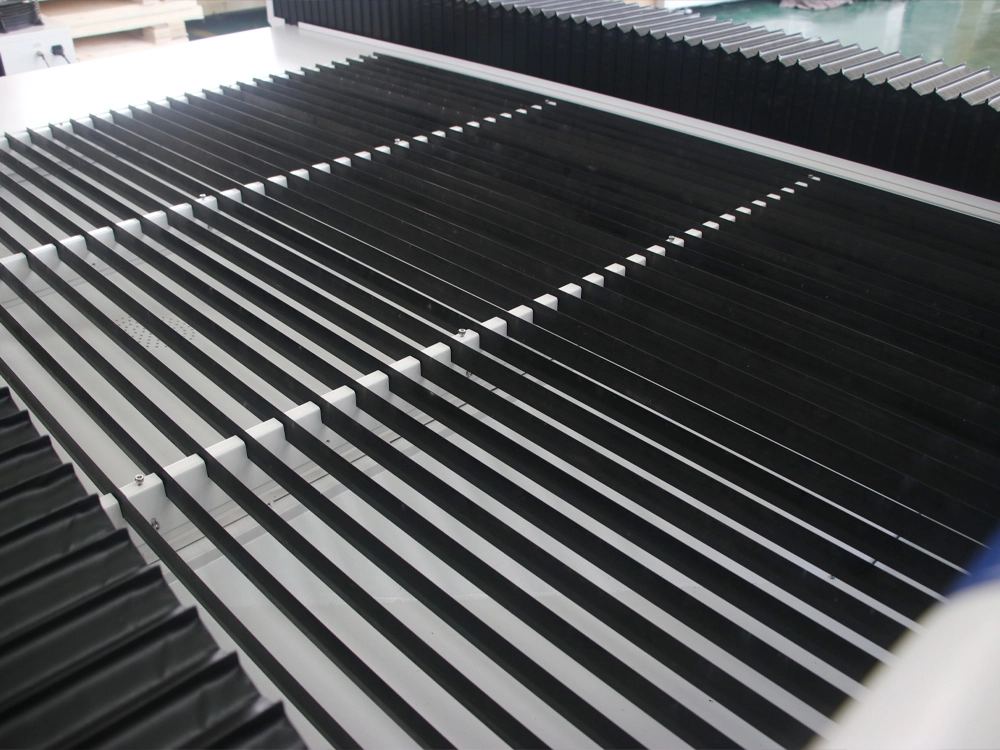

- The aluminum alloy blade workbench provides a flat material support surface to facilitate laser penetration and cutting, and effectively reduce reflection damage.

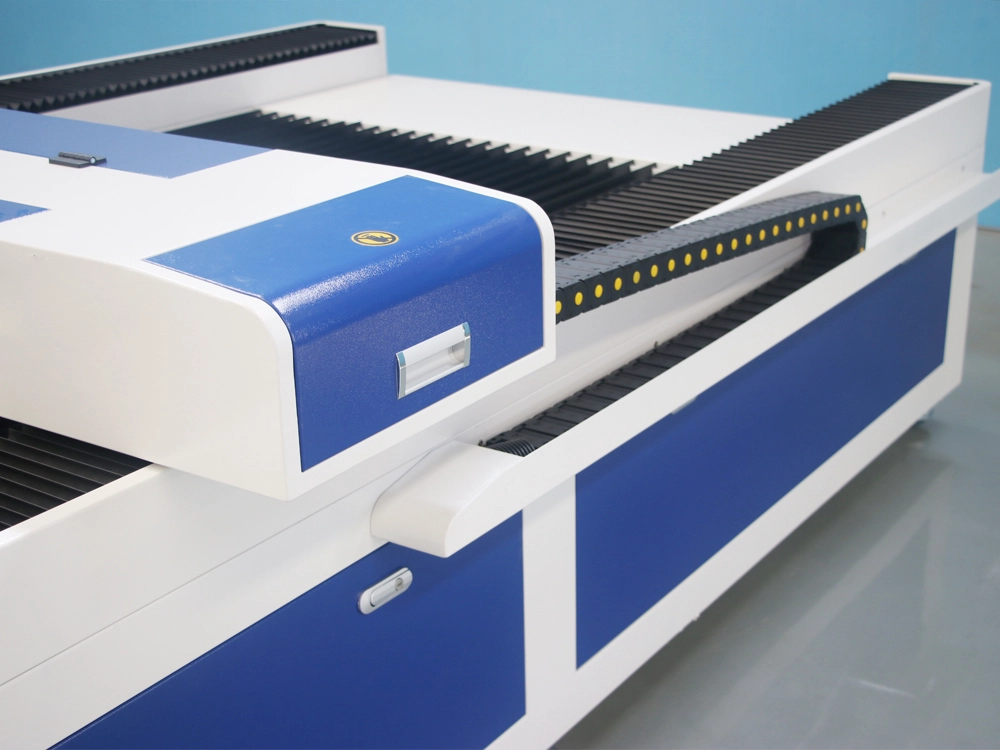

- The Y-axis uses a dual-motor drive design to effectively share the load pressure and achieve high-precision and high-speed output.

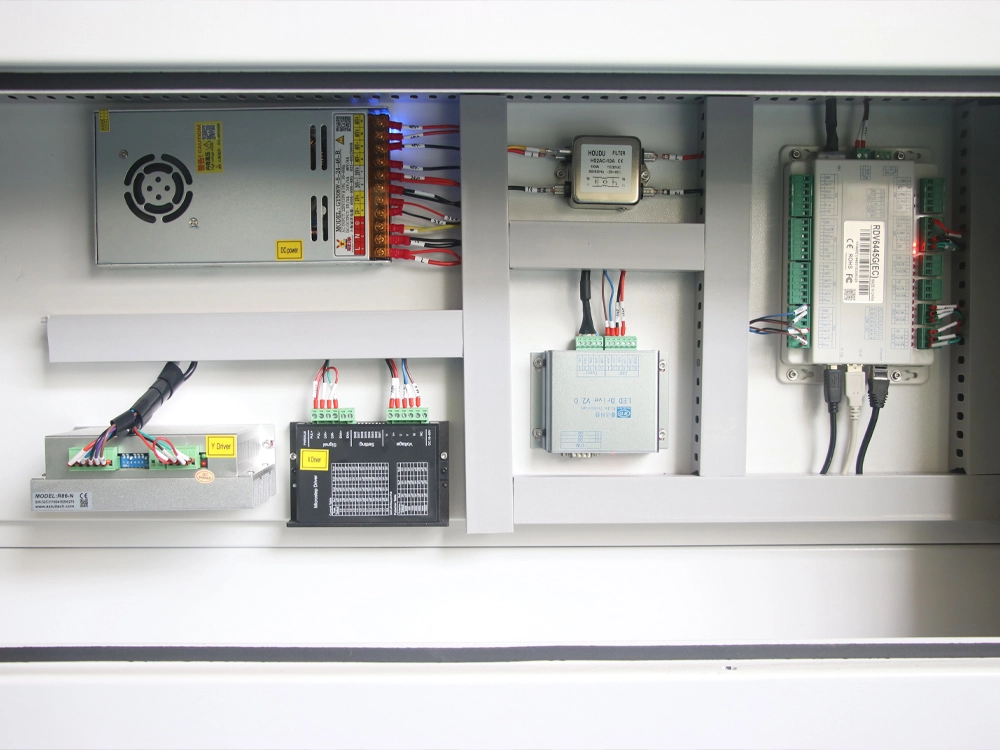

- The Ruida 6445S CNC system is simple to operate, with intuitive key operations and easy to use.

Details of 4*8 1325 CO2 Laser Engraving Machine

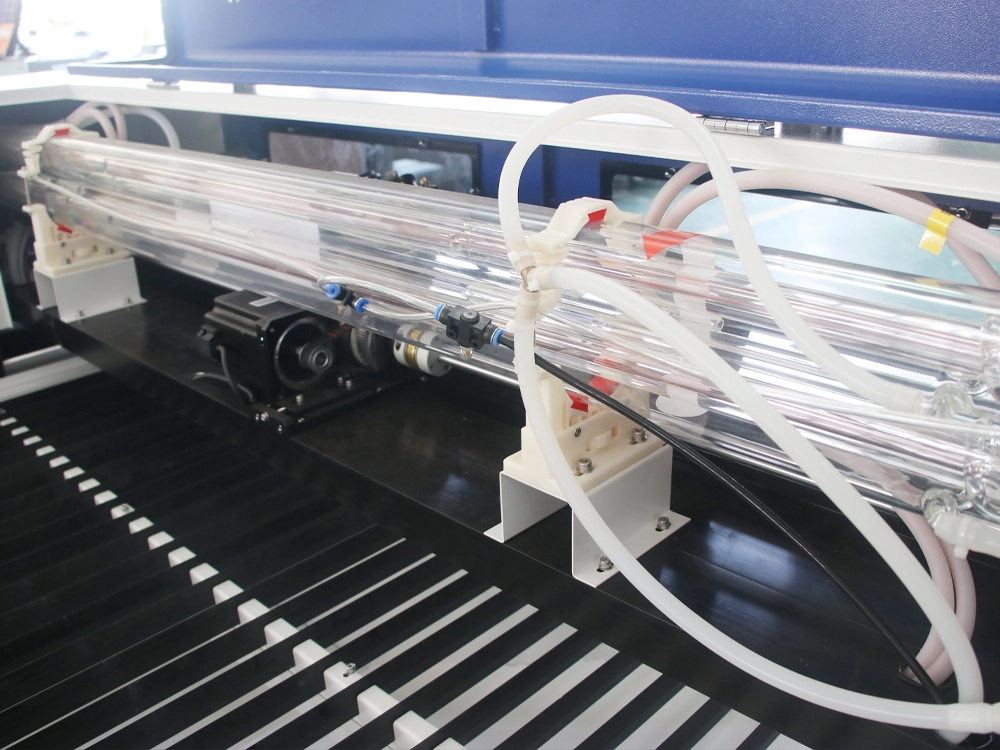

- Sealed CO2 laser glass tube

It uses a closed three-layer sleeve heat dissipation design, which is easy to use, requires no maintenance, and has a service life of more than 10,000 hours.

- CO2 laser head

The high-quality carbon dioxide laser cutting head is made of all-aluminum alloy. The laser beam is reflected by the laser reflector and guided to the laser cutting head. After being focused by the focusing lens inside the laser head, a high-energy laser beam is formed to achieve high-speed engraving and cutting.

- Aluminum alloy blade workbench

Multiple aluminum alloy structure design, aluminum alloy material is easier to dissipate heat, and the waste of laser-cut products falls into the blade table to keep the table clean.

- Ruida 6445S CNC system

It supports multiple languages, can be connected to a computer or used offline, and is compatible with a variety of bitmap and vector files, such as jpg/dxf/ai/cdr, etc. It is simple to operate and easy to use.

- Y-axis dual drive dust cover

Both sides of the Y-axis use accordion-type protective covers, which can effectively prevent the waste chips generated during the processing from falling into the transmission device and affecting the life of the machine.

- S&A CW6000 water Chiller

S&A CW6000 water chiller uses a highly efficient water cooling circulation system, which can be controlled at a constant temperature, effectively maintaining the normal operation of the CO2 laser tube and can work continuously for 24 hours.

- High quality laser power supply

High-frequency laser switching power supply can provide stable high-voltage DC output, and can achieve precise laser output through CNC system control.

- Multi-function input interface

Equipped with 220v power socket, compressed air interface, water cooler interface, circulating water interface, easy to use.

Technical Parameters of 4*8ft 1325 CO2 Laser Engraving Machine

| Model | CK-1325-C |

|---|---|

| Machine Color | Customizable |

| Working Size | 1300*2500mm(4*8ft) |

| Laser Tube | Reci/Yongli/EFR etc. |

| Laser Type | CO2 |

| Focusing Lens | US II-VI diameter 20 focal length 63.5 |

| Guideway | PMI -15(X) 25(Y)(Taiwan) |

| Drive Belt | High precision synchronous belt drive |

| Motor Driver | Leadshine motor drive |

| Control System | Ruida 6445S |

| Workbench | Aluminum Alloy Blade Workbench |

| Exhaust Fan | 550w |

| Air Pump | HAILI ACO-009E 165w |

| Water Cooler | S&A CW-6000 |

| Engraving Speed | 0-60000mm/min |

| Cutting Speed | 0-36000mm/min |

| Supported File Formats | BMP, PLT, DST, DXF, AI, JPG, GIF, PGN, TIF, etc. |

| Supported Software | CorelDraw,PhotoShop,AutoCAD,etc. |

| Laser Control Mode | 1-100% Software Control |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Repeat Positioning Accuracy | ±0.01mm |

| Total Power | <3200W |

| Minimum Processing Size | 1x1mm |

| Operating Voltage | 220V/50Hz-60Hz |

| Dimensions | 3900*2000*1500mm |

| Weight | 1700kg |

Application Scope of 1325 Carbon Dioxide Laser Engraving and Cutting Machine

The 1325 CO2 laser engraving machine has a wide range of application materials and is suitable for various non-metallic materials: wood, acrylic (plexiglass), plastic (such as PVC, ABS), leather, cloth, rubber, paper, two-color board, MDF, plywood, bamboo products, shells, coconut shells, bones, horns, resin, ceramics, glass, crystal, stone, etc.

Application Products:

Photo frames, decorative panels, wooden puzzles, architectural models, ships, aviation models, wooden toys, wood carvings, advertising standard, acrylic crystal characters, display boards, lighting panels, packaging boxes, model parts, seals, molds, applique embroidery, belts, shoe uppers, bags, fabric toys, carpets, cardboard, corrugated boxes, gift boxes, greeting cards, paper-cuts, paper sculptures, handicrafts, souvenirs, bookmarks, ornaments, etc.

FAQs of 1325 CO2 Laser Engraving Machine

The engraving line is not straight:

- The screws at both ends of the belt are not tightened. You need to tighten the screws at both ends of the belt.

- The laser bracket extends too much, causing the laser to shake during operation. You need to raise the laser and tighten the laser screws to reduce laser vibration.

- The synchronous belt is not tight. Tighten the belt.

The pattern cannot be engraved or the pattern is not clearly engraved:

- The laser focal length is not adjusted properly, and the laser focal length needs to be adjusted.

- The engraving power is too small or the engraving speed is too high. The engraving power needs to be adjusted according to the material parameters.

- The imported image is not clear or the processing is not ideal. Confirm whether the imported image is clear and whether the image processing is ideal.

- The engraving machine is not leveled and tilted. Check whether the engraving machine is level.

- There is dust or debris in the laser output hole. Check whether there is dust or debris in the laser hole.

Insufficient or uneven engraving depth:

- The material surface is uneven or the laser power is set too low.

- The synchronous belt or parts are worn, clean the lens/laser tube, and replace the worn parts.

- Reduce the engraving speed and increase the laser power.

- Check the file path and reset the software parameters.

Cutting/engraving position offset or misalignment:

- Motor wire contact is poor or driver is faulty, replace the damaged driver or motor wire.

- Limit switch is faulty or sensor is dirty, clean the limit switch and check the sensor connection.

- Electrostatic interference or poor grounding, check the machine grounding and eliminate interference.

No response when powered on or abnormal reset:

- The power is not connected and the emergency stop switch is not reset. Check the power switch and emergency stop button.

- The control card is loose/damaged or the mainboard is faulty. Check the control card.

The software cannot connect or data transmission fails:

- The data cable is in poor contact, please replace the data cable.

- The software parameter setting is wrong (such as serial port mismatch), please reinstall the software.

- The computer system or driver is faulty, please check the driver and update the operating system.

| Model | CK-1325-C |

|---|---|

| Machine Color | Customizable |

| Working Size | 1300*2500mm(4*8ft) |

| Laser Tube | Reci/Yongli/EFR etc. |

| Laser Type | CO2 |

| Focusing Lens | US II-VI diameter 20 focal length 63.5 |

| Guideway | PMI -15(X) 25(Y)(Taiwan) |

| Drive Belt | High precision synchronous belt drive |

| Motor Driver | Leadshine motor drive |

| Control System | Ruida 6445S |

| Workbench | Aluminum Alloy Blade Workbench |

| Exhaust Fan | 550w |

| Air Pump | HAILI ACO-009E 165w |

| Water Cooler | S&A CW-6000 |

| Engraving Speed | 0-60000mm/min |

| Cutting Speed | 0-36000mm/min |

| Supported File Formats | BMP, PLT, DST, DXF, AI, JPG, GIF, PGN, TIF, etc. |

| Supported Software | CorelDraw,PhotoShop,AutoCAD,etc. |

| Laser Control Mode | 1-100% Software Control |

| Operating Temperature | 0-45℃ |

| Operating Humidity | 5-95% |

| Repeat Positioning Accuracy | ±0.01mm |

| Total Power | <3200W |

| Minimum Processing Size | 1x1mm |

| Operating Voltage | 220V/50Hz-60Hz |

| Dimensions | 3900*2000*1500mm |

| Weight | 1700kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.