CNC Furniture Making Machine with 4-tool Switch and Automatic Loading and Unloading

4-in-1 CNC Wood Nesting Machine with Automatic Loading and Unloading

[Function Description]

CK-1325-A-4T is a highly automated CNC router with high-efficiency processing capabilities. It has automatic loading and unloading functions and four automatically switchable spindles. It is mainly used for the processing of panel furniture, cabinet doors, wooden doors and other products. At the same time, it combines the automatic loading and unloading system and the multi-spindle automatic switching function, which can realize the cutting, drilling, grooving, engraving and other processes of the plate, which can greatly improve the production efficiency and processing accuracy.

The automatic loading and unloading system is an important part of the four-spindle CNC router with automatic loading and unloading platform, which realizes the automatic loading and unloading of plates by means of the lifting and lowering structure and the rolling conveyor function. These functions work in tandem to ensure that the plates are accurately transported and positioned during the machining process, thus guaranteeing the quality of the machining. The machine is equipped with four spindles, each of which can be fitted with different tools for cutting, punching and grooving. It can automatically switch spindles according to different processing needs, avoiding the time wasted on manual tool changing and enabling the machine to complete multiple processes in a single run, effectively improving productivity.Workflow of Four-Function-Switch CNC Wood Router with Plate Feeding

- Automatic loading: The hydraulic lifting automatic loading device can automatically adjust the height according to the thickness and quantity of the plate. The plate is dragged from the loading platform to the vacuum adsorption workbench with the help of the suction cup device behind the gantry bracket, and then the plate is fixed to the processing position through the 4+2 positioning cylinder and side push cylinder of the workbench.

- Automatic processing: The four spindles are equipped with different tools respectively, which can be automatically switched according to different processing tasks to accurately perform cutting, drilling and grooving operations on the plate. It is controlled by the CNC system. After the processing parameters are input, the servo motor drives each axis to move to complete various processing needs.

- Automatic unloading: After machining, the finished plate is automatically pushed to the unloading table by utilizing the pushing system. The conveyor belt of the unloading table is designed so that even if the plate is cut into several pieces during processing, the unloading operation can be completed efficiently without moving the position of each finished product, avoiding secondary transportation. At the same time, the pushing system carries out secondary dust removal on the working table to keep the table surface clean.

Features of Four-Function-Switch CNC Router with Plate Feeding for Mass Production

- four 6KW air-cooled spindles, four ceramic bearings are used inside, with stable speed and low noise.

- Taiwan LNC CNC system, highly automated control, complete functions, fully automatic operation, simple operation.

- Each spindle is independently equipped with a dust cover, which automatically removes dust during processing and is environmentally friendly.

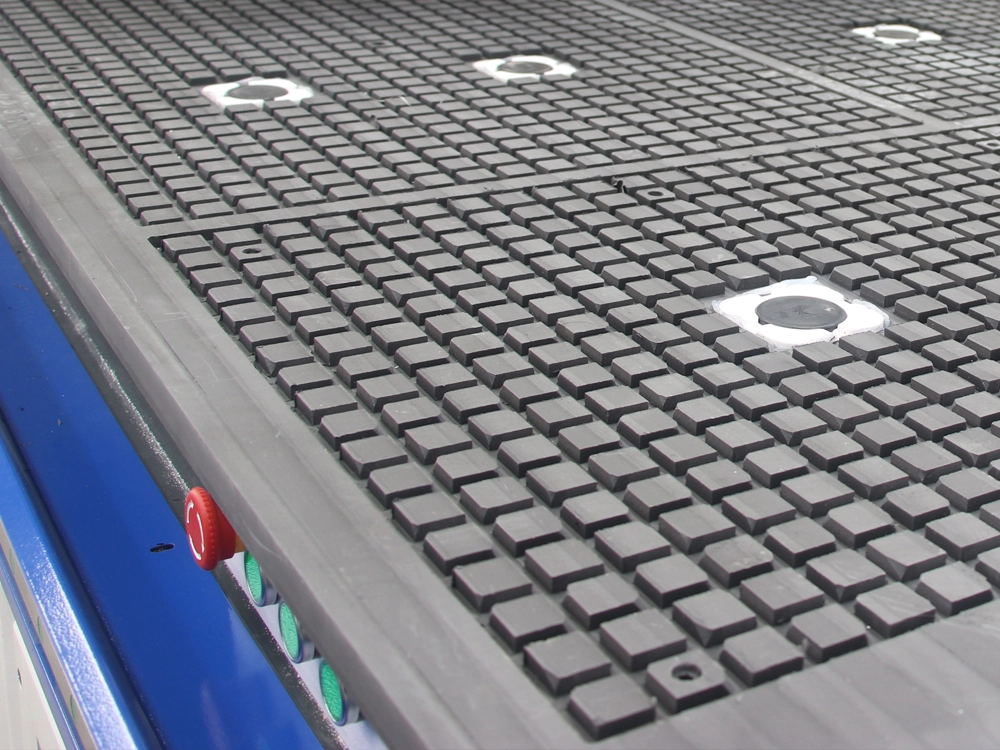

- Vacuum adsorption workbench, 6 zones and 24 holes, can adsorb various small-sized parts.

- High-power water-cooled vacuum pump, high vacuum extraction efficiency, stable negative pressure.

- Lifting automatic loading platform, can load more than 3000kg, hydraulic power.

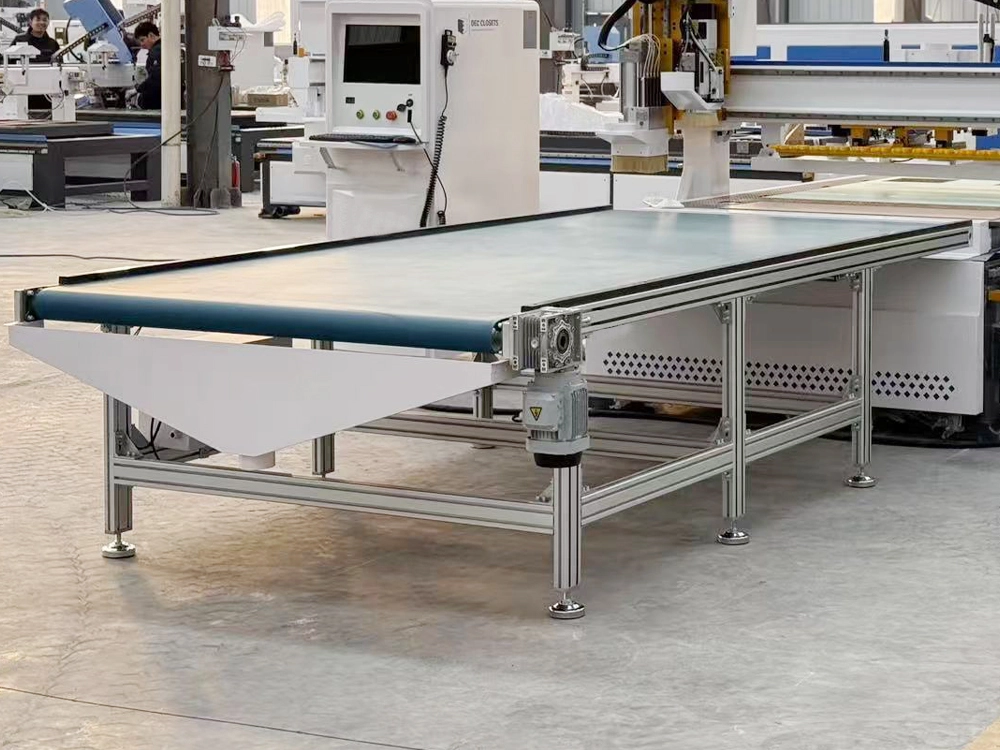

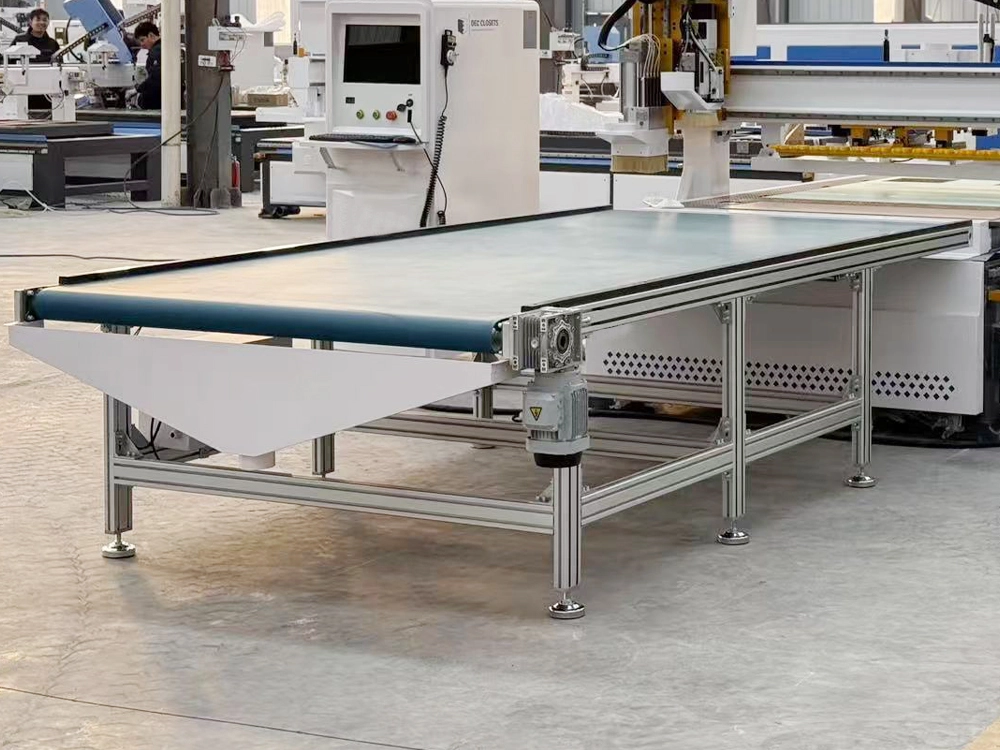

- Conveyor belt unloading platform, can be connected to various production lines, and transferred to the designated location after processing, saving the time wasted by manual unloading of materials.

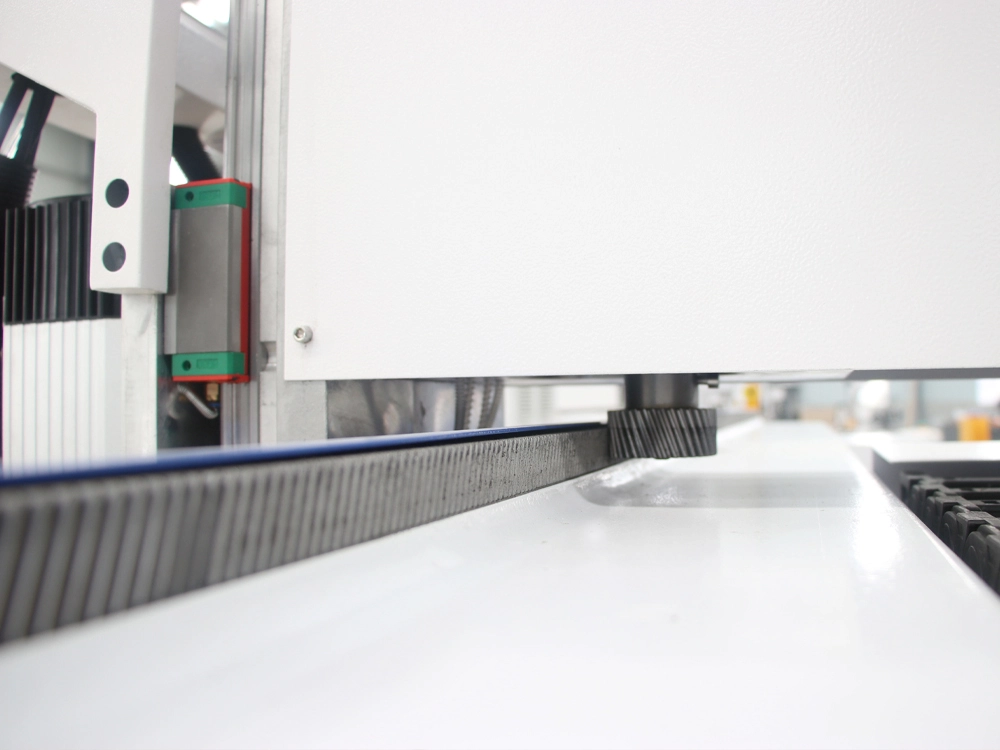

- Helical rack/gear, Hiwin guide rail, linear bearing, stable operation, high positioning accuracy.

- 1500W high-power servo motor, large output torque, low operating noise, fast speed.

- Compatible with various cad/cam type software, supports various nesting software, recognizes G code operation, and has a very low operating threshold.

- Free nesting software is provided, equipped with operation manual and operation video.

Details of 4x8 Four-Function-Switch CNC Router with Automatic Loading and Unloading

- Four switchable spindles

Four 6KW air-cooled spindles, 18000r/mim, stable speed.

- Vacuum adsorption platform

Using an 11KW vacuum pump with a 6-zone 24-hole vacuum adsorption platform can strongly adsorb plates of different sizes, ensuring that the plates will not move or offset during processing, thereby improving processing accuracy and efficiency.

- Automatic tool setting device

Even if the four spindles are equipped with tools of different lengths or diameters, the zero point can be automatically calibrated.

- 4+2 positioning cylinder

It can realize rapid positioning of full-size plates.

- Transmission system

High-precision helical racks and gears, Taiwan Hiwin 30 guide rails.

- Feeding suction cups

Double automatic feeding suction cups, adsorbing the plate more stably.

- Automatic lubrication system

The lubrication interval and lubrication duration can be set to achieve automatic lubrication.

- Automatic loading platform

The loading platform can hold multiple panels and can be automatically raised and lowered.

- Automatic unloading platform

The unloading platform is equipped with a conveyor belt to realize the automatic transfer of the plates.

Technical Parameters of 4x8 Four-Function-Switch CNC Router With Automatic Loading & Unloading

| Model | CK-1325-A-4T |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 6KW high power air-cooled spindle * 4 |

| Spindle Speed | 6000-18000r/min |

| Driving Mode | 1.5KW servo motor drive (Z-axis brake motor)) |

| Reducer | Japan Shimpo reducer |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Processing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 4500kg |

| Dimensions | 9500*2150*2250mm |

Application Scope of 4x8 Four-Function-Switch CNC Router

CNC wood router can process all kinds of insulation parts, plastic sheets, bakelite sheets, solid wood sheets, multilayer sheets, density sheets, particle boards, finger-jointed sheets, plywood, aluminum honeycomb sheets, acrylic sheets, PVC sheets, aluminum-plastic sheets, PCB sheets, etc.

- Furniture industry application

It can be used for cutting MDF, HDF and other sheets to make all kinds of furniture, including: wooden doors, wardrobes, cabinets, wine cabinets, solid wood furniture, panel furniture, office furniture, small and medium-sized cabinets, cabinet doors, guest furniture, bedroom furniture, dining room furniture, study furniture, coffee tables, computer tables, bedside tables, sideboards, shoe cabinets, bookcases, entrance cabinets, display cabinets, etc.

- Woodworking industry application

- Casket and coffin production.

- Relief and hollowing craftsmanship of solid wood doors, photo frame carving.

- Wood mold cutting, 3D carving.

- Production of corrugated boards, grooved boards, decorative boards, and special-shaped cutting of artificial boards.

- Screen and window processing.

- Musical instrument industry applications

Parts of speakers, pianos, guitars, violins, wooden boxes and other musical instrument accessories.

- Advertising industry applications

Advertising letters, crystal letters, mini letters, acrylic letters, advertising signs, acrylic light boxes, signboards, etc.

| Model | CK-1325-A-4T |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 6KW high power air-cooled spindle * 4 |

| Spindle Speed | 6000-18000r/min |

| Driving Mode | 1.5KW servo motor drive (Z-axis brake motor)) |

| Reducer | Japan Shimpo reducer |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Pushing | Fully automatic push cylinder device |

| Loading | Automatic lifting loading platform |

| Unloading | Automatic rolling conveyor unloading platform |

| Maximum Pocessing Speed | 18000mm/min |

| Maximum No-Load Running Speed | 25000mm/min |

| Weight | 4500kg |

| Dimensions | 9500*2100*2250mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.