7×10ft Linear ATC CNC Router with Horizontal/Vertical Drilling Capabilities

7×10ft Linear ATC CNC Router with 9+8 Drilling Unit

[Function Description]

As users demand increasingly personalized furniture, conventional panel sizes can no longer meet these requirements, giving rise to the need for 7*9ft panels. Traditional 1325-model CNC wood routers cannot handle 7*9ft panels, prompting CATEKCNC to develop this CK-2130-TD CNC router with a drilling unit specifically for this panel size.

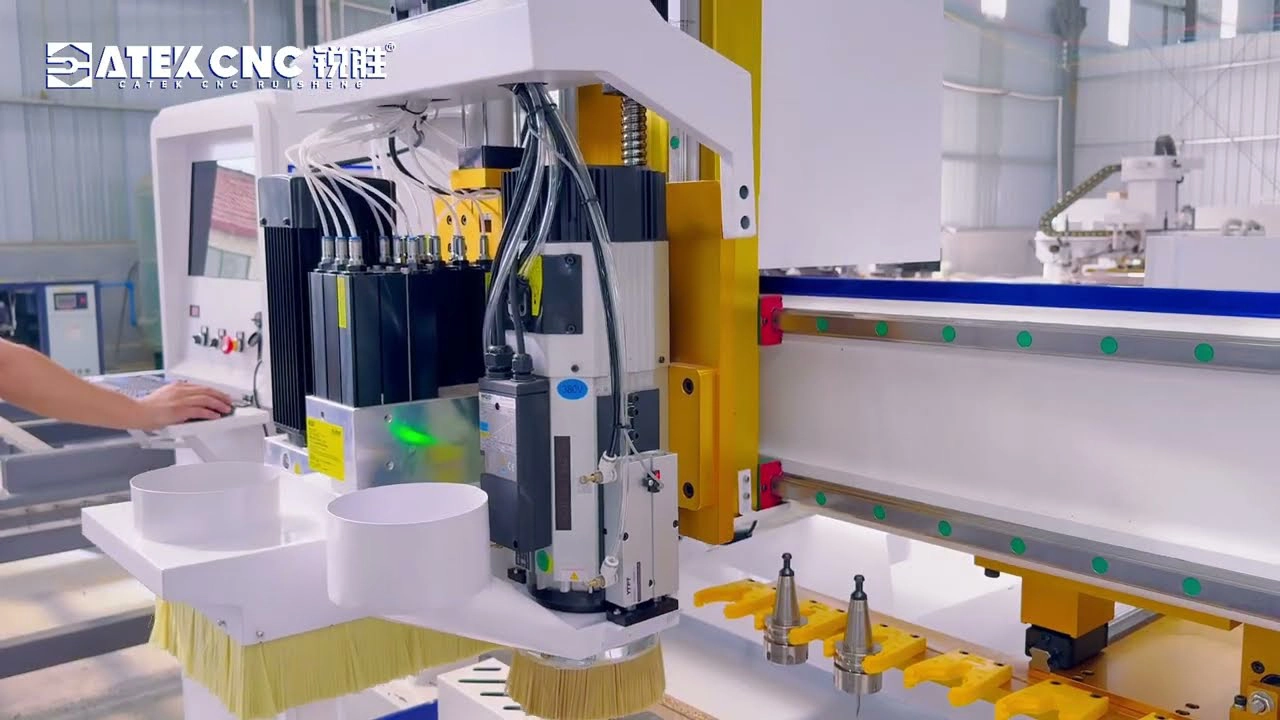

This machine features a full-size 2100*3000mm vacuum worktable, a 9KW air-cooled ATC spindle, and a linear tool magazine capable of holding 12 tools. During machining, the machine can automatically change tools as needed based on drawings or code. For example, when processing wooden doors, operations such as pattern engraving, milling, and cutting are required on the panel surface—meaning the entire process demands more than three different tools. In this case, the CNC router machine's control system automatically guides the ATC spindle to the linear tool magazine to swap tools. After tool changing is complete, an automatic tool setter measures and compensates for the tool tip position. The entire process requires no manual intervention, solving the challenge of manual tool changes when processing complex products on conventional CNC routers.

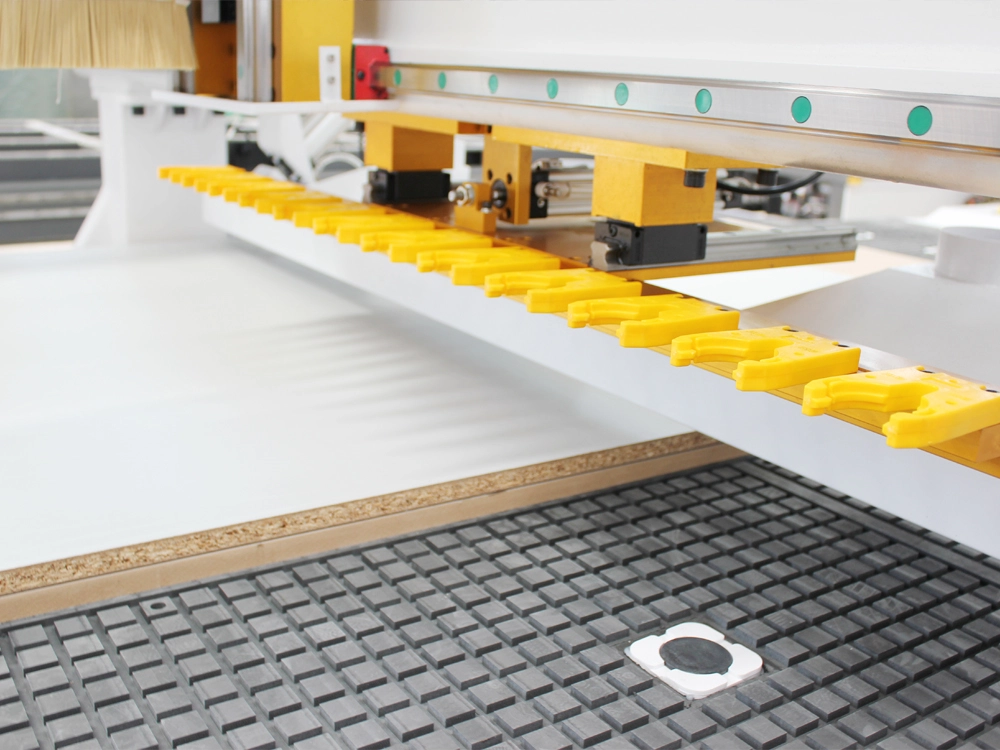

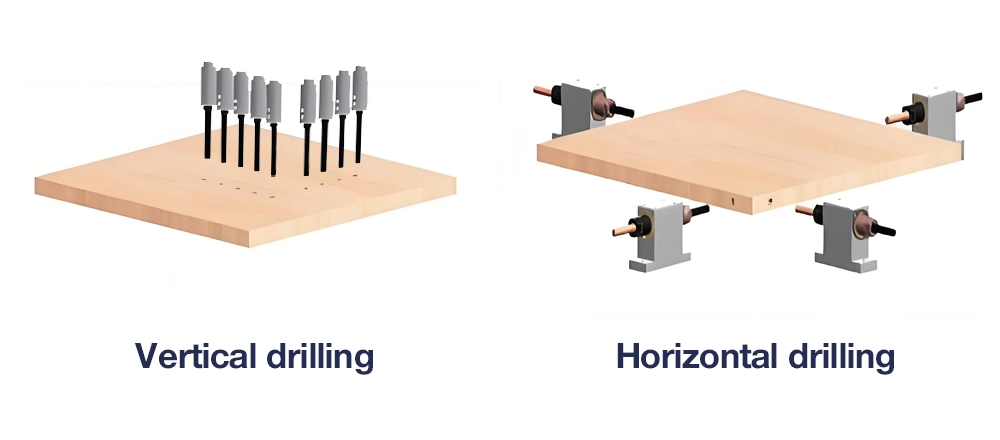

In addition, the additionally equipped drilling unit can accommodate a total of 17 drill bits (9 vertical drill bits and 8 horizontal drill bits). By loading and switching different drill bits, it can quickly complete various drilling tasks and perform simultaneous operations on multiple adjacent hole positions, effectively improving processing speed by more than double. Using the side drilling bits allows for more comprehensive coverage of furniture manufacturing requirements. It can be used to efficiently process cabinet doors, wooden door hinges, handles, and other components requiring side drilling. With a single setup, all drilling tasks on multiple surfaces of the panel can be completed. This CK-2130-TD CNC wood router, through its equipped drilling bank, enables a single machine to perform various processing functions on panels including cutting, grooving, milling, engraving, edge routing, vertical drilling, and side drilling. It effectively reduces machine cost investment and space occupation, making it highly suitable for small-scale enterprises and workshops pursuing high efficiency and precision. It is also one of the most economical solutions in today's furniture industry.

Features of 2130 ATC CNC Router with Side Drilling Unit

- The machine uses a thickened steel tube welded bed frame, with an 8mm thick steel plate laid on the bed surface. After annealing and vibration aging treatment to eliminate internal stress, a large 5-axis gantry milling machine is used to process the guide rail mounting surfaces, rack installation surfaces, and vacuum worktable mounting surfaces, achieving extremely high overall flatness and ensuring very stable equipment operation.

- The 9KW HQD high-speed air-cooled ATC spindle operates at 24,000 rpm, enabling rapid processing of various materials, including wood, plastic, PVC, MDF, as well as soft metals such as copper and aluminum.

- The 12-tool linear tool magazine can hold 12 tools, supports ISO30 tool holders and ER32 collets, and accommodates tool shanks with a diameter of 20mm.

- The HQD drilling bank can hold up to 9 vertical drill bits and 8 horizontal drill bits. Compared to the common 5+4 vertical drilling bank, it adds eight horizontal drill bits, allowing drilling on both the horizontal and side surfaces of workpieces.

- Four sets of 1500W bus-type absolute servo motors are used, offering higher stability, faster response, and improved processing efficiency compared to conventional pulse servos. Additionally, no homing operation is required upon startup, making operation simpler and more convenient.

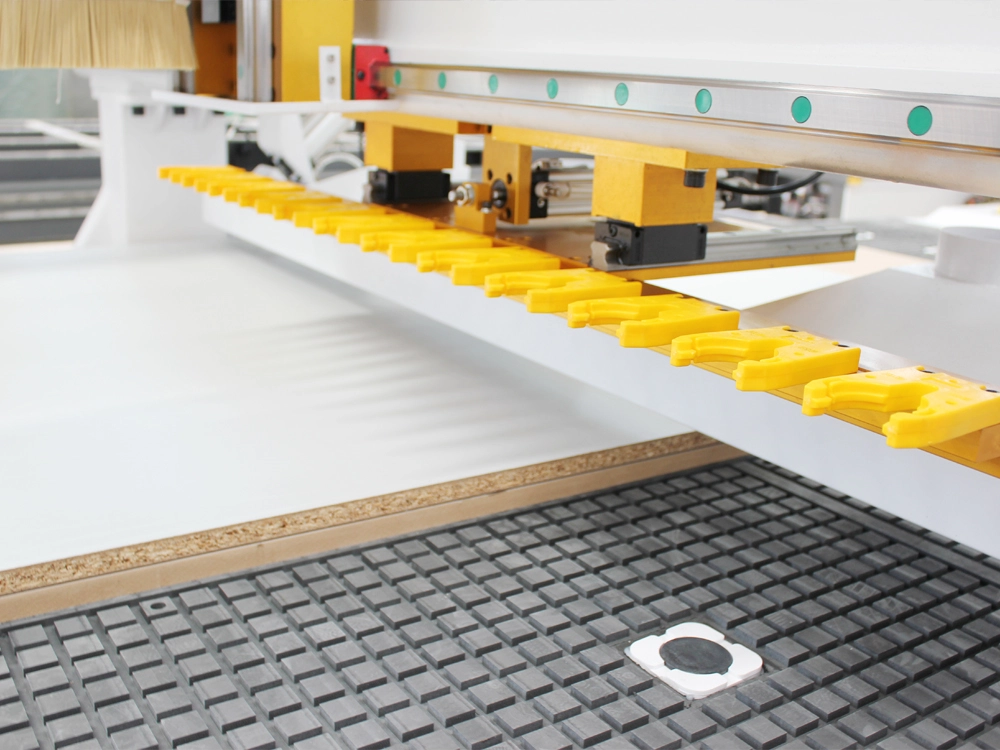

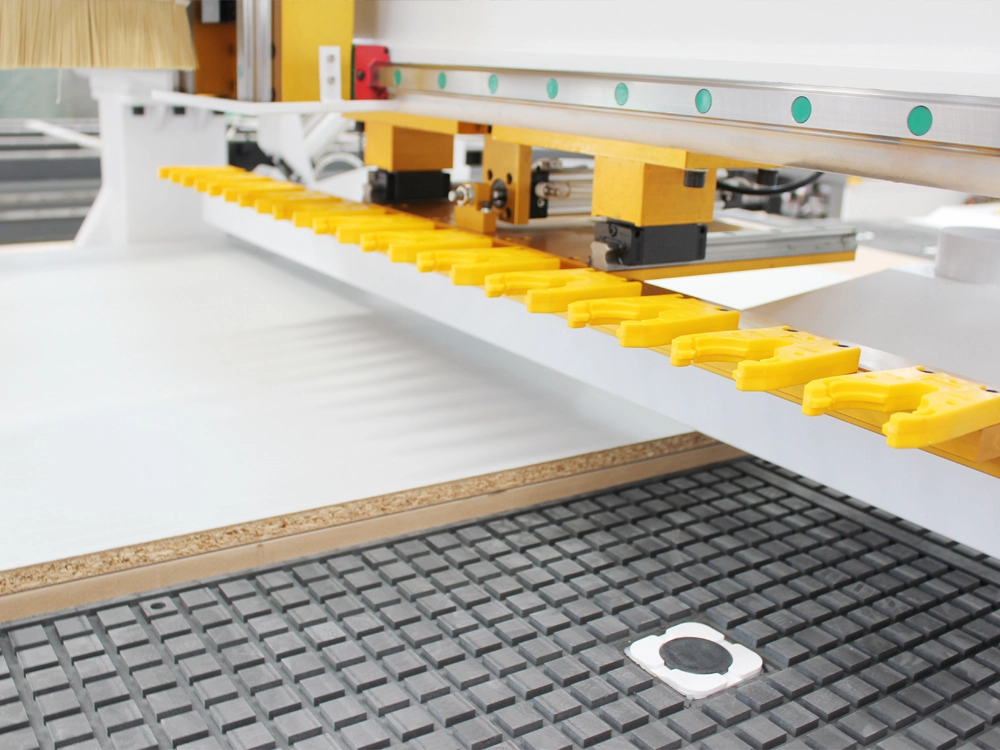

- Equipped with a large 2100*3000mm vacuum adsorption worktable, connected to the vacuum pump via 50mm tubing. The vacuum table is divided into 9 zones, each with an independent switch, allowing selective activation of vacuum zones based on the size of the workpiece. This ensures strong adsorption force, secure material fixation, and greater energy efficiency.

- The entire machine uses 30mm Taiwan HIWIN linear guides and linear bearings. The X and Y axes employ high-precision ground helical racks and gears, while the Z axis uses a TBI 3210 ball screw, ensuring extremely high operational accuracy and long service life.

- Features 4+3 positioning cylinders. When positioning a panel is required, activating the cylinder switch extends the positioning device, and the pusher cylinder pushes the panel against it for quick alignment, making operation highly convenient.

- The Taiwan-made LNC CNC router-specific control system supports various functional expansions, is compatible with G-code files in NC and TAP formats, and features an English interface with multi-language support. The intuitive and simple interface makes it easy to learn and operate.

- The fully automatic lubrication system can be programmed based on machine usage frequency to lubricate the entire transmission system, effectively extending the machine’s service life.

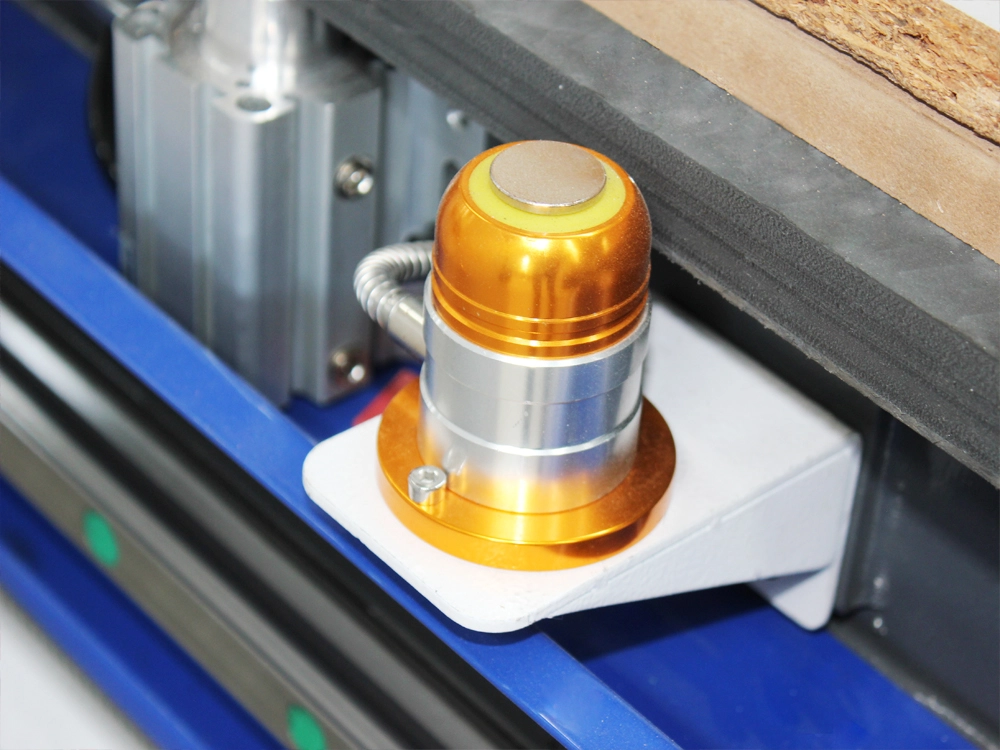

- Equipped with an automatic tool setter, which measures and compensates for the tool tip position after each tool change, eliminating the need for manual calibration and saving time.

- The machine’s rear end features loading rollers, allowing a single operator to load full-sized panels, significantly reducing labor requirements.

Details of Multi-Function 2130 ATC CNC Router with Side Drilling Unit

- HQD ATC spindle and 9+8 drill unit

The spindle is driven by an 11KW frequency converter, with adjustable rotation speed as needed. It uses ceramic bearings internally, ensuring stable rotation, high precision, and long service life. The HQD pneumatic drilling unit can accommodate 9 vertical drill bits and 8 horizontal drill bits simultaneously. It allows either single drill bit operation or multiple drill bits working concurrently, effectively improving drilling efficiency.

- Linear tool magazine

Capable of accommodating 12 tools. Compared to carousel-type tool changers, the linear tool magazine features a simpler structure, requires no additional servo motors or reducers, offers lower overall costs, and provides easier maintenance.

- 7*10 feet vacuum worktable

9 zones, each zone is equipped with independent switches and exhaust holes, materials are firmly fixed, and it is more energy-saving to use.

- Drive system

1500W bus-type absolute servo motor paired with Japan Shimpo planetary gear reducers delivers ultra-fast operating speeds and shorter stopping response times, enabling more efficient machining.

- Automatic tool setter

After tool changing, since the length and tip position of each tool are different, the automatic tool setter automatically measures the tool tip position and generates corresponding compensation values, eliminating the need for manual tool calibration and ensuring user-friendly operation.

- Automatic lubrication system

The lubrication duration and interval can be set, and the oil pot will automatically lubricate the machine's transmission components according to the preset parameters.

- Taiwan LNC control system

Supports multiple languages, features a simple and intuitive interface, with XYZ-axis coordinates, function switches, and alarm reminders all displayed clearly. Moreover, the operation is very straightforward, making it exceptionally user-friendly for beginners.

Technical Parameters of Multi-Function 2130 ATC CNC Router with Side Drilling Unit

| Model | CK-2130-TD |

|---|---|

| XYZ Working Travel | 2100*3000*200mm |

| Gantry | Reinforced aged steel gantry, heavy-duty stress-relieved steel beam |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | HSD 9KW air-cooled automatic tool change spindle |

| Spindle Speed | 6,000-24,000rpm |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Collet | ISO30/ER32 φ20 |

| Drilling Bank | HQD 5+4+8 pneumatic drilling bank |

| Drilling Bank Speed | 4,500rpm |

| Table | Vacuum table 9 zones, 30 holes |

| Positioning | 4+2 pneumatic positioning cylinders |

| Tool Setting | Automatic tool setter |

| Driving Mode | 1.5KW bus-type absolute servo motors (Z-axis with brake) |

| Reducer | Shimpo (Japan) planetary gear reducers |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision 30 linear square rail / linear-motion bearing |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Dust Collection | 3KW dual-canister bag-type dust collector |

| Vacuum Pump | 11KW water-ring vacuum pump |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Central lubrication oil filling maintenance system |

| Pushing | Automatic pneumatic pusher |

| Operating Voltage | AC380V 50/60Hz |

| Engraving Instructions | G code |

| Security System | Optical limit switches on XYZ axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 30,000mm/min |

| Maximum No-Load Running Speed | 80,000mm/min |

| Weight | 3200kg |

| Dimensions | 4200*3100*2150mm |

What Products Can the Multi-Function 2130 Atc CNC Router With Side Drilling Unit?

Applicable Materials

- Wood: Solid wood, MDF, particleboard, OSB, plywood, multi-layer board, bamboo, etc.

- Plastics & Composites: PVC, ABS, dual-color board, acrylic, polycarbonate (PC), carbon fiber, aluminum-plastic panel, polyurethane (PU), artificial stone, foam, etc.

- Metals: Copper, aluminum, brass, and other soft metals.

Applicable Industries

- Woodworking: Wardrobes, cabinets, wine cabinets, bedside tables, TV stands, wall panels, tables, wooden doors, beds, chairs, wooden furniture, rosewood furniture, screens, office furniture, sofas, decorative crafts, etc.

- Decorative products: Wood carvings, decorative frames, jewelry boxes, advertising signs, plaques, relief patterns, etc.

- Musical instruments: Guitars, violins, cellos, pianos, instrument cases, speaker boxes, etc.

- Mold products: Mooncake molds, biscuit molds, chocolate molds, candy molds, wooden ship models, aircraft models, sand table models, etc.

- Advertising production: Advertising signs, logo letters, outdoor signage, light-up letters, advertising lightboxes, display boards, LED lightboxes, KT board, bulletin boards, directional signs, acrylic cutting, etc.

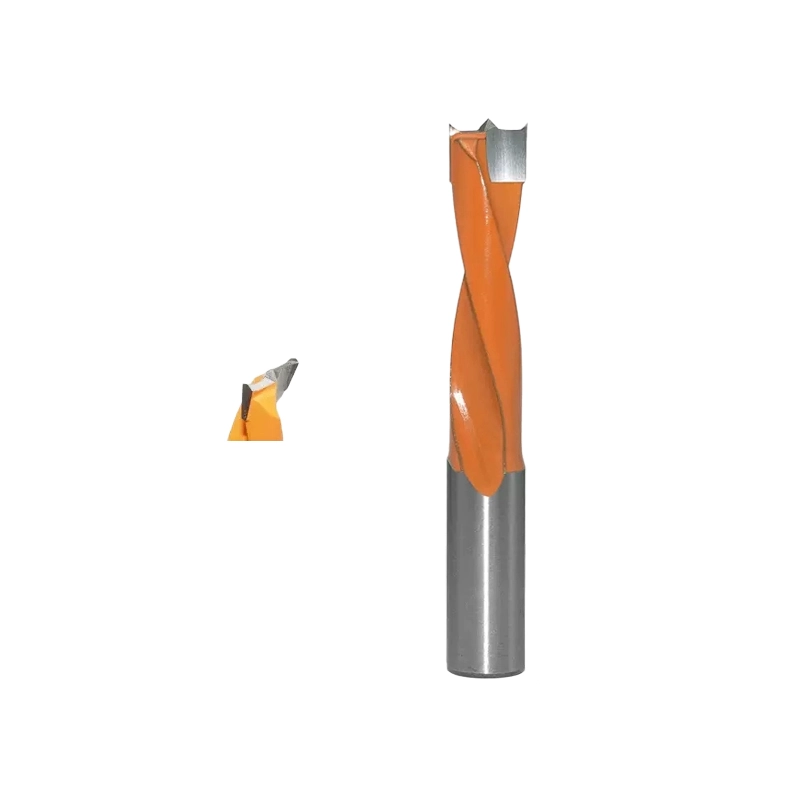

What Types of Drill Bits Are Used in CNC Drilling Units?

Twist drill bits: Used for standard through-holes and regular holes in panels.

Two-tooth drill bits (Three-point drill bits): Designed for hinge holes and non-through holes in furniture.

Four-tooth drill bits: Four-edge design for larger hinge holes.

Six-tooth drill bits: Large-diameter six-edge design for bigger holes.

Step drill bits: Multi-level design for creating holes with varying depths and diameters in one operation, ideal for countersunk holes and hinge holes.

| Model | CK-2130-TD |

|---|---|

| XYZ Working Travel | 2100*3000*200mm |

| Gantry | Reinforced aged steel gantry, heavy-duty stress-relieved steel beam |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | HSD 9KW air-cooled automatic tool change spindle |

| Spindle Speed | 6,000-24,000rpm |

| Tool Change Magazine | 8/12/16 linear tool magazine |

| Collet | ISO30/ER32 φ20 |

| Drilling Bank | HQD 5+4+8 pneumatic drilling bank |

| Drilling Bank Speed | 4,500rpm |

| Table | Vacuum table 9 zones, 30 holes |

| Positioning | 4+2 pneumatic positioning cylinders |

| Tool Setting | Automatic tool setter |

| Driving Mode | 1.5KW bus-type absolute servo motors (Z-axis with brake) |

| Reducer | Shimpo (Japan) planetary gear reducers |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision 30 linear square rail / linear-motion bearing |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Dust Collection | 3KW dual-canister bag-type dust collector |

| Vacuum Pump | 11KW water-ring vacuum pump |

| Control System | Taiwan Syntec control system / Mach3 |

| Lubrication System | Central lubrication oil filling maintenance system |

| Pushing | Automatic pneumatic pusher |

| Operating Voltage | AC380V 50/60Hz |

| Engraving Instructions | G code |

| Security System | Optical limit switches on XYZ axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 30,000mm/min |

| Maximum No-Load Running Speed | 80,000mm/min |

| Weight | 3200kg |

| Dimensions | 4200*3100*2150mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.