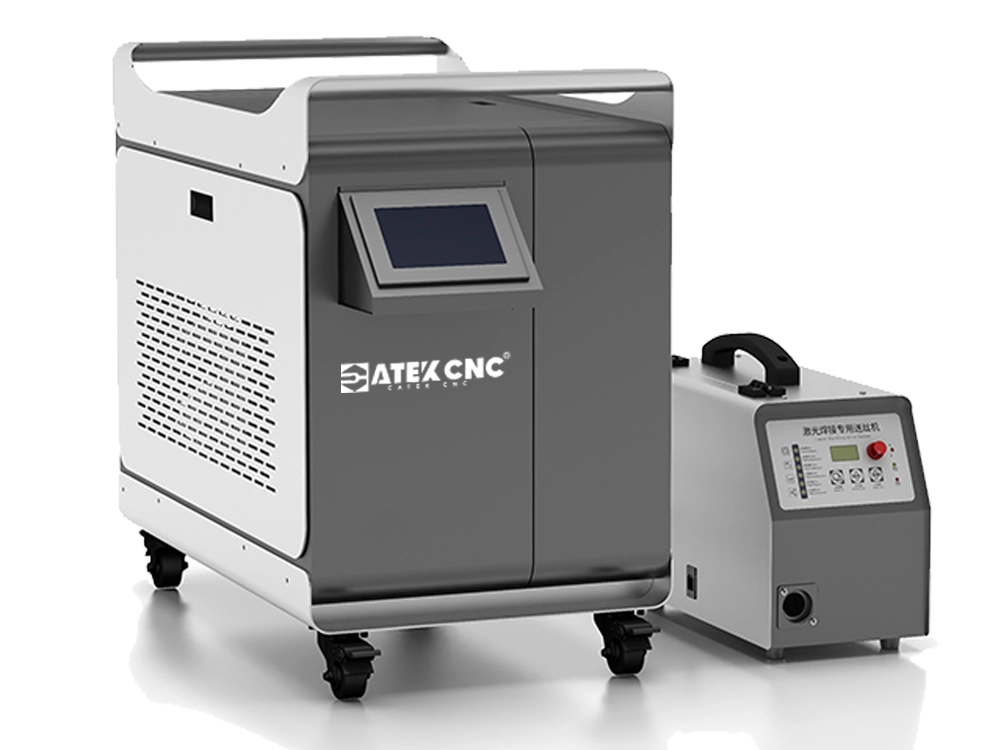

Cheap 4-In-1 Water-Cooled Handheld Laser Welding Machine for Sale

4-In-1 Water-Cooled Handheld Laser Welding Machine Suitable for Beginners

[Function Description]

The 4-in-1 water-cooled handheld laser welding machine integrates a laser generator, welding system, laser welding gun, and high-efficiency cooling system into one unit. It employs advanced fiber laser technology to achieve high-precision welding by near-infrared laser beams. Laser welding is a thermal fusion welding process where the workpiece surface is precisely heated by laser radiation, with heat rapidly conducting to the interior to form a uniform molten pool. Users can flexibly adjust parameters such as laser pulse width, energy, peak power, and repetition frequency to precisely control the welding effect. After the laser beam is removed, the molten pool quickly cools and solidifies, forming a strong and aesthetically pleasing weld seam.

This device is specifically designed for welding thin-walled materials and high-speed welding applications. It supports fine adjustments to weld seam width, depth-to-width ratio, and heat-affected zone, enabling functions such as welding, cutting, cleaning, and weld seam finishing for metal materials to meet diverse industrial needs. The equipped water-cooling system ensures high-performance output while enhancing stability during prolonged operation. Its portable design facilitates mobility, and when paired with the handheld laser welding head, it allows for more flexible workpiece processing.

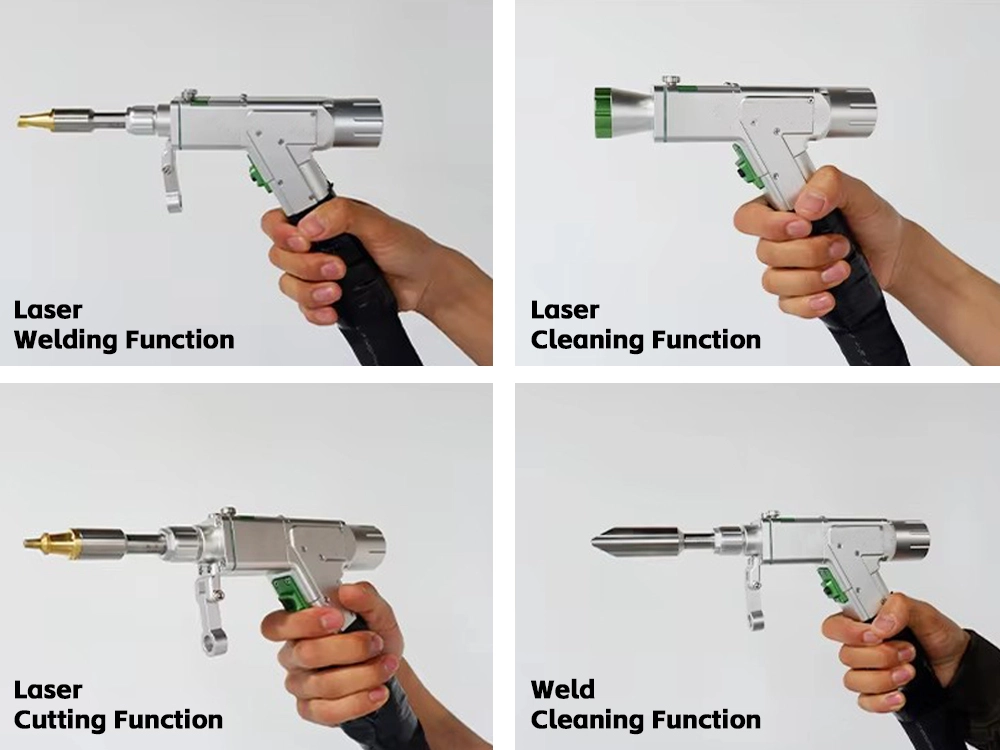

What Are the Functions of a 4-In-1 Laser Welding Machine?

Welding function

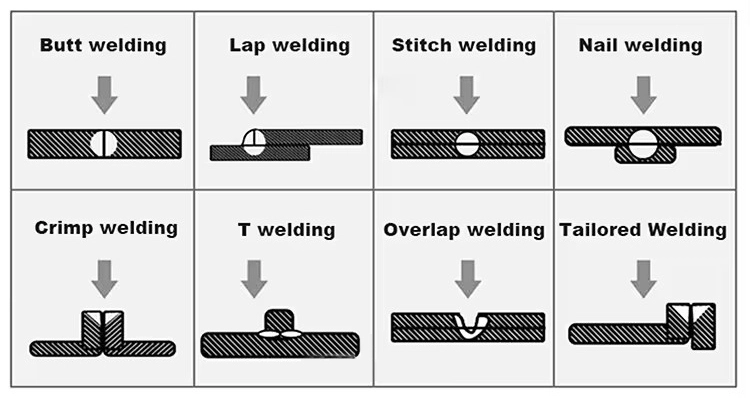

The 4-in-1 laser welding machine can achieve high-quality metal welding and is applicable to various metal materials such as stainless steel, carbon steel, aluminum, and copper. Laser welding technology offers the advantages of high energy density and a small HAZ, improving welding precision and quality. The galvanometer system equipped with the laser welding machine allows the laser beam to automatically move along a specified path, enabling easy implementation of various weave beads.

Cutting function

It supports the cutting of metal materials. The cutting speed is fast, the HAZ is small, and the cut surface is smooth and flat, making it suitable for cutting various thin metals and small metal parts.

Cleaning function

It can remove contaminants such as rust, paint, and oxides from the surface of workpieces without the need for any chemical cleaners, avoiding damage to the part's surface. It is suitable for applications requiring the removal of surface impurities from metal workpieces, such as in the automotive and shipbuilding industries.

Weld cleaning (weld finishing) function

The portable laser welding machine can clean residues and spatter from welds, ensuring the weld surface is clean and tidy, thereby improving welding quality.

Advantages of 4-In-1 Water-Cooled Handheld Laser Welding Machine

- Compact size and lightweight, easy to carry and move, making it more suitable for mobile operations or welding in confined spaces.

- Compared to traditional welding equipment, the welding speed is faster, with efficiency 2-10 times higher than MMA, TIG, and MIG welders.

- The control system is user-friendly for beginners, with a simple, intuitive, and easy-to-learn human-machine interface. Newer can master it in less than an hour.

- Equipped with a water-cooling system for effective cooling, supporting high-power lasers, enabling the laser welding machine to adapt to a wider temperature range.

- The 4-in-1 welding machine not only supports welding but also integrates cutting, cleaning, and seam cleaning functions, meeting various process requirements.

- High welding quality, with smooth weld surfaces, no porosity, and no deformation, eliminating the need for post-processing and meeting precision welding demands.

- The handheld laser welding gun offers high flexibility, capable of performing flat, straight-line, arc, and any trajectory welding, suitable for various complex-shaped welding needs.

- The fiber laser source has a long service life (over 100,000 hours), with stable and reliable equipment operation, enabling 24-hour continuous work.

Details of 4-In-1 Water-Cooled Handheld Laser Welding Machine

- Raytools handheld laser welding gun

The nozzle can be replaced as needed for different work requirements, such as inner corner welding nozzles, outer corner welding nozzles, standard wire-feeding welding nozzles, outer corner wire-feeding welding nozzles, cutting nozzles, and laser cleaning kits. The nozzles help protect the welding area while optimizing airflow structure, reducing welding porosity and achieving higher-quality welding results.

- Laser source

Max laser source is standard, Raycus, JPT, RECI, BWT laser sources are optional.

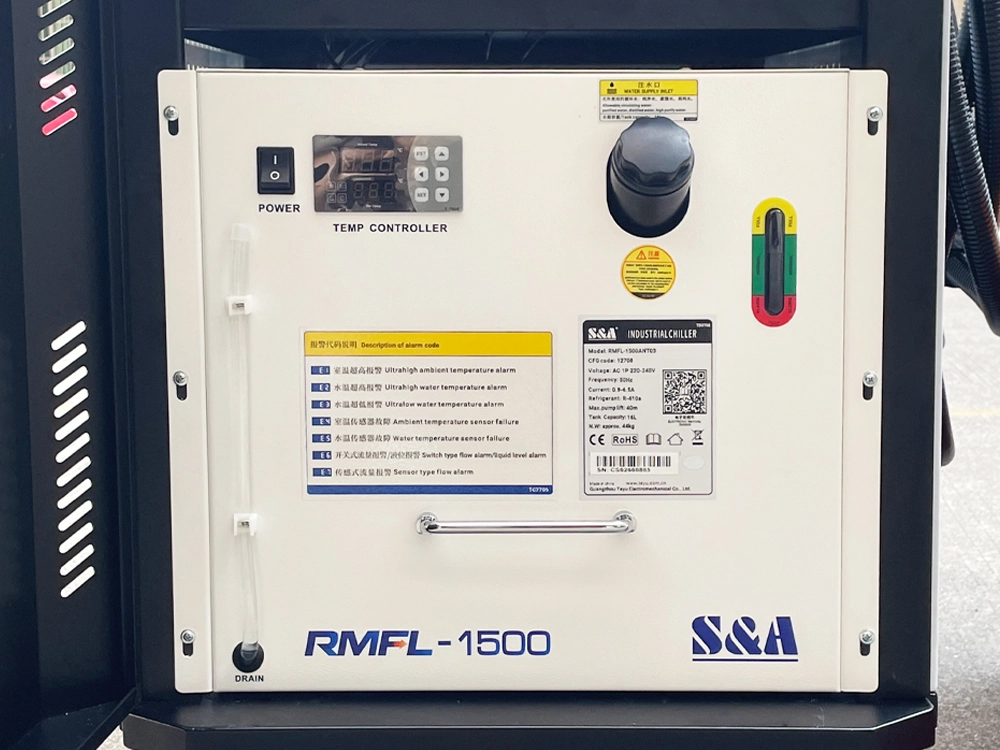

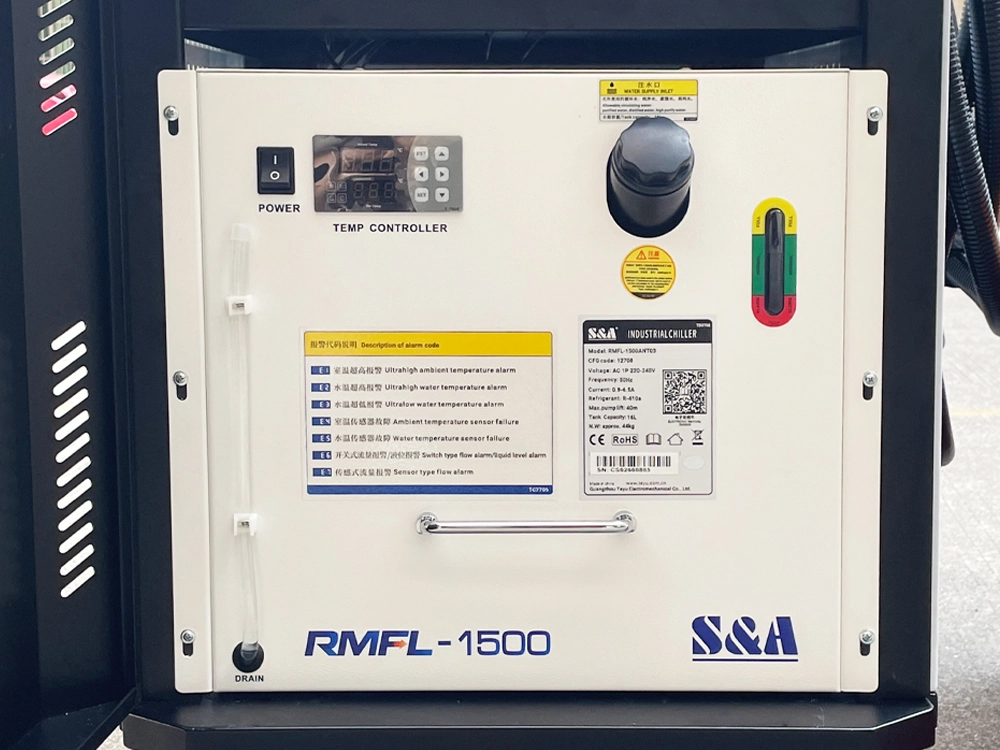

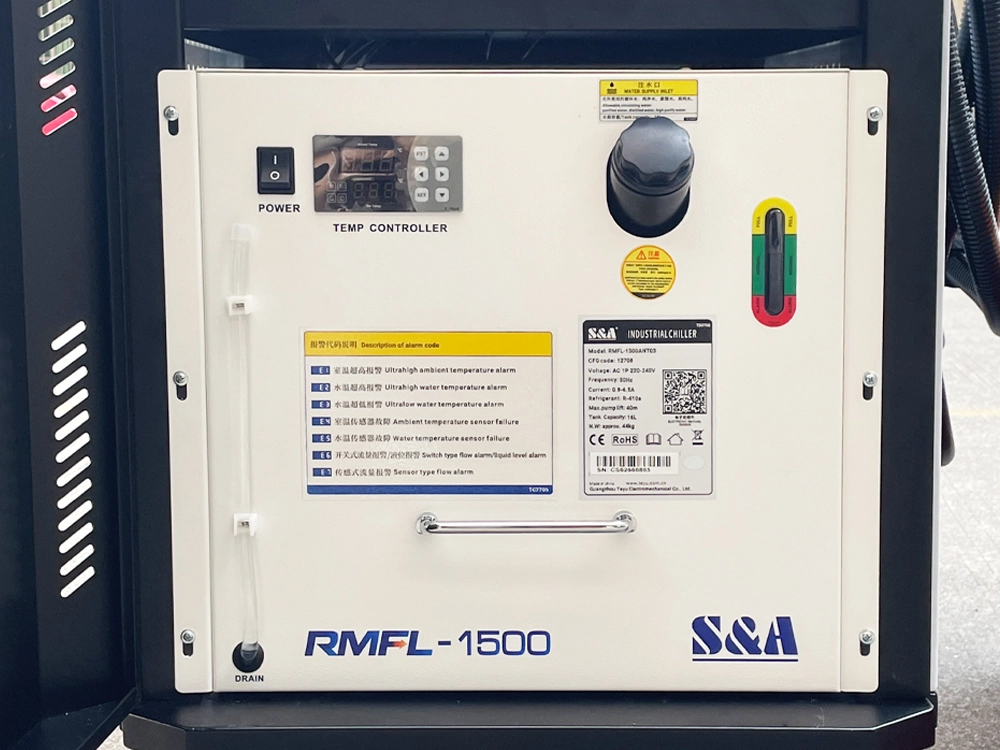

- S&A chiller

The machine is equipped with a built-in S&A rack-mounted industrial chiller - RMFL-1500, specifically designed for cooling 1.5kW handheld laser welding/cutting/cleaning machines. It features a high-performance water pump, dual-temperature control, and can simultaneously cool the fiber laser source and optical components/laser gun. The temperature stability is ±0.5°C, with a temperature control range of 5°C to 35°C.

- Wire feeder

Featuring touchscreen control and a four-wheel dual-drive wire feeding mechanism, it supports both continuous and pulsed wire feeding modes. The wire feeding speed is adjustable from 15-600 cm/min. It can be connected to the welding CNC system for coordinated operation to meet more precise wire feeding requirements.

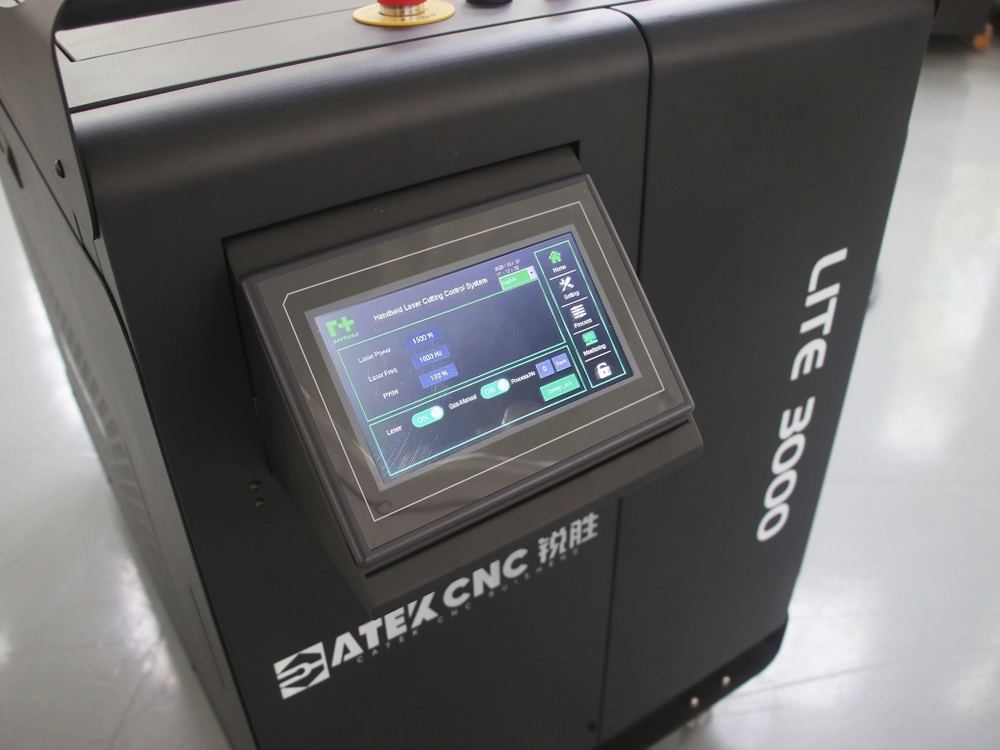

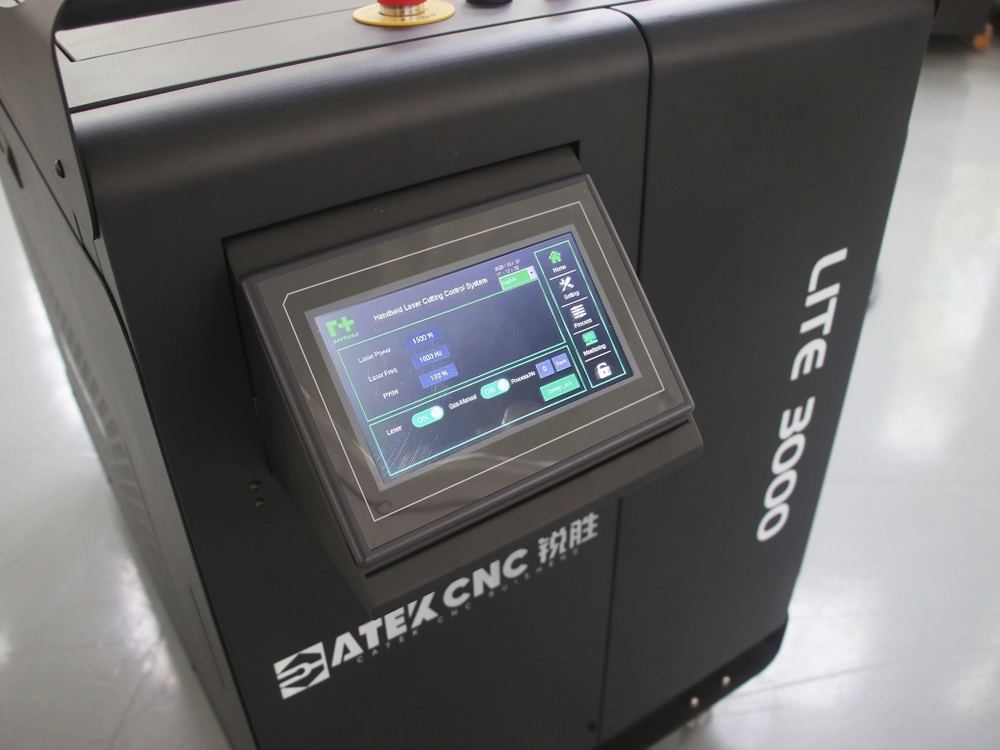

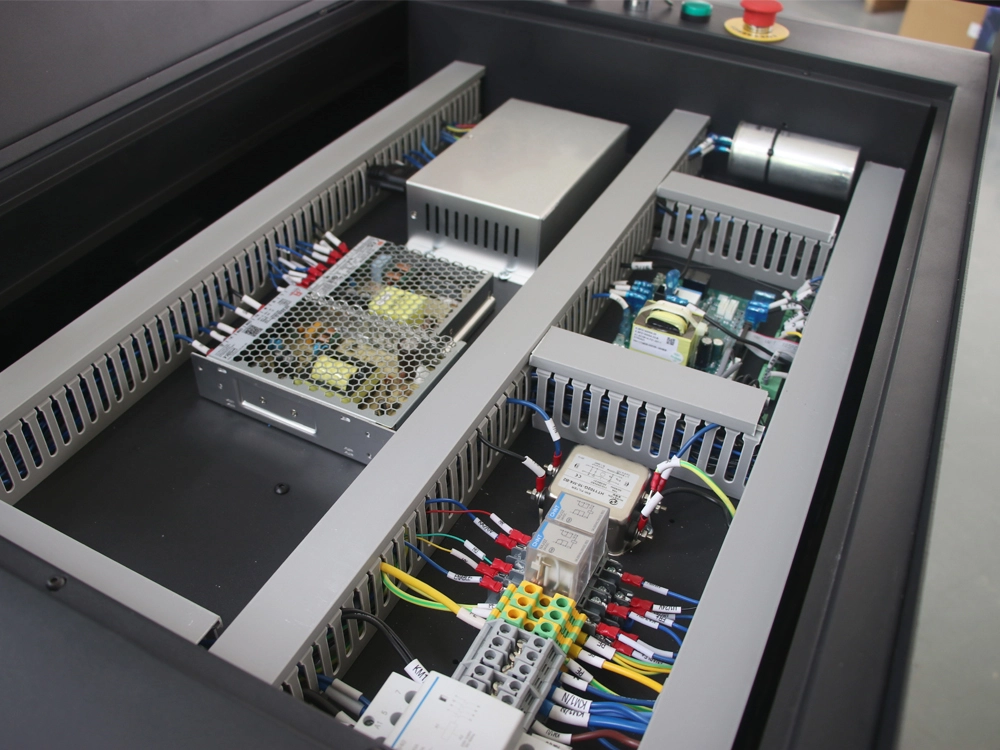

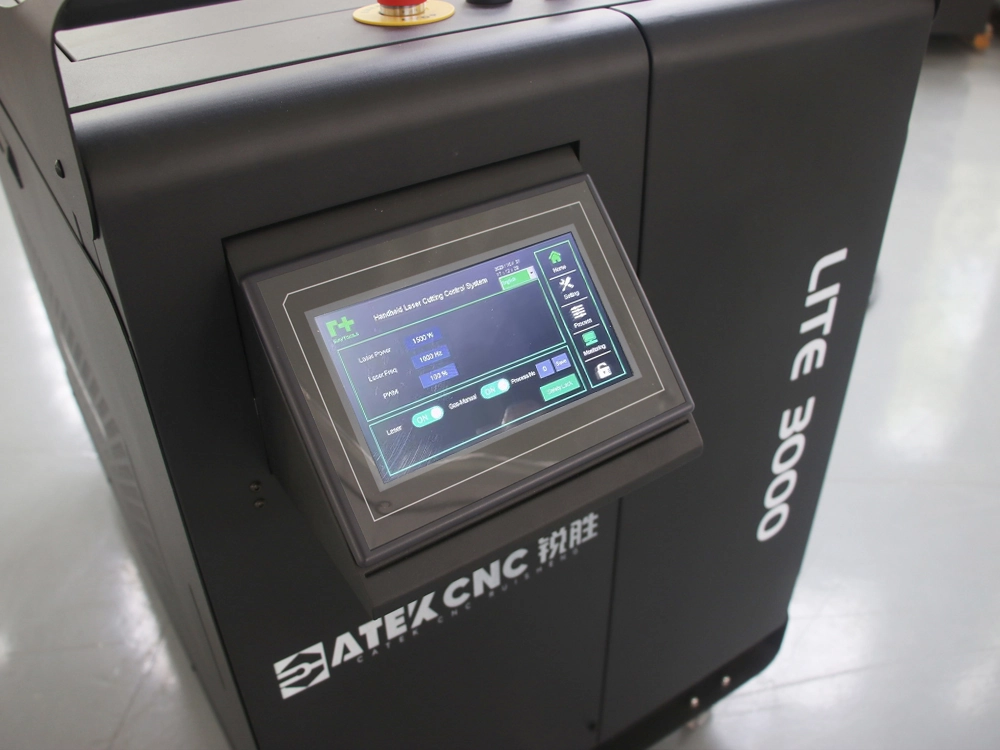

- Raytools control system

The wiring inside the control cabinet is neat, and CE-certified power supplies and related electrical components are used.

Equipped with a touch screen with an intuitive interface, it is easy to monitor and set various parameters, even for welding novices.

The control button group located on the top of the machine can quickly and conveniently control the start and stop of the machine.

- Accessories

The accessories shipped with the machine include laser nozzles, focusing lenses, welding protective masks, wrenches, gloves, etc.

Technical Parameters of 4-In-1 Water-Cooled Laser Welding Machine

| Model | CK-1500-WCH-4 | CK-2000-WCH-4 | CK-3000-WCH-4 |

|---|---|---|---|

| Max. Output Power | 1500W | 2000W | 3000W |

| Stainless/Carbon Steel Welding Thickness | 0.3-4mm | 0.3-5mm | 0.3-7mm |

| Aluminum Welding Thickness | 0.3-2mm | 0.3-3mm | 0.3-5mm |

| Cutting Thickness | 5mm | 6mm | 8mm |

| Loose Rust Cleaning Efficiency | 40㎡/h | 60㎡/h | 80㎡/h |

| Heavy Rust Cleaning Efficiency | 8㎡/h | 10㎡/h | 14㎡/h |

| Indicator Light | Red Light | ||

| Central Wavelength | 1080nm | ||

| Torch Weight | 750g | ||

| Laser Cable Length | 10m (20m optional) | ||

| Cooling Method | Water Cooling | ||

| Max. Air Pressure | 10bar | ||

| Working Mode | Continuous/Pulse | ||

| Working Humidity | ≤70% RH | ||

| Operating Temperature | -20℃ to +50℃ | ||

| Power Supply | 220V 50/60Hz | 380V 50/60Hz | |

| Dimensions (L*W*H) | 970*550*720mm | 1400*700*950mm | |

| Weight | 114kg | 116kg | 202kg |

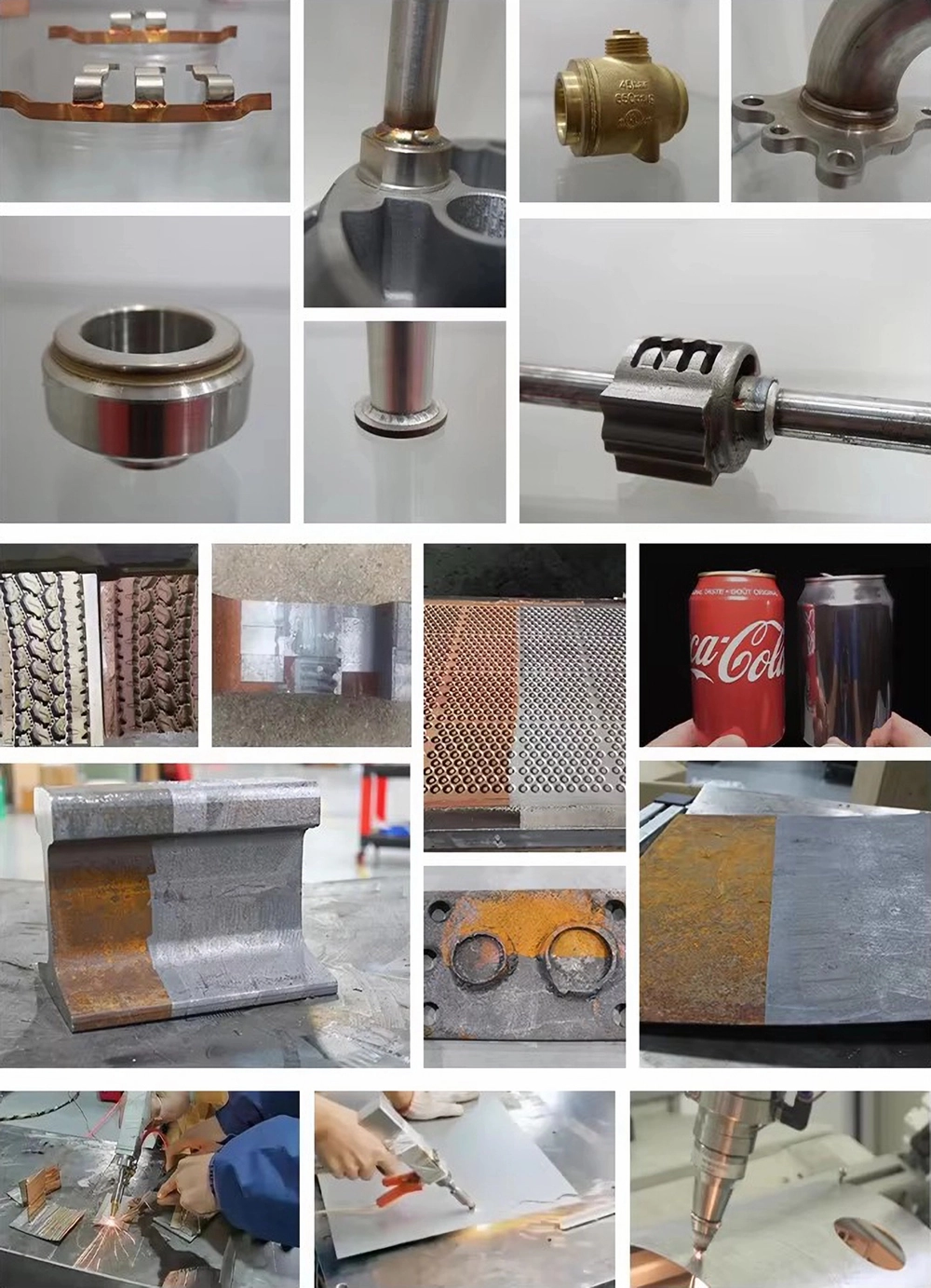

Application Scope of Portable Fiber Laser Welding Machines

Suitable for welding similar or dissimilar metals and alloys such as thin sheet metal, stainless steel, carbon steel, galvanized sheet, copper, aluminum, gold, silver, chromium, nickel, titanium, and tantalum, as well as cleaning tasks like rust removal, paint stripping, and oil stain removal.

- Automotive manufacturing: Engine housings, automotive parts, bodywork, chassis welding.

- Aerospace: Aircraft fuselage, engine components, turbine blades, aviation parts welding.

- Shipbuilding: Ship propellers, deck, bulkhead, hull, and component welding.

- Home appliance manufacturing: Air conditioner casings, washing machine casings, refrigerators, dishwashers, and other appliance casings and parts welding.

- Handicraft manufacturing: Jewelry, metal ornaments, artware welding.

- Kitchen & sanitary wareBathroom fixtures, kitchenware, metal frame welding.

- Architectural decoration: Metal door frames, window frames, fireproof doors, alloy door welding.

- Advertising production: Lightbox frames, metal signage, signboard frame welding.

- Furniture manufacturing: Metal tables, chair frames, bed frames, and other furniture welding.

FAQ for Laser Welding Machines

Can a laser welding machine weld different metals?

Yes, you can use a laser welding machine to weld dissimilar metals, such as stainless steel and aluminum, stainless steel and carbon steel, carbon steel and copper, etc.

Can a laser weld metals of different thicknesses?

Yes, you can weld metals of different thicknesses together, such as 5mm-thick stainless steel and 2mm-thick stainless steel.

Is a laser welding machine easy to use?

The laser welding machine is simple to operate, featuring touchscreen controls with intuitive parameter settings and a user-friendly interface. No prior experience is required—even if it's your first time using a laser welding machine, you can master it within an hour.

What is the maximum welding thickness for a laser welding machine?

The welding thickness depends on the material type and laser power. For example:

- A 1500W laser welding machine can weld up to 4mm-thick stainless steel or carbon steel plates.

- A 2000W laser welding machine can weld up to 5mm-thick stainless steel or carbon steel plates.

- A 3000W laser welding machine can weld up to 8mm-thick stainless steel or carbon steel plates.

For other metals, the maximum welding thickness under the same wattage may vary. The above examples refer to single-sided welding—if double-sided welding is performed, the thickness can be doubled.

Is a laser welding machine safe?

Yes, the laser welding machine is designed with multiple safety features, including alarm functions and safety interlocks. In emergencies, you can immediately press the emergency stop button to shut down the machine. Additionally, it comes with protective gear such as safety goggles and gloves.

What should I pay attention to when using a laser welding machine?

- Monitor the water temperature — ensure the chiller system stays between 15-25°C.

- Wear proper protective gear, including safety goggles and gloves.

- Ensure assist gas is correctly connected to avoid damaging the lenses.

- Properly ground the machine to prevent electric shock hazards.

| Model | CK-1500-WCH-4 | CK-2000-WCH-4 | CK-3000-WCH-4 |

|---|---|---|---|

| Max. Output Power | 1500W | 2000W | 3000W |

| Stainless/Carbon Steel Welding Thickness | 0.3-4mm | 0.3-5mm | 0.3-7mm |

| Aluminum Welding Thickness | 0.3-2mm | 0.3-3mm | 0.3-5mm |

| Cutting Thickness | 5mm | 6mm | 8mm |

| Loose Rust Cleaning Efficiency | 40㎡/h | 60㎡/h | 80㎡/h |

| Heavy Rust Cleaning Efficiency | 8㎡/h | 10㎡/h | 14㎡/h |

| Indicator Light | Red Light | ||

| Central Wavelength | 1080nm | ||

| Torch Weight | 750g | ||

| Laser Cable Length | 10m (20m optional) | ||

| Cooling Method | Water Cooling | ||

| Max. Air Pressure | 10bar | ||

| Working Mode | Continuous/Pulse | ||

| Working Humidity | ≤70% RH | ||

| Operating Temperature | -20℃ to +50℃ | ||

| Power Supply | 220V 50/60Hz | 380V 50/60Hz | |

| Dimensions (L*W*H) | 970*550*720mm | 1400*700*950mm | |

| Weight | 114kg | 116kg | 202kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.