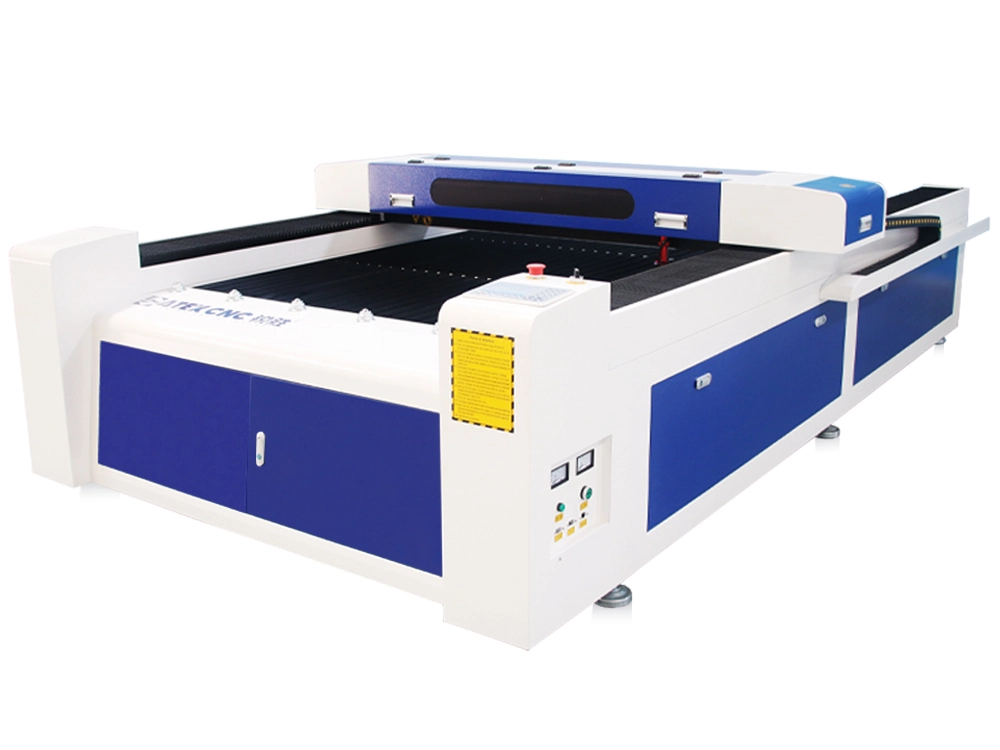

CO2 Laser Cutting Machine With Vision Positioning and Conveyor for Production Line

6x5ft CO2 Laser Fabric Cutter With Vision Positioning and Conveyor

[Function Description]

The CK-1815-CCD is a CO2 laser engraving machine that combines a Canon DSLR camera with a conveyor belt worktable, specifically designed for processing various printed fabrics such as cotton, linen, silk, wool, and synthetic fibers (polyester, nylon, acrylic, and polyester fiber).

Equipped with a high-precision camera and vision system, it enables rapid image capture and analysis of materials. Through visual algorithms, it automatically identifies the contours, patterns, and designs of the material, achieving a positioning accuracy of 0.01 mm. This allows for automatic cutting and engraving of complex patterns without manual alignment.

The machine features a conveyor belt worktable and a loading device, enabling automatic material loading, unloading, and transportation. This ensures continuous material processing, achieving fully automated production line operations.

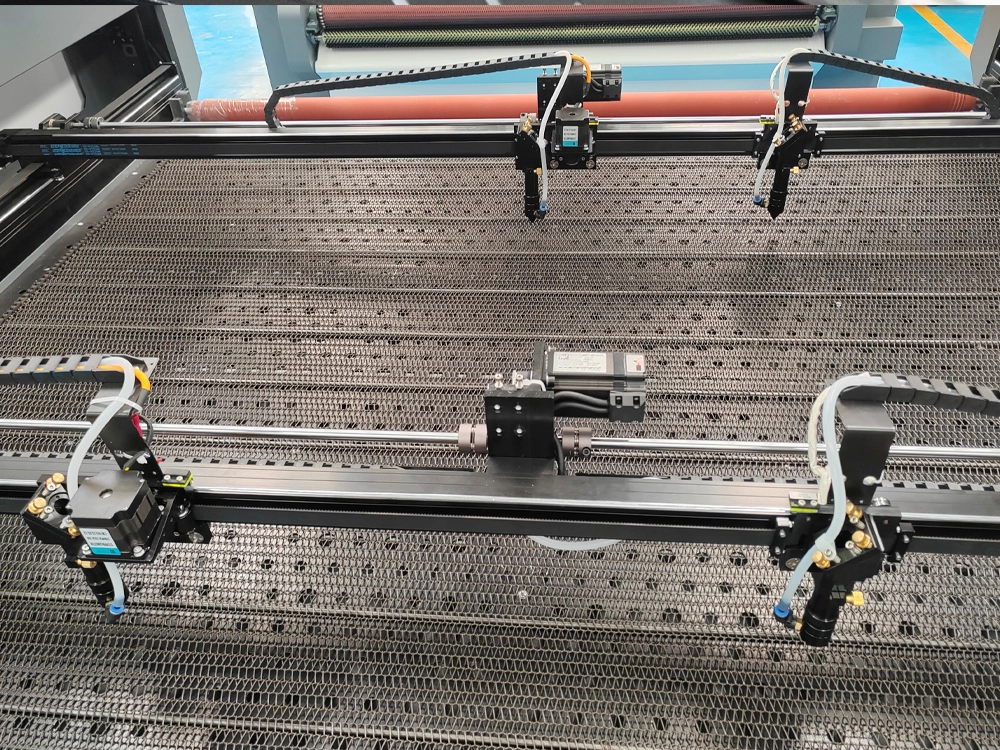

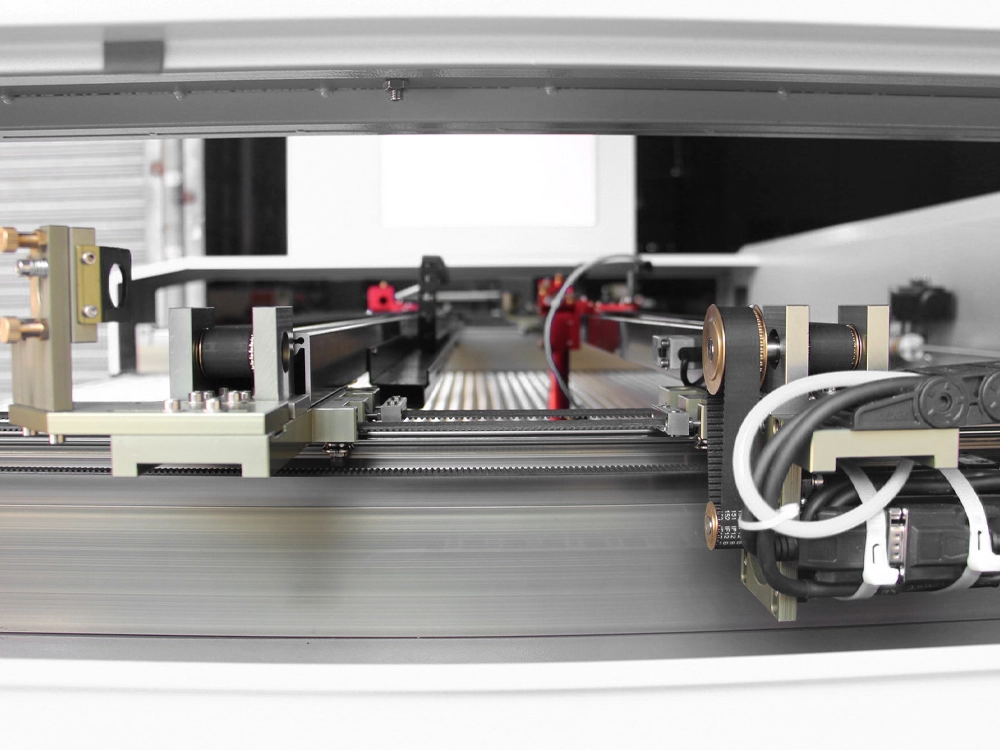

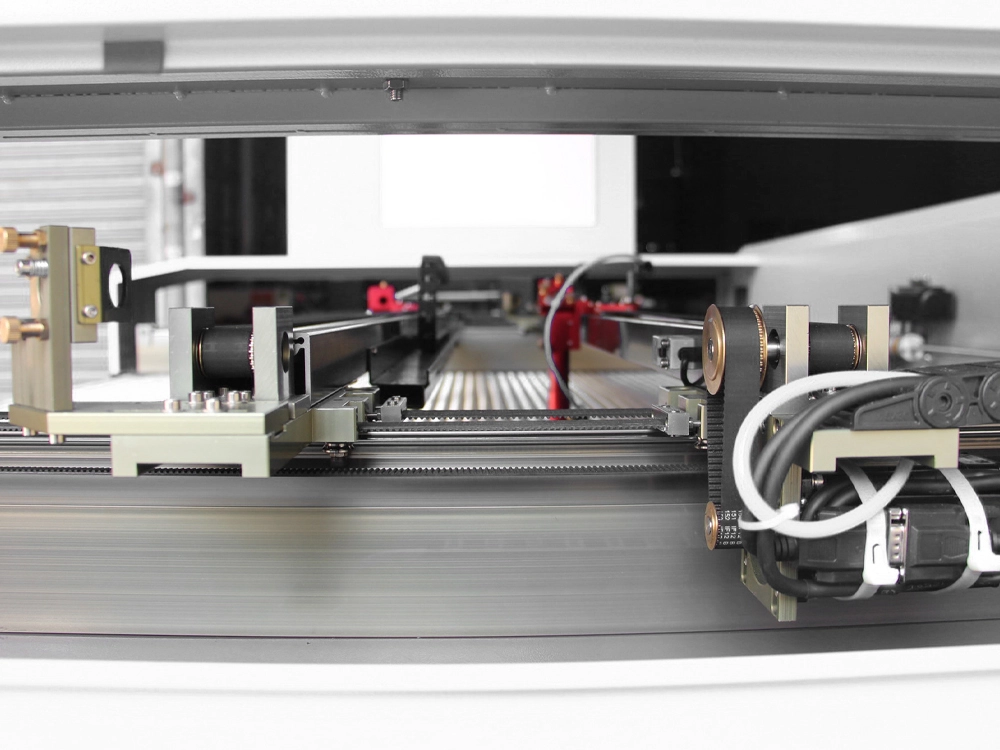

Additionally, the machine is equipped with four sets of laser systems. The processing area includes two crossbeams, each fitted with two laser heads. The laser heads on the same crossbeam can only perform identical tasks, while those on different crossbeams can execute different tasks. As a result, the machine can simultaneously perform four identical tasks or use two laser heads from different crossbeams to collaboratively process the same product. Whether for mass production or complex single-product processing, this machine significantly enhances efficiency.

Features of CO2 Laser Engraving Machine with CCD and Conveyor for Factory

- Equipped with CCD Camera: The machine features a CCD camera that quickly and accurately identifies and collects shape information of materials to be processed, enabling high-precision edge-following engraving and cutting.

- Non-Contact Processing: The non-contact processing method ensures that the material is not subjected to mechanical pressure during processing, preventing deformation. This allows for safe handling of fragile or flexible materials, avoiding errors caused by material distortion.

- Conveyor Processing Platform: The conveyor automatically transports materials to the working area, making it suitable for continuous production lines. The conveyor is highly durable and elastic, operates smoothly with low noise, and minimizes impact and vibration on materials, enhancing processing quality.

- Wide Material Compatibility: The CO2 laser engraving machine can engrave and cut almost any non-metallic material, including leather, fabric, ceramics, glass, rubber, bamboo, wood products, and more, making it highly versatile.

- High-Performance CO2 Laser: The high-performance CO2 laser provides efficient engraving and cutting capabilities, suitable for large-area products. The combination of continuous conveyor feeding and high-speed laser processing significantly improves overall production efficiency.

- Water Cooling System: The machine is equipped with a water circulation cooling system, a high-precision temperature control system, and multiple alarm functions to ensure comprehensive protection of the laser. It also features dual-inlet and dual-outlet water circulation interfaces and a water level gauge for added convenience.

- User-Friendly Control System: The control system is easy to operate and supports multiple language interfaces. It is compatible with file formats from various software such as AutoCAD, CorelDRAW, Photoshop, and Illustrator (e.g., PLT, DXF, BMP, JPG, AI). It can be controlled via PC connection or USB file input, offering flexible operation.

- CCD Edge-Following System: The CCD edge-following system can also be used for cutting pre-printed products. It offers fast recognition and cutting speeds, with simple operation. This system eliminates the issue of waste caused by inaccurate manual positioning in traditional methods. With just one button, it automatically recognizes edges, eliminates the need for engraving drawings or templates, and ensures fast positioning and high cutting precision.

Details of CO2 Laser Fabric Cutting Machine

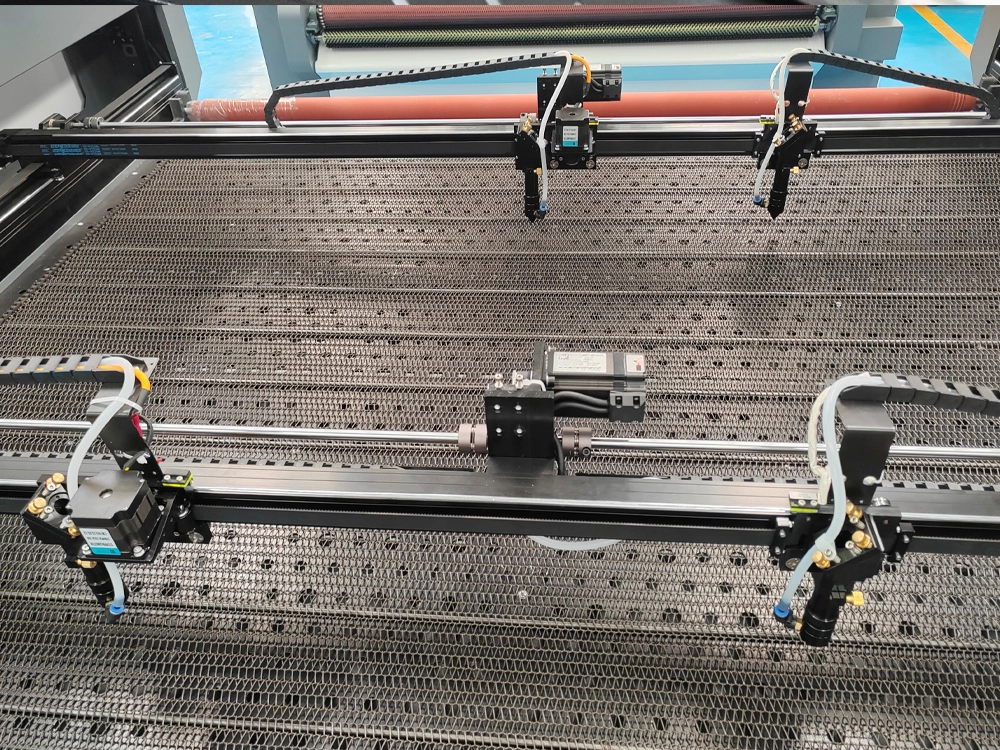

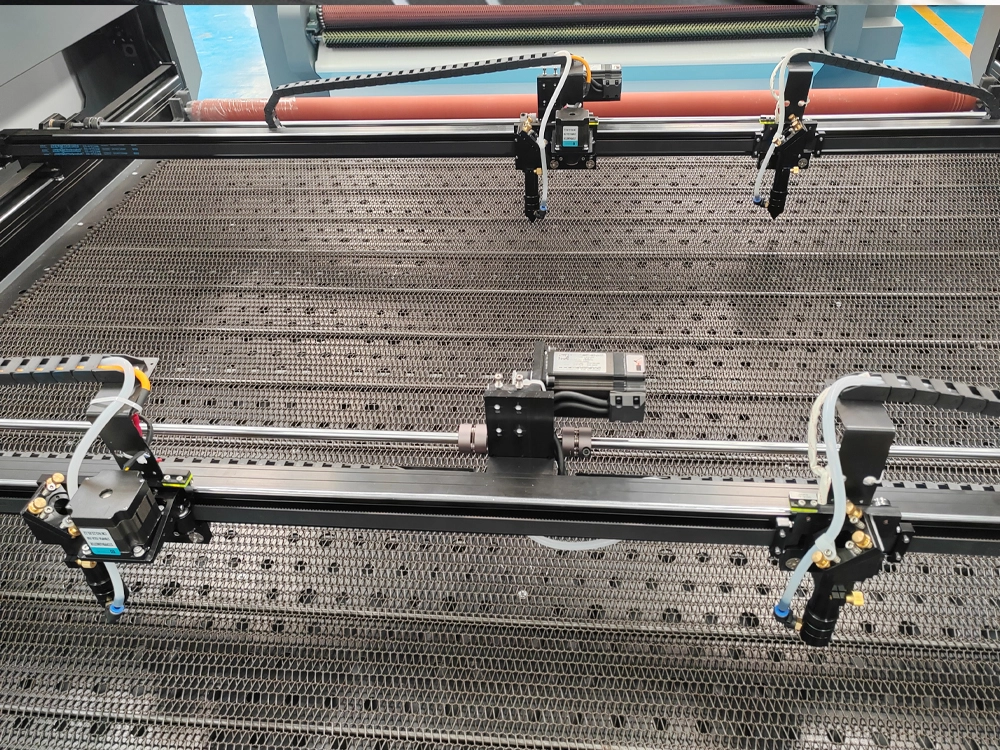

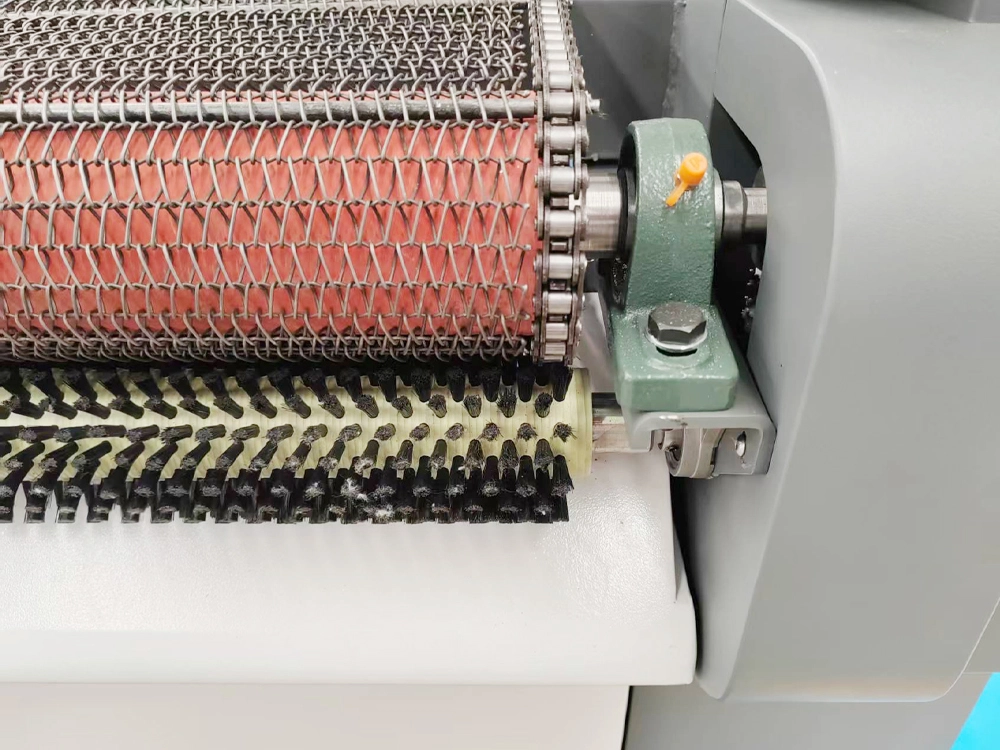

- Mesh belt Workbench and four laser components

-

The stainless steel mesh belt workbench is more suitable for placing fabric products. It is equipped with two beams, each of which is fitted with two laser heads. The laser heads on different beams can work collaboratively and simultaneously, allowing the use of all four laser heads to perform four identical tasks at the same time.

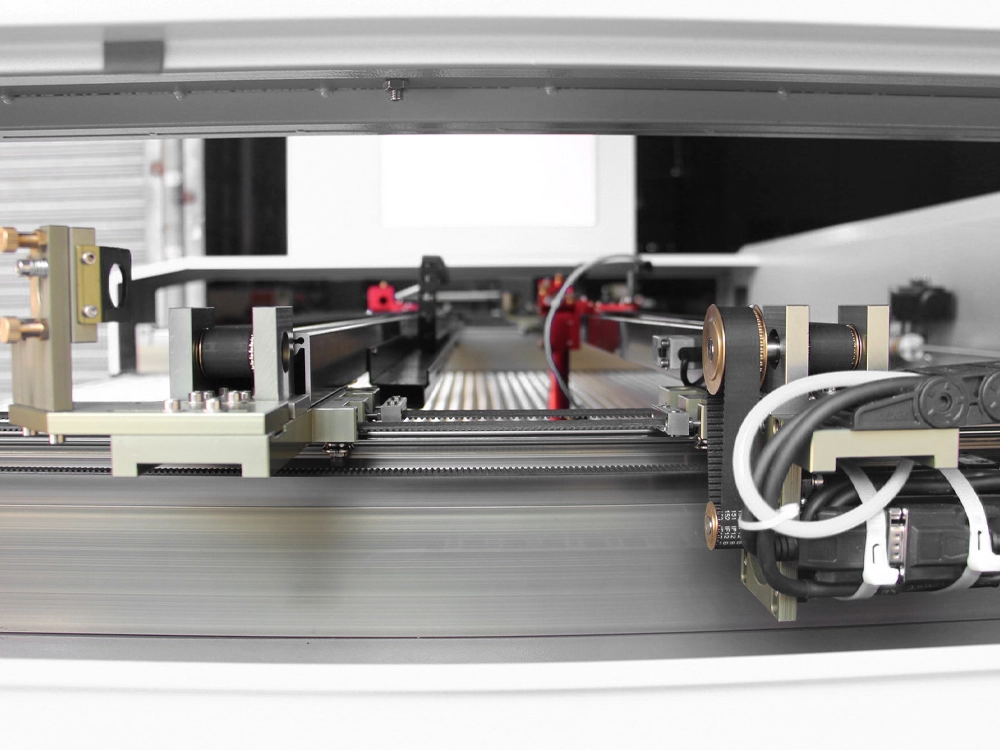

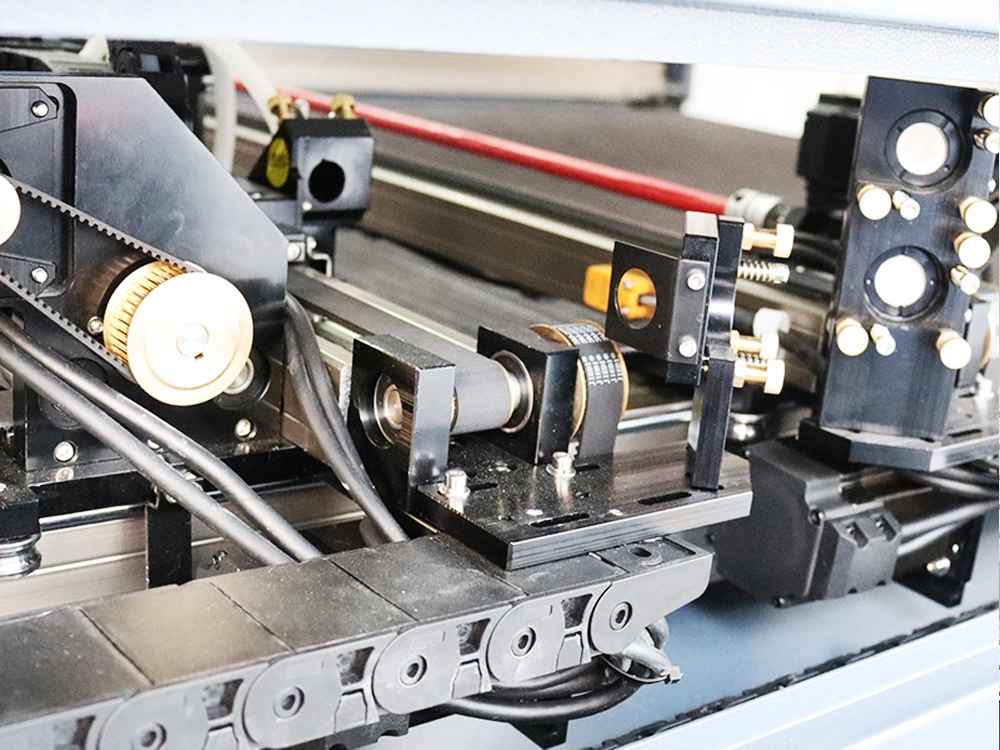

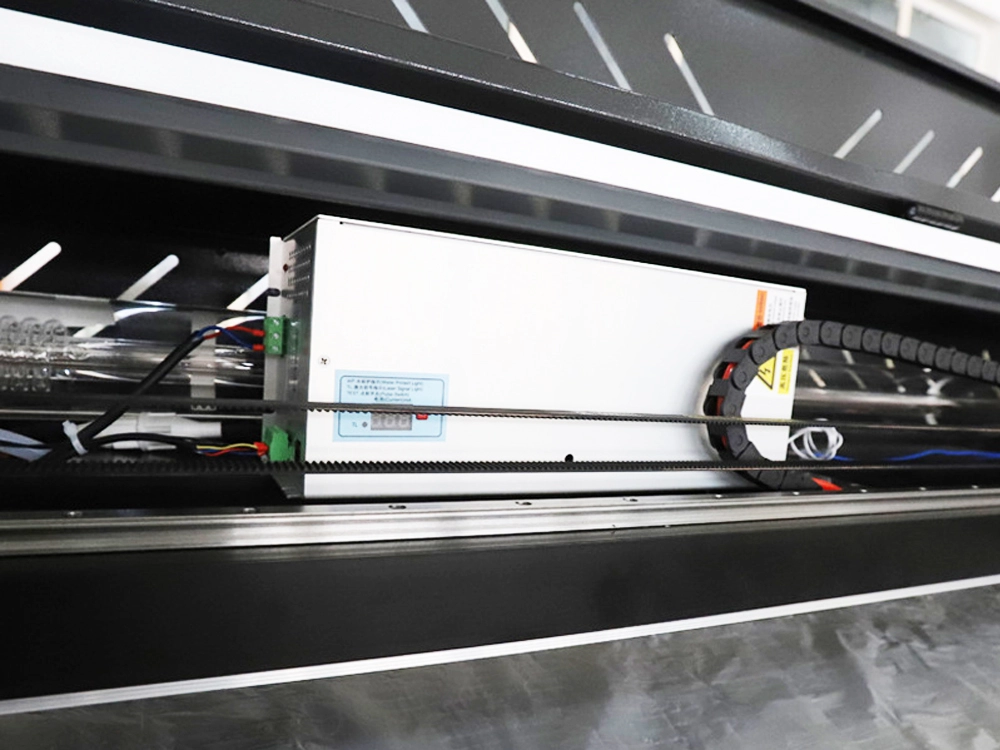

- Transmission system

-

The transmission system adopts synchronous belt transmission, The belt has high toughness and elasticity, runs smoothly, has low noise, and can alleviate impact and vibration.

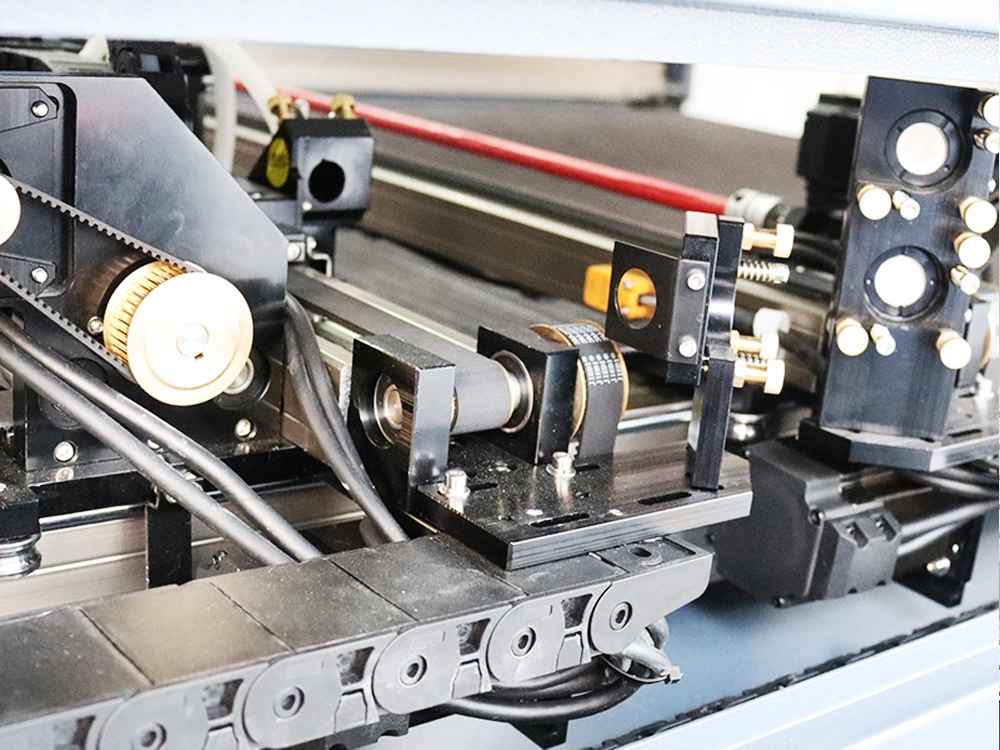

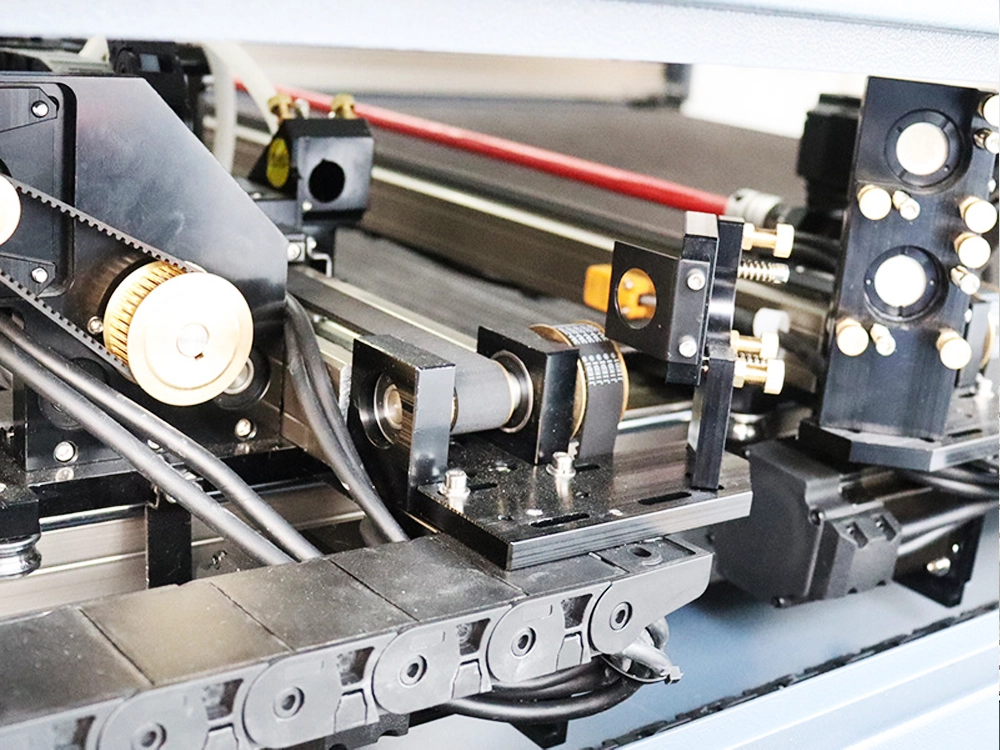

- Vision system

-

The image is provided by a fixed Canon 18MP high-definition wide-angle camera mounted at the top.

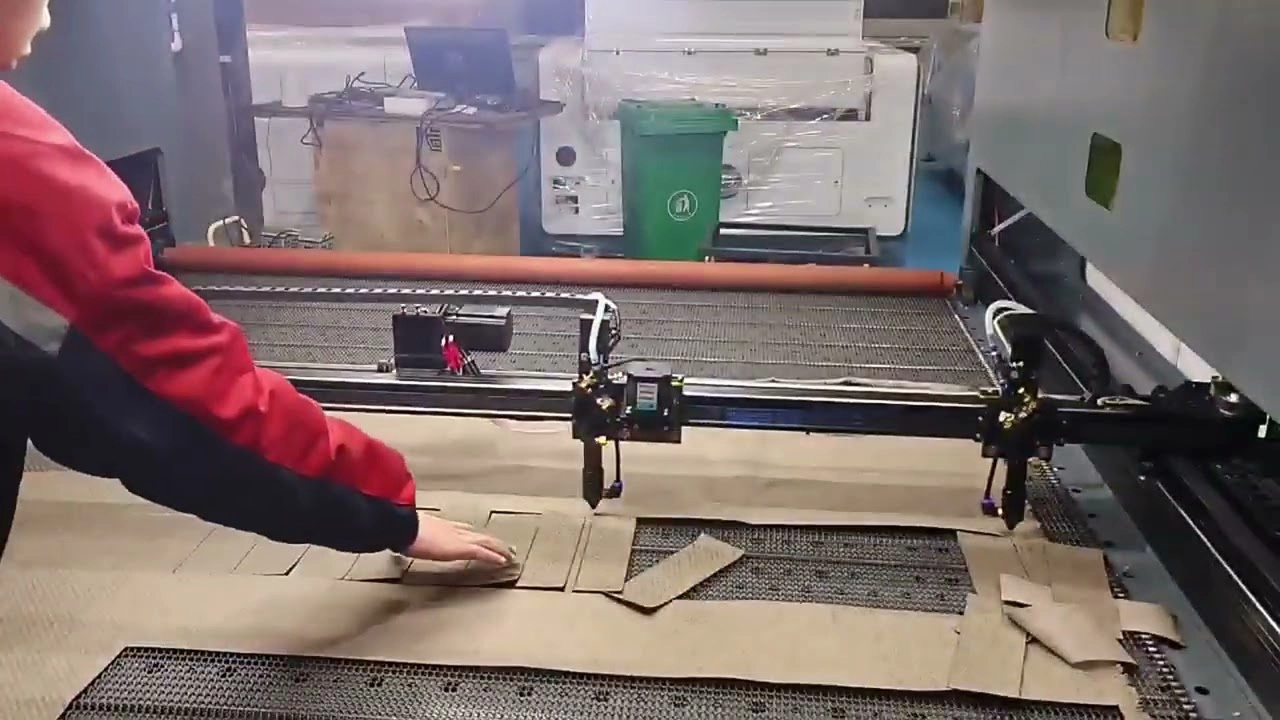

- Mesh belt conveyor

-

The fabric is placed on the conveyor belt and moves as the belt rolls. The tail end of the conveyor belt is equipped with a brush roller, which can sweep away waste and debris generated during the processing.

- Optional coiled material feeding device

-

Coiled material can be placed in the unit, which automatically feeds them as processing proceeds.

- Control panel

-

TL5269 has the functions of 9-axis, 6-head laser independent control, single-beam 3 heads mutual movement, double-beam asynchronous, automatic feeding function, and it equipped with 7-inch TFT LCD touch screen, 32-bit high-speed DSP, and USB2.0 high-speed interface.

Technical Parameters of CO2 Laser Cutter with Vision and Conveyor

| Model | CK-1815-CCD |

| Work Area | 1800 * 1500mm (customizable according to processing requirements) |

| Laser Type | CO2 laser |

| Laser Power | 150W/180W/200W/300W |

| Laser Tube | EFR Laser Tube |

| Laser Head | Auto focus, red light positioning |

| Focusing Lens | US Import II-VI |

| Resolution | ≤0.0125mm |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Motor | Servo motor |

| Table | Automatic feeding mesh belt conveyor Follow-up feeder |

| Cooling | S&A CW6000 Water Chiller |

| Visual Identity | 18 milion pixels Cannon DSLR camera (View size 2600 * 2250 * 1750mm) |

| Control System | Ruida/Trocen |

| Supported Formats | JPG,JPEG, PLT, DST, PLT, BMP, DXF, AI |

| Engraving Speed | 1-60000mm/min |

| Cutting Speed | 1-10000mm/min |

| Cutting Thickness | ≤ 25mm (depending on material) |

| Weight | 1700kg |

| Dimensions | 2600mm*2250mm*1750mm |

What Materials Can CO2 Laser Engravers Be Used For?

- Fabrics and Leather: Woven labels, ribbons, fabric belts, soft textiles, denim, cotton, linen, polyester, synthetic fibers, curtains, embroidery, leather, genuine leather, synthetic leather, technical fabrics, carbon fiber fabrics, etc.

- Plastics: Acrylic, advertising signs, crystal letters, PCB boards, PVC, EVA, foam, plexiglass, resin, PP, PE, ABS, PC, PET, etc.

- Wood: MDF boards, solid wood boards, wooden puzzles, toys, wooden products, bamboo and wood products, plywood, cork, etc.

- Other Materials: Silicone, rubber, paper, cardstock, glass, ceramics, marble, jade, anodized aluminum, etc.

The Following Are the Processable Products of 4x8 CO2 Laser Engraving Machine with CCD and Conveyor

| Model | CK-1815-CCD |

|---|---|

| Work Area | 1800 * 1500mm (customizable according to processing requirements) |

| Laser Type | CO2 laser |

| Laser Power | 150W/180W/200W/300W |

| Laser Tube | EFR Laser Tube |

| Laser Head | Auto focus, red light positioning |

| Focusing Lens | US Import II-VI |

| Resolution | ≤0.0125mm |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Motor | Servo motor |

| Table | Automatic feeding mesh belt conveyor Follow-up feeder |

| Cooling | S&A CW6000 Water Chiller |

| Visual Identity | 18 milion pixels Cannon DSLR camera (View size 2600 * 2250 * 1750mm) |

| Operating Voltage | 110V/220V 50/60hz |

| Control System | Ruida/Trocen |

| Supported Formats | JPG,JPEG, PLT, DST, PLT, BMP, DXF, AI |

| Engraving Speed | 1-60000mm/min |

| Cutting Speed | 1-10000mm/min |

| Cutting Thickness | ≤ 25mm (depending on material) |

| Weight | 1700kg |

| Dimensions | 2600mm*2250mm*1750mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.