CNC Wood Router Machine for 2D and 3D Engraving

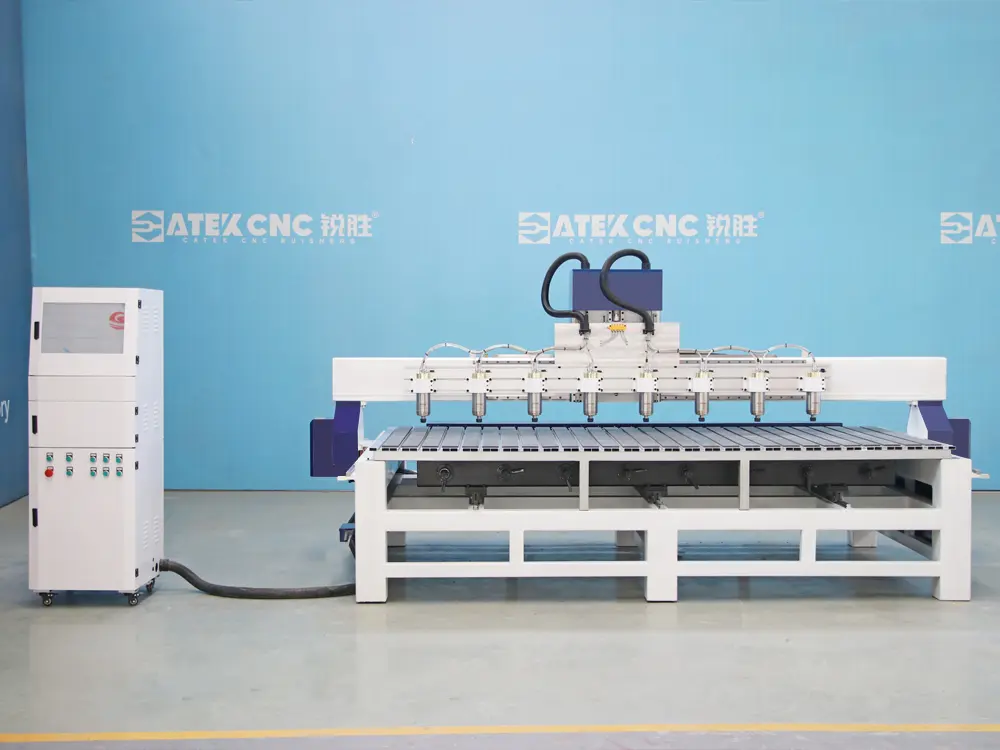

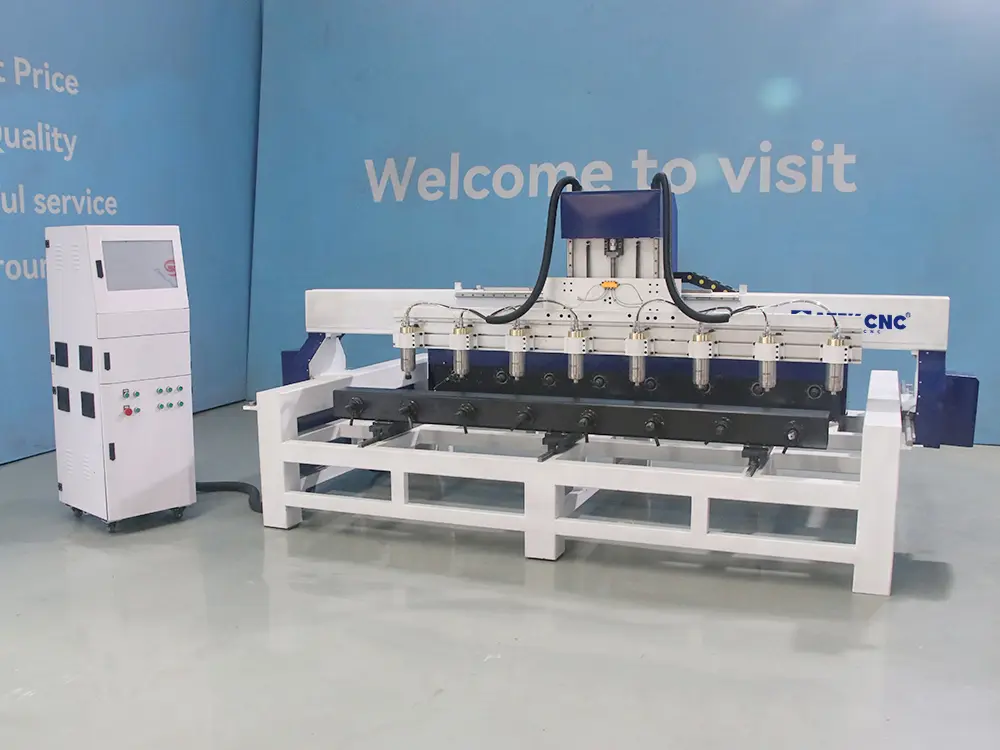

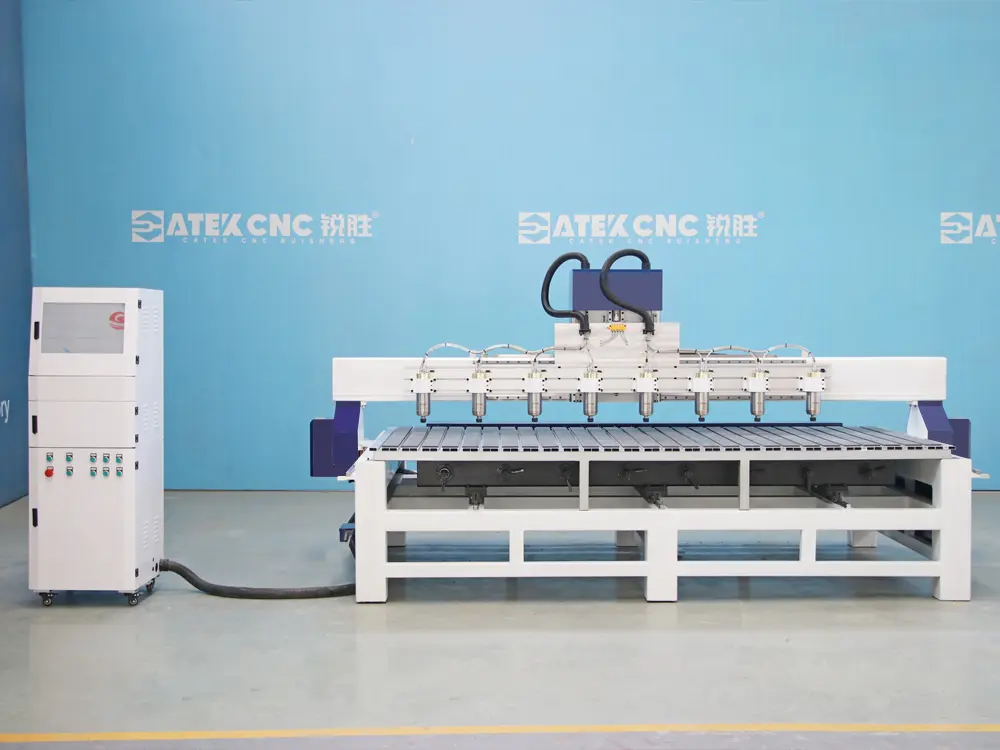

The High-Efficiency 8-Station 3D & 2D Integrated CNC Router

[Function Description]

The 8-station 3D & 2D integrated CNC wood router integrates eight independent processing stations, a 4-axis linkage control system, a 3D indexing rotary device, and a flat worktable into a single mahine, enabling both batch 3D carving and 2D engraving on one machine. Through multi-station synchronous processing, it can complete eight identical products in a single operation, significantly improving the efficiency of manufacturing complex 3D workpieces or flat components. It is particularly suitable for high-volume, multi-variety production scenarios such as furniture manufacturing and craft product processing, ensuring product consistency while dramatically increasing production capacity.

The 8-station 3D & 2D integrated CNC wood router is equipped with eight independently controlled processing stations. Each station is equipped with a 2.2KW high-speed water-cooled variable-frequency spindle, independently driven by a Fuling inverter, supporting synchronous processing of 8 identical workpieces. Users can also flexibly activate only some of the spindles according to processing needs to accommodate the machining of larger workpieces.

Switching between 2D and 3D processing modes is achieved via a detachable aluminum alloy T-slot worktable: install the worktable for 2D processing, and remove it for 3D carving. The worktable features a quick-disconnect structure with high-precision positioning screws, allowing one person to perform installation or removal quickly without specialized tools. Combined with clamp fixtures, it can securely hold workpieces of different sizes and shapes, enabling rapid positioning and stable clamping.

This model is equipped with a Weihong 4-axis control system, compatible with various CAD/CAM software, and is easy to operate. It can process materials such as wood, plastic, foam, and acrylic. It is capable of performing 3D carving tasks like furniture legs, stair columns, and decorative ornaments, as well as efficiently handling 2D processing tasks such as feature walls, screens, decorative panels, plaques, and table/chair panels.

Features of the Efficient 8-Station 3D & 2D Integrated CNC Router

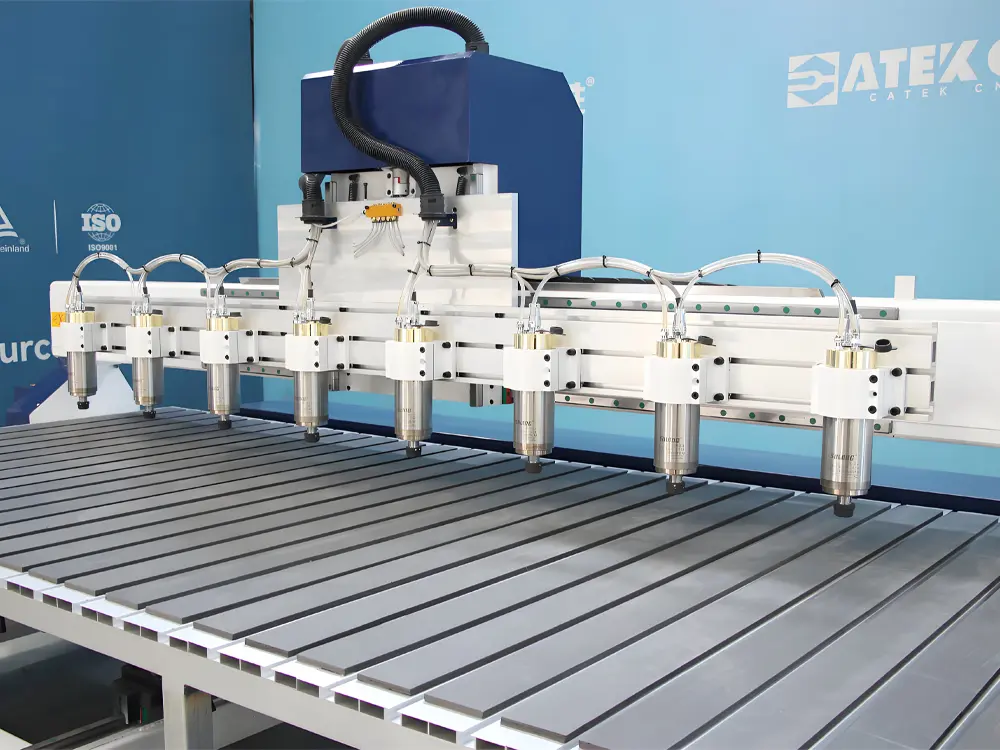

1. High-Speed Water-Cooled Spindle System for Efficient Processing

Equipped with eight 2.2KW high-speed water-cooled variable-frequency spindles, with a maximum speed of 24,000 RPM. Utilizing circulating water cooling technology, the system operates with low noise and superior heat dissipation compared to air-cooled designs. Each spindle is driven by an independent Fuling inverter and features a dedicated start/stop switch, allowing all eight spindles to operate simultaneously or individually to flexibly adapt to workpieces of different sizes. The inverter module enables smooth spindle acceleration and deceleration, preventing sudden impacts that could damage tools or displace workpieces. During shutdown, spindles slow down gradually, protecting both spindles and tools. The inverters incorporate multiple protection functions including overcurrent, overvoltage, and overheating safeguards, ensuring stable operation and extended service life.

2. Double-Layer Bed, Extended Mounting Plate & Reinforced Gantry

- Double-Layer Bed: Constructed from heavy-duty thickened steel tubes welded together and stress-relieved through annealing and vibration aging to eliminate internal stresses and prevent long-term deformation. The guide rail mounting surfaces are precision-machined with a gantry mill, achieving over 99% contact accuracy with XY-axis rails to minimize precision loss from uneven force distribution. The upper and lower bed design houses the 3D rotary axes in lower recesses while the detachable flat worktable mounts on the upper level. This optimized mechanical layout significantly enhances overall rigidity and stability, making the machine suitable for high-speed cutting and heavy-duty processing.

- Extended Aluminum Mounting Plate: Features an extended dual T-slot plate that securely and precisely mounts multiple high-speed water-cooled spindles to the machine's moving components. The spindle spacing can be flexibly adjusted according to workpiece dimensions for convenient and adaptable operation.

- Reinforced Gantry: Built with reinforced steel and dual guide rails, providing high-rigidity support for the X and Z-axis motion systems. Excellent impact resistance and stability make it ideal for multi-station, heavy-load processing scenarios, ensuring precision during high-speed operation and long-term reliability.

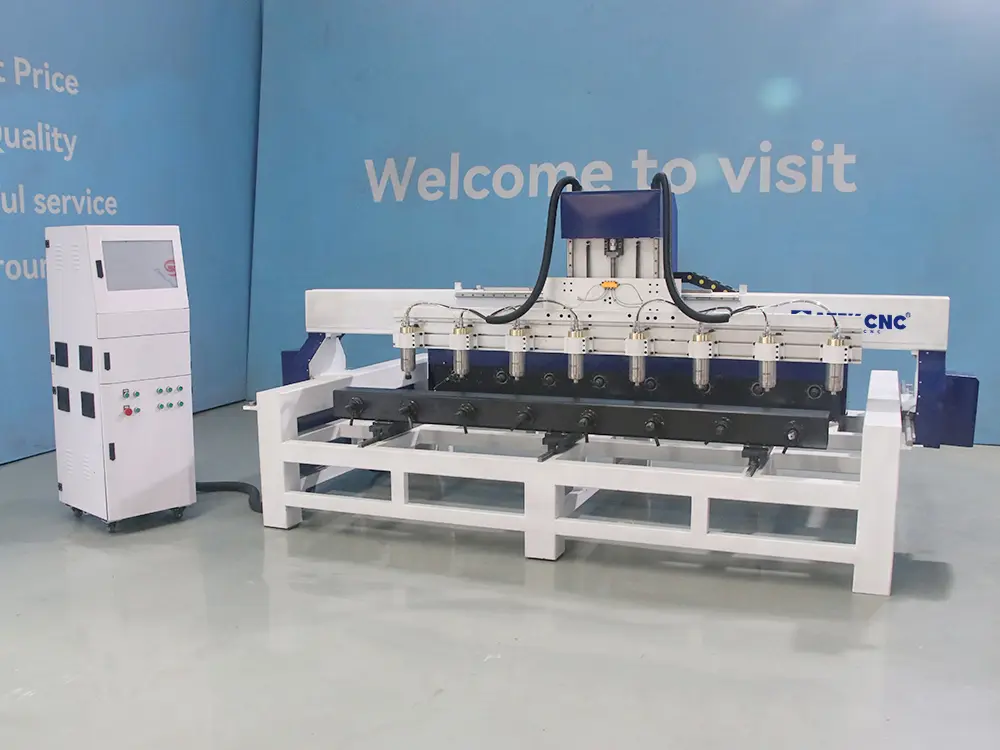

3. Dual Worktable Configuration: 3D Rotary Axes & Flat Worktable

- 3D Rotary Axes Worktable: Integrates eight 3D rotary axes specifically for indexed rotary machining of cylindrical workpieces. The drive system consists of two 1300W Yaskawa servo motors and eight worm gear reducers interconnected via couplings. The servo motors drive the worms to rotate the worm wheels, achieving speed reduction and torque increase. The worm gear reducers transmit power through continuous helical teeth, providing smooth operation, low noise, and compact structure. With a 90° right-angle transmission layout, their volume is only 60% of same-power gear reducers, facilitating multi-station integration, reducing machine footprint, and improving space utilization.

- Flat Worktable: Configured with a detachable aluminum T-slot worktable featuring integrated tabletop, support frame, and connectors. Mounted via bolts to the upper layer of bed, it allows quick installation and removal as processing requires. Using clamp fixtures that slide multidirectionally in the slots, workpieces can be rapidly secured horizontally, vertically, or at angles, adapting flexibly to various processing needs.

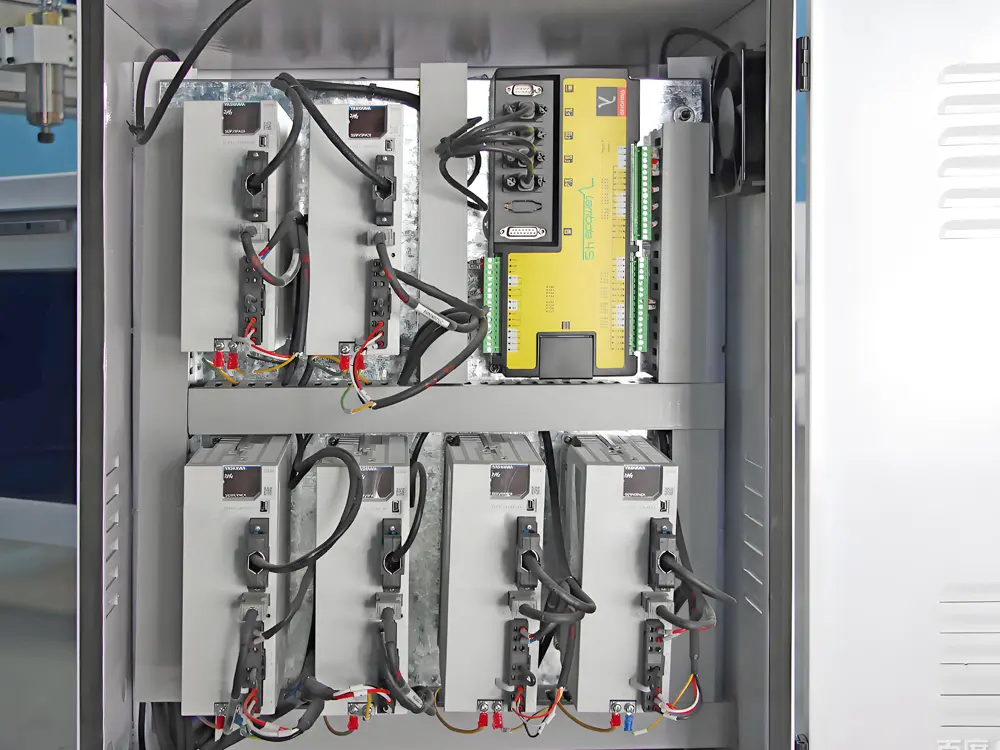

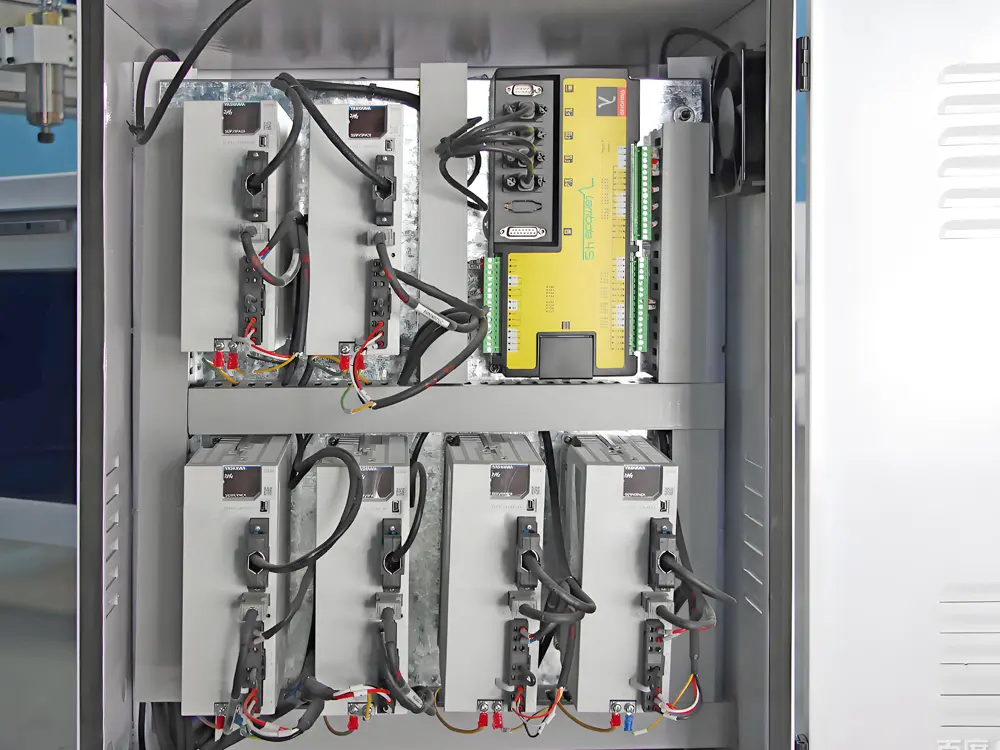

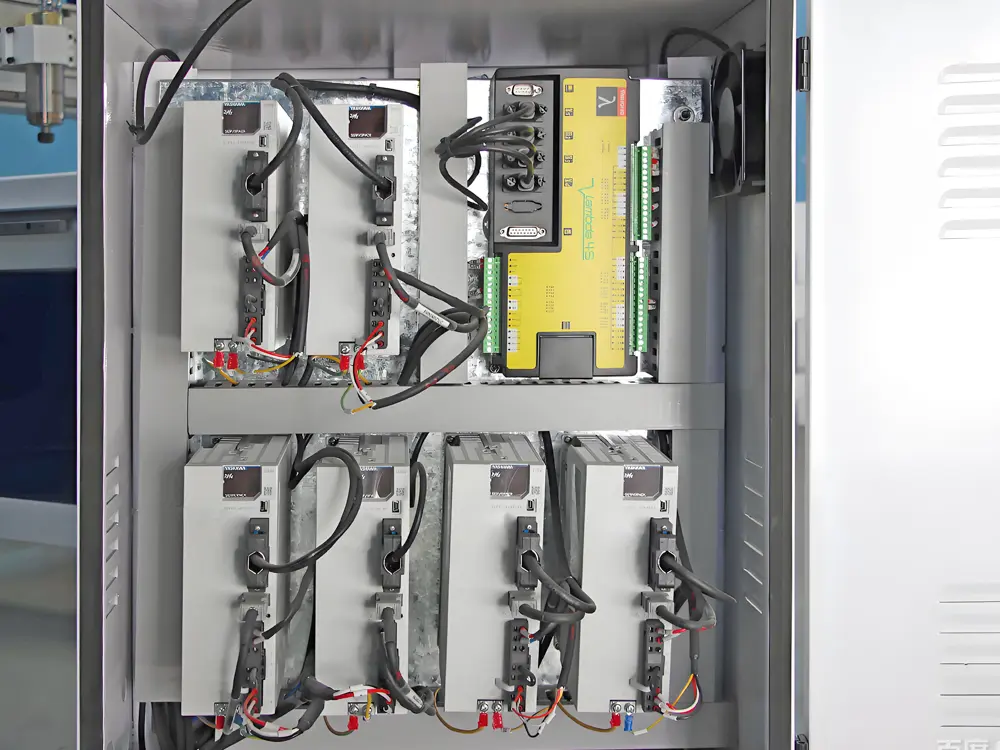

4. Drive System

- Yaskawa Servo Motors: The machine includes six 1300W Yaskawa servo motors in total. The X and Z axes each use one servo motor, while the Y-axis and the eight rotary axes are driven by two servo motors each. Yaskawa servo motors provide higher positioning accuracy and response speed, offering over 30% higher rotational speed than standard servos and start/stop acceleration times ≤0.1s. The drives incorporate overload, overvoltage, overcurrent, and overheating protection, effectively handling instantaneous load impacts during multi-station router operation. With higher protection ratings and industrial-grade durability, they prevent ingress of wood chips and debris during processing, withstand high-temperature and humid environments, and support 24 hour continuous operation.

- Shimpo Planetary Reducers: The X and Y-axis servo motors are paired with Japanese Shimpo planetary gear reducers. Their internal helical gear design effectively reduces operating noise compared to spur gears. The planetary reducers enhance the machine's load adaptability and torque output, with strong overload and impact resistance, enabling the machine to withstand higher radial and axial forces. Suitable for heavy-duty applications, they ensure high repeatability positioning accuracy and motion performance, fully leveraging the servo system's advantages for optimal performance in multi-station CNC routers.

5. High-Precision Transmission System

- Linear Guideways/Bearings: Utilize HIWIN heavy-duty linear guides and bearings from Taiwan, with a four-row single-arc groove contact structure that provides over 30% higher rigidity than same-size alternatives. Low friction coefficient and no-slip operation ensure machining accuracy.

- Helical Racks: Fitted with YYC helical racks, offering larger meshing contact area for smooth transmission, low noise, minimal vibration, and higher torque capacity. Effectively improves machine speed, stability, and service life.

- Ball Screws: Employ TBI ball screws from Taiwan, with transmission efficiency exceeding 90% and drive torque only one-third that of sliding screws. Preloading eliminates axial clearance, achieving extremely high positioning accuracy.

6. 4-Axis Control System

Equipped with the Weihong NCStudio V10 4-axis control system, supporting simultaneous 4-axis linkage of XYZ linear axes and the fourth rotary axis (A-axis). The intuitive, user-friendly interface offers multiple language options and compatibility with various CAD/CAM software and file formats including G-code, TAP, and NC. Features like power-off recovery and breakpoint resume carving allow precise continuation after interruptions, minimizing material waste.

Details of the Efficient 8-Station 3D & 2D Integrated CNC Router

- High-speed water-cooled variable-frequency spindles

Equipped with eight high-speed water-cooled variable-frequency spindles, reaching a maximum speed of 24,000 RPM. The circulating water cooling system ensures efficient and stable temperature control, supporting 24 hour continuous operation.

- Detachable aluminum t-slot worktable

The worktable frame is constructed from welded thickened square tubes, surfaced with aluminum profiles and hard PVC strips for robust structural integrity. It allows quick installation and removal, and when used with clamp fixtures, can securely hold workpieces of various sizes and shapes for convenient operation.

- 3D rotary axes

Integrated with eight 3D rotary axes, driven by two 1300W Yaskawa servo motors and eight worm gear reducers working in coordination, ensuring smooth operation and precise indexed positioning.

- Yaskawa servo system

A total of six 1300W Yaskawa servo motors are configured throughout the machine, delivering high positioning accuracy and operational speed while maintaining very low noise levels.

- High-torque Fuling inverters

Each spindle is powered by an independent Fuling inverter, featuring multiple protection functions such as overload, overvoltage, and overcurrent. The system supports simultaneous operation of all eight spindles or selective activation of individual units, allowing flexible adjustment based on processing needs.

- Reinforced cable carriers

Utilizes strengthened, thickened cable carriers to effectively protect cables from damage, enhancing both the service life and operational safety of the machine.

- Automatic electric lubricator

Includes a fully automatic electric lubricator that supports user-defined lubrication duration and intervals. Equipped with a low-level automatic alarm function, it simplifies and optimizes equipment maintenance.

Technical Parameters of the Efficient 8-Station 3D & 2D Integrated CNC Router

| Model | CK-1020-8SF |

|---|---|

| 3D Carving Capacity(Length * Diameter) | 1000 * 200mm * 8 (Customizable size and quantity) |

| 2D Carving Capacity(Length * Width) | 1000 * 200mm * 8 (Customizable size and quantity) |

| Bed | Heavy-duty thickened bed, independent anti-interference control cabinet |

| Gantry | Thickened cast iron gantry with reinforced cast iron supports |

| Spindle | 2.2KW high-speed water-cooled spindle*8 (Spindle quantity/power customizable) |

| Spindle Speed | 6000-24000 RPM |

| Drive System | Yaskawa 1300W servo motors (Z-axis equipped with brake motor) |

| Rotary Axes | Worm gear reducer-driven rotary axes * 8 |

| Flat Worktable | Aluminum alloy T-slot worktable |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high-precision linear square rail / flange slider |

| Cables | High-flexibility pure copper cables |

| Tool Shank Compatibility | 3.175mm, 4mm, 6mm, 12.7mm, etc. |

| Lubrication System | Fully automatic lubrication and oil maintenance system |

| Control System | Weihong NCStudio V10 4-axis control system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | ArtCam, Type3, CAD, CDR, SolidWorks, UG, PowerMill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Rapid Traverse Speed | 18000mm/min |

| Max. Working Speed | 36000mm/min |

| Dimensions | 2300*1800*1650mm |

| Weight | 1700kg |

Application of the Efficient 8-Station 3D & 2D Integrated CNC Router

Furniture Manufacturing: European-style table legs, chair legs, chair arms, Queen Anne legs, sofa legs, bed legs, wardrobes, cabinets, wine cabinets, bookcases, wooden doors, wardrobe doors, cabinet doors, wall panels, ceiling panels, TV feature walls, drawer fronts, furniture decorations, relief and 3D carvings, etc.

Crafts & Artworks: Buddha statues, deity statues, ritual objects, figure sculptures, animal sculptures, cartoon characters, vases, pen holders, wooden photo frames, commemorative coins, etc.

Signage & Advertising: Wooden signs, directional signs, road signs, advertising letters, store signs, plaques, acrylic advertising letters, plastic display items, etc.

Outdoor & Sporting Goods: Baseball bats, cricket bats, axe handles, hammer handles, agricultural tool handles, etc.

Customized Products: Guitar necks, violin necks, instrument bodies, pet products, company logos, custom crafts, etc.

How to Maintain a 3D & 2D Integrated CNC Router

The 8-station 3D & 2D integrated CNC router requires regular and timely maintenance to ensure long-term stable operation and machining accuracy, due to its multi-station synchronous operation and high-load processing characteristics. Below are detailed maintenance recommendations:

1. Daily Pre-Startup Checks

- Inspect the main power supply, servo drive terminals, control system connections, and emergency stop button for any looseness.

- Verify that the spindle circulation water pump is operating correctly, promptly replenish coolant, and add antifreeze in cold weather.

- Check that the spindle rotates smoothly without abnormal noise, and monitor whether its operating temperature remains within the normal range.

- Observe whether lubrication is even and sufficient on transmission components such as guide rails and ball screws.

- Clamping inspection: When using 3D rotary axes, ensure workpieces are securely fixed; when using the flat worktable, verify that clamps are properly tightened.

2. Monitoring During Processing

- Continuously monitor spindle temperature and machine operating sounds during processing, and pay attention to the synchronization performance of multiple spindles.

- If abnormalities such as unusual spindle noise or system alarms occur, stop the machine immediately and only resume operation after troubleshooting is complete.

3. Cleaning and Organization After Shutdown

- Use compressed air to remove machining debris from the spindle, guide rails, ball screws, and other areas.

- After completing flat processing, promptly clean accumulated dust and wood chips from T-slots to keep the work surface clean.

- Check tool wear conditions and replace severely worn tools in a timely manner.

- Clean dust and debris around the equipment to ensure good ventilation in the working area.

4. Regular Maintenance Items

- Periodically check the lubrication condition of guide rails and ball screws, and replenish the lubricating oil reservoir appropriately.

- Systematically inspect and tighten all connection screws to ensure mechanical structure stability and reliability.

- Regularly clean dust from inside the electrical control cabinet and verify that cooling fans are operating normally.

- Replace spindle coolant according to schedule and clean the cooling tank and circulation pipes.

- Test the sensitivity and reliability of emergency stop buttons and limit switches to ensure safety protection functions remain effective.

| Model | CK-1020-8SF |

|---|---|

| 3D Carving Capacity(Length * Diameter) | 1000 * 200mm * 8 (Customizable size and quantity) |

| 2D Carving Capacity(Length * Width) | 1000 * 200mm * 8 (Customizable size and quantity) |

| Bed | Heavy-duty thickened bed, independent anti-interference control cabinet |

| Gantry | Thickened cast iron gantry with reinforced cast iron supports |

| Spindle | 2.2KW high-speed water-cooled spindle*8 (Spindle quantity/power customizable) |

| Spindle Speed | 6000-24000 RPM |

| Drive System | Yaskawa 1300W servo motors (Z-axis equipped with brake motor) |

| Rotary Axes | Worm gear reducer-driven rotary axes * 8 |

| Flat Worktable | Aluminum alloy T-slot worktable |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan Hiwin high-precision linear square rail / flange slider |

| Cables | High-flexibility pure copper cables |

| Tool Shank Compatibility | 3.175mm, 4mm, 6mm, 12.7mm, etc. |

| Lubrication System | Fully automatic lubrication and oil maintenance system |

| Control System | Weihong NCStudio V10 4-axis control system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | ArtCam, Type3, CAD, CDR, SolidWorks, UG, PowerMill, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max. Rapid Traverse Speed | 18000mm/min |

| Max. Working Speed | 36000mm/min |

| Dimensions | 2300*1800*1650mm |

| Weight | 1700kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.