The Most Popular 4x8 CNC Router Machine with Rotary Fourth Axis

4x8 CNC Wood Router Machine with Rotary 4th Axis

[Function Description]

Why Are CNC Routers with Rotary 4th Axis So Popular?

A 4*8 CNC router with rotary fourth axis is essentially a four-axis linkage router. It comes standard with a 1300*2500mm worktable and is equipped with a fourth rotary axis kit. In addition to processing materials like boards, it can also use the fourth axis to perform 3D carving on workpieces with rotational surfaces (such as cylinders, square columns, spheres, etc.). This multifunctional CNC router combines the capabilities of a flatbed CNC router and a 3D CNC sculpting machine, enabling not only cutting, drilling, milling, flat engraving, and 2.5D engraving but also 3D carving. One machine offers the functions of two, at a price lower than buying two separate machines, reducing investment costs and requiring only the space of a single machine. It is easy to operate, making it accessible even for CNC beginners. This makes CNC routers with a side rotary axis highly popular among personal studios and hobbyists. For small-batch production, one machine can handle all tasks, fulfilling a variety of design ideas.

What Are the Advantages of a CNC Router with Rotary 4th Axis Compared to a Standard CNC Router?

- Expanded Machining Functions: The rotary axis enables 3D engraving and cutting of parts, including hollow carving and relief engraving. It supports four-axis linkage, three-dimensional machining, localized rotary machining, and multi-face positioning machining.

- Expanded Machining Range: With the rotary axis, the CNC router can process complex surfaces such as curved, arched, and irregular surfaces. It also allows for four-directional machining, improving both efficiency and precision.

- Expanded Machining Applications: Compared to standard flatbed CNC routers, the addition of a rotary axis allows for the machining of more three-dimensional parts, such as table legs, sofa legs, vases, pen holders, and similar products.

- Enhanced Machining Performance: It can securely process cylindrical or irregular workpieces that are difficult for standard CNC routers to handle. The ability to complete parts in a single setup avoids repeated material clamping, saving processing time.

Advantages of a CNC Router with Rotary 4th Axis

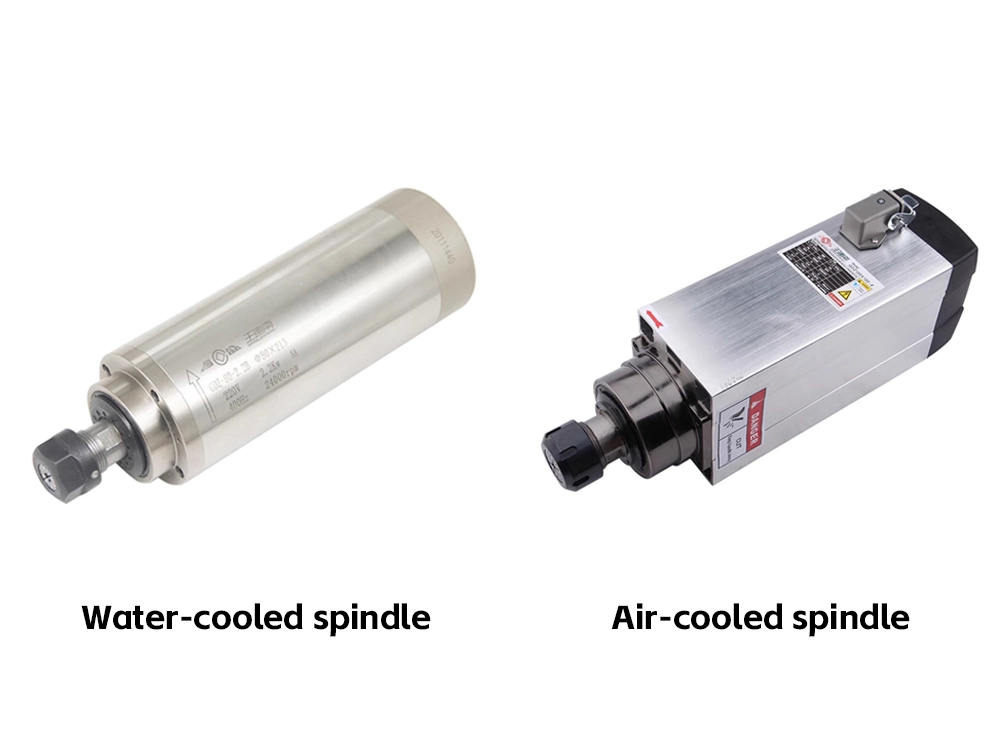

- 3.5KW high-speed water-cooled spindle, capable of 24-hour uninterrupted operation, with low noise and a rotation speed of up to 24,000 rpm.

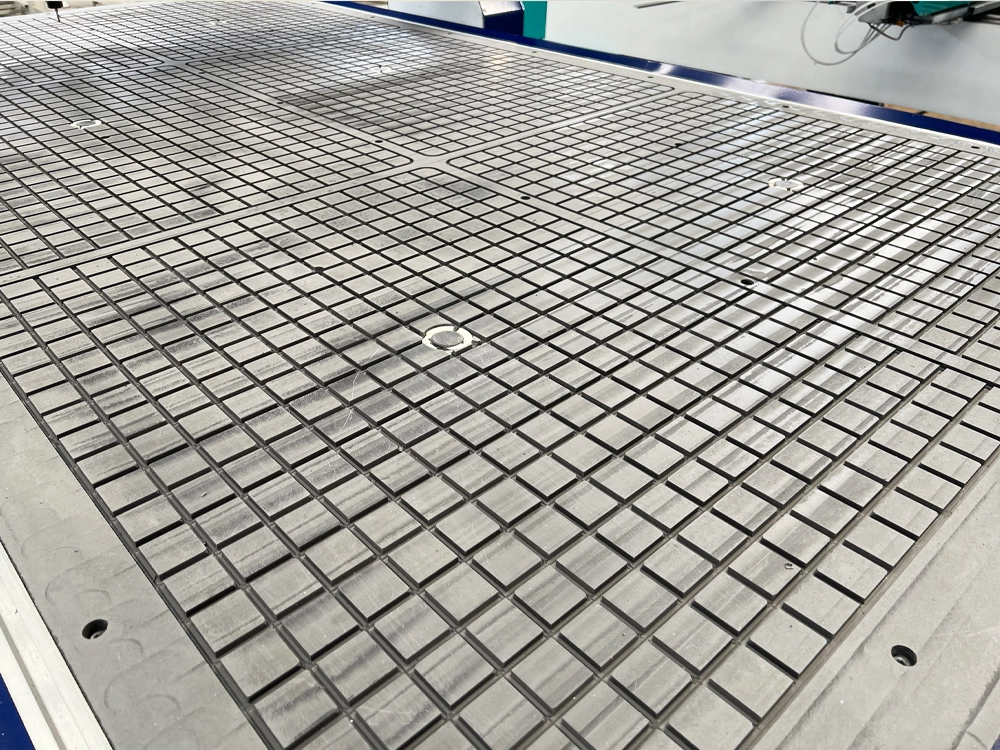

- Uses an aluminum alloy T-slot worktable, with free fixed clamps included, allowing flexible fixation of workpieces of various sizes (optional vacuum adsorption worktable available).

- The bed base is made of welded steel pipes, undergoing multiple vibration aging treatments to eliminate stress and improve accuracy, ensuring long-term machining stability.

- 4x8 feet machining size, capable of processing any workpiece within 13002500mm, easily handling various machining tasks.

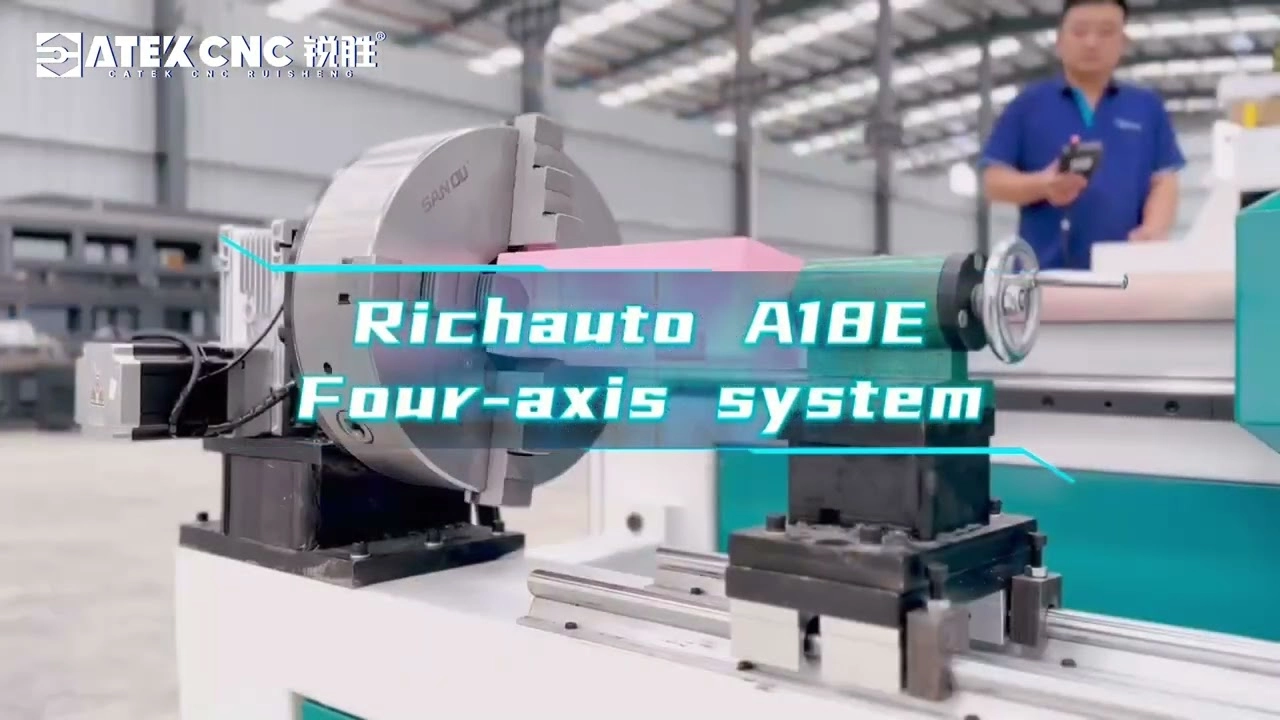

- DSP control system, no need to connect to a computer, simple and easy-to-use operation, even beginners can easily master the machine.

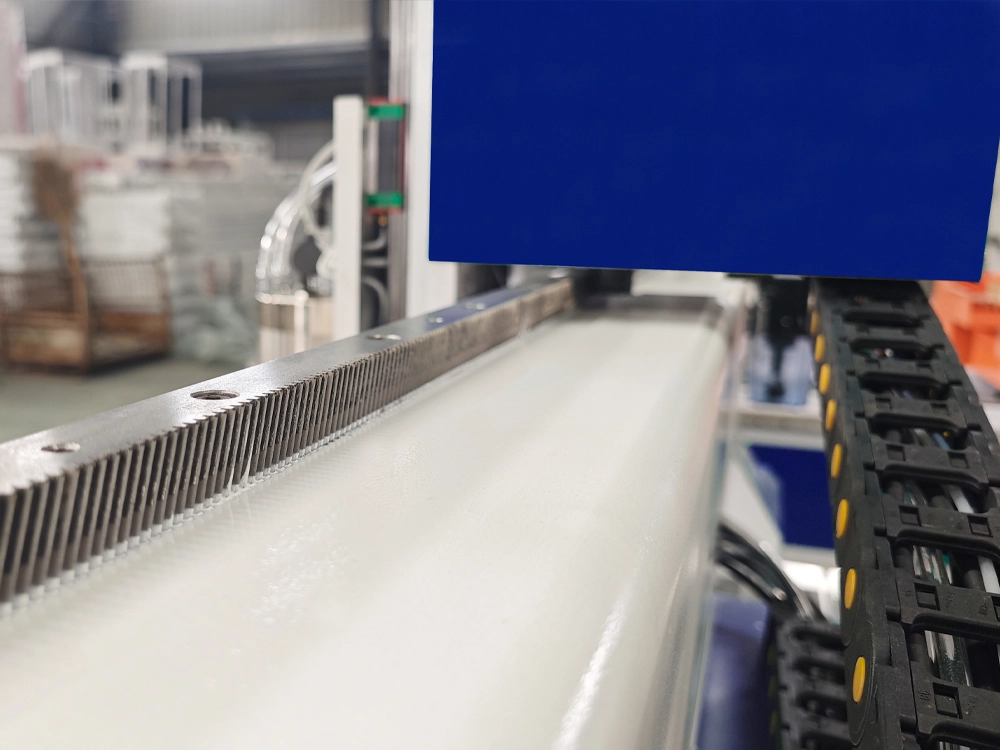

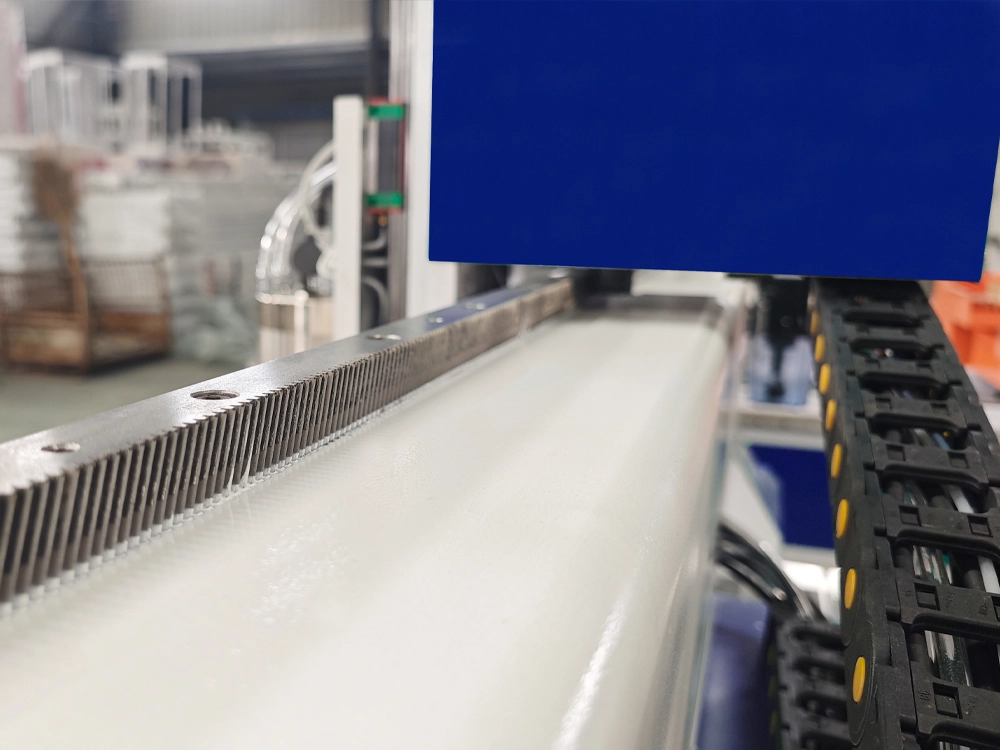

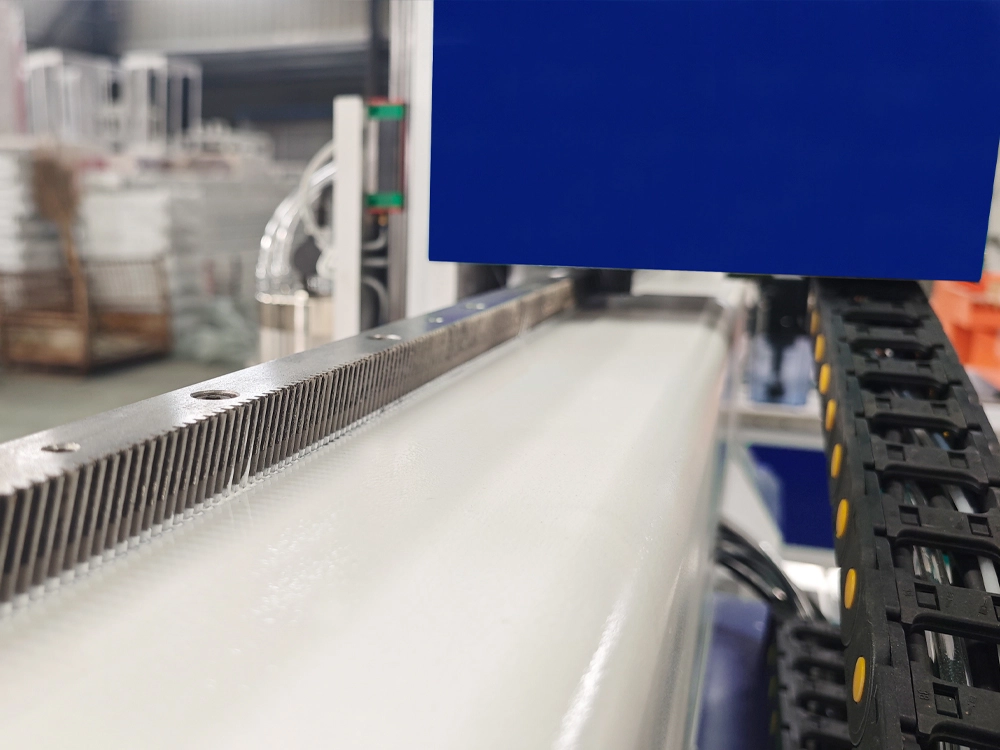

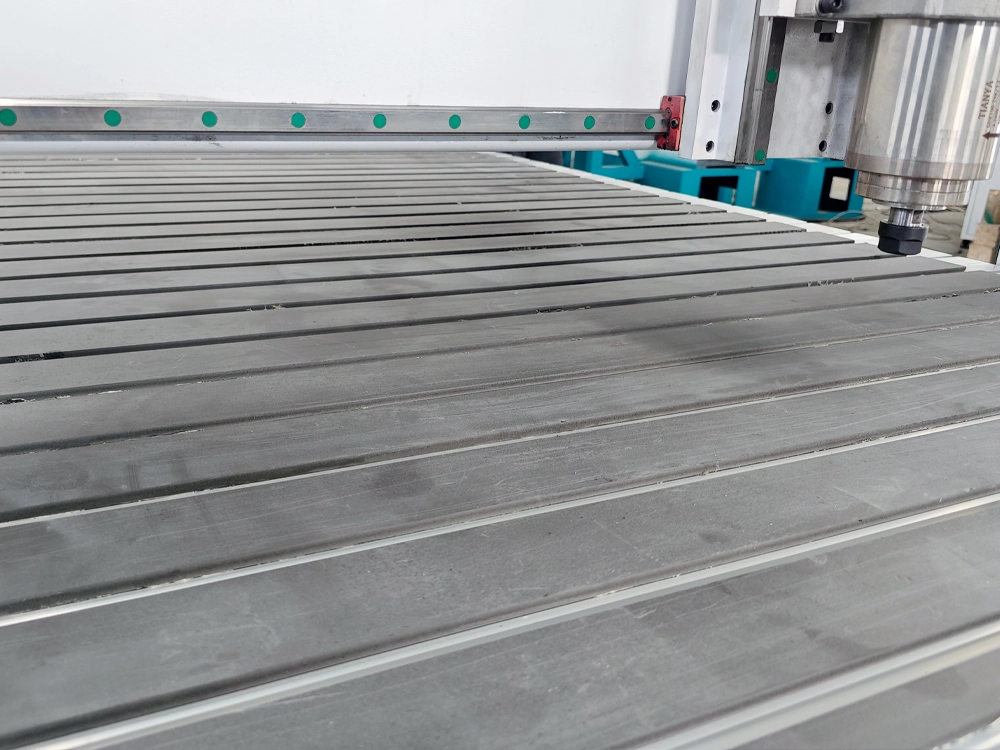

- Transmission system uses TBI ball screws, high-precision helical racks, and Taiwan Hiwin guides/linear bearings, ensuring smooth operation and high accuracy.

- YAKO/Leadshine drive motors, enabling high-precision positioning and movement, with the ability to adjust multiple motion modes and operating parameters.

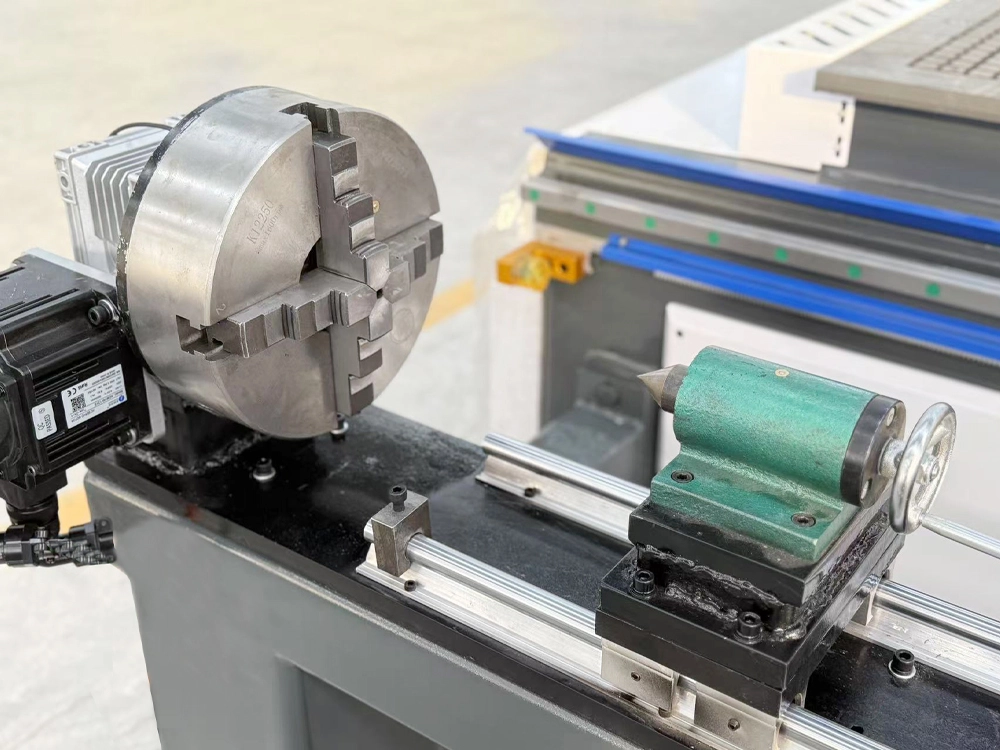

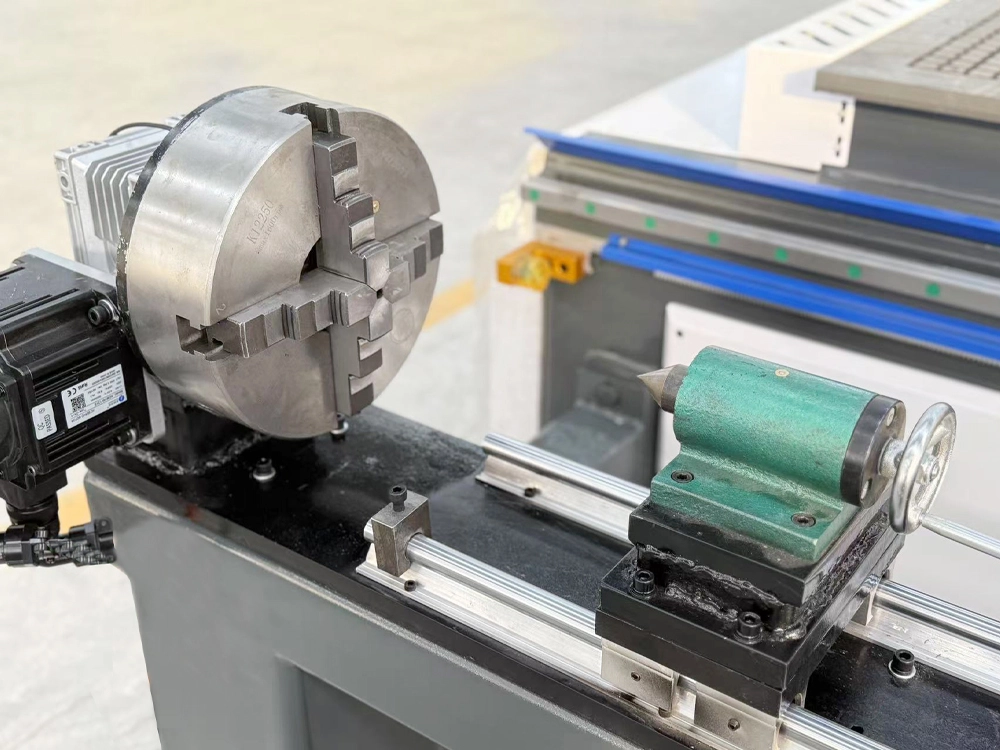

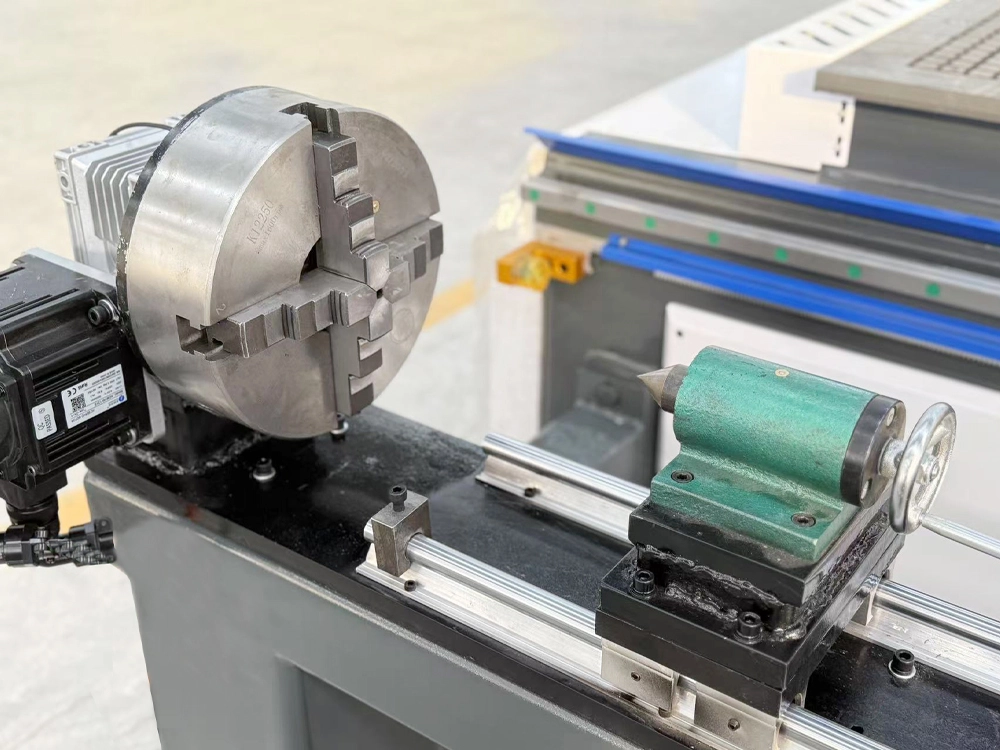

- Chuck-type rotary axis, flexible and convenient to use, allowing single-end clamping or dual-end clamping for machining.

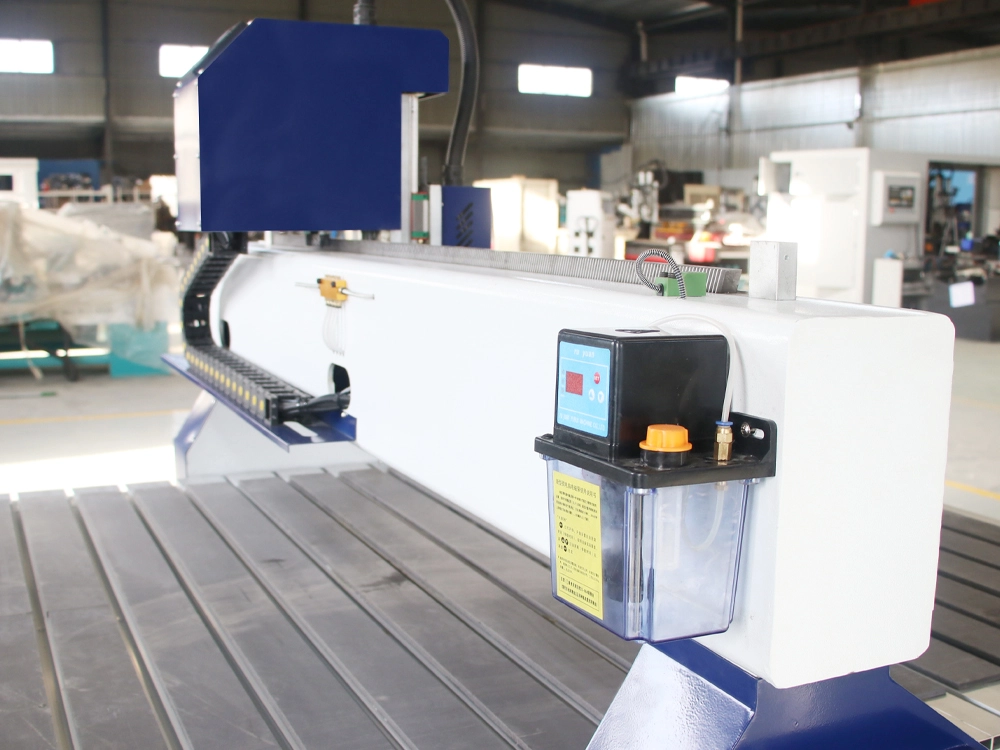

- Lubrication system uses an automatic oil pump, fully automatically lubricating the machine's moving parts, ensuring the machine is always in optimal condition.

- Software compatible with various CAD/CAM design software, such as ArtCAM, PowerMill, MasterCAM, Fusion 360, etc.

Details of CNC router with Side Rotary 4th Axis

- Chuck type rotary fourth axis

-

Has two usage modes, can be clamped at one end, or can be clamped at both ends.

- Spindle

-

Air-cooled spindle or water-cooled spindle is optional.

- Transmission system

-

TBI ball screw, high-precision helical rack and Taiwan Hiwin guide rail/linear bearing.

- Two work surfaces available

-

T-slot tabletop is standard, and vacuum adsorption tabletop is optional.

- Lubrication system

-

Fully automatic lubricating oil pump automatically and regularly lubricates and maintains the machine.

- DSP control handle

-

DSP control handle, no need to connect to PC, offline processing.

Technical Parameters of a CNC Router with Rotary 4th Axis

| Model | CK-1325-R |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Lathe Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Yako/Leadshine motor driver |

| Frequency Converter | Best/Hpmont inverter |

| Table | Aluminum alloy T-slot table (optional: vacuum adsorption platform) |

| Rotary Axis Chuck Size | 160mm |

| Processable Size of Rotary Axis | 200mm diameter*2000mm length |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP A11 / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1550kg |

| Dimensions | 3100*2250*1750mm |

What Products Can The Multifunctional CNC Router with 4th Rotary Axis Be Applied to?

- Woodworking industry: Wooden furniture, classical furniture, wardrobes, wooden doors, tables, chairs, table legs, beds, MDF, artificial wood boards, bookshelves, etc.

- Advertising industry: Transparent signs, illuminated signs, acrylic light boxes, billboards, plaques, medals, hanging signs, etc.

- Crafts industry: Buddha statues, animal statues, human statues, ornaments, vases, pen holders, trophies, decorative wood carvings, etc.

- Model making industry: Architectural models, aviation models, nautical models, assembly toys, etc.

- Other material processing: Materials such as plastics, stone, foam, aluminum, copper, and other soft metals, as well as PCB boards, insulating parts, chemical plastic parts, ABS resin, PP, PS, and other chemical materials.

How is a CNC Router Packaged?

- When the machine is ready for shipment, we perform preparatory work on the machine. First, the tools are disassembled to prevent damage during transportation. Then, the entire machine is treated with anti-rust measures to avoid rust issues during long transit times.

- Anti-collision foam protection is applied, with foam wrapping used for protruding and vulnerable parts of the machine.

- Stretch film packaging is used to wrap the entire machine comprehensively.

- Export wooden crate packaging is employed, placing the machine into an export-grade plywood crate, with strapping tightened around the exterior to prevent the crate from coming apart.

- If you have specific packaging requirements, we will pack the machine according to your needs.

What Should You Do If the CNC Router Malfunctions?

- After a machine malfunction occurs, please contact an engineer for troubleshooting. CATEKCNC provides 24/7 online engineer support.

- If the issue is due to software, the engineer will resolve it for you online.

- If there is a hardware problem and it is within the three-year warranty period, we will send you free replacement parts. After receiving the parts, please contact the engineer for online guidance on replacement.

- Engineers will provide after-sales service and support through phone, WhatsApp, email, or any other contact method available to you.

| Model | CK-1325-R |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened cast iron gantry, cast iron bracket |

| Lathe Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 3.5KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Yako/Leadshine motor driver |

| Frequency Converter | Best/Hpmont inverter |

| Table | Aluminum alloy T-slot table (optional: vacuum adsorption platform) |

| Rotary Axis Chuck Size | 160mm |

| Processable Size of Rotary Axis | 200mm diameter*2000mm length |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP A11 / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 1550kg |

| Dimensions | 3100*2250*1750mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.