3-In-1 Handheld Laser Welding Machine With Chiller

3-In-1 Water-Cooled Handheld Laser Welding Machine With Large-Shell

[Function Description]

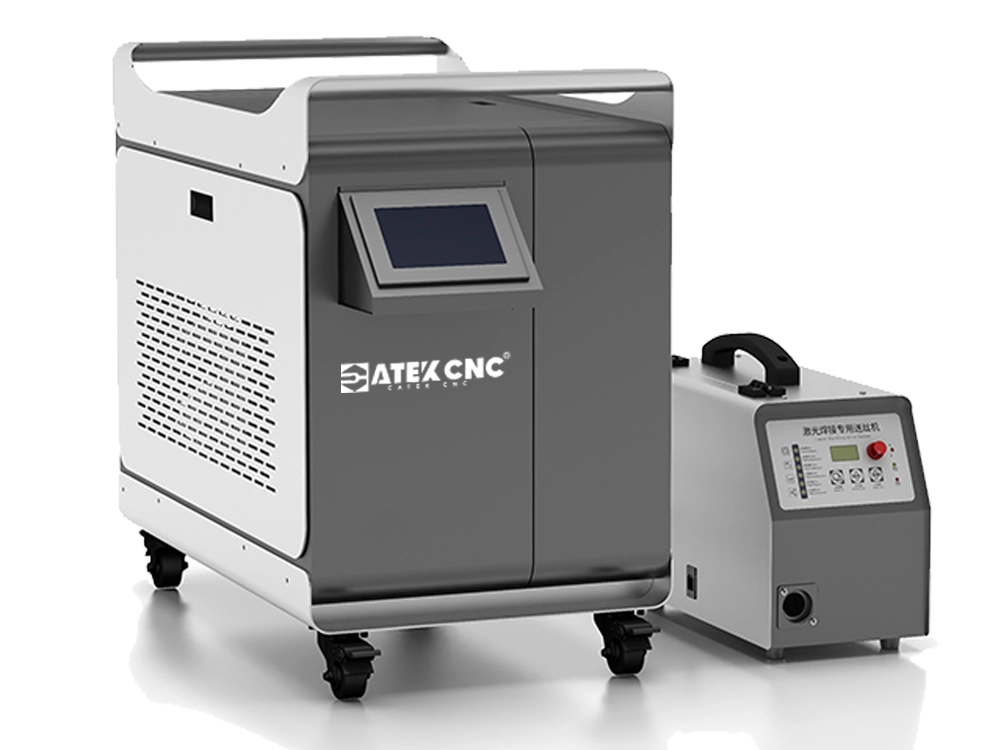

The 3-in-1 water-cooled handheld laser welding machine integrates the laser generator, welding gun, and intelligent control system into a single unit, significantly simplifying equipment deployment and operation procedures while markedly improving work efficiency. At its core is a 1080nm wavelength laser generator offering three selectable power levels (1500W, 2000W, 3000W) to precisely match different processing requirements. With integrated welding, cutting, and cleaning capabilities, this versatile machine effortlessly handles diverse industrial applications.

The equipment features an industrial-grade control system that supports flexible parameter adjustment and rapid mode switching, enabling even beginners to operate it quickly. Its high-efficiency water-cooling system, equipped with an industrial chiller, ensures stable operation of both laser generator and welding gun during prolonged high-temperature operation. Combined with a 100,000-hour extended laser lifespan and low maintenance costs, it delivers worry-free long-term performance.

Compared to traditional laser welding equipment, this 3-in-1 model maintains equivalent functionality while being priced at just 60% of standard models, making it an ideal choice for budget-conscious users. With advantages including multifunctional integration, user-friendly operation, and cost-effective durability, it has gained widespread popularity across Southeast Asian and African markets, emerging as a premium solution for SMEs to reduce costs and enhance productivity.

Advantages of the 3-In-1 Water-Cooled Laser Welding Machine

- Compared to air-cooled models with identical configurations, it is more affordable and better suited for budget-conscious users.

- Simple operation, requiring low technical skills from operators, even beginners can easily operate it.

- Comprehensive functions, equipped with welding, cutting, and cleaning capabilities.

- Handheld welding gun allows flexible and convenient operation, enabling multi-angle welding.

- Wide range of supported welding materials, capable of welding dissimilar materials together.

- Non-contact processing ensures safety, with small HAZ, high precision, and minimal material loss.

- Fast welding speed, approximately 3-10 times faster than traditional TIGW or MIGW machines.

- Smooth and flat weld seams with high-quality results, free from defects like pores or slag inclusions, eliminating the need for secondary polishing.

- Equipped with a galvanometer system, allowing the laser beam to move along specified paths during welding, easily achieving various weld weave patterns.

- Environmentally friendly, producing no exhaust fumes or pollution during operation, meeting environmental requirements.

Details of the 3-In-1 Water-Cooled Laser Welding Machine

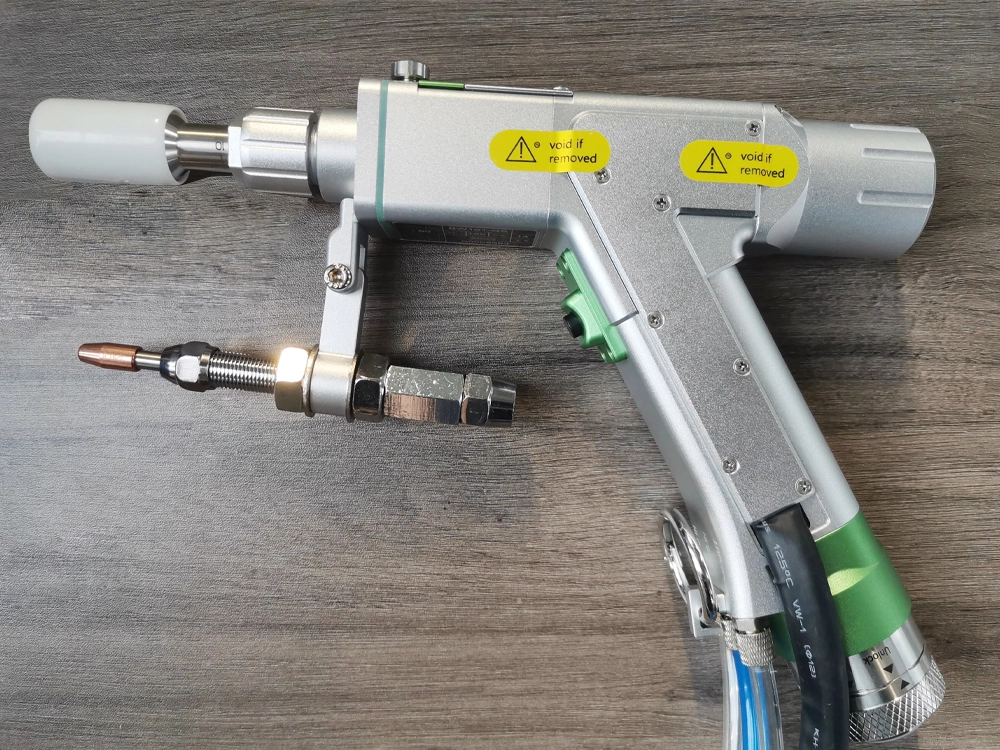

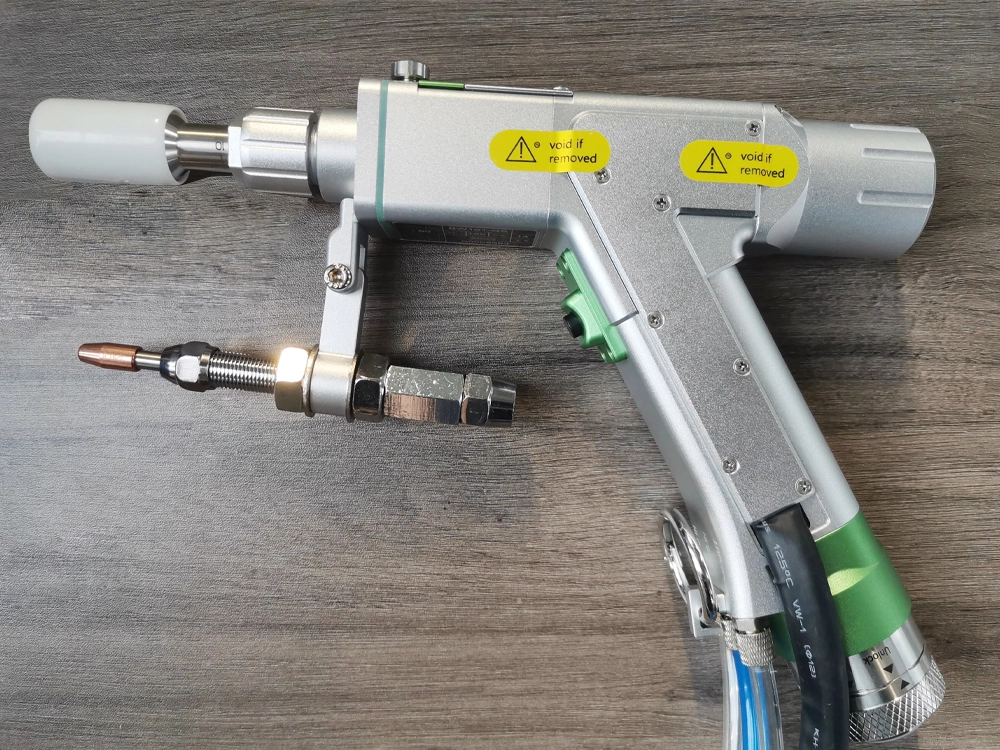

- Raytools welding gun

It supports metal welding, metal cutting, and removal of surface rust/oil stains from metals. With a weight of only 0.7kg, it prevents fatigue even during prolonged handheld operation.

- Laser source

Raycus laser source is standard, Max, JPT, RECI, BWT laser sources are optional.

- S&A chiller

The machine is equipped with a built-in S&A RMFL series rack-mounted industrial chiller, specifically designed for cooling handheld laser welding/cutting/cleaning machines. It features a high-performance water pump and dual-temperature control, capable of simultaneously cooling the fiber laser source and optical components/laser gun. The temperature stability is ±0.5°C, with a temperature control range of 5°C to 35°C.

- Wire feeder

Precise wire feeding with anti-jamming anti-recoil function, equipped with a single-drive/dual-drive wheel wire feeding system reaching speeds up to 2m per minute. The wire loading speed is continuously adjustable, suitable for feeding welding wires of various diameters. This system doubles work efficiency while reducing labor intensity and saving both manpower and equipment costs.

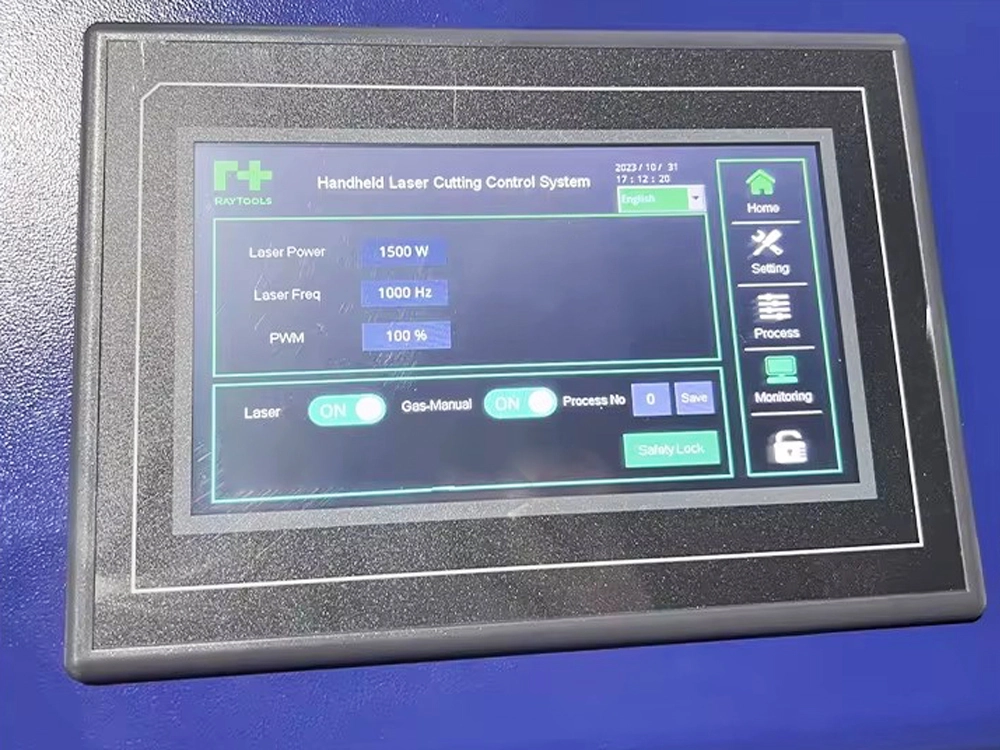

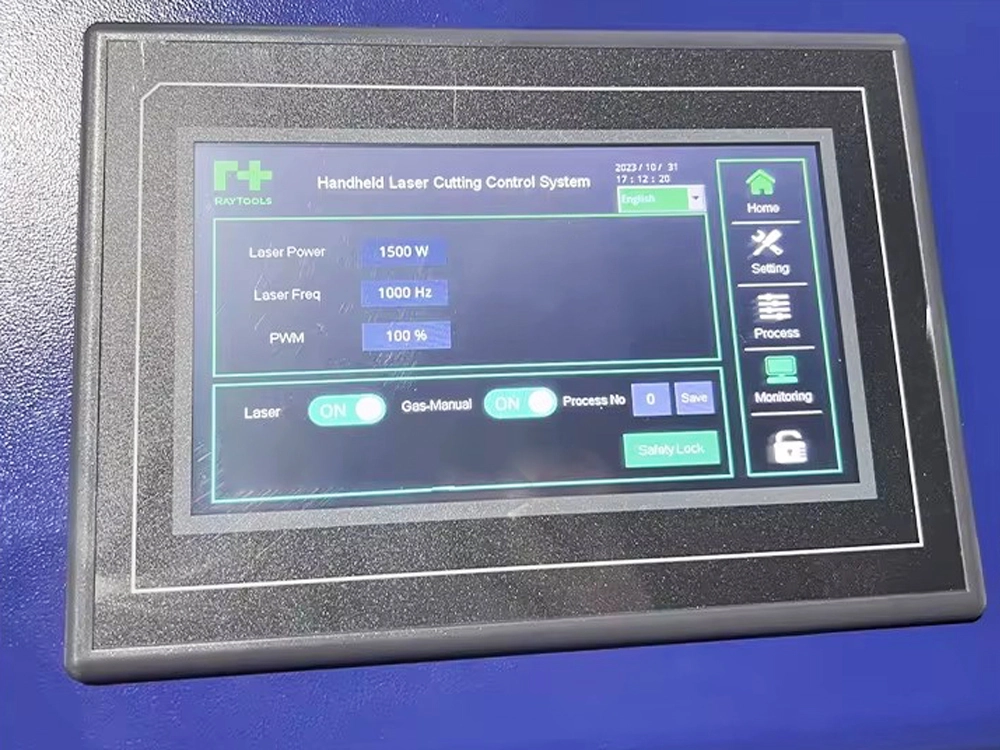

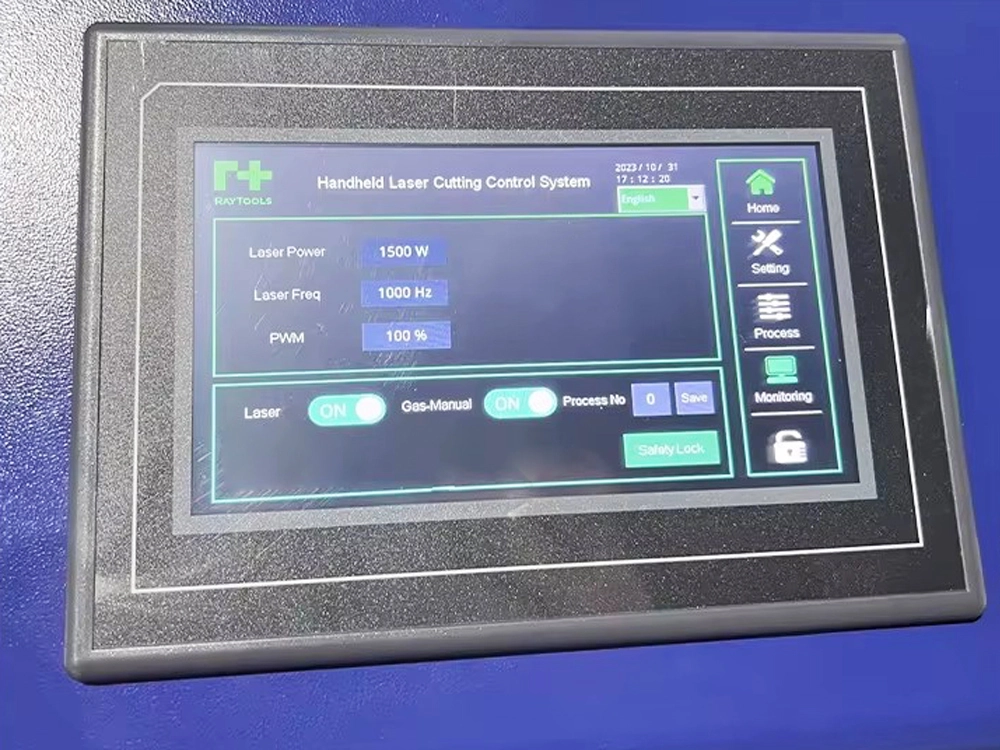

- Control panel

The machine adopts Raytools control system, and features a touchscreen for setting various laser parameters and monitoring operational status.

Technical Parameters of 3-In-1 Water-Cooled Handheld Laser Welding Machine

| Model | CK-1500-WCH-3 | CK-2000-WCH-3 | CK-3000-WCH-3 |

|---|---|---|---|

| Max. Output Power | 1500W | 2000W | 3000W |

| Stainless/Carbon Steel Welding Thickness | 0.3-4mm | 0.3-5mm | 0.3-7mm |

| Aluminum Welding Thickness | 0.3-2mm | 0.3-3mm | 0.3-5mm |

| Cutting Thickness | 5mm | 6mm | 8mm |

| Loose Rust Cleaning Efficiency | 40㎡/h | 60㎡/h | 80㎡/h |

| Heavy Rust Cleaning Efficiency | 8㎡/h | 10㎡/h | 14㎡/h |

| Indicator Light | Red Light | ||

| Central Wavelength | 1080nm | ||

| Torch Weight | 750g | ||

| Laser Cable Length | 10m (20m optional) | ||

| Cooling Method | Water Cooling | ||

| Max. Air Pressure | 10bar | ||

| Working Mode | Continuous/Pulse | ||

| Working Humidity | ≤70% RH | ||

| Operating Temperature | -20℃ to +50℃ | ||

| Power Supply | 220V 50/60Hz | 380V 50/60Hz | |

| Dimensions (L*W*H) | 990*600*1170mm | 1100*600*1180mm | |

| Weight | 165kg | 173kg | 203kg |

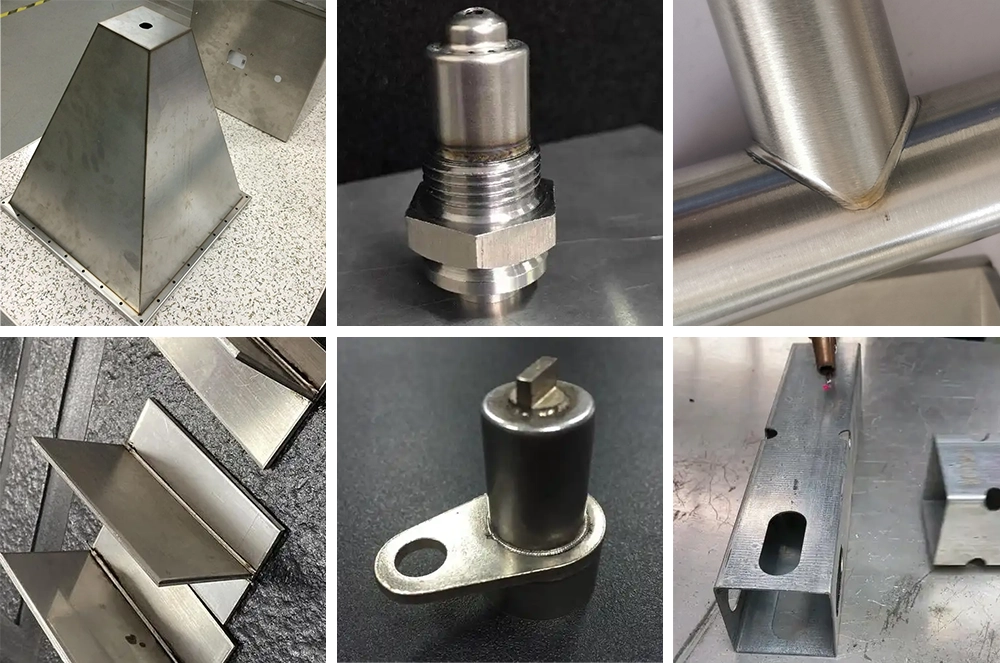

What Products Can the 3-In-1 Water-Cooled Handheld Laser Welder Be Used to Process?

The 3-in-1 water-cooled handheld laser welding machine can be used for welding or cutting various metal materials, such as: metal stair railings, cabinet kitchenware, metal doors/windows, metal furniture, shelves, window/door guards, automotive frames, aerospace components, home appliances, medical devices, etc.

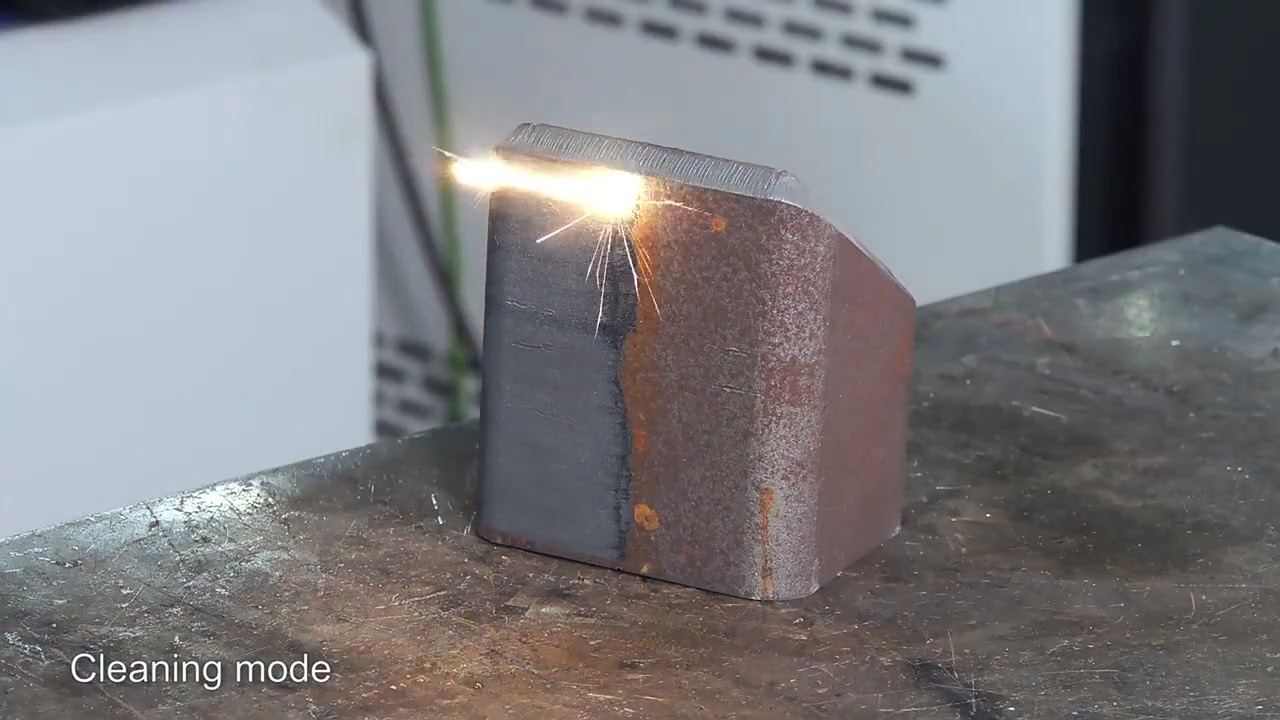

The 3-in-1 handheld water-cooled laser welding machine can be used for metal surface cleaning applications, including rust removal, paint stripping, oxide film removal, dust cleaning, and oil stain elimination.

Advantages of Water Cooling in Laser Welding Machines

- The water cooling system utilizes water's high specific heat capacity to rapidly absorb heat generated by the laser, offering higher cooling efficiency than air cooling, effectively reducing equipment operating temperature while improving laser stability and service life.

- Through constant temperature, constant flow and constant pressure coolant circulation, the water cooling system provides stable cooling performance, avoiding machine instability caused by temperature fluctuations. The working temperature can be precisely controlled within ±0.5℃, effectively ensuring welding process stability and consistent weld quality.

- Water-cooled laser welding machines can support higher power outputs - for example, 3000W and higher power welders cannot use air cooling.

- Due to their superior heat dissipation, water-cooled laser welding machines enable higher welding speeds.

- Water cooling systems have strong environmental adaptability, suitable for various complex conditions including high temperature, high humidity, extreme cold and other harsh environments.

- The water cooling system can be equipped with filters to remove impurities like aquatic plants and sediment, preventing clogging.

| Model | CK-1500-WCH-3 | CK-2000-WCH-3 | CK-3000-WCH-3 |

|---|---|---|---|

| Max. Output Power | 1500W | 2000W | 3000W |

| Stainless/Carbon Steel Welding Thickness | 0.3-4mm | 0.3-5mm | 0.3-7mm |

| Aluminum Welding Thickness | 0.3-2mm | 0.3-3mm | 0.3-5mm |

| Cutting Thickness | 5mm | 6mm | 8mm |

| Loose Rust Cleaning Efficiency | 40㎡/h | 60㎡/h | 80㎡/h |

| Heavy Rust Cleaning Efficiency | 8㎡/h | 10㎡/h | 14㎡/h |

| Indicator Light | Red Light | ||

| Central Wavelength | 1080nm | ||

| Torch Weight | 750g | ||

| Laser Cable Length | 10m (20m optional) | ||

| Cooling Method | Water Cooling | ||

| Max. Air Pressure | 10bar | ||

| Working Mode | Continuous/Pulse | ||

| Working Humidity | ≤70% RH | ||

| Operating Temperature | -20℃ to +50℃ | ||

| Power Supply | 220V 50/60Hz | 380V 50/60Hz | |

| Dimensions (L*W*H) | 990*600*1170mm | 1100*600*1180mm | |

| Weight | 165kg | 173kg | 203kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.