Linear ATC Wood Router with Drilling Bit Kit and 3D Rotary Axis for Panel Furniture

Linear ATC CNC Nesting Machine with Drilling Bank and 3D Rotary Axis

[Function Description]

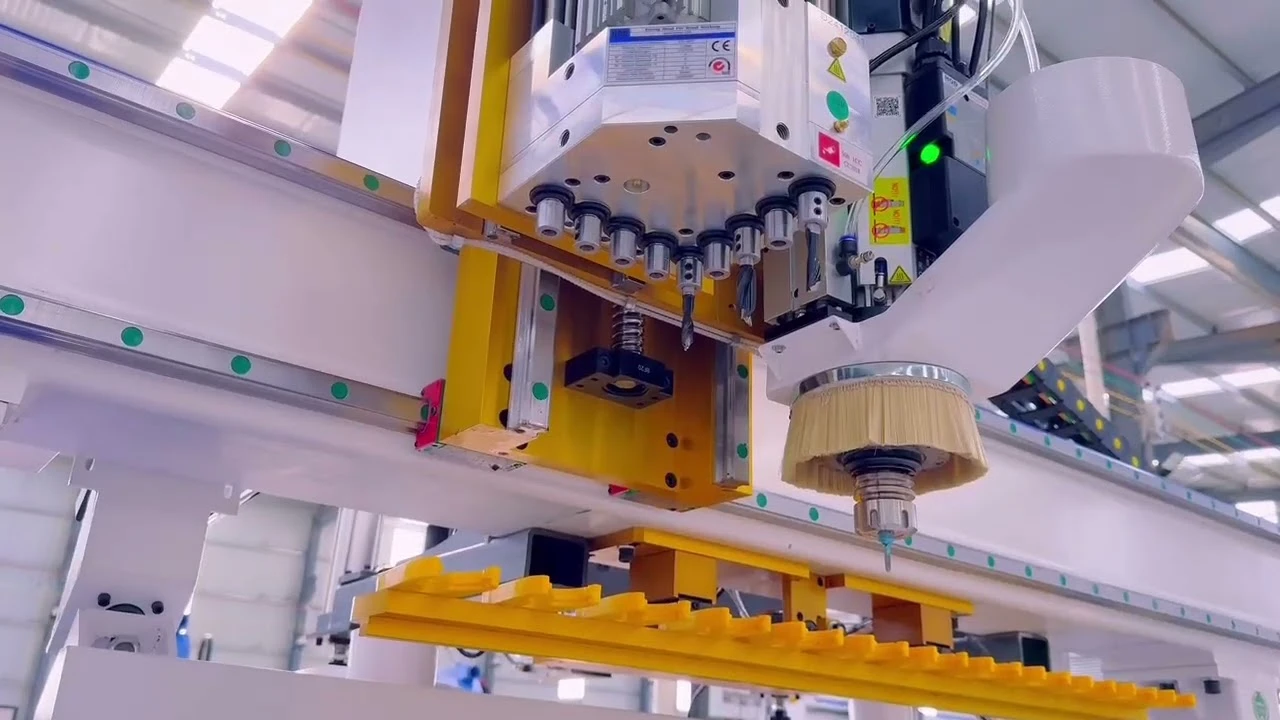

The CK-1325-TDS is a highly efficient and multifunctional automated CNC router that builds upon the linear ATC router by adding a 5+4 pneumatic drilling device and a 3D rotary axis. It features a linear automatic tool-changing system capable of holding up to 16 tools at once, with tool changes completed in just two seconds. This allows for automatic tool switching when processing various complex parts, eliminating the time wasted on manual tool changes. The included 5+4 pneumatic drilling kit uses a "5+4" vertical drill bit layout, meaning a total of nine drill bits can easily handle vertical drilling processes in cupboard production lines, quickly completing adjacent vertical hole drilling (alternatively, a drilling device supporting horizontal and vertical arrangements can be chosen to meet complex horizontal hole requirements). The automatic tool-changing spindle and the drilling kit work in tandem, significantly reducing the number of tool changes and improving drilling efficiency by over 60% when processing tasks with extensive drilling needs. Additionally, the machine is equipped with a 3D rotary axis, supporting four-axis linkage, making it suitable for carving three-dimensional products such as columns and statues, thereby broadening its range of applications.

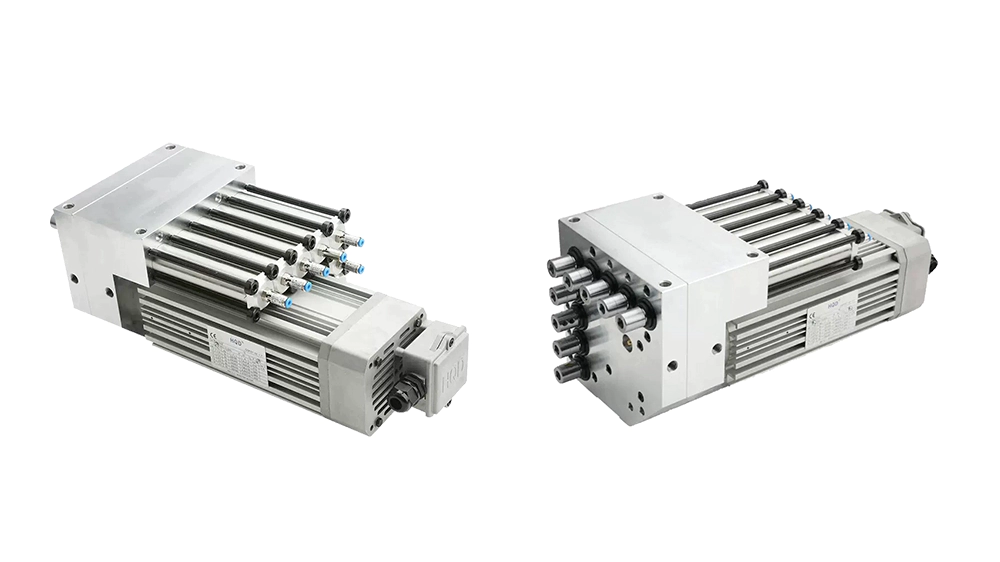

What is a 5+4 Drill Bank and How Does it Work?

The 5+4 pneumatic drilling bank used by the ATC CNC router consists of 9 drill bits, which are distributed in an L-shape on the two sides of the drill bit row, which can meet the needs of holes with different spacing on the board, and are very suitable for the rapid drilling of adjacent holes in cabinet processing (such as the mounting holes of three-in-one connectors). All drill bits are arranged in a vertical direction and are specially used to process vertical holes in furniture (such as the mounting holes of side panels and layer boards), effectively ensuring the accuracy and verticality of the holes. And it uses a special drill bit to drill holes. Compared with using a milling cutter to expand the hole, the edge of the drilled hole is smoother and the quality is better.

The pneumatic drill bit is controlled by the CNC system, driven to rotate by a servo motor, and different drill bits are switched with the help of a cylinder. It can automatically switch to the appropriate drill bit combination according to the pre-set program. When processing adjacent holes, multiple drill bits can be operated simultaneously to complete the drilling, without the need to process holes one by one, without manual intervention throughout the process, and without stopping to change tools. This drill pack can be equipped with drill bits of different diameters (e.g. 8mm, 10mm, etc.), and can automatically match various hole diameter requirements through software settings. For example, when processing hinge holes, a large-diameter drill bit can be used; when processing three-in-one connector holes, a standard drill bit is used. Compared with traditional CNC routers equipped with only a spindle, the 5+4 drill bank can increase drilling efficiency by more than 5 times, making it more suitable for mass production of wardrobes and cabinets.

Advantages of Linear ATC CNC Router with Drilling Bank and 3D Rotary Axis

- Linear automatic tool changer: Up to 16 tools can be installed at a time, and different tools have clear division of labor and can be automatically switched through the control system.

- 5+4 pneumatic drilling bank: 9 drill bits can be installed at a time, and the drill bits can be automatically switched according to the processing hole position to improve drilling efficiency.

- Taiwan LNC CNC system, simple operation, highly intelligent, all functions are intuitively displayed on the system interface, and CNC novices can also operate easily.

- The CNC router is specially made of thickened square steel welded bed base, thickened gantry beam, and finely processed by the gantry milling machine. The guide rail is installed more accurately and does not deform during use.

- The automatic tool change spindle and pneumatic drill bank can be switched for use. The drilling device is dedicated to drilling, and the spindle is used for cutting, milling, and engraving, which effectively improves the processing speed.

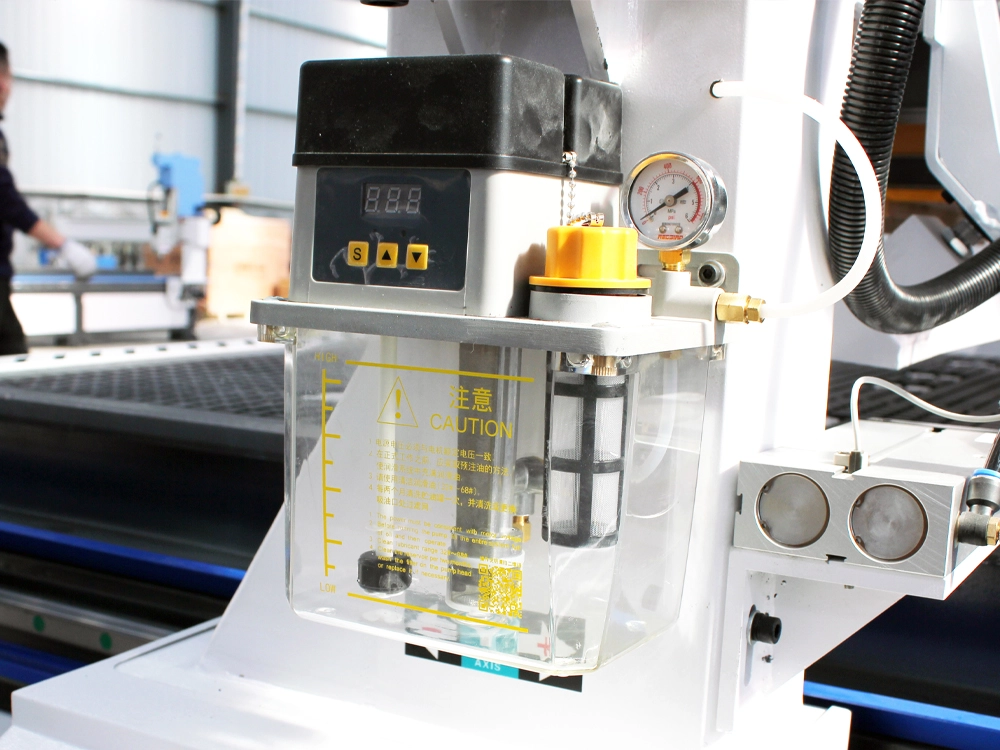

- Timing automatic lubrication system, the lubrication time and interval time can be set according to the usage to extend the service life of the machine.

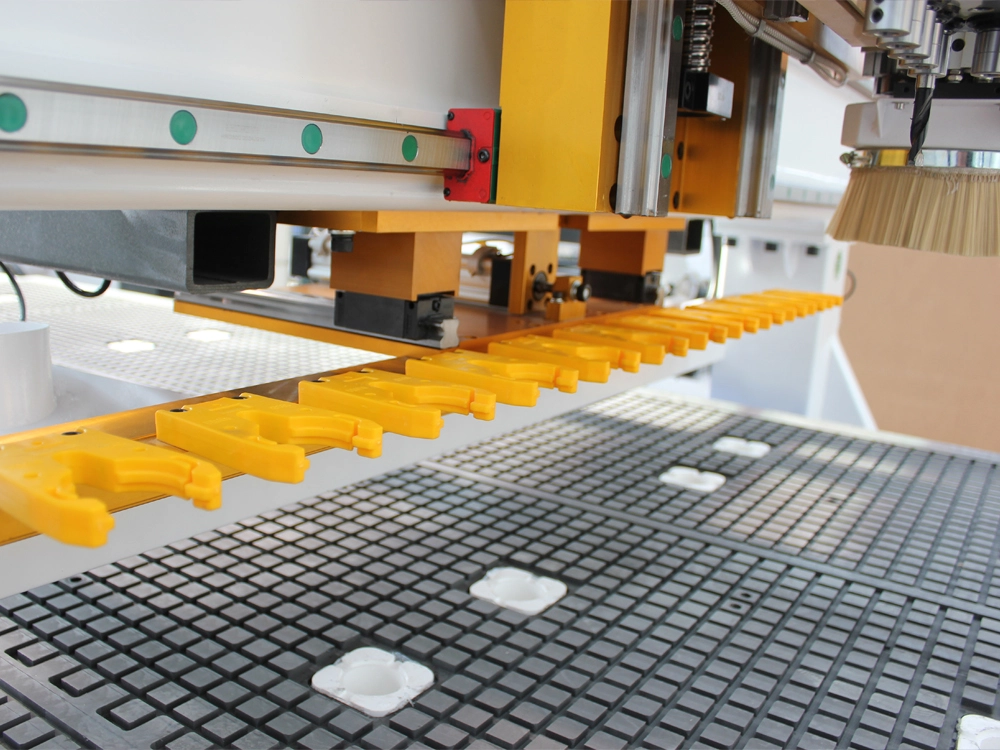

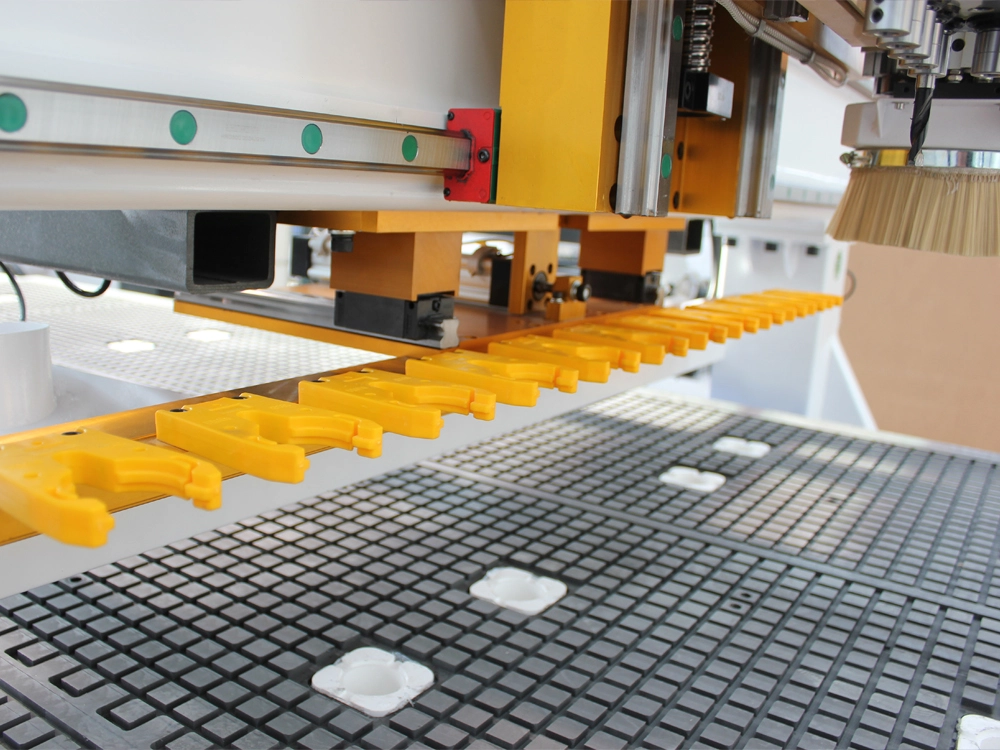

- Vacuum adsorption workbench, 4+2 positioning cylinders, after the plate is placed on the workbench, it can be automatically placed in a fixed position, which is easy to use.

- Automatic tool setting device, tools of different lengths and diameters can be automatically calibrated, eliminating the trouble of manual calibration of zero point.

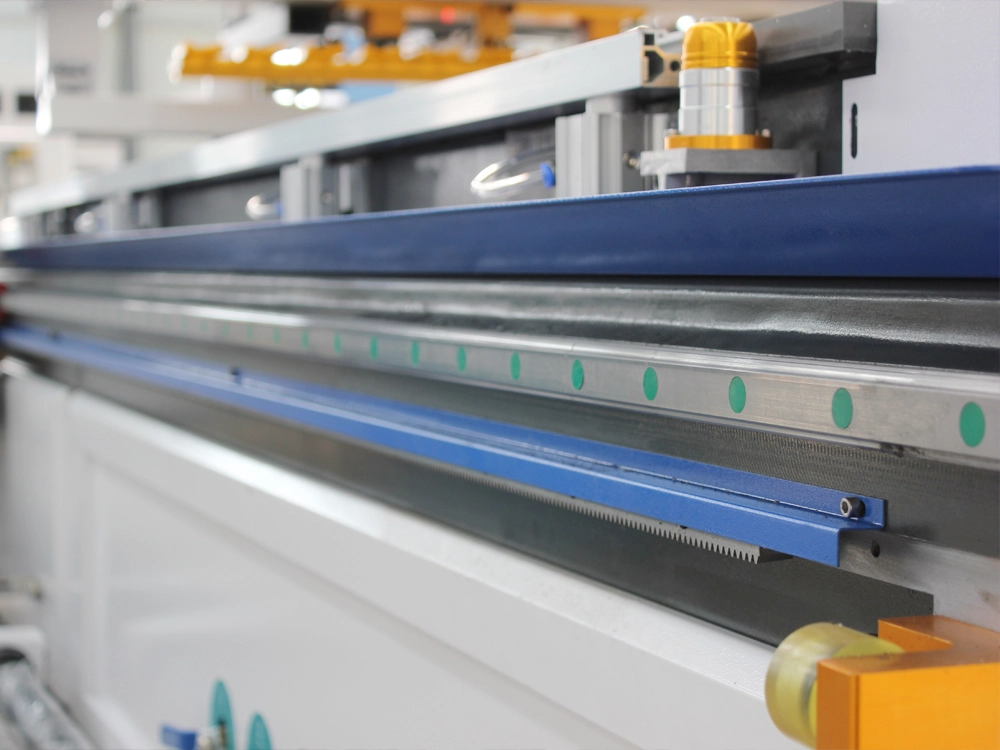

- TBI ball screw, 30 guide rails/linear bearings, low operating noise and stable operation.

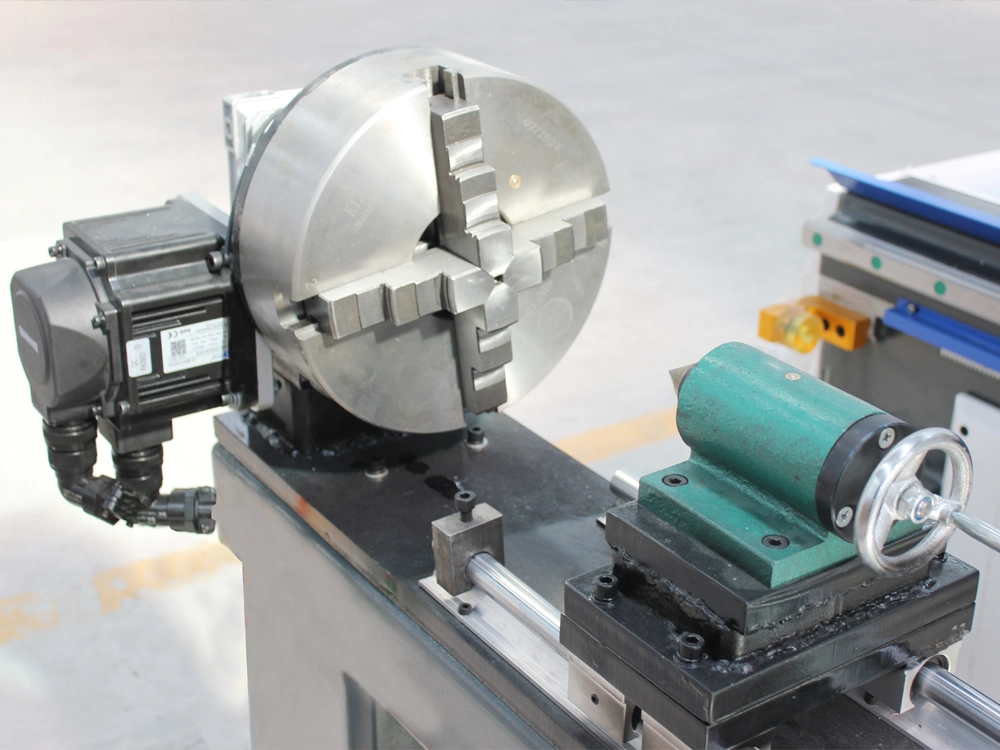

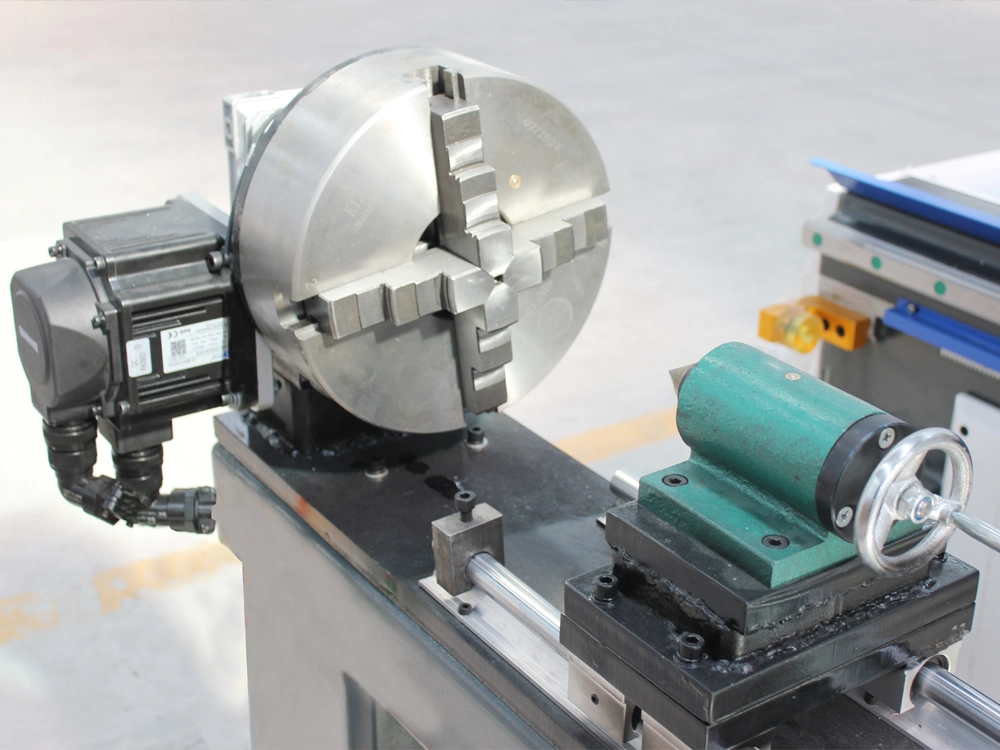

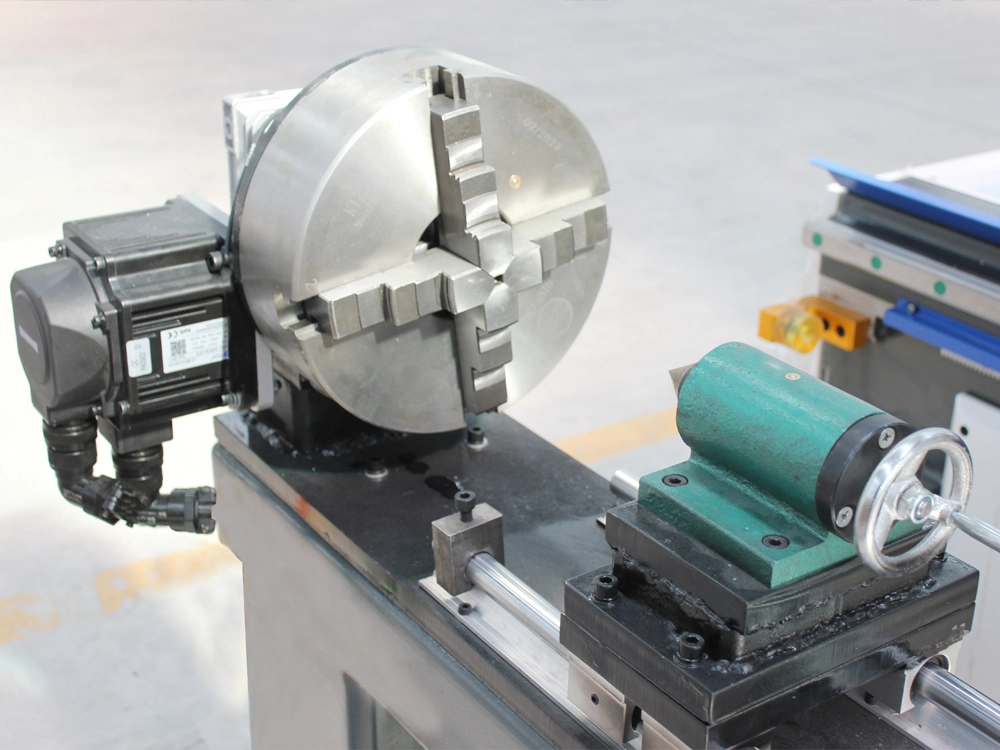

- 3D three-dimensional rotating axis with a length of 2000mm and a diameter of 200mm, used for carving the surface-of-revolution of Roman columns and handicraft ornaments.

Details of Linear ATC CNC Router with Gang Drill Package and 3D Rotary Axis

- 9kw automatic tool change spindle

High speed, high torque, fast processing speed, and support for automatic tool change.

- Linear tool changer

Fixed on the gantry, it moves together with the gantry, reducing the spindle moving distance when changing tools and increasing the tool changing speed.

- Automatic tool setting device

Before initial machining or after each tool change, this device automatically measures the tool length, determines the position of the tool tip, and instructs the system to compensate accordingly.

- Vacuum adsorption zone control valve

This valve group can control the opening and closing of each air hole on the vacuum adsorption workbench.

- Central automatic lubrication system

The lubrication interval and lubrication duration can be set to automatically lubricate the transmission parts.

- LNC control system

Taiwan LNC control system, mature and stable, with user-friendly operation interface.

- Rack

Grinded helical rack for higher precision.

- Clamping device for separating the tool and the holder

When separating the blade from the knife holder, this device can be used to clamp the knife holder to facilitate removal of the blade.

- Gang drill

It use HQD supercharged CNC drill, which is high quality, low temperature, low noise, 3200r/min, can hold 9 drill bits, and perform batch hole opening work on wood. We use high-quality two-position three-way direct-acting solenoid valves, which are sensitive to reversing and can start at zero pressure/low vacuum. The valve group uses double-row solenoid valve integrated wiring, which greatly reduces the single sub-space in the length direction. The single valve of the integrated valve group uses a pin-type coil, and the plate-type with sealing gasket is installed for easy maintenance.

- 4th rotary axis

It can clamp cylindrical workpieces and rotate them to process their surfaces-of-revolution.

Technical Parameters of Linear ATC CNC Router with Gang Drill Package and 3D Rotary Axis

| Model | CK-1325-TDS |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Drill | 5+4 Pneumatic Drilling Kit |

| Control System | Taiwan LNC cutting machine dedicated control system / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3000kg |

| Dimensions | 3900*2150*2100mm |

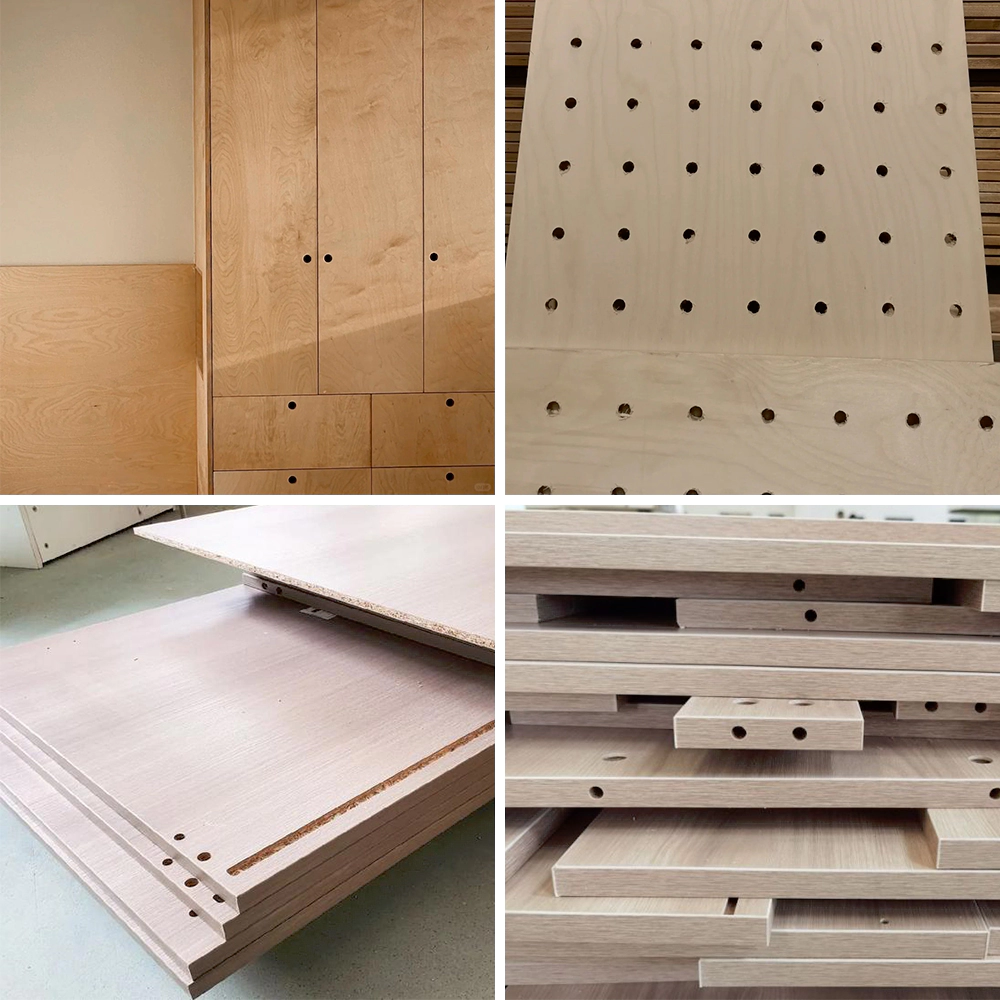

Application Range of CNC Nesting Machine with Drilling Bank and 3D Rotary Axis

Wardrobes, cabinets, cabinets, cabinets, wooden doors, composite doors, wine cabinets, tatami, bedside tables, sliding doors, door and window frames, display cabinets, office furniture, wood decorations, wainscoting, picture frames, tables, chairs, beds, corrugated boards, perforated boards and other furniture and accessories.

The rotary axis can be used to carve Roman columns, columns, figure statues, stair railings, Queen Anne legs, table legs, sofa legs, bed legs and other three-dimensional parts.

The Following Are the Processable Products of Linear ATC CNC Router with Drill Bank

| Model | CK-1325-TDS |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Double-layer vacuum table with with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Drill | 5+4 Pneumatic Drilling Kit |

| Control System | Taiwan LNC cutting machine dedicated control system / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3000kg |

| Dimensions | 3900*2150*2100mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.