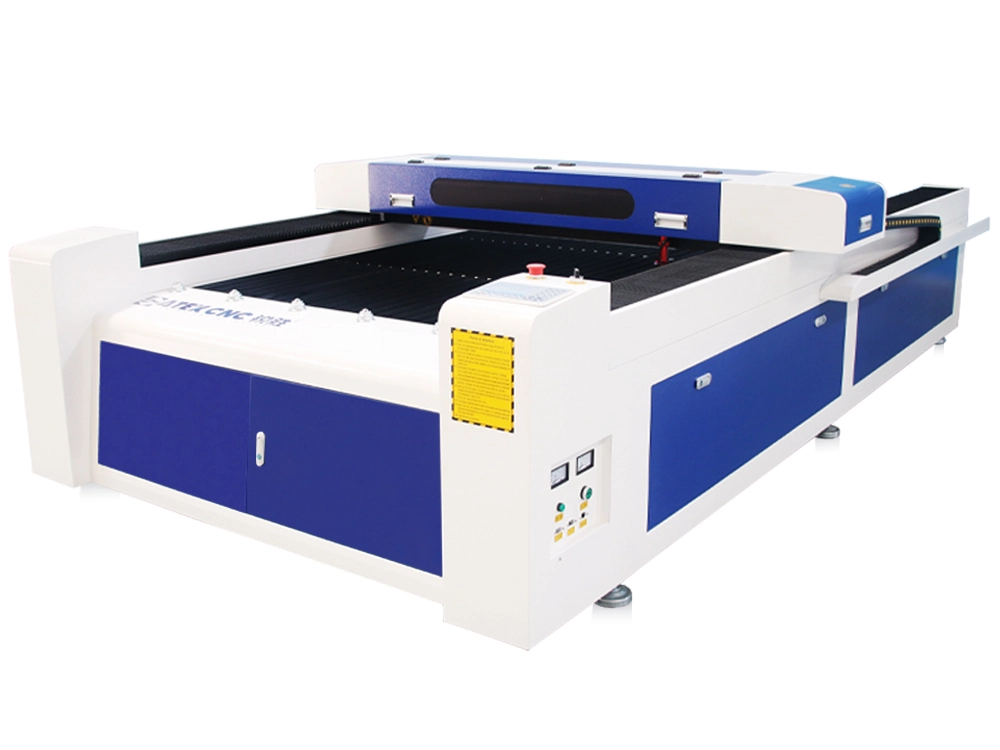

Out of the Box CO2 Laser Cutter With Two Laser Cutting Heads

2-Station CO2 Laser Engraving Machine Suitable for Batch Processing

[Function Description]

The 2-station CO2 laser engraving machine is equipped with two independently movable laser heads. Each laser head features an independent laser tube and optical transmission line, and the laser beam is precisely directed onto the material surface through a system of mirrors and focusing lenses. The dual-head design allows for the simultaneous execution of two identical processing tasks, improving efficiency by 70%-90% compared to standard single-laser-head machines. It also enables independent control of a single laser head for processing. Additionally, this design offers a degree of fault redundancy; if one laser head malfunctions, the other can continue operating, reducing downtime risks. A dual-head CO2 laser engraving machine can replace two standard single-head machines, saving on procurement costs and factory space.

Advantages of CO2 Laser Engraving and Cutting Machine with Two Laser Heads

- The machine features two optical systems, two laser heads, and two laser tubes that can operate simultaneously, enhancing processing efficiency and making it more suitable for large-scale production, significantly increasing production speed.

- With two laser heads working concurrently, the processing cost per product is reduced, offering greater economic benefits and lower processing costs for high-volume production needs.

- It utilizes two separate sealed CO2 laser tubes, each operating independently without interference. If one laser head fails, the other can continue working.

- Both laser heads employ the same design of three mirrors + dynamic focusing lenses, with optical path calibration accuracy ≤ 0.05mm, ensuring consistent output from both heads.

- Cooling is achieved through a water-cooling system with constant temperature control, maintaining water temperature between 20°C and 25°C via a temperature control module, ensuring stable laser output power.

- The aluminum alloy beam support is lightweight, suitable for high-speed moving processing, with low load and fast speed.

- Taiwan HIWIN square linear guides ensure repeat positioning accuracy ≤ 0.01mm, enabling fast movement and high-speed processing without trailing issues.

- The machine uses RDWorks control software specifically designed for CO2 engraving and cutting machines, supporting multi-layer processing task management and allowing simultaneous editing of processing paths for both heads.

Details of 2-station CO2 Laser Engraving Machine

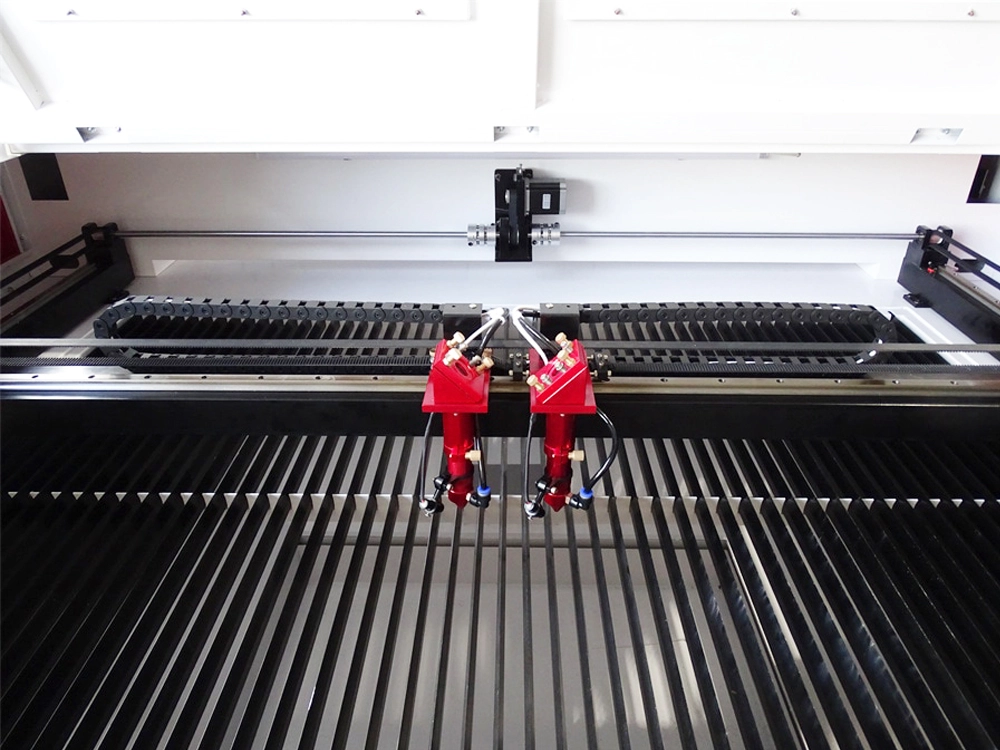

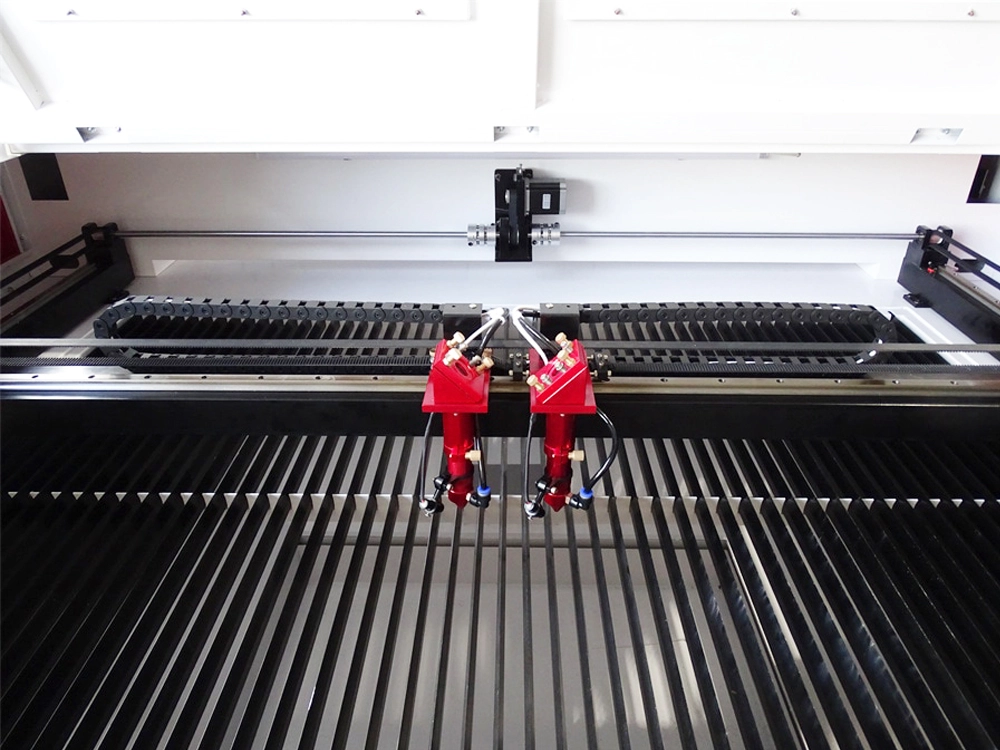

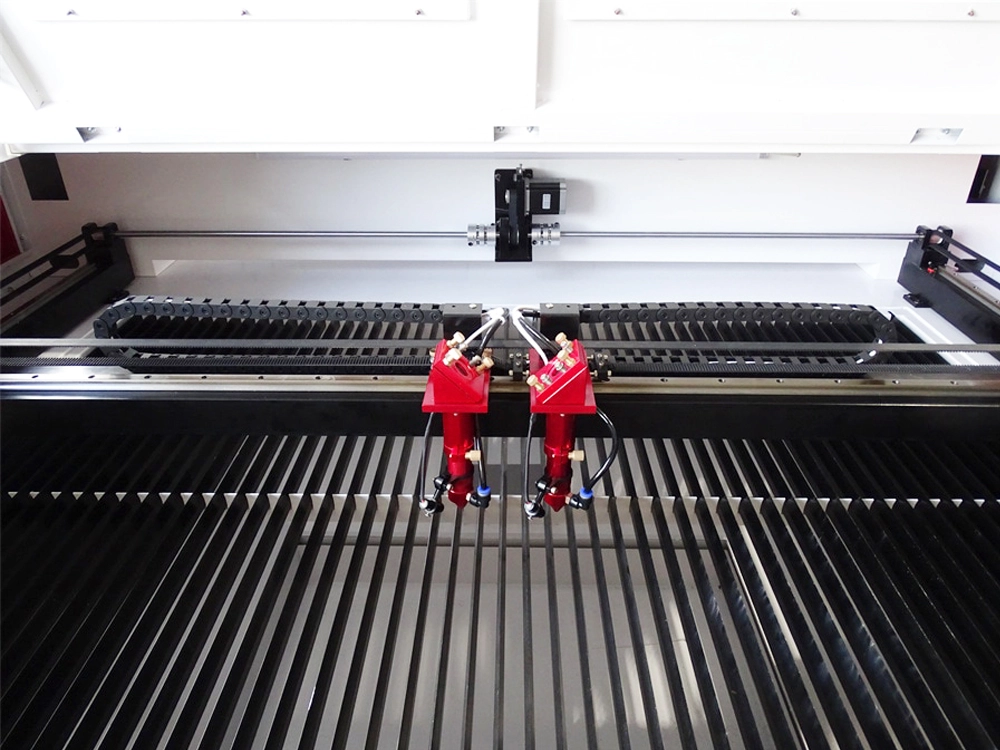

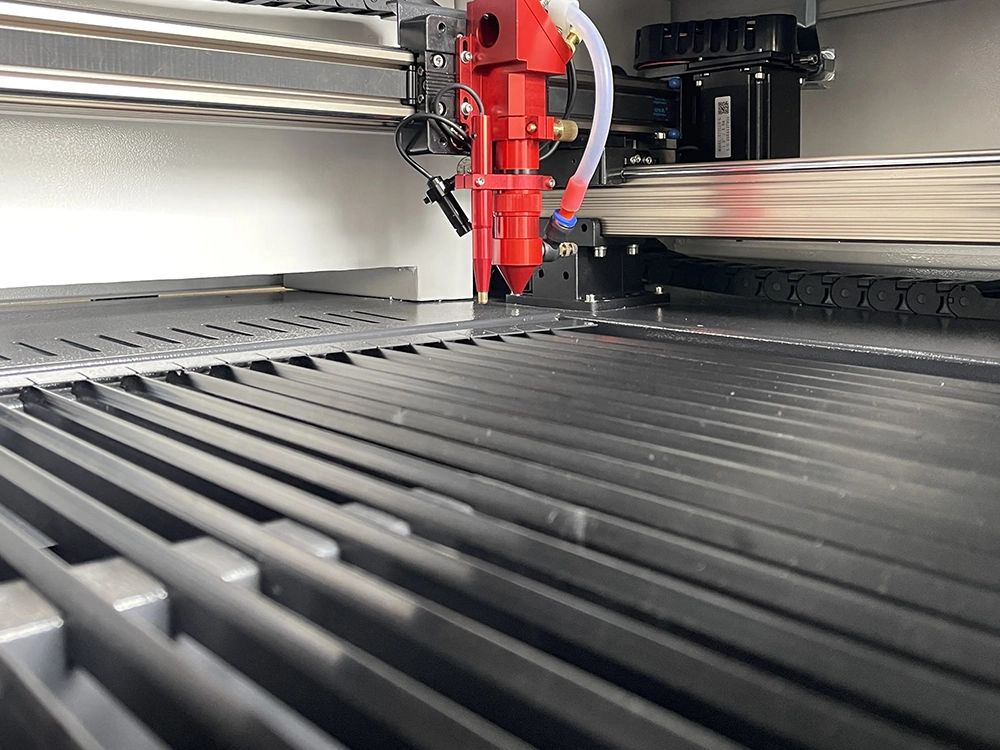

- Laser heads

-

Equipped with two laser heads, two identical products can be processed simultaneously.

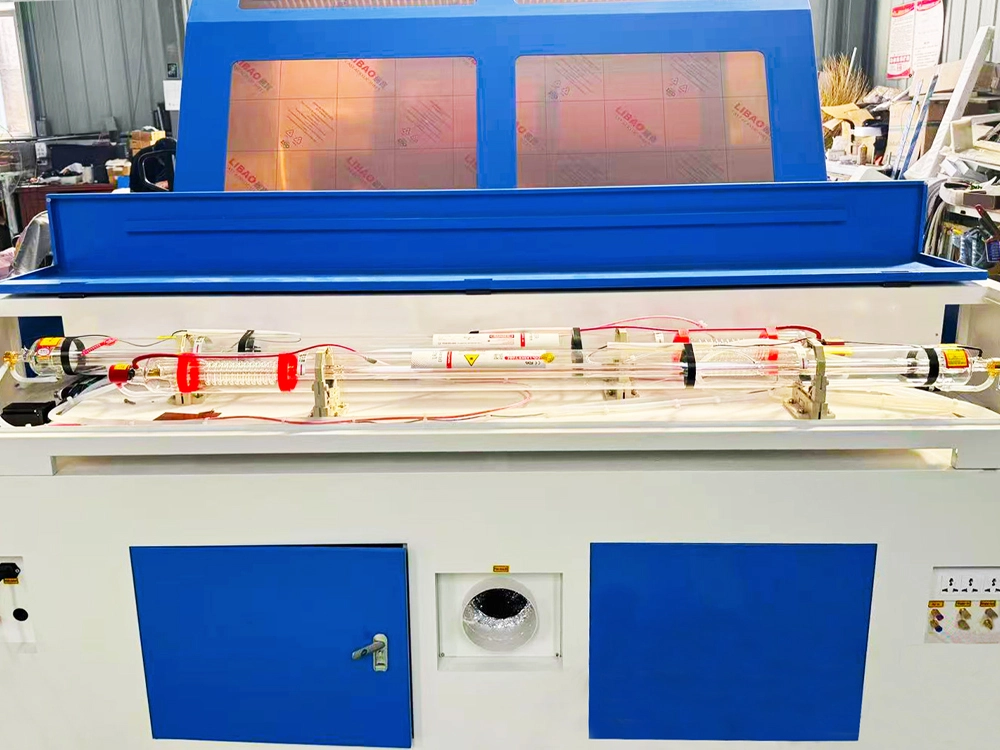

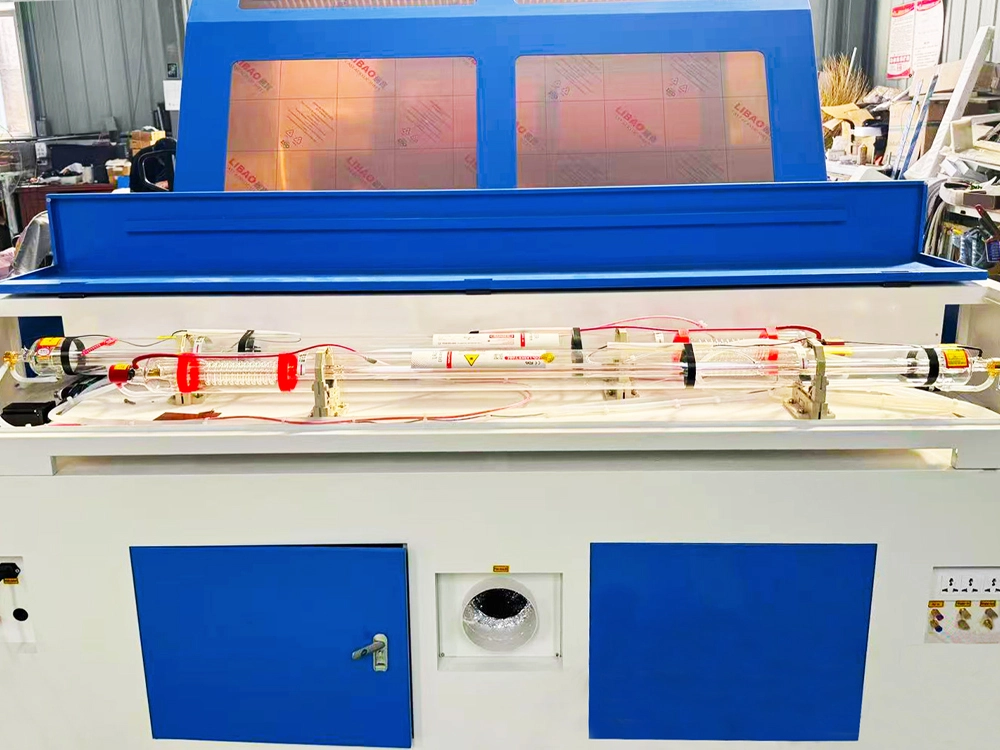

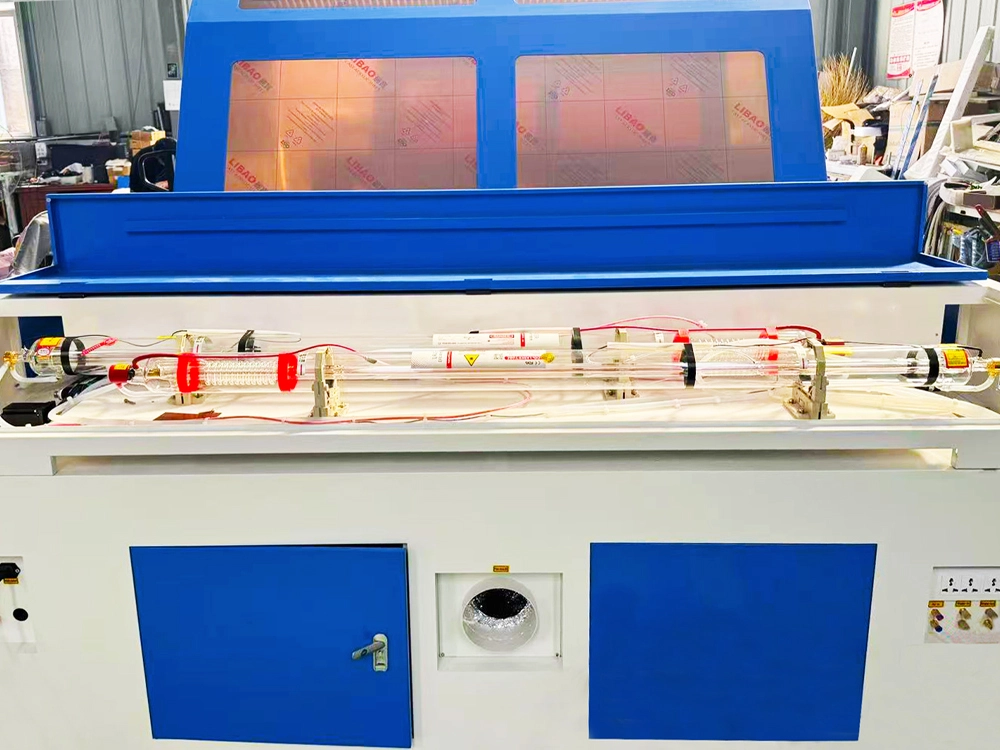

- CO2 laser glass tubes

-

Equipped with two DC CO2 laser glass tubes.

- Air pump

-

Equipped with two air pumps to blow air on the laser head to cool the workpiece.

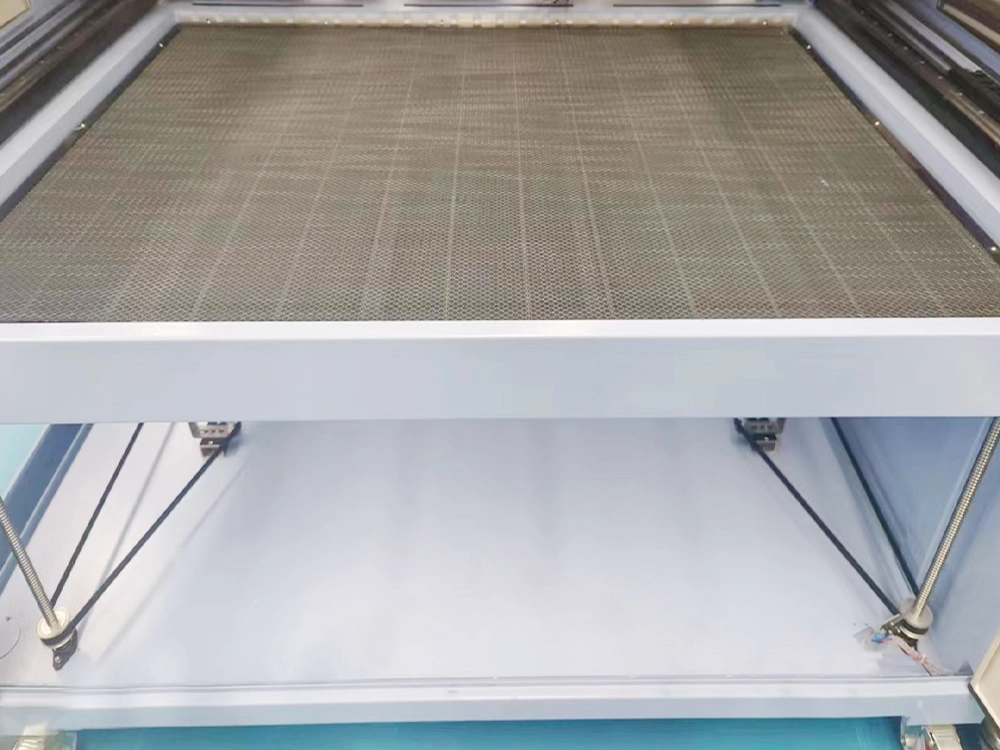

- Slats workbench

-

The slatted workbench has a simple structure, strong load-bearing capacity, easy heat dissipation, and simple waste cleaning.

- Honeycomb workbench

-

The honeycomb workbench provides even and good support for workpieces that are susceptible to deformation

- Panel

-

The rear of the machine is equipped with power sockets, air switch, power inlet, air intake port, water inlet/outlet ports, and water chiller control cable.

The side of the machine features ammeter/voltmeter, indicator light switches, laser power switch, USB port for computer connection, and an Ethernet port.

- Ruida control panel

-

Ruida control system has multi-language support. It supports online control by connecting to a computer and also supports offline operation.

- Two-station CO2 laser cutting machines in the production workshop

-

The machine supports customized appearance and color.

Technical Parameters of 2-Station CO2 Laser Engraving Machine

| Model | CK-1390-2C |

| Work Area | 1300 * 900mm (customizable according to processing requirements) |

| Laser Type | CO2 laser |

| Laser Power | 80W/100W/150W |

| Laser Tube | RECI/YongLi AS6 Laser Tube |

| Laser Head | Auto focus, red light positioning |

| Focusing Lens | US Import II-VI |

| Resolution | ≤0.0125mm |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Motor | Stepper motor (customizable servo motor) |

| Workbench | Slats workbench or honeycomb workbench |

| Security System | Open cover stop system (optional) |

| Cooling | S&A CW5000 Water Chiller |

| Protective Cover | XY dust cover protection |

| Control System | RDC6442S/ RDC6445G RUIDA |

| Control Software | RDWORKS V8 |

| Supported Formats | JPG,JPEG, PLT, DST, PLT, BMP, DXF, AI |

| Engraving Speed | 1-60000mm/min |

| Cutting Speed | 1-10000mm/min |

| Cutting Thickness | ≤ 25mm (depending on material) |

| Weight | 700kg |

| Dimensions | 2100mm*1500mm*1200mm |

What Products Can a CO2 Laser Engraving Machine Process?

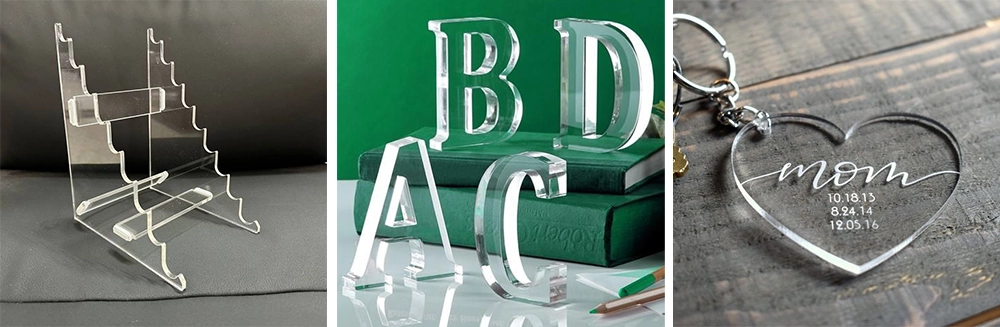

- Acrylic Products: Signs, doorplates, directional signs, floor index signs, backlit advertising letters, LED lightbox panels, acrylic display stands, POP advertising stands, acrylic display holders, acrylic crafts, etc.

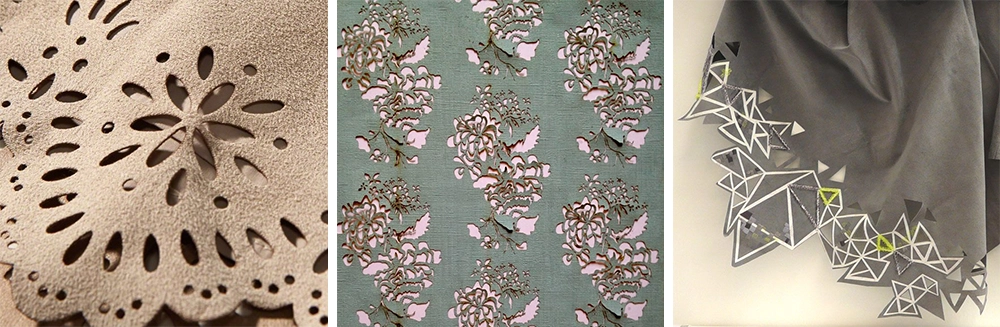

- Apparel and Textiles: Lace trim, shoe upper cutouts, leather trademarks, handbag decorative patterns, shoe soles, curtain cutouts, tablecloth cutouts, fabric cutting, denim cutting, carbon fiber fabric cutting, etc.

- Crafts and Gifts: Wooden carvings, photo frames, jewelry boxes, bamboo scrolls, tea set trays, tea set bases, cup holders, wooden plaques, wooden badges, MDF puzzles, MDF building blocks, architectural models, toy parts, etc.

- Packaging: Paper packaging, corrugated cardboard, wine boxes, cosmetic boxes, tea boxes, shoe boxes, gift boxes, airplane boxes, etc.

- Other Products: Rubber stamps, anti-slip mats, rubber molds, circuit boards, silicone buttons, insulation sheet cutting, phone case engraving, keychain engraving, etc.

- Bamboo wood cutting and engraving

- Acrylic cutting and engraving

- Paper cutting and hollowing

- Fabric cutting and hollowing

- Leather cutting and hollowing

Installation and Use of CO2 Laser Engraving and Cutting Machines

The installation of a CO2 laser engraving machine involves multiple steps, including the installation of the laser tube, setup of the cooling system, power connection, and optical path adjustment. Below are detailed installation steps for your reference:

- 1. Laser Tube Installation

-

First, ensure the laser tube is not damaged during transportation, such as cracks or dents. Then, install the laser tube by inserting it into the groove and tightening it to the required height using the side screws. Finally, connect the high-voltage and low-voltage wires of the laser power supply to the corresponding terminals of the laser tube, and seal the terminals with silicone for safety.

- 2. Cooling System Setup:

-

Fill the water chiller with water and connect the water inlet and outlet of the machine to complete the water circulation circuit. Then, connect the chiller to the power supply and observe if the water fills the internal pipes of the laser tube and the water flow from the outlet pipe to ensure the water pump is functioning properly.

In cold weather where freezing may occur, add antifreeze to the water tank to prevent ice formation. After use, drain the water from the laser tube to avoid freezing and cracking.

- 3. Power Connection:

-

Connect the power cord to the machine via a socket, ensuring the machine is properly grounded. Connect the air pump to the machine, linking the air pump's outlet pipe to the machine's inlet pipe.

- 4. Optical Path Adjustment:

-

Adjust the optical path of the CO2 laser engraving machine by calibrating the angles of the three mirrors to ensure the laser beam hits the center of the laser head's entrance hole. If the beam does not align or enter the laser head, readjust the optical path.

- 5. Safety Check:

-

After completing all installation steps, perform a safety check to ensure all connections are secure and there are no loose parts, guaranteeing the machine operates normally.

By following the above steps, you can successfully complete the installation of a CO2 laser engraving machine. If you encounter any issues during installation, feel free to contact our engineers for assistance. CATEKCNC engineers provide 24/7 online support and can offer after-sales service via Skype, Google Meet, WhatsApp, email, and other methods.

| Model | CK-1390-2C |

|---|---|

| Work Area | 1300 * 900mm (customizable according to processing requirements) |

| Laser Type | CO2 laser |

| Laser Power | 80W/100W/150W |

| Laser Tube | RECI/YongLi AS6 Laser Tube |

| Laser Head | Auto focus, red light positioning |

| Focusing Lens | US Import II-VI |

| Resolution | ≤0.0125mm |

| Transmission Mode | Taiwan Hiwin high precision linear square rail, Taiwan Hiwin slider |

| Motor | Stepper motor (customizable servo motor) |

| Workbench | Slats workbench or honeycomb workbench |

| Security System | Open cover stop system (optional) |

| Cooling | S&A CW5000 Water Chiller |

| Protective Cover | XY dust cover protection |

| Control System | RDC6442S/ RDC6445G RUIDA |

| Control Software | RDWORKS V8 |

| Supported Formats | JPG,JPEG, PLT, DST, PLT, BMP, DXF, AI |

| Engraving Speed | 1-60000mm/min |

| Cutting Speed | 1-10000mm/min |

| Cutting Thickness | ≤ 25mm (depending on material) |

| Weight | 700kg |

| Dimensions | 2100mm*1500mm*1200mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.