7x10ft Four-Axis CNC Wood Sculpting Machine With 180° Swing Head and Automatic Tool Changer

7x10ft Four-Axis Linear ATC CNC Wood Router with Tiltable Spindle

[Function Description]

What Is a Four-Axis CNC Router with Swing Head?

This four-axis CNC router enhances the traditional three-axis CNC router by incorporating a fourth axis that allows the spindle to tilt up to 180 degrees. This enables the machine to not only move along the X, Y, and Z axes but also to perform curved or side surface machining through the rotation of the spindle around its endpoint. The spindle can rotate ±90 degrees within the X-Z plane, breaking the limitation of being perpendicular to the workpiece and expanding the machining angle within a 180-degree range in the X-Z plane. As a result, it reduces the need for flipping and angle adjustment of parts during machining, minimizes manual intervention, avoids secondary calibration errors caused by human intervention, and shortens production time. The multi-axis linkage machining capability allows the four-axis CNC router to handle complex tasks that are difficult for traditional three-axis CNC machines. Whether in woodworking, advertising, or other machining fields, the four-axis CNC router demonstrates strong application potential and broad adaptability.

How Does a Four-Axis Swing Head Router Work?

This machine is equipped with traditional X, Y, and Z linear axes and a rotary axis. During the machining process, the spindle can tilt (±90°) within the X-Z plane to meet the engraving requirements of complex curved or sloped surfaces. The CNC system controls the movement of the three axes and the tilting of the spindle to complete the engraving and milling of intricate patterns. The addition of the fourth-axis tilting engraving head enables this machine to handle complex surface machining needs, allowing it to process shapes such as hemispheres, arcs, or semi-cylinders that ordinary engraving machines cannot achieve.

Additionally, this four-axis CNC router is equipped with a linear automatic tool changer. The tools are arranged in sequence in the tool magazine, which can hold up to 12 tools at once. When a tool change is required during machining, the automatic tool-changing spindle will place the currently used tool back into the magazine and then retrieve the next required tool from the magazine, securing it to the 9KW automatic tool-changing spindle. Controlled by the Taiwan Syntec four-axis control system and driven by servo motors, the machine achieves high-precision and high-speed machining.

In addition to wood, the four-axis swing head CNC router can also be used for plastics, foam and other materials. It is widely used in furniture manufacturing, handicraft production, advertising decoration, model making and other fields.

Advantages of a 7x10ft Four-Axis Swing Head CNC Router with Automatic Tool Changer Kit

- Equipped with a large table of 7x10 feet, it can process panels with a maximum size of 2.1m * 3m.

- Equipped with a linear tool-changing kit, supporting automatic switching of up to 12 tools (ISO30 tool holder, ER32 collet).

- Utilizes a 9KW automatic tool-changing spindle combined with a tilting spindle, enabling engraving, drilling, milling, and cutting on both the surface and the left/right sides simultaneously, and capable of machining various types of 3D curved surfaces (e.g., chair backs).

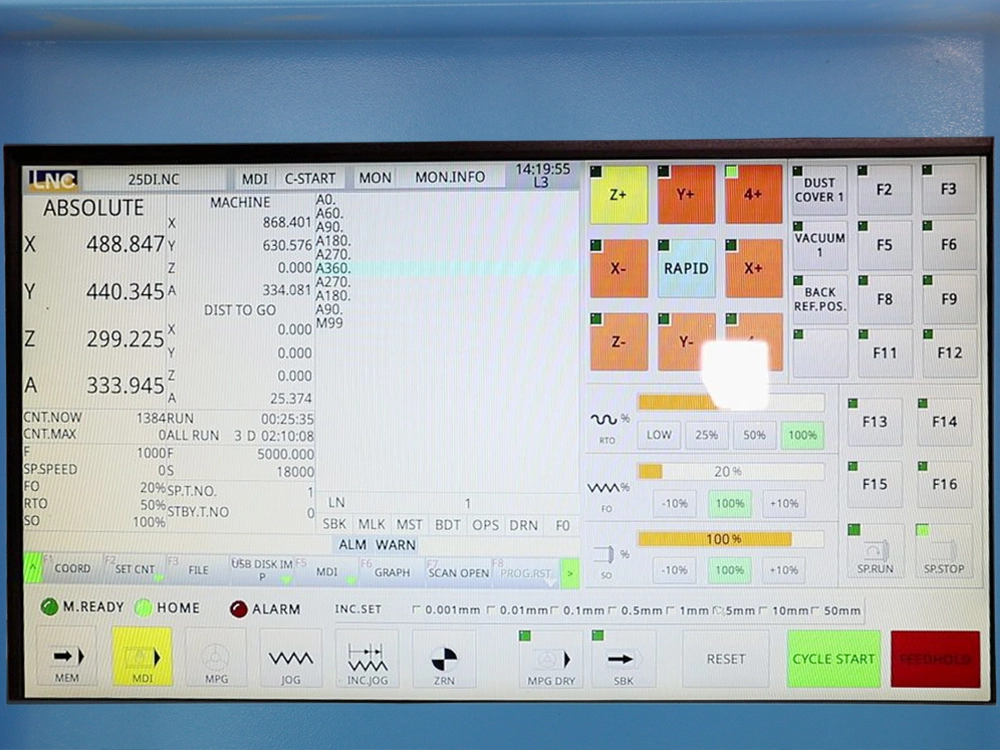

- Features the Taiwan Syntec four-axis CNC system, which is user-friendly and supports various functional expansions.

- Includes an external pulse handwheel control, supporting handwheel simulation for simpler operation.

- High-quality 1.5KW servo motors paired with Japanese Shimpo reducers, providing high torque and precise positioning.

- Equipped with 4+2 positioning cylinders, simplifying sheet positioning. Full-size sheets only need to be pressed against the positioning cylinders, and the vacuum suction can be activated.

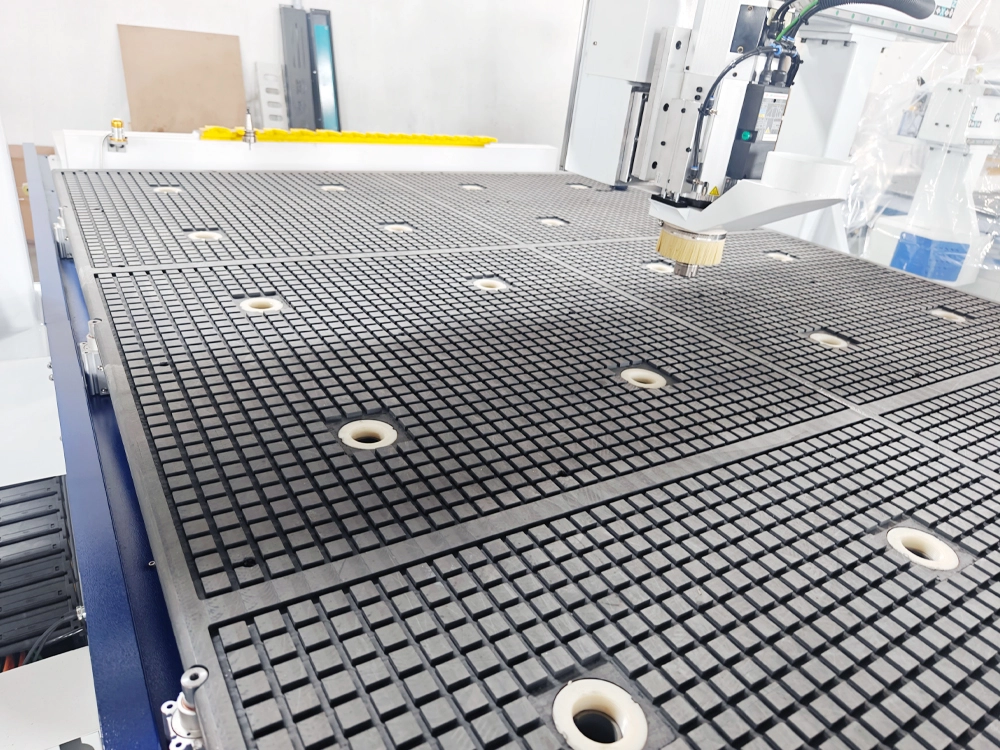

- Uses a vacuum suction + T-slot worktable. The vacuum suction table can be designed and partitioned according to your requirements to meet specific machining needs.

- Includes an automatic lubrication system for regular maintenance, minimizing machine failure rates.

- Heavy-duty welded bed structure, subjected to multiple high-temperature annealing treatments for enhanced stability.

- Utilizes imported ball screws for smoother machine operation and ensured precision.

Details of 7x10ft Four-Axis Swing Head CNC Router with Automatic Tool Changer Kit

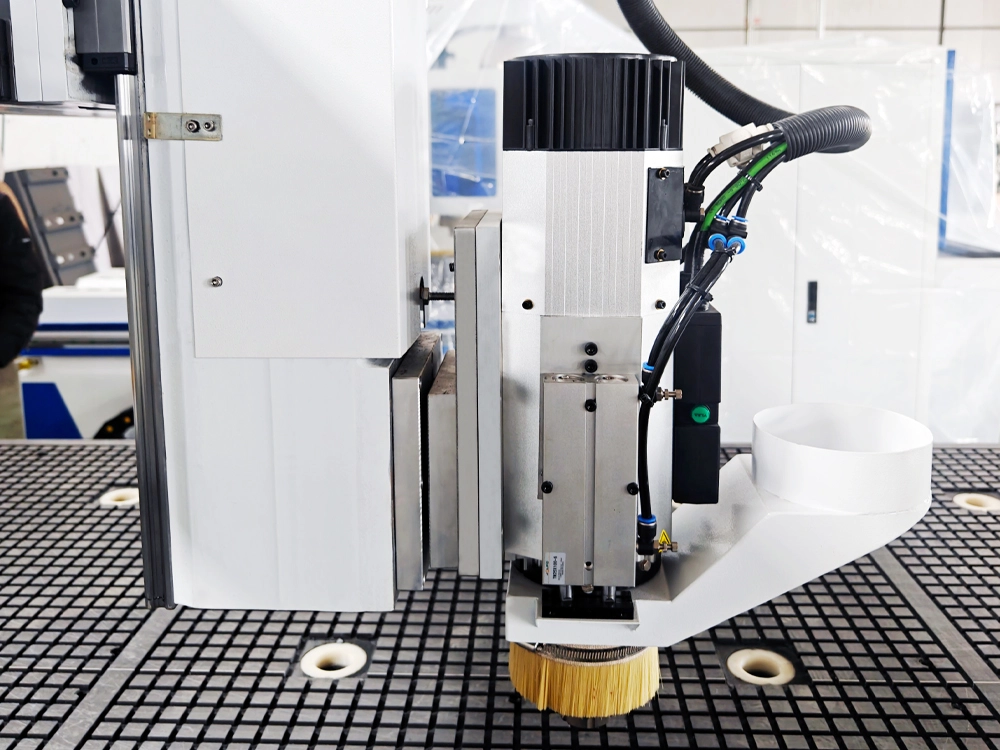

- 9KW automatic tool change spindle

High power, high torque, air-cooled spindle, simple and convenient maintenance.

- Rotary axis for spindle

This part can be rotated up to ±90° in the X-Z plane to allow the spindle to be tilted.

- Linear tool changer

Linear automatic tool-changing kit with a capacity of 12 tools, allowing all required tools for machining to be installed at once, ensuring simplicity in use.

- Automatic tool setter

Calibrating the tool zero point automatically with precision up to 0.001mm, featuring one-click tool setting for ease of use.

- Vacuum suction workbench

Divided into 9 zones with 30 holes, capable of securing parts of various sizes, with each zone independently controllable.

- Adsorption suction block for heightening

This suction block can be embedded into the vacuum suction workbench. During use, its central air hole aligns with the workbench's air hole. When the sheet material is placed on top and vacuum suction is activated, the sheet is firmly held in place. This device is primarily used to elevate the sheet material when machining its side surfaces, allowing the tilted spindle to reach the sheet.

- Lubrication system

Central automatic lubrication system, automatically lubricating the machine's transmission parts to keep it in optimal condition.

- Pulse handwheel

The coordinates of each axis can be adjusted simply and directly, and it is easy to use.

- LNC control system

The LNC CNC system features high-precision control, powerful programming capabilities, a user-friendly interface, stable performance, and excellent compatibility.

- Optional workpiece clamping rotary axis

Can clamp and rotate the workpiece for machining multiple faces or surfaces-of-revolution of the workpiece.

Upgrade Options Available for the 7x10ft Four-Axis Swing Head ATC CNC Router

- Increased machining height: 600mm / 700mm / 800mm, etc.

- Rotary axis: For clamping and rotating workpieces, enabling multi-surface machining.

- Spindle: Italian HSD/HITECO automatic tool-changing spindle.

What Can a 7x10ft Four-Axis Swing Head CNC ATC Router Process?

- Woodworking Industry: Production of furniture, doors, windows, cabinets, wardrobes, bookshelves, tables, chairs, stair railings, beds, office furniture, and various other products.

- Advertising Industry: Processing of various plastics and composite materials, such as acrylic, PVC boards, foam, EVA, fiberglass, carbon fiber, PCBs, etc.

- Mold Making Industry: Wooden boat molds, aircraft models, aviation models, sand table models, architectural models, car models, etc.

- Other Industry: Instrument cases, musical instrument accessories, speaker enclosures, toy boxes, etc.

Technical Parameters of 7x10ft Four-Axis Swing Head CNC Router with Automatic Tool Changer Kit

| Model | CK-2130-4ST |

|---|---|

| Processing Size | 2100*3000*500mm |

| Gantry | Thickened aged steel gantry, steel beam, thickened gantry column |

| Bed | The bed by machining center processed (heavy-duty bed) independent anti-interference control cabinet |

| Spindle Power | HQD 9KW high-power air-cooled automatic tool change spindle |

| Spindle Speed | 0-24000r/min |

| Fourth Axis | A axis ±90 degrees |

| Tool Magazine | 12 tool linear magazine |

| Collet | ISO30/ER32 |

| Drive Mode | 1.5KW high-power servo motor drive (Z axis uses brake motor) |

| Reducer | Japan planetary gear reducer |

| Transmission Mode | XY axis high-precision grinding helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan HIWIN high-precision 30 linear square rail / flange slider |

| Table | Vacuum adsorption worktop + T-slot worktop |

| Vacuum Pump | High-power water ring vacuum pump |

| Dust Collection Method | 3KW dust collector |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/50/60Hz |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Positioning | 4+2 positioning cylinders |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2600kg |

| Dimensions | 3900*2550*2700mm |

Additional Services for CATEKCNC's CNC Routers

- Free color customization service according to your requirements.

- Customization of various appearances, including overall design, shape, control cabinet, etc. Such customizations may incur charges depending on complexity.

- Machine configuration customization tailored to your needs, down to specific parts such as brand, power, and type.

- Other OEM/ODM services are available.

What Services Can CATEKCNC Provide Throughout Your Entire Process of Purchasing a CNC Router?

- Before Ordering

- Based on your processing requirements, workpiece materials, part dimensions, etc., our pre-sales team will offer professional purchasing advice.

- Installation and Debugging

- When the machine is shipped, we will include an operation manual and instructional videos free of charge. Additionally, we provide 24/7 engineer support, offering free troubleshooting and problem-solving services to ensure you can operate the machine proficiently for processing tasks.

- Warranty Service

- After the machine arrives at your factory, we provide a free 36-month warranty. During the warranty period, if any machine malfunction occurs (excluding human-caused damage), we will supply replacement parts free of charge. After the warranty period, we can still provide relevant replacement parts, and you only need to cover the cost of the parts.

- After-Sales Service

- If you encounter any issues during use, you can contact our engineers, who will provide all-day after-sales support via email, online chat, or other means. If needed, we can also arrange for a technician to visit your factory for face-to-face guidance.

| Model | CK-2130-4ST |

|---|---|

| Processing Size | 2100*3000*500mm |

| Gantry | Thickened aged steel gantry, steel beam, thickened gantry column |

| Bed | The bed by machining center processed (heavy-duty bed) independent anti-interference control cabinet |

| Spindle Power | HQD 9KW high-power air-cooled automatic tool change spindle |

| Spindle Speed | 0-24000r/min |

| Fourth Axis | A axis ±90 degrees |

| Tool Magazine | 12 tool linear magazine |

| Collet | ISO30/ER32 |

| Drive Mode | 1.5KW high-power servo motor drive (Z axis uses brake motor) |

| Reducer | Japan planetary gear reducer |

| Transmission Mode | XY axis high-precision grinding helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan HIWIN high-precision 30 linear square rail / flange slider |

| Table | Vacuum adsorption worktop + T-slot worktop |

| Vacuum Pump | High-power water ring vacuum pump |

| Dust Collection Method | 3KW dust collector |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Electric lubrication oil injection maintenance system |

| Operating Voltage | AC380V/50/60Hz |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Positioning | 4+2 positioning cylinders |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 2600kg |

| Dimensions | 3900*2550*2700mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.