4-Axis ATC CNC Router with Carousel-Type Automatic Tool Changer, Auto-Labeling, Vertical & Horizontal Drilling

7x10ft Carousel-Type ATC 4-Axis CNC Router with Labeler and Vertical Drilling Bank

[Function Description]

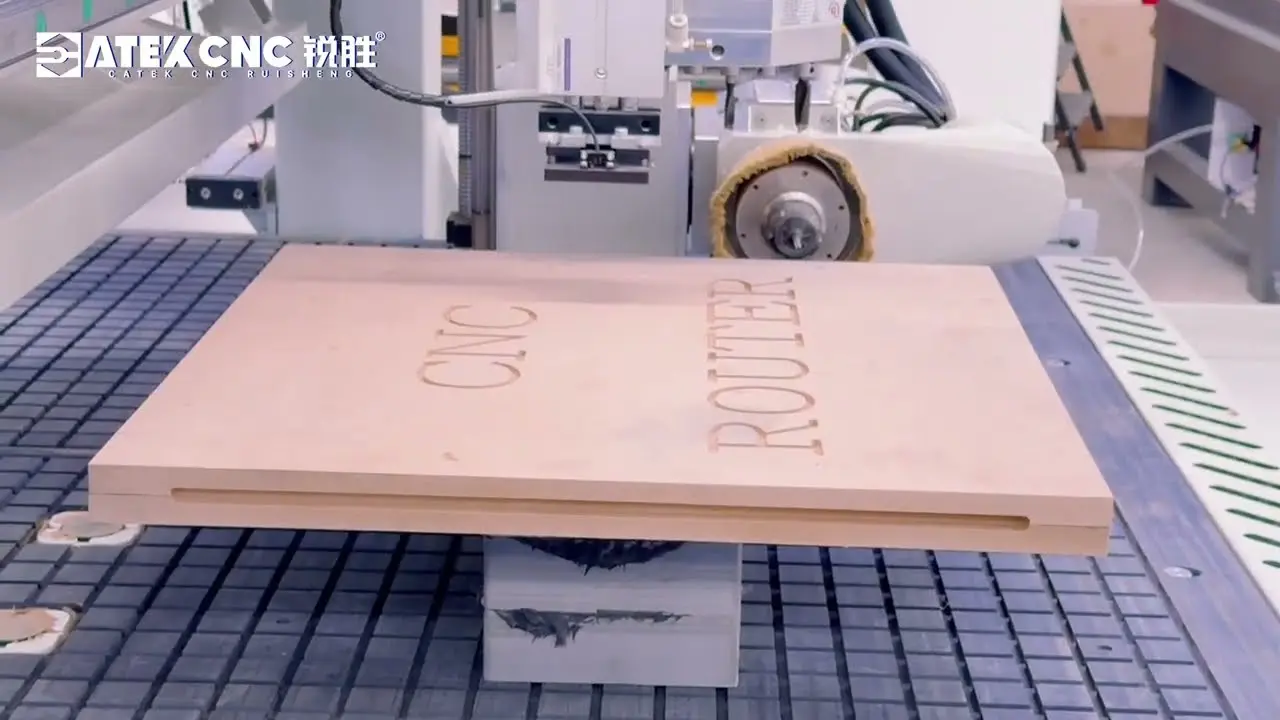

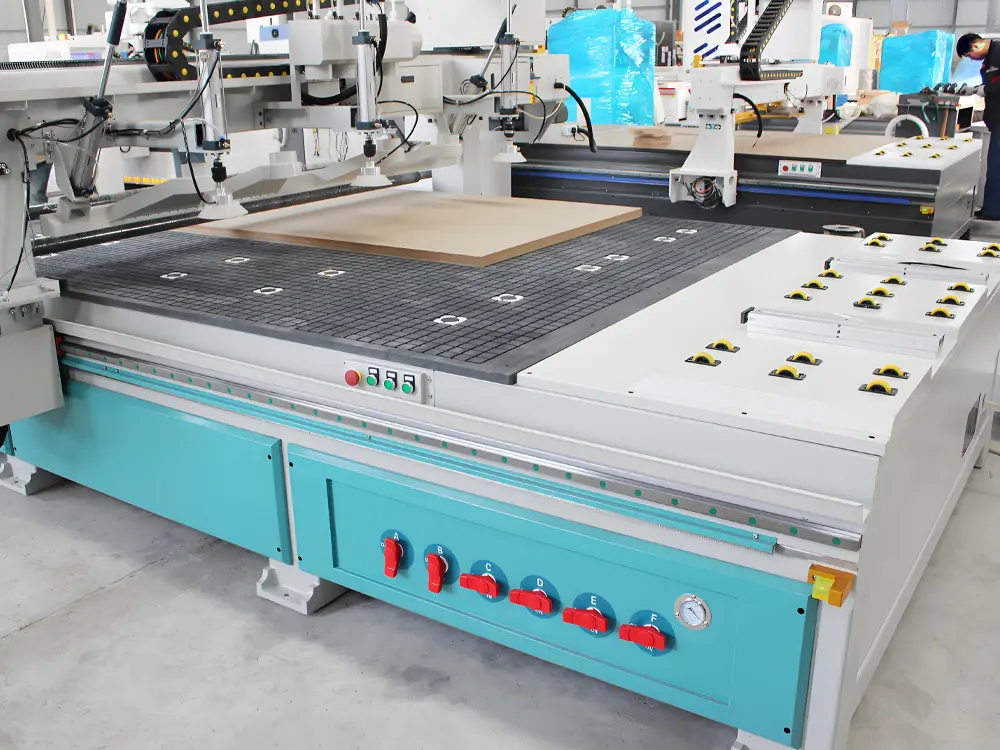

The CK-2130-4S-ADL is equipped with a 12-tool carousel-type automatic tool-changing system and integrates an automatic labeling system, a 5+4 vertical drilling bank, and a swivel head. As a core equipment for smart panel furniture manufacturing, it enables batch production of panel furniture such as cabinets and wooden doors.

This CNC woodworking router features a 12-tool carousel-type tool magazine paired with an automatic tool-changing spindle, allowing on-demand tool changes during machining. It also incorporates multiple functional kits adapted for panel furniture processing: the automatic labeling system enables automatic barcode application on panels, facilitating precise traceability through barcodes and significantly improving workflow efficiency; the 5+4 vertical drilling bank quickly completes various connection hole machining tasks; the 4-axis swivel head overcomes planar machining limitations, enabling side panel drilling, grooving, customized door panel processing, and 3D curved surface machining. The coordinated configuration of these functional kits allows all processes—cutting, grooving, drilling, and engraving—to be completed on a single machine, achieving one-stop panel processing. Whether for batch production of panel furniture like cabinets and wooden doors, or for small-batch custom orders, the CK-2130-4S-ADL can deliver with high efficiency, precision, and quality.

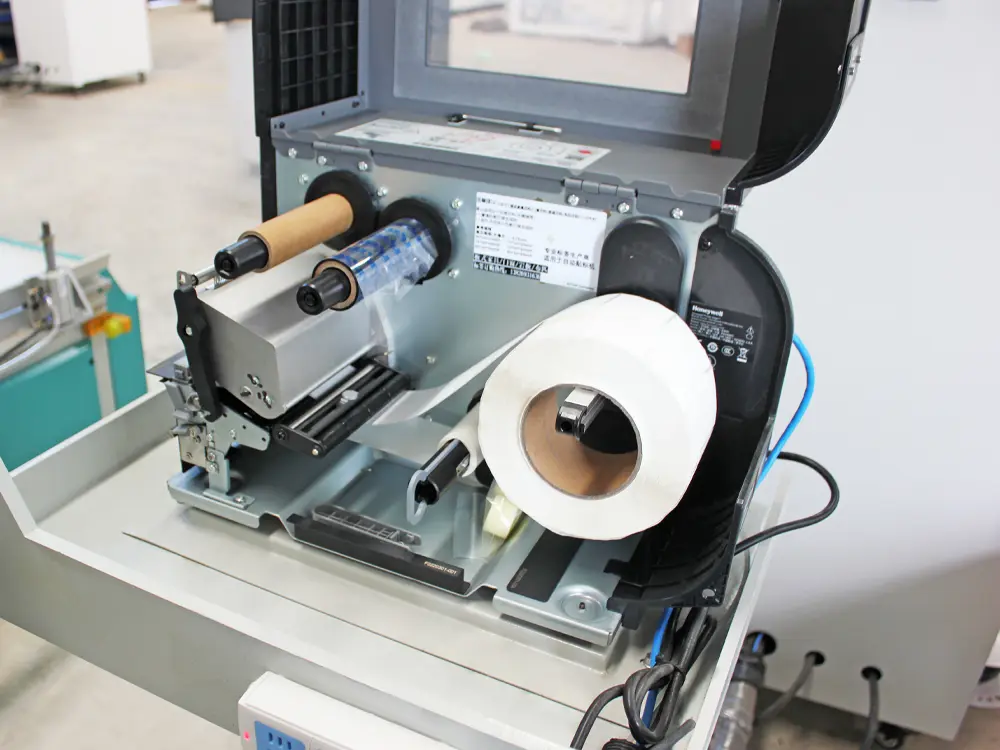

Furthermore, the automatic labeling system seamlessly integrates with the entire processing workflow. Before machining, front-end automatic nesting software automatically disassembles and converts orders, generating corresponding production instructions (including cutting dimensions, drilling positions, labeling locations, and barcode content). These instructions are automatically synchronized to the labeling machine without manual input. After loading, the labeling machine uses precise positioning technology to lock labeling positions and quickly completes label application—all without manual intervention. This process entirely eliminates missed or incorrect labeling, ensuring full traceability of panels from processing to finished products. This not only reduces material waste and rework but also simplifies order management and after-sales traceability procedures, making production both efficient and standardized.

Features of The Carousel-Type ATC 4-Axis CNC Router with Labeler and Vertical Drilling Bank

1. Ultra-High-Strength Welded Bed Frame + Heavy-Duty Gantry Beam

Ultra-High-Strength Welded Bed Frame: The bed is constructed from heavy-duty, thickened square steel with every weld seam meticulously executed using a multi-layer, multi-pass process to ensure robust bonding. It undergoes both annealing and vibration aging treatments to thoroughly eliminate internal stresses. The bed surface is overlaid with an 8mm ultra-thick steel plate. The guide rail/rack mounting surfaces are then precision-machined using a large 5-axis gantry milling machine through a complete process of rough milling, fine milling, and grinding, ensuring flatness errors are strictly controlled.

Heavy-Duty Gantry Beam: The beam is made from high-strength low-carbon steel, subjected to two aging treatments to fully release internal stresses, and precisely straightened to guarantee straightness errors are tightly controlled within 0.01mm/m. Finally, a gantry milling machine performs fine machining on the guide rail and rack mounting surfaces. This ensures the transmission system operates on an absolutely vertical and horizontal installation datum, providing reliable assurance for the machine's high-precision, high-speed operation.

2. Comprehensive Functionality for All-Round Machining Needs

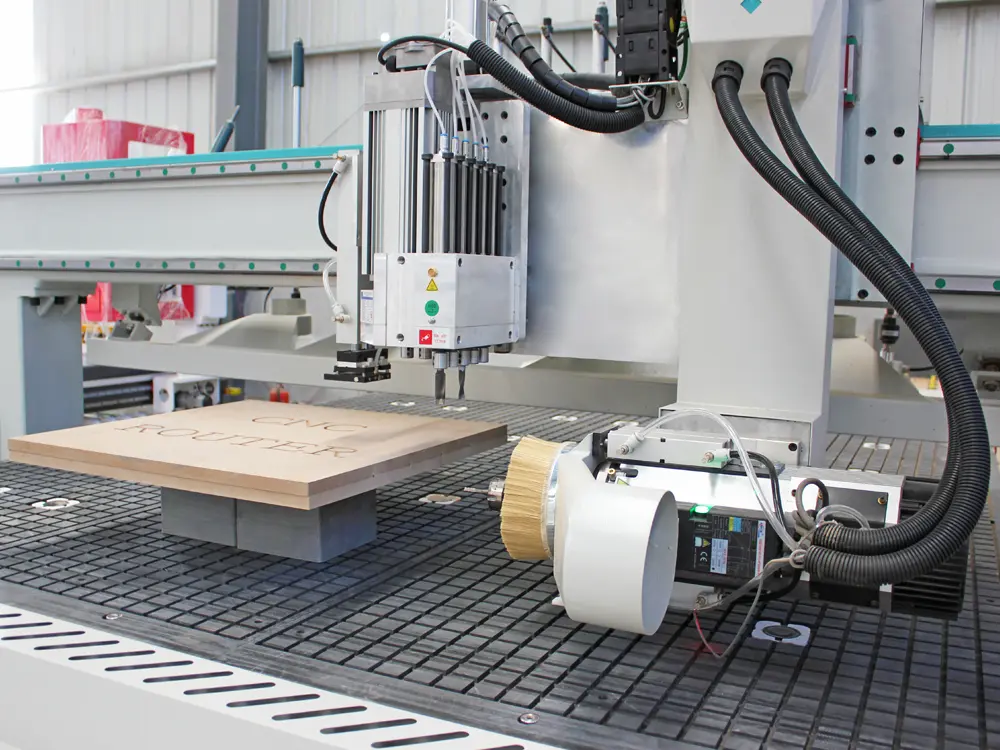

Automatic Tool Changing Spindle: Employs a 9KW air-cooled ATC spindle with a maximum speed of 18,000 RPM. It offers high output torque and strong cutting power, easily handling cutting, drilling, slotting, profiling, and side hole machining on various hard materials like plywood, MDF, and OSB. The air-cooled design requires no external plumbing, offering easy installation, simple maintenance, stable cooling efficiency, and enabling 24/7 continuous operation.

Carousel-Type Automatic Tool Changer: Features a carousel-type tool magazine compatible with ISO30 tool holders and ER32 collet chucks. Twelve tools are evenly distributed in a ring. Different tools can be pre-loaded into the 12 stations. When a tool change is required during machining, the control system automatically issues a command. The magazine rapidly rotates to the target station while the spindle moves beside it to complete the change. The entire tool change process takes less than 10 seconds. Compared to manual changes, efficiency increases by over 80%, significantly reducing non-cutting time. Additionally, the carousel design avoids the limitation on maximum workpiece thickness imposed by gantry-type linear tool magazines.

4-Axis Swivel Head: In addition to the X, Y, Z linear axes, the machine features a fourth rotary axis (swivel head) capable of ±90° rotation. This greatly expands the machining envelope, allowing a panel to undergo multiple operations—profiling, engraving, drilling, slotting—on vertical faces, sides, bevels, and curved surfaces in a single setup. Through the precise synchronized control of the CNC system, the relative position between the swivel head and workpiece is calibrated in real-time, enabling neat and smooth machining results even for angled holes or curved surface cuts and engraving textures.

5+4 Vertical Drilling Bank: Specifically designed for vertical drilling in panel furniture like wardrobes and cabinets, this unit can hold 9 drill bits of different specifications simultaneously. The 9 bits are arranged in an L-shaped pattern, each with an independent pneumatic control unit, suitable for machining adjacent dense hole patterns or holes of different diameters.

Automatic Labeling System: Equipped with a Honeywell automatic labeler, its core capabilities are data linkage, precise positioning, and automatic application. Designed for workpiece traceability needs, it translates order information into label content, covering the entire process from label printing, workpiece positioning, to label application—all without manual intervention. Before panel processing, the machine automatically applies labels to the sheets. This facilitates subsequent quality checks and issue resolution while enabling smooth handoff to other downstream processes. The labeler supports 24/7 continuous operation and is particularly well-suited for high-volume production scenarios like furniture manufacturing.

3. High-Precision Transmission System

Linear Guideways / Linear Bearings: Utilizes HIWIN (Taiwan) 30mm heavy-load linear guides and bearings with a four-row single-arc groove contact design. Compared to standard products of the same size, this configuration achieves significantly larger load capacity while increasing rigidity by over 30%. The minimal rolling friction loss and extremely low backlash provide the foundation for the machine to maintain stable machining accuracy over the long term.

Helical Rack and Pinion: The X and Y-axis transmission employs high-precision ground helical racks. Compared to spur racks, the helical design offers greater contact area during meshing, resulting in smoother overall transmission, lower operating noise, and reduced vibration. Furthermore, helical racks possess greater torque-bearing capacity, effectively increasing machine traverse speed while enhancing operational smoothness and extending component lifespan.

4. Drive System

Leadshine EtherCAT Absolute Servo Motors: Equipped with six sets of Leadshine servo motors in total: 1500W for X, Y, Z, A axes, and 750W for the carousel-type tool magazine. The EtherCAT bus control architecture enables faster data transmission between the drive and control systems, stronger anti-interference capability, lower command response latency, and faster dynamic response, making it better suited for multi-axis coordination in complex machining scenarios. The absolute feedback characteristic eliminates the need for homing calibration at every startup, allowing direct and precise positioning to the initial location. This saves startup preparation time and avoids positioning deviations caused by power loss or interference common in incremental servo systems, providing reliable power support for the machine's consistently stable machining performance.

Shimpo (Japan) Planetary Gear Reducers: Utilizing a planetary gear architecture, these reducers offer advantages of high precision, high rigidity, and low noise. The symmetrical distribution of planet gears enhances load-bearing capacity, enabling them to withstand stronger load impacts and ensuring smooth, reliable power transmission in high-precision, high-speed operating scenarios.

5. Vacuum Table, Double-Rod Air Press Rollers, and Vacuum Cups

Vacuum Table: Features a 9-zone, 29-hole vacuum table with independent zone control and an optimized hole layout, offering extremely high holding stability and usage flexibility. The 9 independently controlled zones can be precisely activated or deactivated based on the workpiece size, saving vacuum pump energy while adapting to diverse processing needs from small parts to full-size sheets up to 7x9 feet. The 29 holes are evenly distributed, ensuring balanced holding force coverage across the entire table to securely fix various materials like wood panels and MDF, preventing machining failures due to workpiece shift or warping during processing.

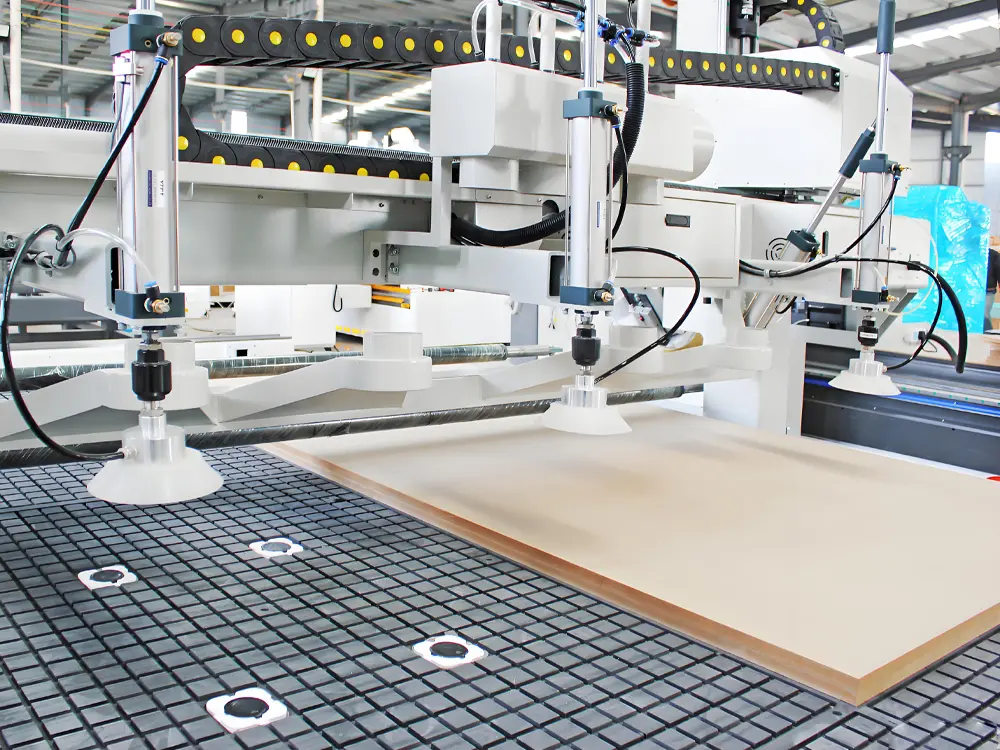

Double-Rod Air Press Rollers: The double-rod structure ensures even distribution of clamping force, avoiding panel deformation caused by concentrated point pressure. Both rollers feature independent pneumatic control, allowing pressure adjustment based on panel thickness and material. The roller surfaces use high-damping, wear-resistant, non-slip material to prevent slipping or scratching the panel. This device works in conjunction with the vacuum table to provide dual fixation, further enhancing workpiece stability.

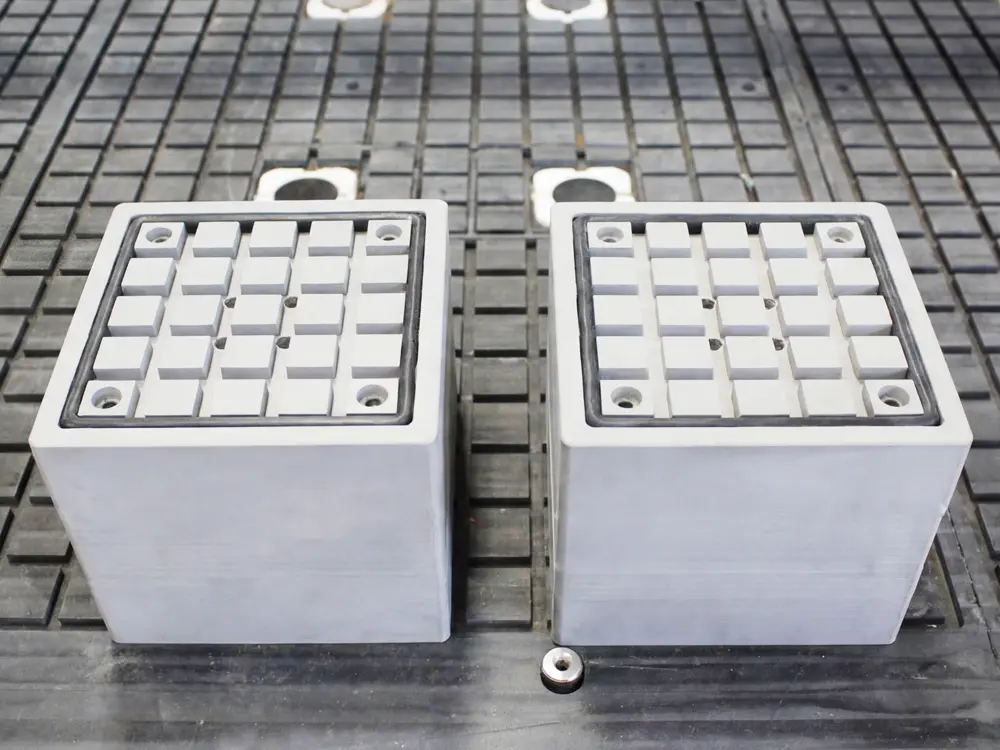

Vacuum Cups: These are specialized support accessories for machining side holes on panels, solving positioning and multi-component interference issues during side hole processing. Placed beneath the panel, they elevate it to avoid interference from the table during side drilling. Each block has four through-holes and a surface with grooves identical to the vacuum table. Once the panel is placed, the vacuum pump can be activated for suction. Used in conjunction with the 4-axis swivel head, they enable drilling, slotting, and other operations on the sides of panels, doors, etc.

6. LNC (Taiwan) CNC System

Employs an LNC (Taiwan) CNC system supporting 4-axis linkage. Paired with the EtherCAT absolute servo system, it requires no homing upon startup. It includes an electronic handwheel for fine adjustment of axis travel and origin setting. The system features a graphical user interface, supports multiple languages, is compatible with various CAD/CAM software and G-code file formats. It supports advanced functions like handwheel simulation, alarm detection, and power failure resume. The machining file can be verified via simulation before processing, reducing trial-and-error costs. The system is user-friendly for beginners, operable via mouse and keyboard, with an intuitive, clean interface layout.

7. High-Quality Auxiliary Systems

Automatic Tool Setter: Uses a contact-type automatic tool setter with a built-in high-precision sensor. After an automatic tool change, it performs the tool setting operation: the tool slowly descends until it contacts the setter's surface, triggering a signal that is transmitted to the CNC system. The system then calculates the tool length based on the preset coordinates and the triggered contact point. This completely replaces the tedious manual tool calibration, increasing efficiency by 80%, significantly reducing machine idle time, effectively ensuring machining accuracy, and boosting productivity.

Automatic Lubrication System: Programmable design allows for timed, metered lubrication of the transmission system (guides, screws, etc.) based on machine usage frequency. Built-in sensors trigger an alarm when oil is low. Compared to traditional manual lubrication, this system offers more precise and controllable lubrication, effectively preventing under-lubrication.

Loading Rollers: The table rear is equipped with 7 rows (21 total) of loading rollers, assisting in quick and smooth panel transfer onto the table. This greatly reduces manual loading effort, allowing a single operator to handle loading, saving labor costs, and effectively preventing panel scratches.

Vacuum Loading Cups: Three vacuum loading cups are mounted behind the gantry, capable of interfacing with a lift-type automatic loading platform. Using vacuum suction to grip panels, they work with the loading rollers and positioning cylinders to achieve fully automatic panel loading and positioning, reducing reliance on manual loading and improving processing efficiency.

Vacuum Zone Control Switches: Each vacuum zone has an independent control switch. During machining, zones can be selectively activated based on needs. This reduces vacuum pump load while adapting to panels of different sizes or irregular shapes, preventing pressure dispersion when holding small panels and making the holding force more concentrated to ensure machining accuracy.

Automatic Unloading/Dust Collection Device: Features a pneumatic automatic panel pusher. After panel processing is complete, the device automatically moves behind the panel and pushes the finished piece to the unloading area. This device can interface with a conveyor-type automatic unloading platform, achieving full automation from machining to unloading, reducing manual labor intensity and minimizing machine idle time.

4+3 Positioning Cylinders: Configured with 3 cylinders in the X-direction and 4 in the Y-direction, these 7 sets are arranged to form an L-shaped right-angle positioning structure. They quickly correct placement offsets from manual loading, ensuring the machining zero point for each panel is accurate. Pneumatically driven, they offer fast response and easy operation, significantly shortening panel positioning time—especially suitable for batch production scenarios requiring frequent load/unload cycles.

3KW Bag-Type Dust Collector: Powered by a 3KW high-power motor generating strong negative pressure, it swiftly sucks in dust and wood chips generated during machining into the storage bag. This prevents dust accumulation on machine guides, screws, and the worktable, ensuring a clean working environment.

Details of the 4-Axis Swivel Head ATC CNC Router with Auto-Labeling Device and Drilling Bank

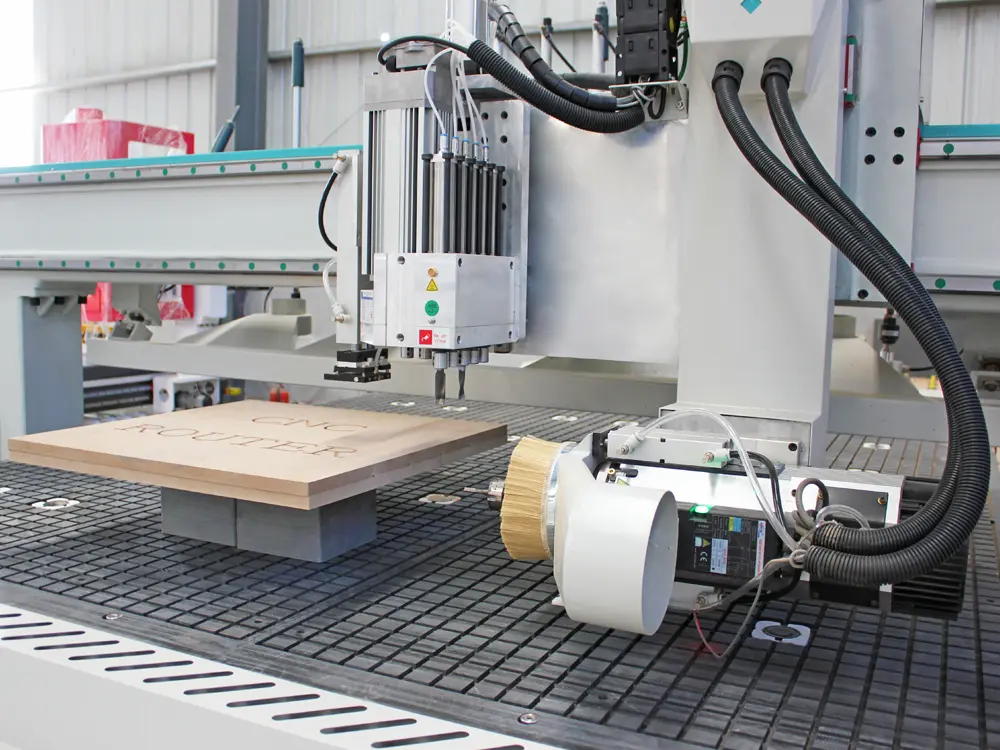

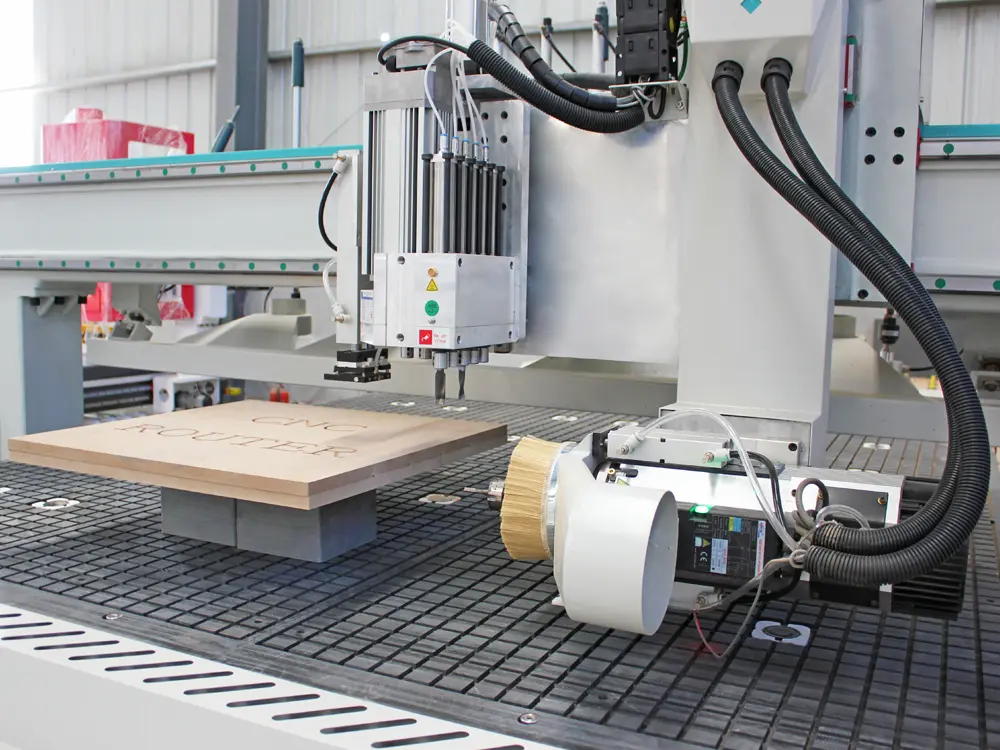

- ATC spindle & 5+4 pneumatic drilling bank

The core machining unit of the CNC router. Through the coordinated operation of the spindle and drilling bank, it enables complete processing, cutting, profiling, slotting, multi-spec drilling—in a single setup, adapting to various machining requirements.

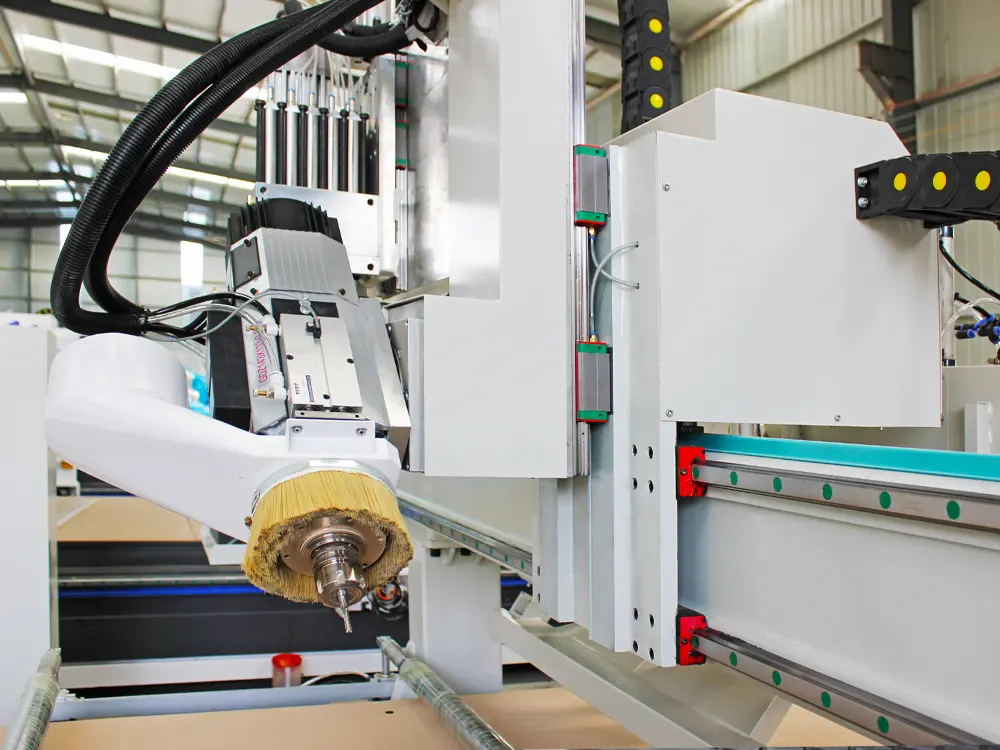

- 4-Axis swivel head

Supports indexed left/right swing of ±90°, easily enabling processes like angled hole drilling, bevel cutting, 3D curved surface cutting, 3D engraving, and profiling of irregular edges/borders—tasks traditional 3-axis CNC machines cannot perform, thereby expanding the machine's processing range.

- Carousel-type tool magazine

Carousel-Type Tool Magazine: A carousel-type magazine holding 12 tools, compatible with ISO30 tool holders and ER32 collet chucks. Paired with the ATC spindle, it automatically changes tools based on machining needs during operation, saving tool change time, and improving machining efficiency.

- Automatic labeler

Can automatically read data like file order numbers and barcodes, precisely print and apply them to the surface of panels to be processed. This enables panel traceability and management, facilitates quick order identification, and reduces management costs.

- Leadshine EtherCAT absolute servo drive system

Utilizes six sets of Leadshine EtherCAT absolute servo motors with EtherCAT bus technology. No homing required on startup, offering faster response and higher machining accuracy.

- Fuling inverter

Employs a spindle-dedicated Fuling inverter for precise speed control. Spindle speed can be flexibly adjusted according to processing material and technique. Built-in multiple protections (over-current, overload, over-voltage, over-temperature) ensure stable spindle operation and reduce failures.

- Automatic tool setter

After automatic tool changes, the automatic tool setter detects the tool length and quickly completes tool parameter compensation, replacing manual tool calibration and improving machining efficiency.

- Electronic handwheel

Used in conjunction with the CNC system, it enables manual fine adjustment and precise positioning of motion axes, allowing quick correction of machining deviations. It supports functions like quick origin setting, handwheel simulation, and angle fine-tuning.

- Vacuum loading cups

Three automatic loading cups mounted behind the gantry can interface with a hydraulic lift-type loading platform to achieve fully automatic loading, saving manual labor.

- Double-rod air press rollers

Pneumatically controlled, pressure can be precisely adjusted via a regulator valve. They work with the vacuum table to ensure the panel remains firmly against the table surface during processing, providing a stable reference for machining.

- Positioning cylinders

The 4+3 positioning cylinders, controlled synchronously by solenoid valves, form an L-shaped right-angle positioning system, ensuring precise and consistent panel placement with each loading cycle.

- Vacuum cups

sed in conjunction with the vacuum table; the suction cups need to be connected to the vacuum ports when in use. This device elevates the panel height to avoid interference from the worktable, facilitating side machining on panels by the 4-axis swivel head.

- Vacuum zone control switches

Each vacuum zone is equipped with an independent valve switch, allowing selective activation of corresponding zones based on workpiece size for convenient and flexible use.

- HIWIN (Taiwan) guideways / racks

Equipped with HIWIN 30mm guides/linear bearings. The X and Y axes feature high-precision helical racks/pinions, offering high positioning accuracy and fast traverse speeds, providing the foundation for the machine's long-term stable machining precision.

- Cable carrier

High-strength cable carriers consolidate power cables, signal lines, and air hoses from moving components on the X, Y, Z axes. This prevents cable tangling, wear, or contamination from wood dust/chips, ensuring stable operation of the machine's electrical system.

- LNC (Taiwan) CNC system

Equipped with a fully-featured, simple-interface LNC CNC system. Compatible with various CAD/CAM software, supports multiple G-code format files, and offers advanced functions like toolpath preview, handwheel simulation, and power failure resume, meeting diverse user needs.

Technical Parameters of Carousel-Type ATC 4-Axis CNC Router with Labeler and Vertical Drilling Bank

| Model | CK-2130-4S-ADL |

|---|---|

| XYZ Work Travel | 2100*3000*200mm (customizable according to processing requirements) |

| Frame Structure | Heavy-duty frame with 8 mm thickened steel plate, quenched and sandblasted |

| Spindle Mounting Plate | 75 mm thick integral anodized aluminum alloy mounting plate |

| Spindle | 9 kW HQD high-speed air-cooled ATC spindle |

| 4-Axis Swivel Angle | ±90° |

| Spindle speed | 0–18000 r/min |

| Table | 9-zone, 29-hole vacuum adsorption table |

| Drilling Bank | 5+4 vertical pneumatic drilling bank |

| Drilling Bank Speed | 3200RPM |

| Tool Magazine | 12-tool carousel-type tool magazine (customizable for 8–16 tools) |

| Tool Holder Type | ISO30 ER32 φ20 |

| Tool Setting Method | Automatic tool setter |

| Servo Motor | Leadshine 1500 W bus-type absolute servo motor / servo drive |

| Frequency Converter | Fuling 11KW high torque inverter |

| Guideways | Taiwan 30 mm HIWIN linear guides / linear bearings |

| Rack (X, Y Axes) | Taiwan YYC 2 M rack |

| Ball Screw (Z Axis) | Taiwan TBI 3210 ball screw |

| Press Roller | Double-rod pneumatic press roller |

| Positioning | 4+3 positioning cylinders |

| Pushing Function | Double cylinder automatic push |

| Loading Suction Cups | Vacuum loading suction cups * 3 |

| Vacuum Pump | 11 kW water-ring vacuum pump |

| Dust Collection | 3 kW bag-type dust collector |

| Control Cabinet | Independent anti-interference control cabinet |

| Control System | Taiwan LNC control system |

| Machine Voltage | 380V/3PH 220V/3PH |

| Max. Rapid Traverse Speed | 100000mm/min |

| Max. Working Speed | 30000mm/min |

| Dimensions | 4200*2900*2450mm |

| Weight | 2800kg |

Application of Carousel-Type ATC 4-Axis CNC Router with Auto-Labeling, Vertical & Horizontal Drilling

Applicable Materials:

Wood: Solid wood, MDF, particle board, laminated wood, finger-jointed board, OSB, plywood, multi-layer board, bamboo, painted board, fireproof board, melamine board, etc.

Plastics & Composites: PVC, ABS, two-color board, acrylic, polycarbonate (PC), insulation board, carbon fiber, aluminum composite panel, polyurethane (PU), artificial stone, foam, honeycomb panel, etc.

Metal Materials: Copper, aluminum, brass, aluminum alloy, and other soft metal sheet materials.

Applicable Industries:

Custom Furniture Industry: Wardrobes, kitchen cabinets, shoe cabinets, wine cabinets, tatami units, TV cabinets, sideboards, cabinet doors, sliding wardrobe doors, hidden doors, wall panels, decorative moldings, etc.

Office Furniture Industry: Desks, office chair frames, filing cabinets, storage cabinets, conference tables, office partitions, etc.

Wooden Door Manufacturing Industry: Solid wood doors, composite wood doors, eco-friendly wood doors, cabinet doors, security doors, double doors, etc.

Display & Exhibition Industry: Cosmetic counters, jewelry showcases, clothing racks, digital kiosks, supermarket shelves, art display stands, display racks, etc.

Advertising Industry: Acrylic display stands, acrylic advertising letters, PVC advertising letters, decorative light boxes, acrylic aquarium frames, etc.

Model & Mold Making Industry: Wooden ship models, aircraft models, aviation models, sand table models, architectural models, car models, etc.

| Model | CK-2130-4S-ADL |

|---|---|

| XYZ Working Travel | 2100*3000*200mm (customizable according to processing requirements) |

| Frame Structure | Heavy-duty frame with 8 mm thickened steel plate, quenched and sandblasted |

| Spindle Mounting Plate | 75 mm thick integral anodized aluminum alloy mounting plate |

| Spindle | 9 kW HQD high-speed air-cooled ATC spindle |

| 4-Axis Swivel Angle | ±90° |

| Spindle speed | 0–18000 r/min |

| Table | 9-zone, 29-hole vacuum adsorption table |

| Drilling Bank | 5+4 vertical pneumatic drilling bank |

| Drilling Bank Speed | 3200RPM |

| Tool Magazine | 12-tool carousel-type tool magazine (customizable for 8–16 tools) |

| Tool Holder Type | ISO30 ER32 φ20 |

| Tool Setting Method | Automatic tool setter |

| Servo Motor | Leadshine 1500 W bus-type absolute servo motor / servo drive |

| Frequency Converter | Fuling 11KW high torque inverter |

| Guideways | Taiwan 30 mm HIWIN linear guides / linear bearings |

| Rack (X, Y Axes) | Taiwan YYC 2 M rack |

| Ball Screw (Z Axis) | Taiwan TBI 3210 ball screw |

| Press Roller | Double-rod pneumatic press roller |

| Positioning | 4+3 positioning cylinders |

| Pushing Function | Double cylinder automatic push |

| Loading Suction Cups | Vacuum loading suction cups * 3 |

| Vacuum Pump | 11 kW water-ring vacuum pump |

| Dust Collection | 3 kW bag-type dust collector |

| Control Cabinet | Independent anti-interference control cabinet |

| Control System | Taiwan LNC control system |

| Machine Voltage | 380V/3PH 220V/3PH |

| Max. Rapid Traverse Speed | 100000mm/min |

| Max. Working Speed | 30000mm/min |

| Dimensions | 4200*2900*2450mm |

| Weight | 2800kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.