Linear ATC CNC Router with Oscillating Knife and CCD for Cutting Foam and Carbon Fiber

Multi-Purpose CNC Router with Oscillating Cutter and CCD

[Function Description]

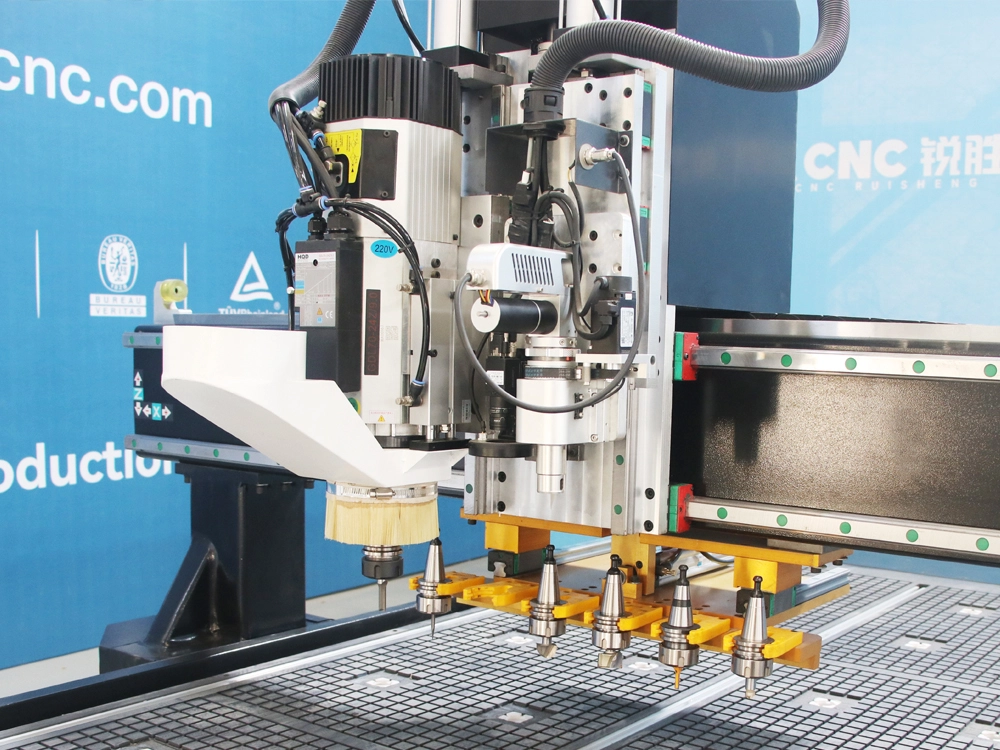

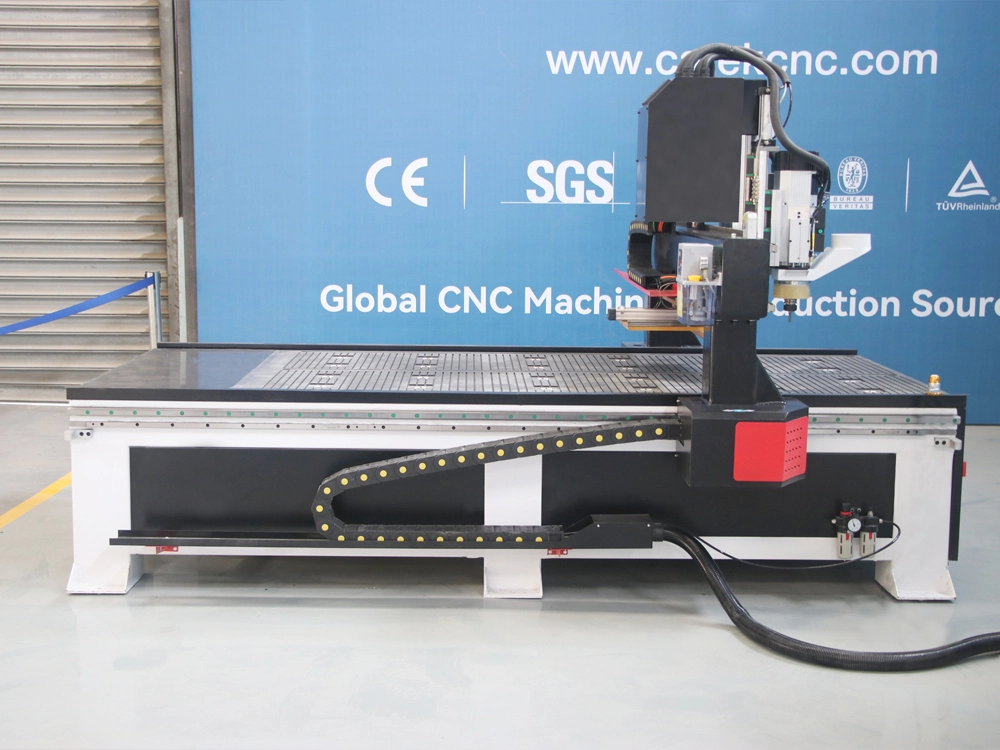

The CK-1325-TK is a versatile multi-functional CNC engraving-cutting machine equipped with an automatic tool-changing system, a oscillating knife, and a CCD camera. It features a 9KW automatic tool-changing spindle and a linear tool magazine, allowing for cutting, engraving, drilling, and milling operations on materials such as furniture and MDF boards without the need for manual tool changes, significantly improving processing efficiency. Additionally, the oscillating knife on this machine can easily handle cutting tasks for flexible materials like fabric, foam boards, leather, and cardboard. The CCD camera accurately identifies printed patterns on materials, enabling system recognized cutting. Integrating linear ATC, oscillating knife, and CCD camera into one machine, the CK-1325-TK is particularly suitable for small workshops or factories with limited space. It not only saves floor space but also fully meets the diverse production needs of factories.

Advantages of ATC CNC Router with Oscillating Knife and CCD Camera

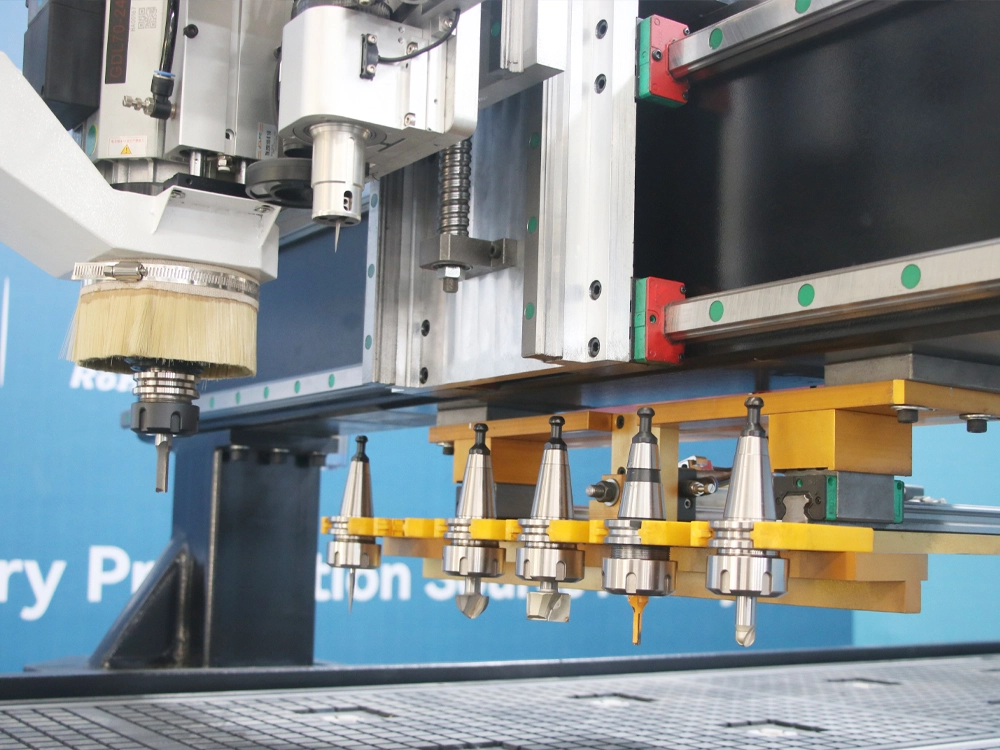

- 9KW automatic tool change spindle, ISO30 tool holder, wide tool compatibility range, can realize automatic switching of 6-12 tools.

- Use XDW four-axis CNC router plus oscillation tool dedicated system, complete functions, humanized operation interface, support various advanced functions.

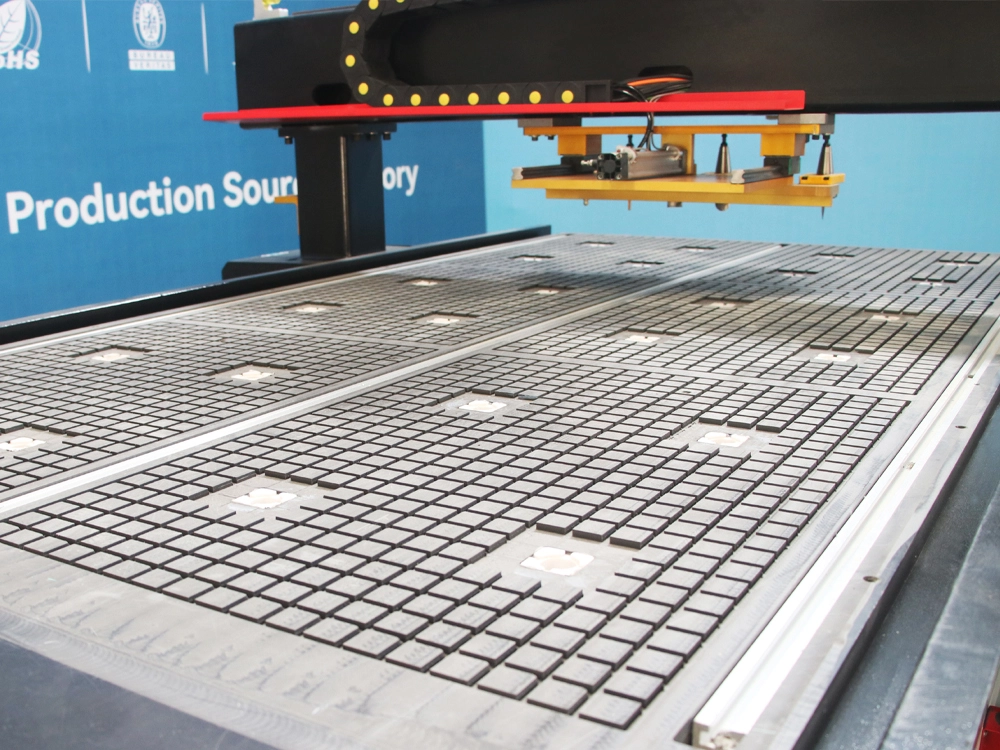

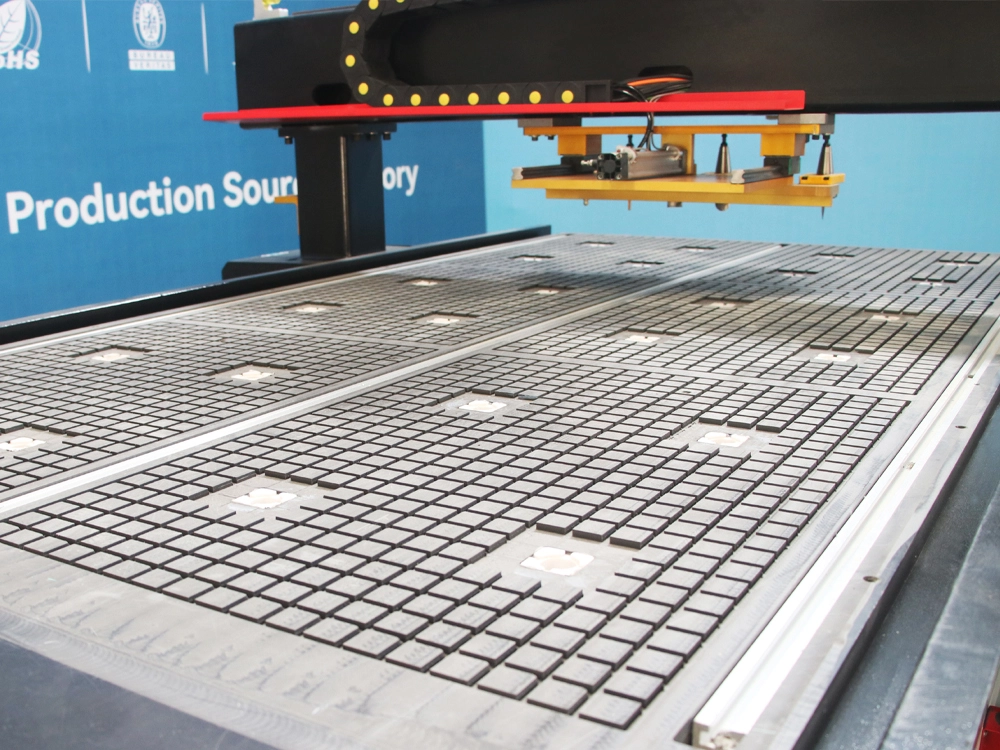

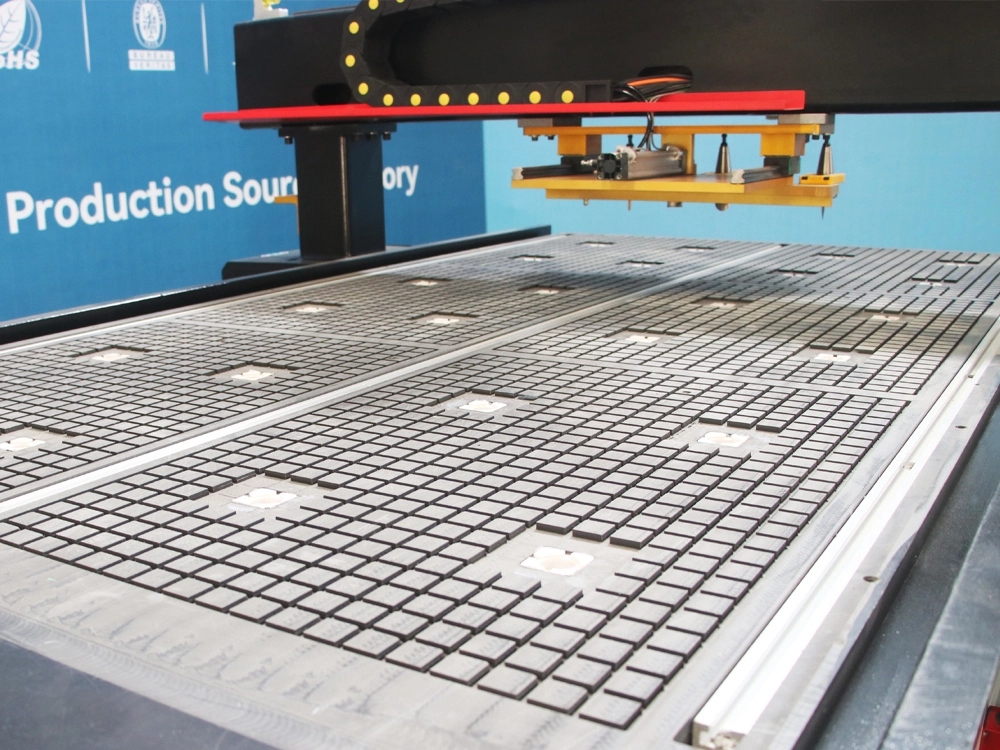

- Vacuum adsorption workbench + T-slot combination workbench. 4+2 positioning cylinders with vacuum adsorption platform can realize rapid positioning of 4*8 full-size plates, and can also use T-slots to fix various small-sized workpieces, which is flexible to use.

- XYZ three-axis uses servo motor and reducer combination, fast positioning, low noise, stable operation.

- Using automatic tool setting instrument, no matter the length and size of the tool used, it can automatically calibrate the zero point.

- The 3KW dust collector is connected to the central dust collection system of the machine, which can achieve 0 dust processing and is more environmentally friendly.

- The combination of CCD camera + oscillating knife can be switched with the automatic tool change spindle for cutting flexible materials such as car mats, foam, EVA, advertising KT boards, etc.

- Equipped with a central lubrication system, it automatically lubricates and maintains all transmission parts of the machine, making maintenance easier.

Details of Linear ATC CNC Router With Oscillating Knife And CCD Camera

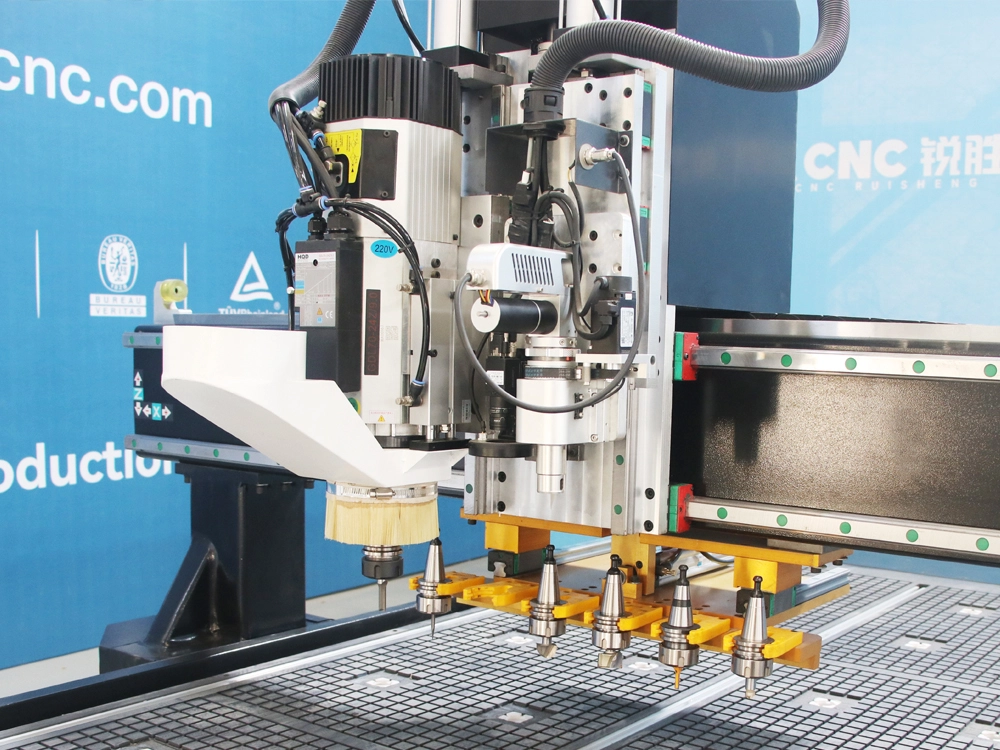

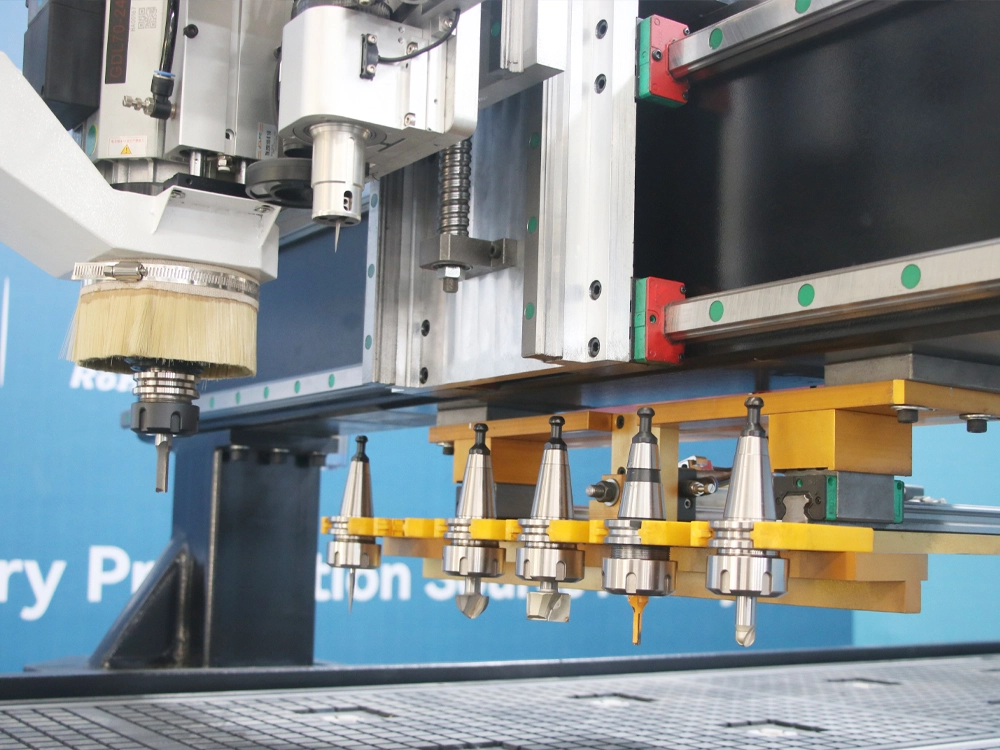

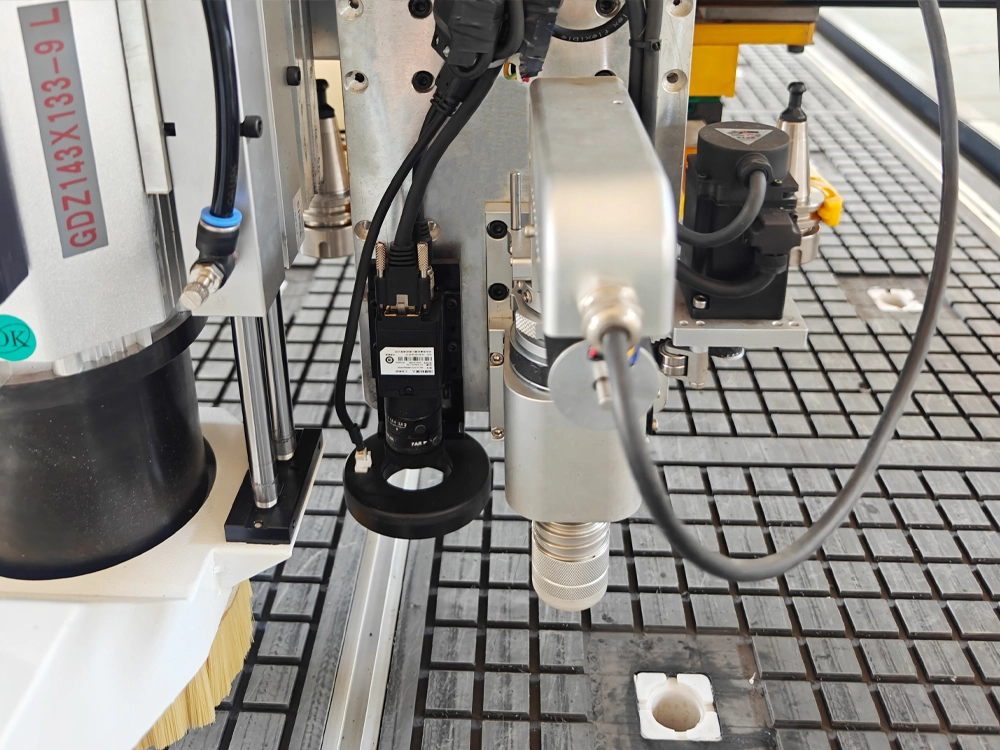

- CCD camera and oscillating tool

The oscillating tool can cut flexible materials, and the CCD camera (with fill light) can perform visual positioning or edge recognition.

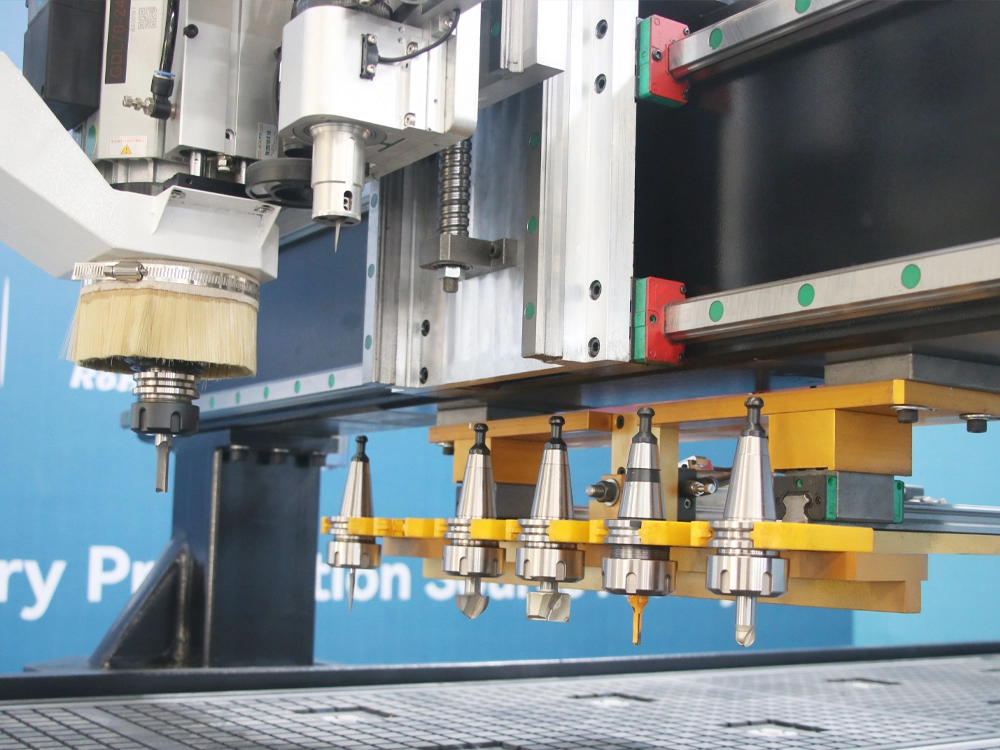

- Automatic tool change spindle and linear tool magazine

The spindle can perform the processing operations of ordinary router machines, and has an automatic tool changing function and is equipped with a linear tool magazine with a capacity of 8/12/16.

- Vacuum adsorption + T-slot combined workbench

Three longitudinal T-slots are added to the vacuum adsorption workbench to make workpiece clamping more flexible.

- Transmission system

High-precision ground helical racks and Taiwan Hiwin guide rails effectively ensure processing accuracy and machine life.

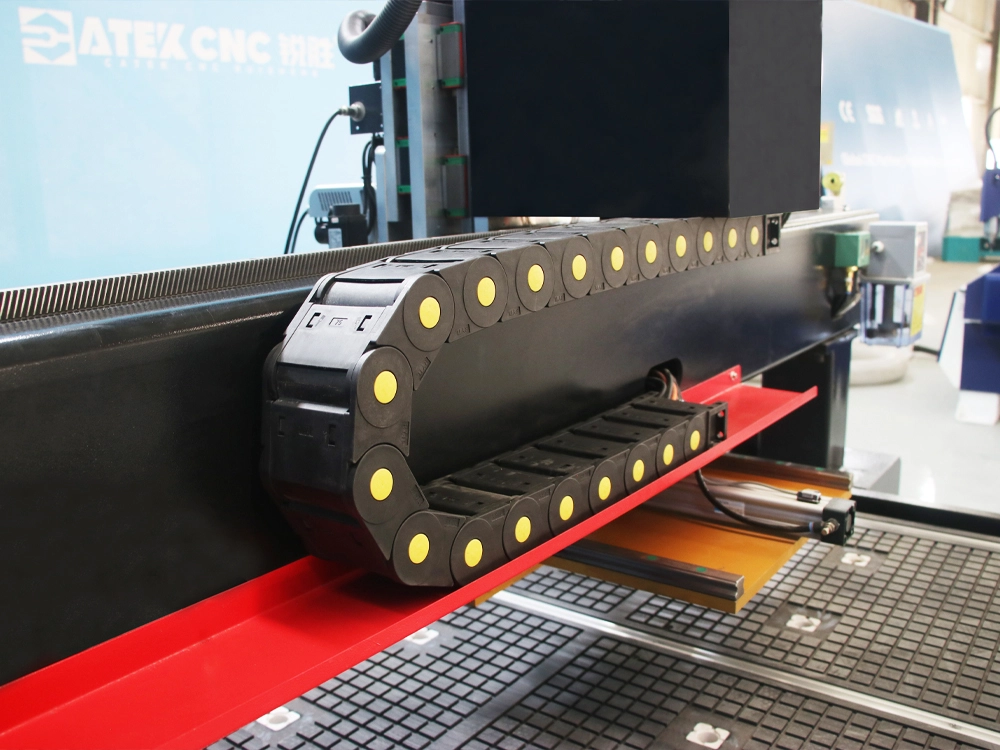

- Drag chains

Protect cables and oil pipes and enable them to move flexibly with moving parts, preventing line wear and entanglement.

- Automatic lubrication system

The lubrication system can automatically lubricate the transmission system according to the preset lubrication intervals and lubrication durations.

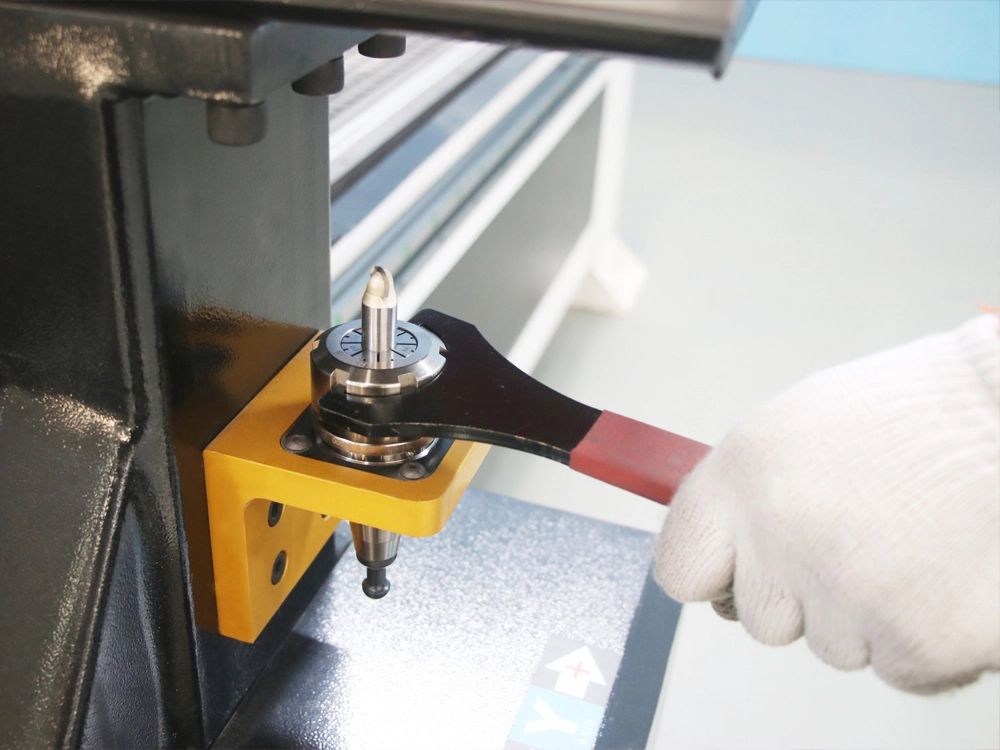

- Clamping device for separating the tool and the holder

When separating the blade from the knife holder, this device can be used to clamp the knife holder to facilitate removal of the blade.

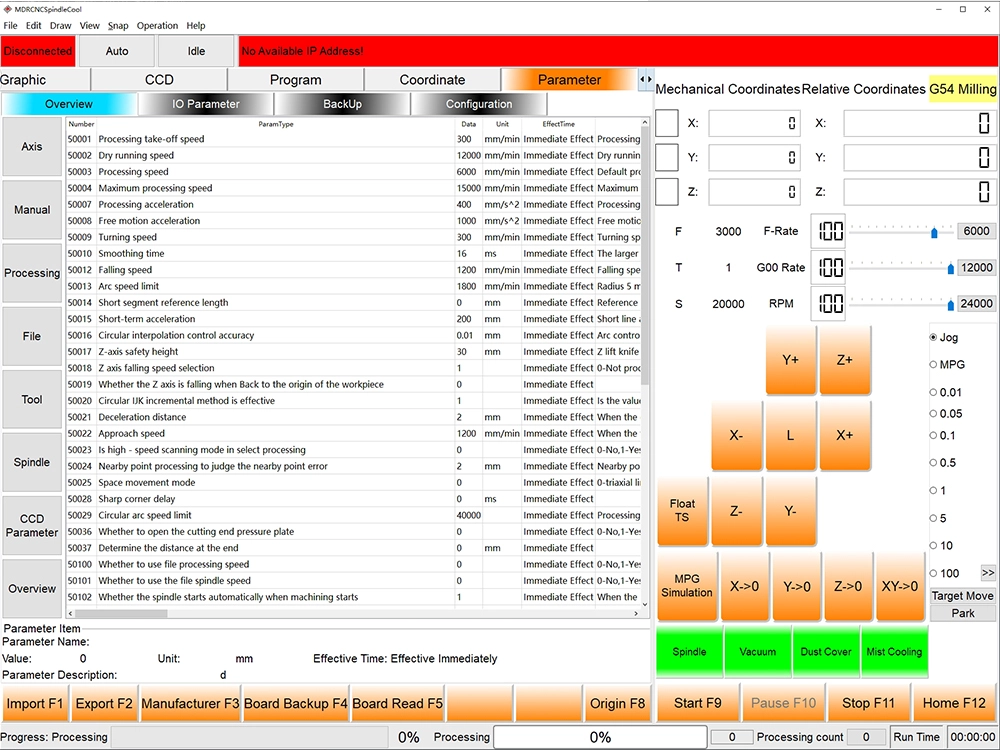

- XDW multi-function four-axis CNC system

Automatic tool change spindle and oscillating cutting tools can be supported.

Technical Parameters of Multifunctional ATC CNC Engraving-Cutting Machine with Visual Oscillating Knife Cutting System

| Model | CK-1325-TK |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Oscillating Knife | Oscillating knife for flexible materials |

| Edge Processing | CCD patrol camera |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3000kg |

| Dimensions | 3950*2150*2200mm |

What Products Can the Multifunctional CNC Router with Automatic Tool Changer and Oscillating Tool Be Applied to?

- Automatic Tool-Changing Spindle

Processable Materials: Solid wood, MDF, particleboard, HDF, PVC board, ABS plastic, acrylic, plexiglass, carbon fiber board, epoxy resin, artificial stone, bamboo, organic board, dual-color board, etc.

Processable Products: Solid wood doors, paint-free doors, cabinet doors, kitchen doors, wood composite doors, MDF doors, screens, craft windows, decorative moldings, paint-free cabinet doors, computer desks, sewing machine tables, bathroom cabinets, cabinets, panels, wave boards, furniture carving patterns, 3D decorative carving boards, openwork grilles, wine cabinets, bedside tables, wardrobes, bookshelves, display cabinets, door and window frames, decorative laminate parts, reliefs, openwork carvings, 3D carved crafts, gift packaging boxes, wooden models, artistic murals, musical instrument casings (e.g., guitar, piano parts), speaker cabinets, illuminated signboards, acrylic high-gloss engraved advertising letters, electrical cabinet panels, sports equipment labels, metal nameplates, soft metal molds (copper, aluminum, iron), wooden molds, plastic molds, PVC molds, instrument casings, electronic jigs, hardware parts, insulating boards, carbon fiber composite cutting, etc.

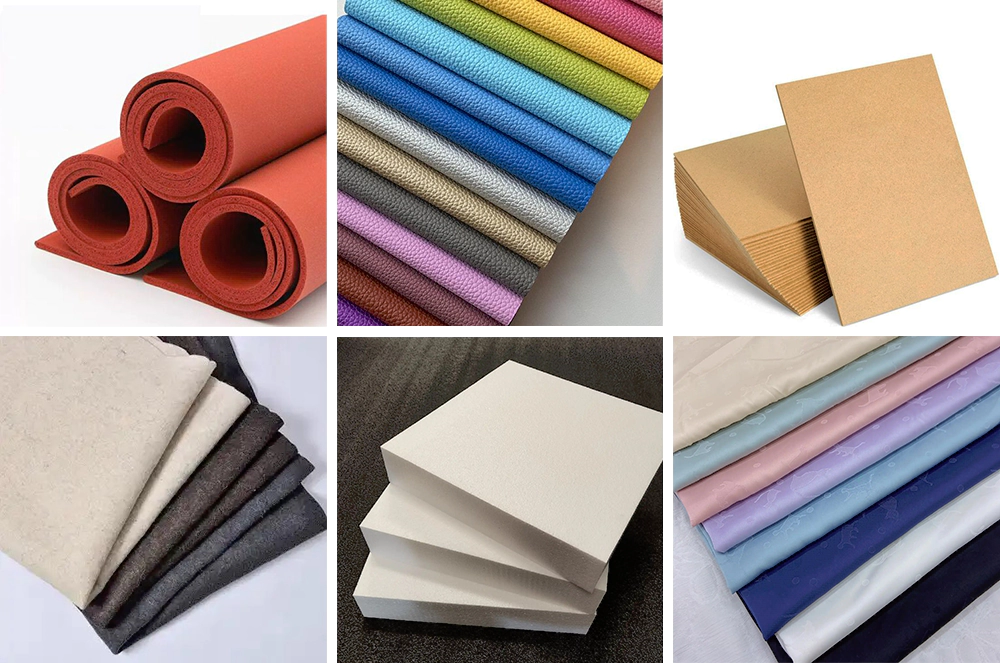

- Oscillating Knife + CCD Camera

Processable Materials: Fabric, leather, paper, cardboard, stickers, film, silk, denim, felt, carpet, rubber, PVC, silicone, corrugated cardboard, honeycomb board, EVA, foam, foam board, PP hollow board, acrylic (partial), carbon fiber (non-metallic base), fiberglass, rock wool board, soft glass, KT board, cartons, car stickers, composite materials (e.g., XPE, EPDM), soundproofing materials, polystyrene board, etc.

Processable Products: Stickers, car decals, curtains, tablecloths, sofa covers, shoe insoles, shoe soles, car interiors, car mats, yacht interiors, asbestos gaskets, imported rubber pads, floor mats, carpets, wallpaper, truck tarps, kites, flags, felt crafts, foam toys, plush toys, color boxes, labels, clothing, jeans, leather shoes, etc.

Processing Case of Multifunctional ATC CNC Router with Visual Oscillating Knife Cutting System

| Model | CK-1325-TK |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | HQD 9KW high power air-cooled automatic tool change spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | High torque 1.5KW pure servo motor drive * 4 (Z axis uses brake motor) |

| Reducer | Japan Shimpo reducer |

| Tool Change Magazine | 8/12/16 straight tool magazine |

| Table | Double-layer vacuum table with with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Oscillating Knife | Oscillating knife for flexible materials |

| Edge Processing | CCD patrol camera |

| Control System | Taiwan LNC cutting machine dedicated control system |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 28000mm/min |

| Maximum No-Load Running Speed | 58000mm/min |

| Weight | 3000kg |

| Dimensions | 3950*2150*2200mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.