4′x8‘ CNC Furniture Making Machine with Four Tool Switching

4x8ft Four-Function Switching CNC Wood Nesting Machine

[Function Description]

Overview of 4x8 CNC Router with Four Switchable Spindle

The 4*8-foot four-function CNC router is mainly used for processing various types of panels and furniture. It is equipped with four 6KW air-cooled spindles, each with a tool for cutting, punching, grooving, milling and other processing tasks. However, these spindles cannot be used at the same time. The automatic switching of these spindles is controlled by the cylinder. During the processing, the spindles can be quickly switched to realize the processing of different processes, thereby saving time and improving efficiency. The pneumatic spindle switching system can achieve spindle switching within 0.1 seconds, and is equipped with a power-off recovery function. Even if an abnormal situation occurs during the processing and the processing is suspended, the machine can still continue processing after it is turned on again, ensuring the continuity and stability of the processing process. The vacuum adsorption table is used in conjunction with the 4+2 positioning cylinder. The 4*8 full-size plate and the positioning cylinder are close to complete the loading, which is easier and saves time.

4*8 feet four function CNC engraving machine is widely used in small and medium-sized furniture factories, furniture production workshop, especially in the production of panel furniture cabinets, closets and door panels with excellent performance.

Advantages of CNC Router with Vacuum Adsorption Table and Four Automatic Switching Spindles

- High efficiency and fast cutting

Using four 6kw high-speed air-cooled spindles with a speed of 18000r/min, it can realize fast cutting and processing of various materials, improve production efficiency, and quickly complete processing operations.

- High precision and zero error

Using a 1.5KW high-torque servo motor with a planetary gear reducer effectively guarantees the accuracy and stability of processing, with an error of no more than 0.1mm, meeting the high requirements of the modern home furnishing industry for processing accuracy and ensuring processing quality.

- Versatility and flexibility

The CNC engraving machine with four spindles can perform cutting, drilling, grooving, engraving, etc., and is suitable for the processing of door panels and cabinets. The four high-speed air-cooled spindles realize the tool changing function through cylinder switching, which increases the flexibility and practicality of the equipment.

- Friendly control system

LNC CNC system has a friendly control interface design and is simple and convenient to operate. Workers can work after simple teaching without any professional skills, which reduces the difficulty of operation and improves work efficiency.

- Save labor costs and improve sheet utilization

One person can operate multiple machines, reducing the number of workers and reducing labor costs. At the same time, by using optimized typesetting software to reasonably utilize the sheet, the utilization rate of the sheet is effectively improved.

- Stability and durability

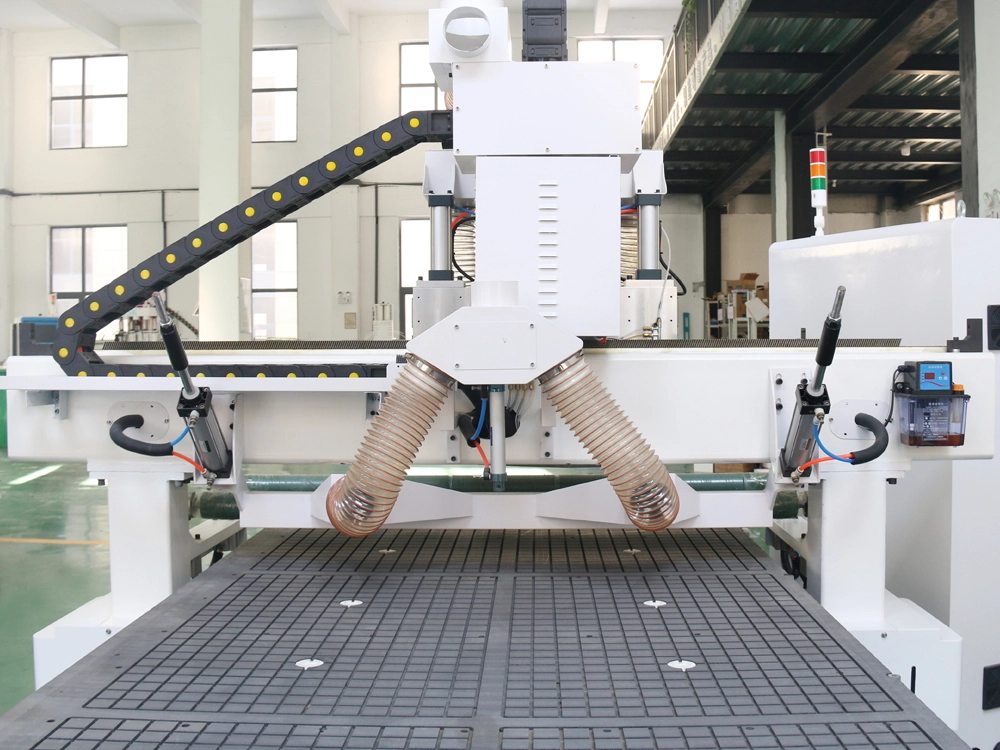

The bed is welded with heavy-duty thickened square steel and has been stress-relieved. The gantry structure is sturdy and durable. It is driven by high-precision gears and racks, and has stable operation, low noise, high speed and high positioning accuracy.

- Environmental protection

It is equipped with a double-head dust collection system, which can effectively absorb the sawdust and wood ash generated during processing, effectively improve the working environment, achieve dust-free processing, and reduce the harm to workers' health.

- Easy to operate

It is equipped with a vacuum adsorption workbench, a positioning cylinder and an automatic tool setting instrument. The vacuum adsorption workbench makes it easier to load and unload the plate. The automatic tool setting instrument can realize fully automatic tool setting for tools of different lengths and diameters, which is easy to use.

Details of 4x8-Foot Four-Function Switching CNC Router

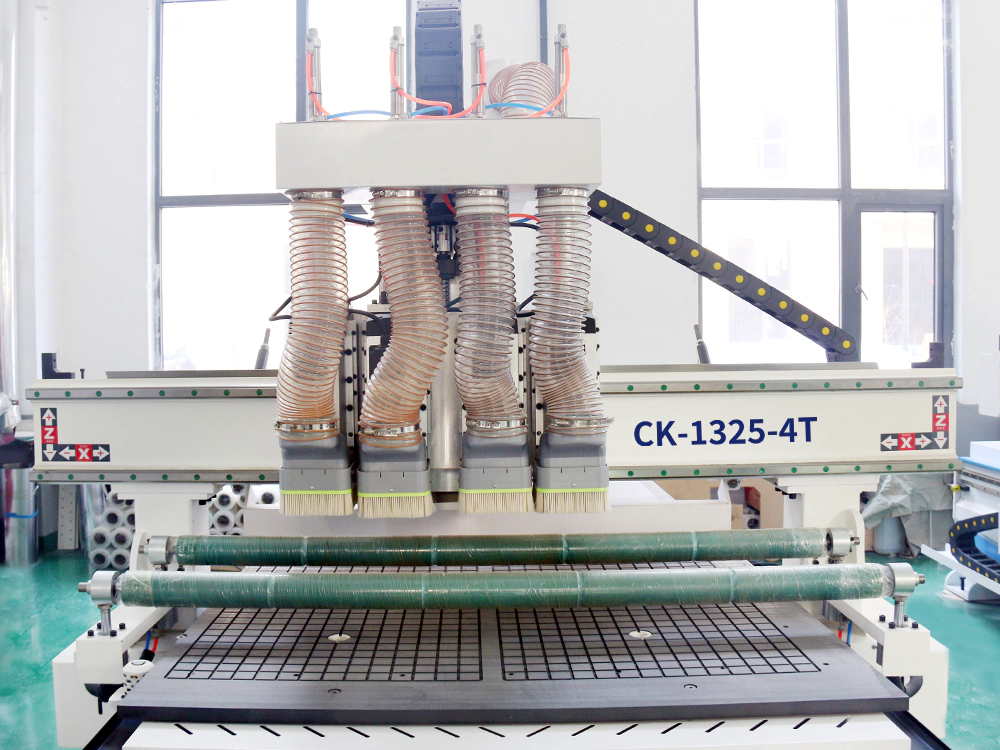

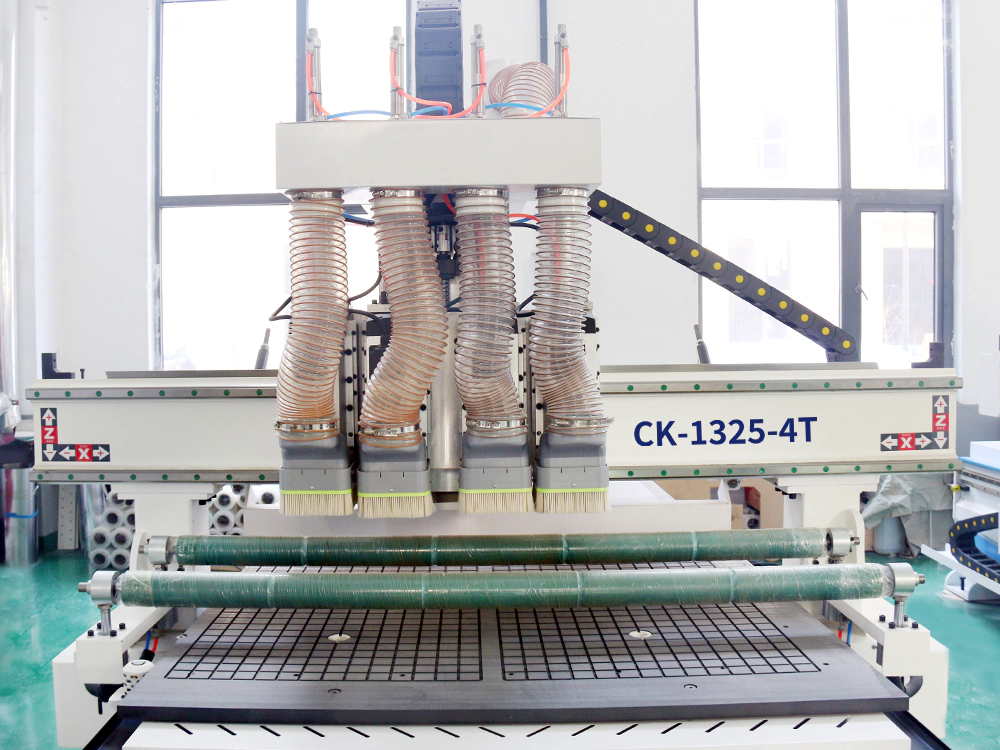

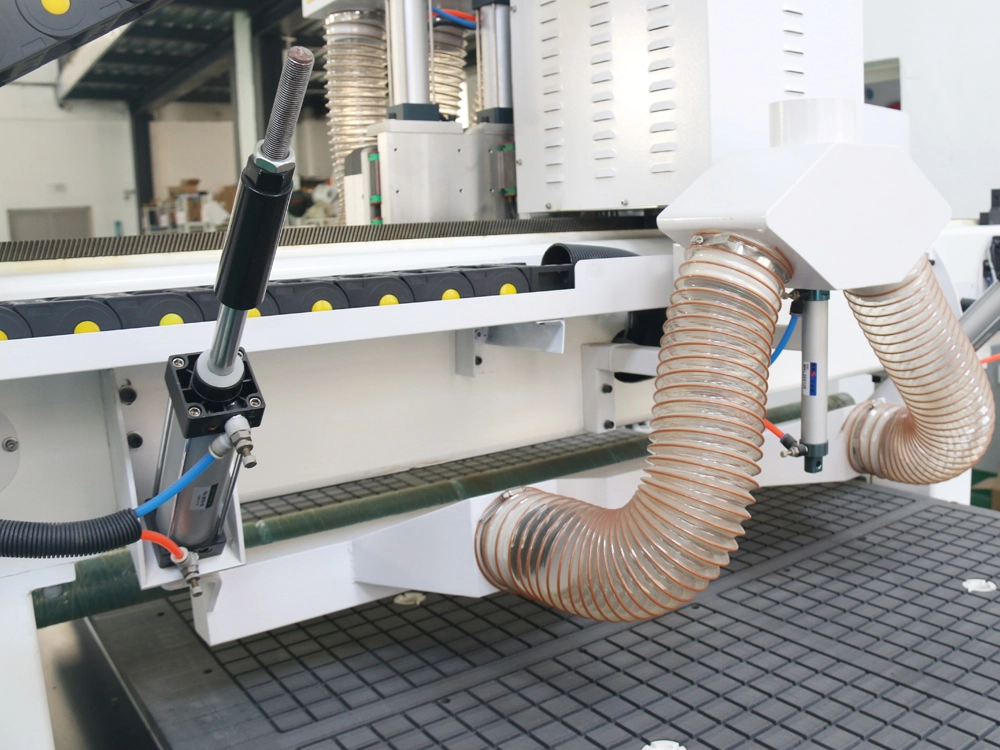

- Four-spindle switching

Using four CATEKCNC dedicated 6KW high-speed air-cooled spindles, the four spindles can be fully automatically switched within 1 second to meet the needs of diverse processing products. During processing, the required tools are installed on the spindles. During processing, only simple settings are required for the control system, and the machine can automatically switch the tools required for each process of the workpiece. A plate can be fully processed in one operation after being placed in the machine, without the need to stop the machine and manually change the tool, which greatly improves the processing efficiency.

- Vacuum adsorption platform

Using an 11KW vacuum pump with a 6-zone 24-hole vacuum adsorption platform can strongly adsorb plates of different sizes, ensuring that the plates will not move or offset during processing, thereby improving processing accuracy and efficiency.

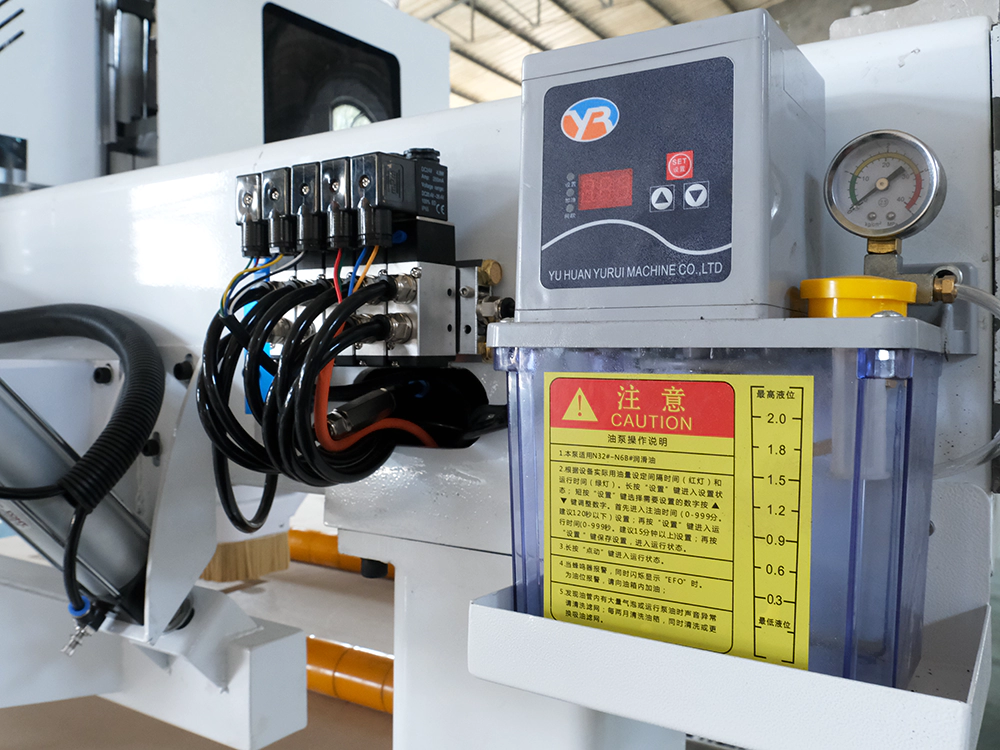

- Solenoid valve and lubrication system

The solenoid valve is used to control the spindle switching. The automatic lubricating oil pot can set the lubrication interval and lubrication time.

- Pulse control handwheel

External pulse control handwheel, convenient for tool setting.

- Drive system

1.5kw high power servo motor, Japan Shinpo planetary gear reducer.

- Dust collection system

Standard dust collection system to effectively collect wood chips and dust generated during processing.

- Automatic push device

Automatic material pushing device, automatically covers the workbench and vacuums it after processing is completed.

- LNC control system

Taiwan LNC control system, simple operation and friendly interface.

Technical Parameters of Four-Function Switching CNC Wood Cutting Machine

| Model | CK-1325-4T |

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 6KW high power air-cooled spindle * 4 |

| Spindle Speed | 6000-18000r/min |

| Driving Mode | 1.5KW servo motor drive (Z-axis brake motor) |

| Reducer | Japan Shimpo reducer |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Processing Speed | 18000mm/min |

| Weight | 2700kg |

| Dimensions | 3950*2150*2100mm |

Application Range of 4x8 Feet CNC Engraving Machine with Four Spindles

4*8 feet four-function CNC router machine is mainly used for furniture processing. It has functions such as drilling, cutting, grooving and milling. It is suitable for home decoration, cabinets, wardrobes, office furniture, TV cabinets, bedside tables, shoe cabinets, bookcases, wine cabinets, background walls, hollow lattices, paint-free doors, woodworking decoration, wooden crafts, cabinet doors, screens, three-dimensional wave boards, advertising production, musical instrument accessories manufacturing and other fields. It can be used to process various types of boards, such as: solid wood boards, honeycomb boards, multi-layer boards, ecological boards, particle boards, density boards, particle boards, European pine boards, gypsum boards, hollow boards, plastic boards, bakelite boards, pcb boards, acrylic boards and other boards.

Machining Process of a CNC Router with Four Switching Spindles and a Vacuum Adsorption Table

- Preparation: Before starting the operation, you first need to check whether the power of the equipment is on, and confirm whether the required tools, fixtures, plates, etc. are complete, and check whether the various functions of the CNC nesting machine are operating normally, such as the motion axis, motor, cutting tool, etc.

- Start-up preparation: Turn on the power switch of the CNC nesting machine and release the emergency stop button to ensure that the equipment has made relevant preparations for startup, enter the operating system, and start operating the machine to prepare for processing.

- Import processing files: Select appropriate processing files according to the material and processing requirements, and import them into the CNC nesting machine.

- Positioning workpieces: Fix the workpieces to be processed on the vacuum adsorption workbench to ensure the stability of the workpiece.

- Set parameters: Set the parameters of the nesting machine according to the size and processing requirements of the workpiece, including speed, feed rate, tool, etc.

- Start processing: Start executing the processing program. During the processing process, the machine operation status should be monitored at any time to ensure that the processing process proceeds smoothly.

- Monitoring and adjustment: During the processing process, if you encounter problems or need to adjust, you can make adjustments manually. For example, if you need to change the tool, you can manually change the tool and recalibrate the tool.

- Finish processing: After finishing processing, turn off the power of the CNC nesting machine and do necessary cleaning.

| Model | CK-1325-4T |

|---|---|

| XYZ Working Travel | 1300*2500*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beams |

| Bed | Heavy duty integral fully cast bed body, independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 6KW high power air-cooled spindle * 4 |

| Spindle Speed | 6000-18000r/min |

| Driving Mode | 1.5KW servo motor drive (Z-axis brake motor)) |

| Reducer | Japan Shimpo reducer |

| Table | Double-layer vacuum table with 6 zones and 24 holes |

| Vacuum Pump | 11KW water ring vacuum pump |

| Transmission Mode | XY axis high-precision ground helical gear drive + Z axis high-precision TBI screw drive |

| Guideway | Taiwan high precision 30 linear square rail / 30 flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Vacuuming Method | 3KW dual-canister bag-type dust collector |

| Control System | Taiwan LNC cutting machine dedicated control system / Mach3 |

| Lubrication System | Fully automatic electric lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, CAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code |

| Positioning | 4+2 positioning cylinder |

| Security System | XYZ three-axis all photoelectric limit (safety protection system) |

| Repeat Positioning Accuracy | ±0.02mm |

| Maximum Pocessing Speed | 18000mm/min |

| Weight | 2700kg |

| Dimensions | 3950*2150*2100mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.