5-In-1 Water-Cooled Handheld Laser Welder With Dual-Oscillation

2026 Best 5-in-1 Water-Cooled Handheld Laser Welding Machine for Sale

[Function Description]

What Are the Functions of the 5-In-1 Handheld Welding Machine?

Welding function:

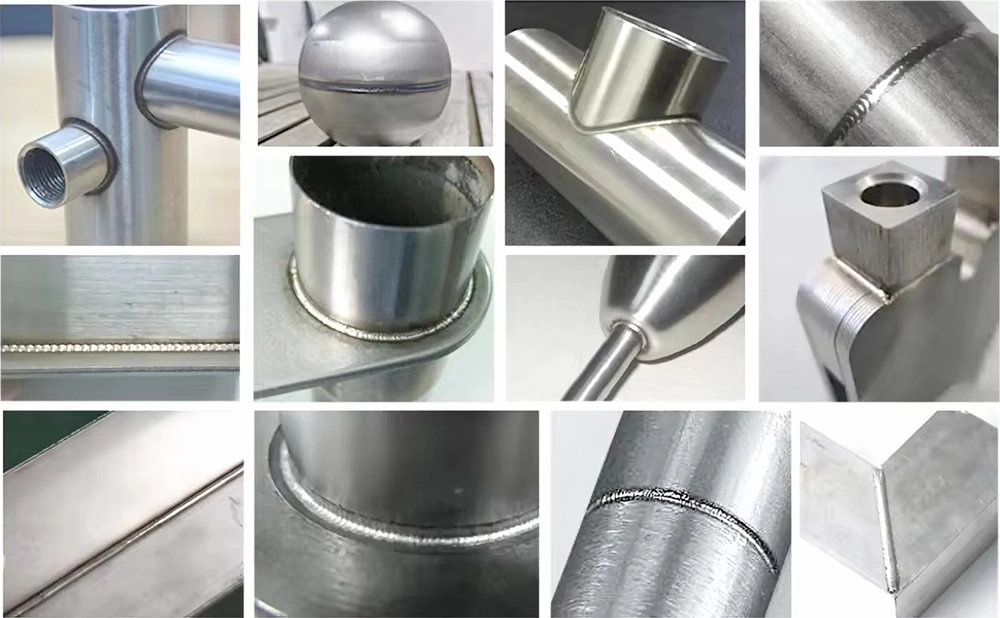

The 5-in-1 laser welding machine can perform high-quality welding on metals, including iron, copper, aluminum, and alloys such as stainless steel, carbon steel, and aluminum alloy. It provides highly concentrated energy and stable laser power output, resulting in fine weld seams, high welding quality, and a small HAZ. It can also achieve various welding patterns, making it suitable for welding precision metal structures or thin sheet materials.

Cutting function:

The 5-in-1 laser welding machine has laser cutting capabilities. It can cut metal sheets or pipes with fast cutting speeds and flexible, simple operation, making it suitable for scenarios requiring quick and simple cutting of blanks.

Cleaning function:

The 5-in-1 laser welding machine can use laser technology to quickly remove rust, grease, oxide layers, and other contaminants from the surface of workpieces. The cleaning effect is visually apparent, the speed is fast, and it avoids damage to workpieces caused by traditional cleaning methods.

Weld seam cleaning function:

The 5-in-1 laser welding machine can quickly clean post-weld seams, removing oxides, rust, welding residues, etc., ensuring the aesthetics and strength of the weld seam and effectively improving weld quality.

Energy storage welding function (battery welding):

It supports energy storage welding technology, meeting the process requirements for battery welding. It is applied to the welding of energy storage battery connection sheets, flow batteries, battery modules, etc., improving the performance and safety of energy storage systems and enhancing efficiency.

Note: The corresponding welding function requires replacing the appropriate nozzle and making the corresponding settings in the control system.

The Advantages and Features of the 5-In-1 Laser Welding Machine

- Integrates five functions—welding, cleaning, cutting, weld seam cleaning, and energy storage welding, to meet various process requirements and improve production efficiency.

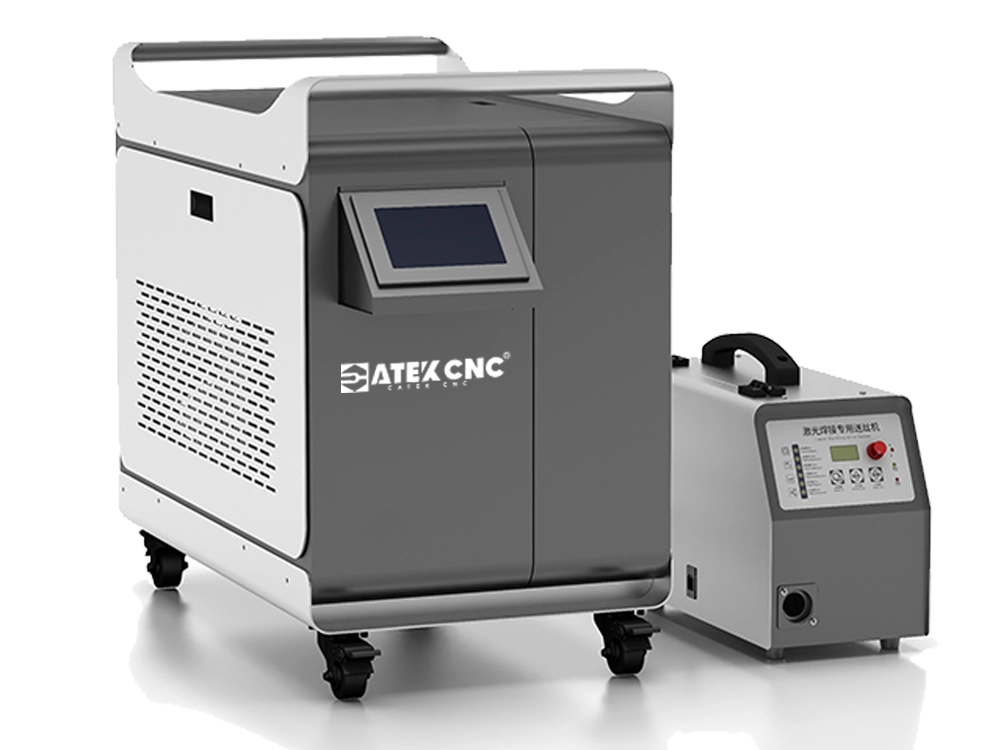

- Portable design with high machine integration, ready to use out of the box, easy to install and move, highly adaptable, and capable of flexibly meeting various welding needs.

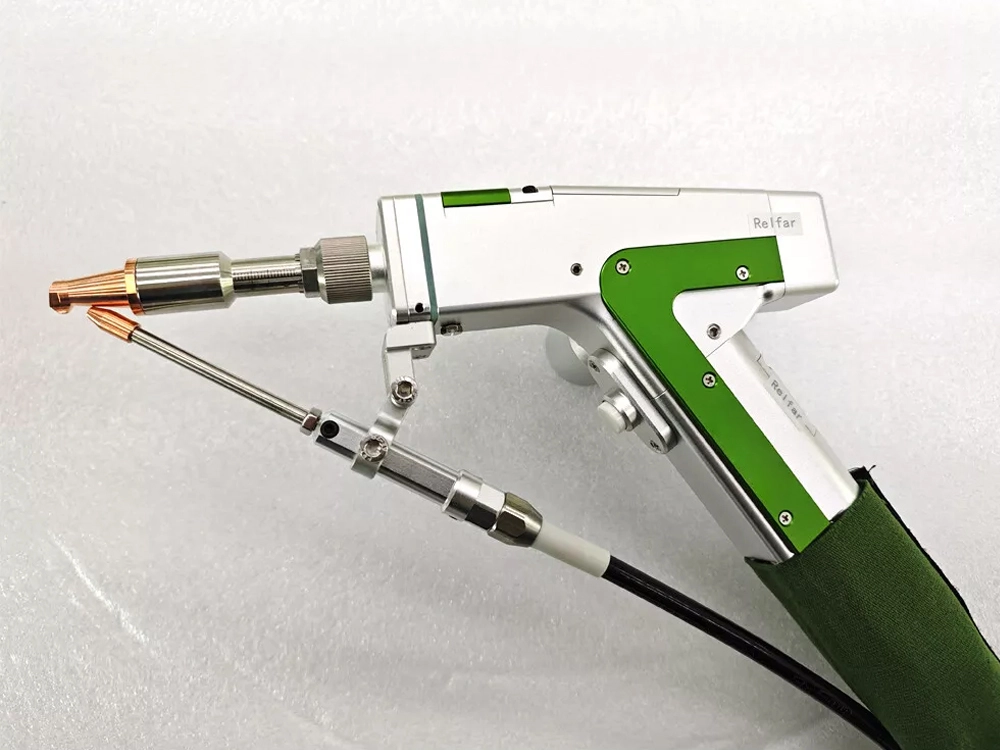

- Equipped with a dedicated control system for the welding machine, requiring no CNC programming. Simply operate with a handheld welding gun for flexible and convenient use.

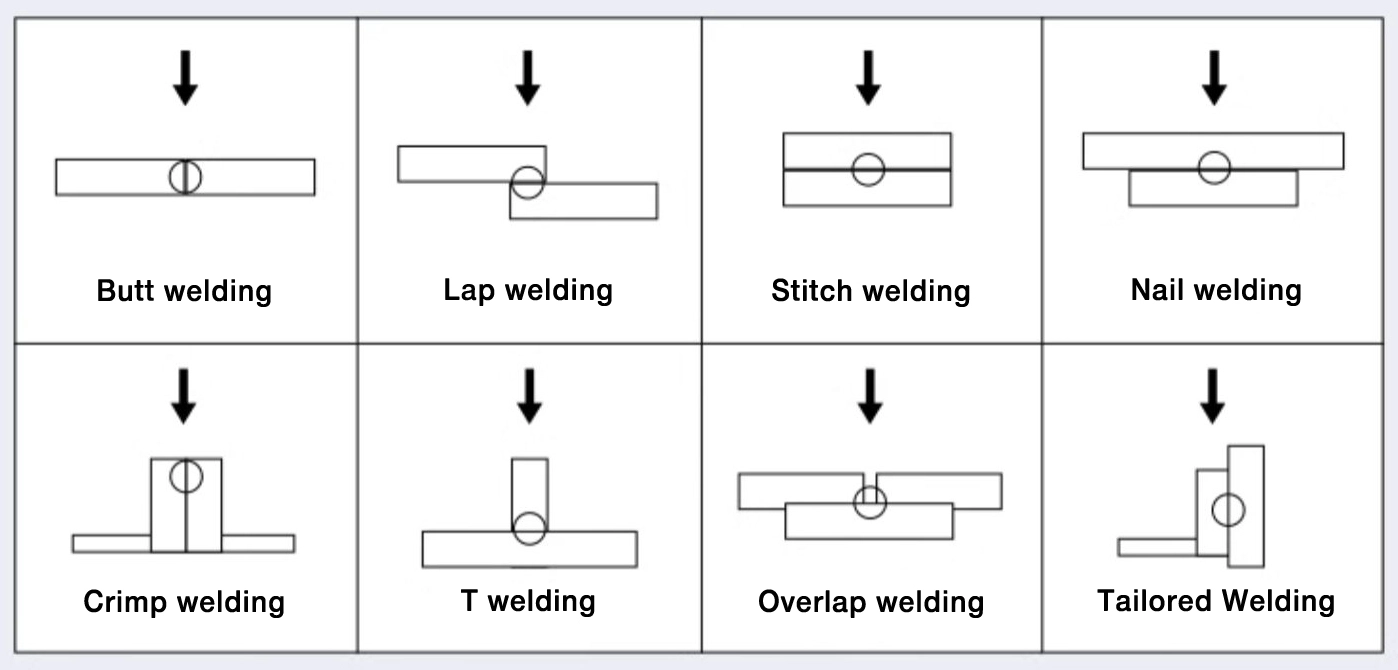

- Supports multiple welding processes, such as butt joint welding, tee joint welding, corner joint welding, lap joint welding, edge joint welding, and more.

- Small HAZ with concentrated laser energy, effectively reducing material deformation and thermal damage, making it suitable for welding precision electronic components or battery materials.

- The laser welding machine delivers high-quality weld seams, with fine and low-porosity welds. Finished products require no secondary processing, saving time and costs.

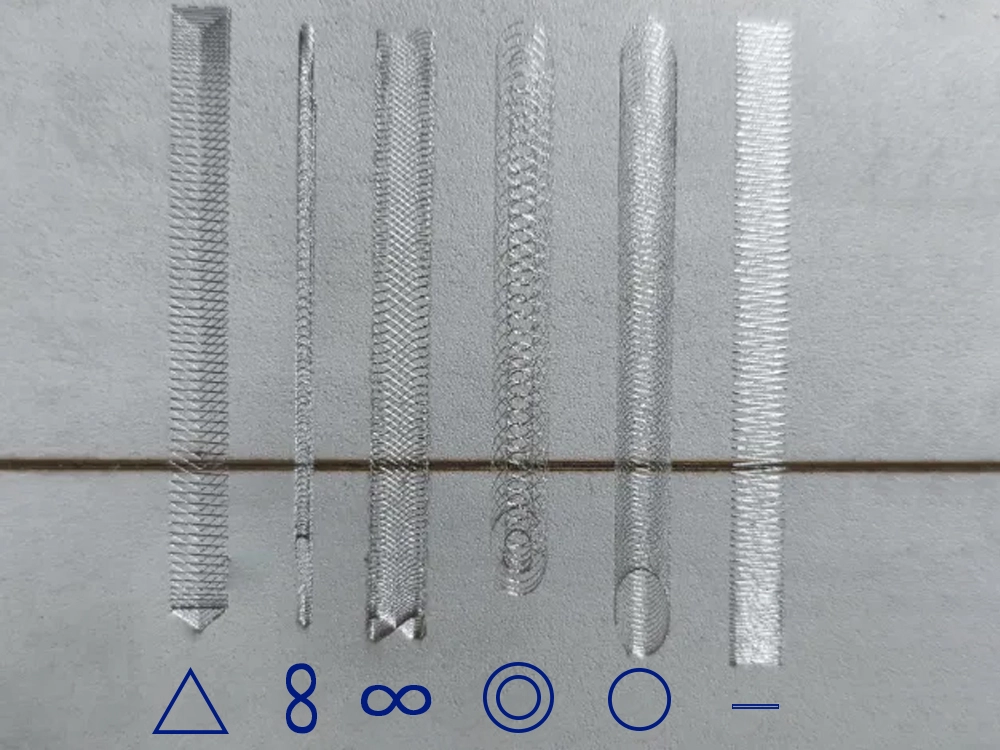

- Equipped with a dual-oscillation laser head, featuring two galvanometer systems that enable the laser beam to move along any trajectory in a two-dimensional space, creating complex welding weave patterns.

- The welding process produces no exhaust gas or wastewater, complying with the ROHS environmental standards of EU countries, ensuring energy savings and emission reduction.

- High safety standards, as laser welding effectively reduces slag splashing, minimizing risks such as fires and burns. It also includes multiple alarm and safety interlock mechanisms to prevent accidents caused by machine malfunctions or misuse.

Details of 5-In-1 Handheld Welding Machine

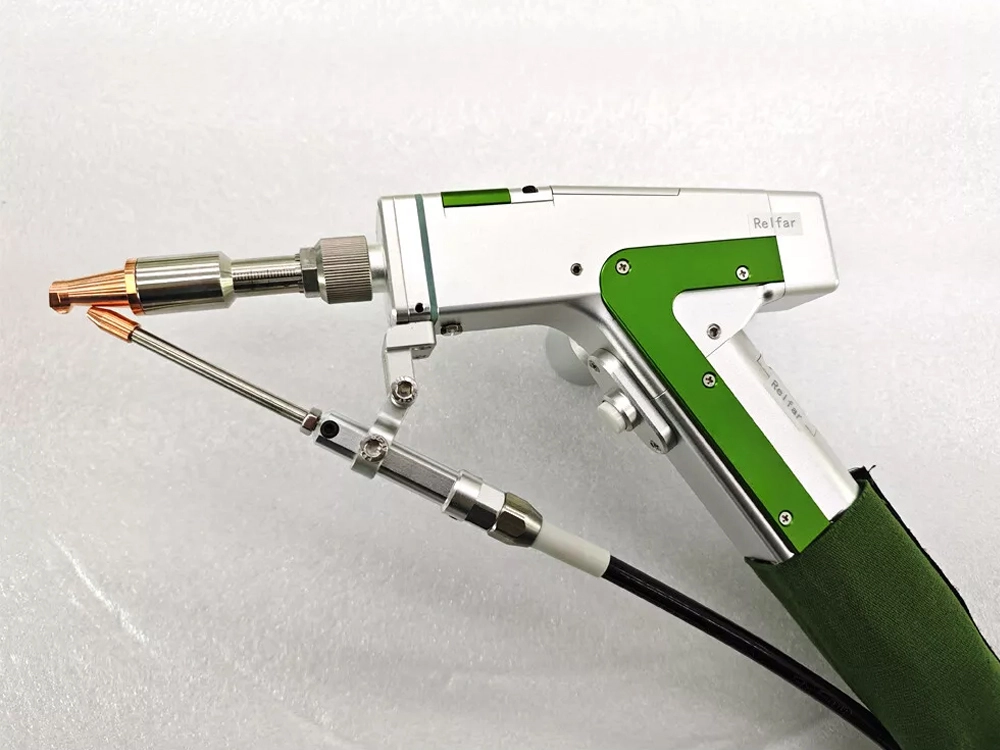

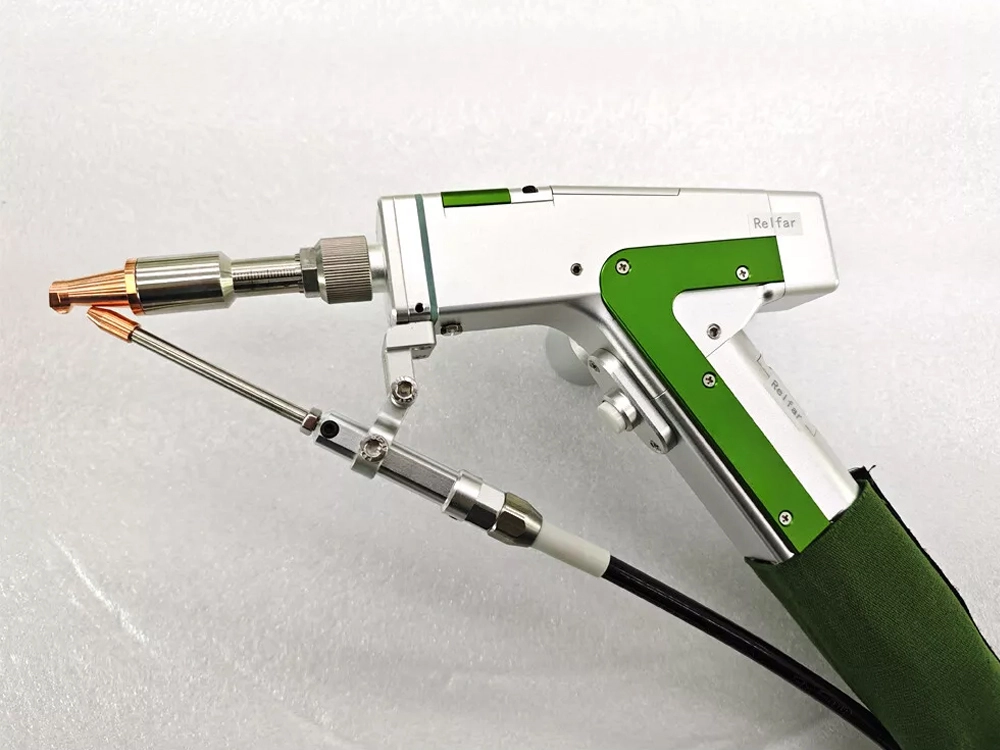

- Relfar welding gun

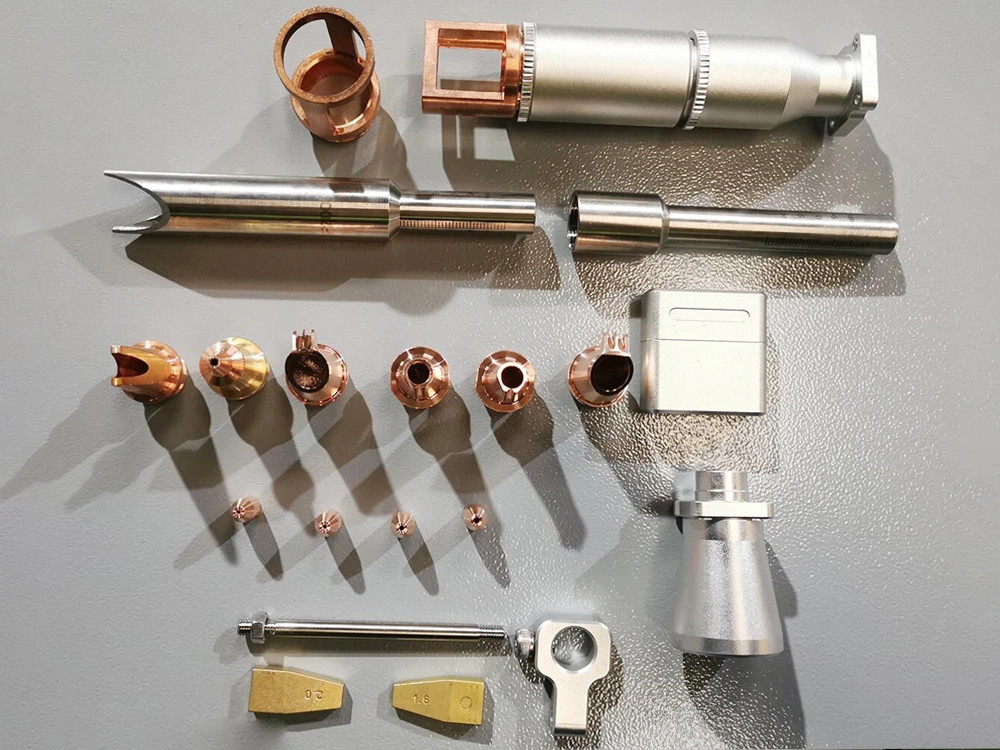

Dual-oscillation laser welding gun with red light positioning function. The equipment is equipped with laser copper nozzles suitable for various welding scenarios, which feature excellent thermal conductivity and high-temperature resistance, effectively preventing metal residue from clogging the nozzle during welding while ensuring stable welding performance. Additionally, nozzles of different specifications can be replaced as needed for processing, offering convenient operation.

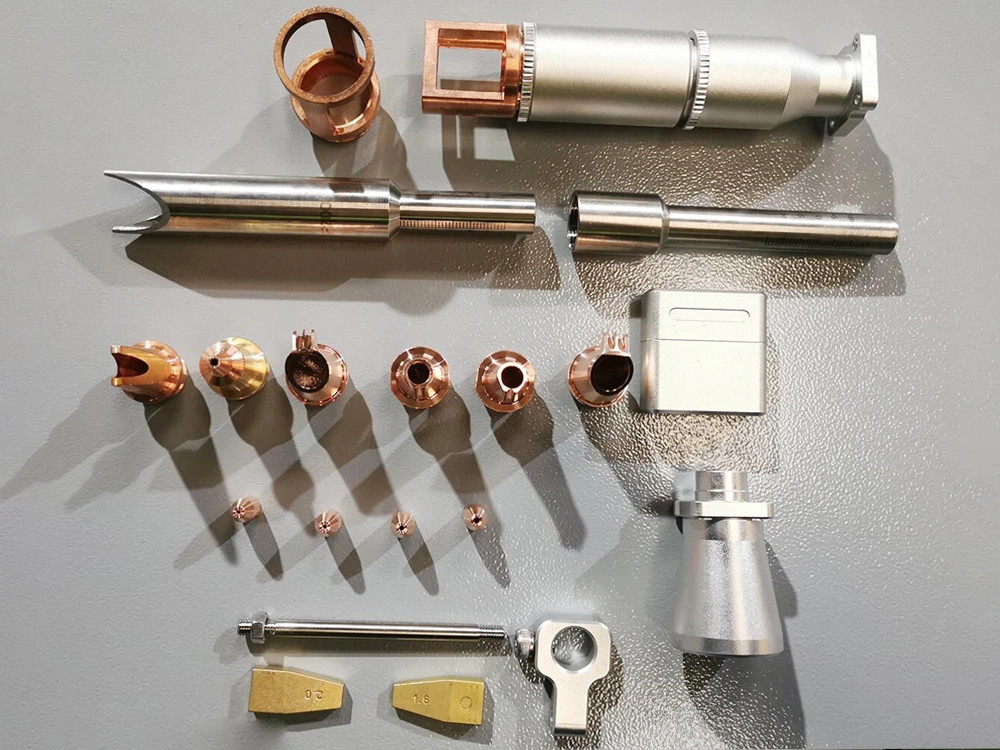

- Accessories of welding gun

Nozzles, lenses, scale connectors and other related accessories

- Laser source

Raycus laser source is standard, Max, JPT, RECI, BWT laser sources are optional.

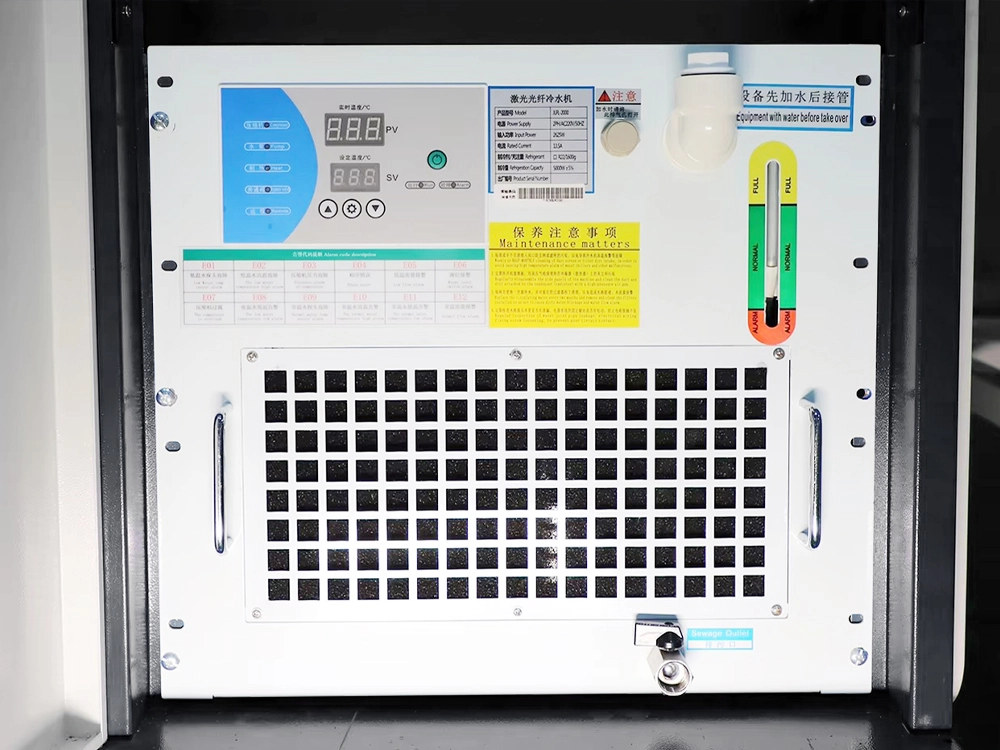

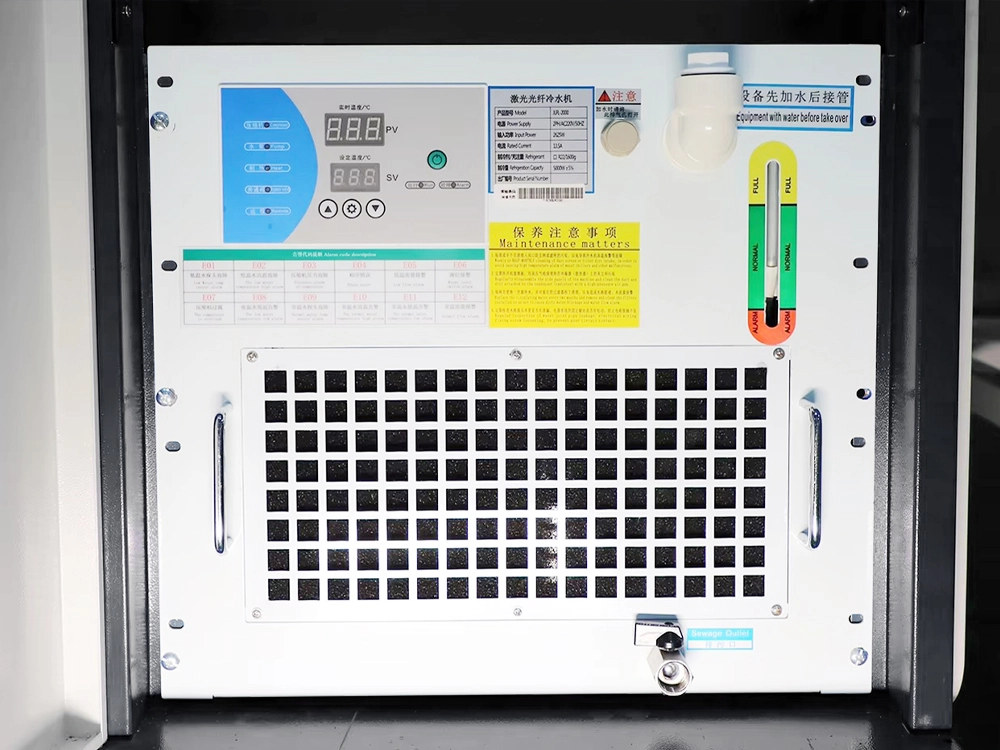

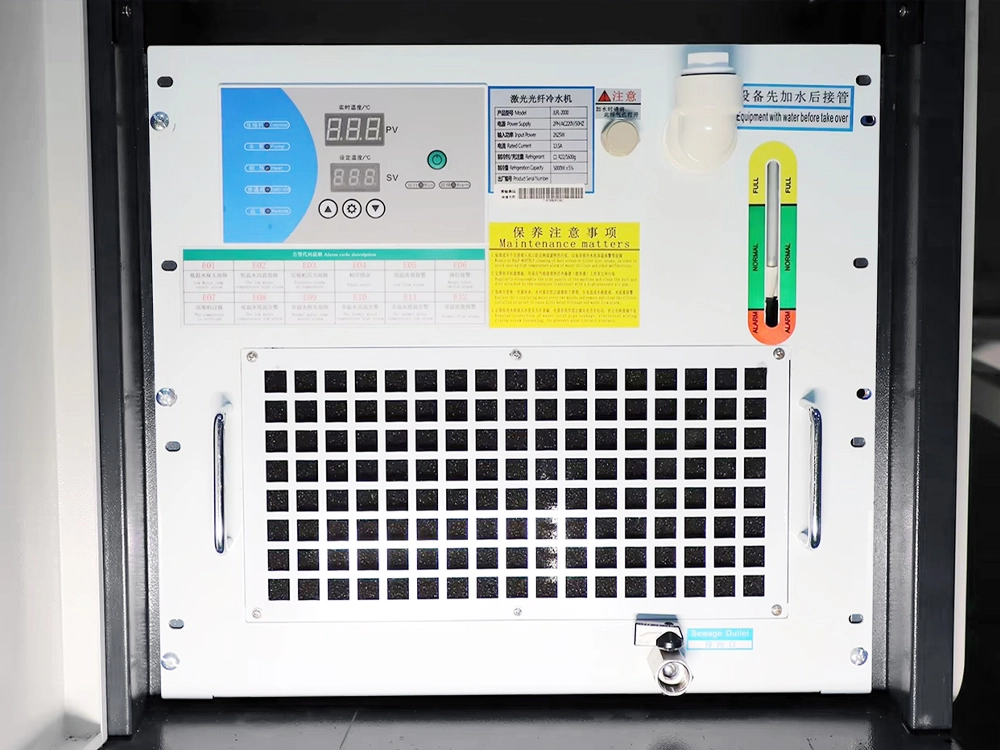

- Chiller

The rack-mounted water cooler is specially designed for handheld welding machines takes up a small space and is integrated inside the cabinet. It can cool the laser system and welding gun at the same time.

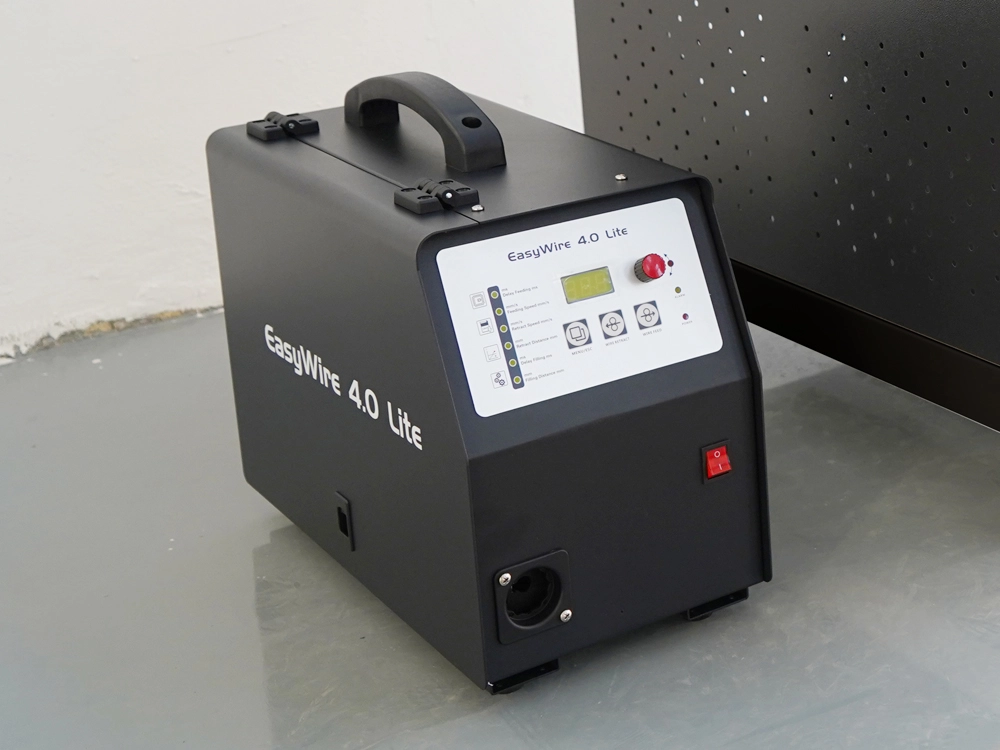

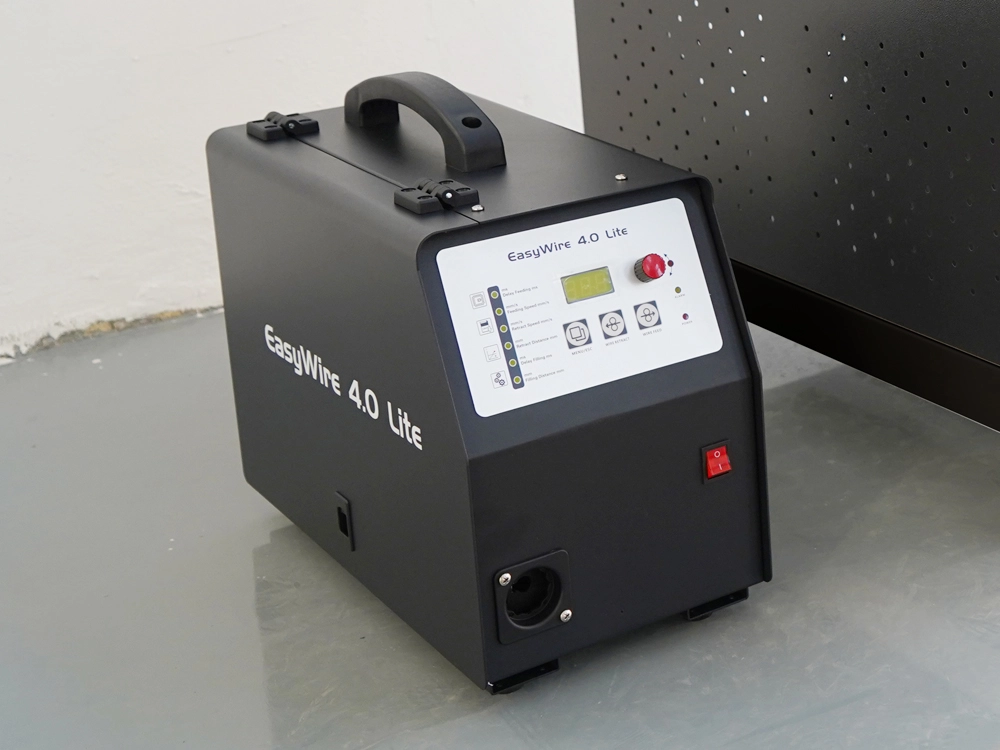

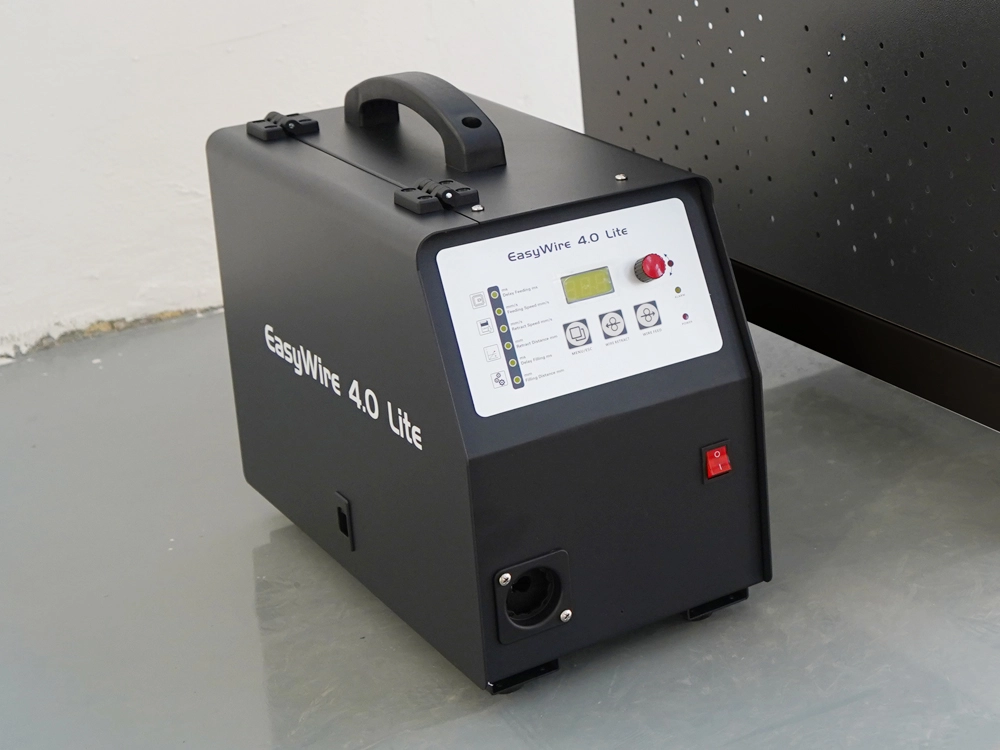

- Wire feeder

Fully automatic wire feeder performs wire feeding for filler welding to enhance welding quality. Equipped with multiple wire feeding modes, compatible with 0.8mm /1.0mm /1.2mm /1.6mm welding wires.

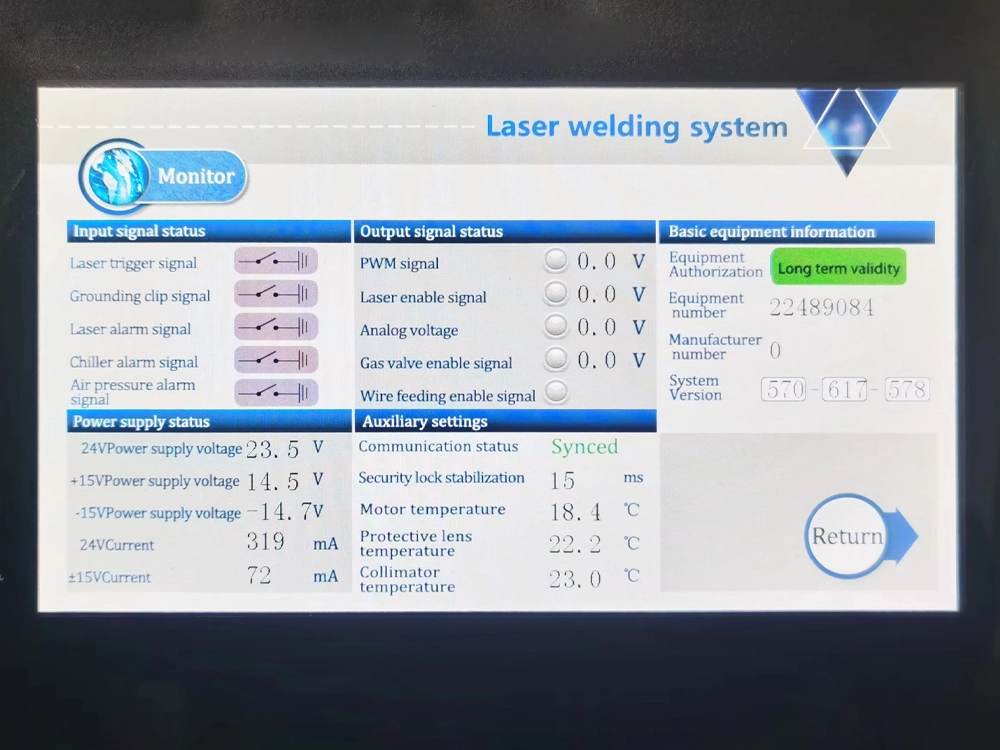

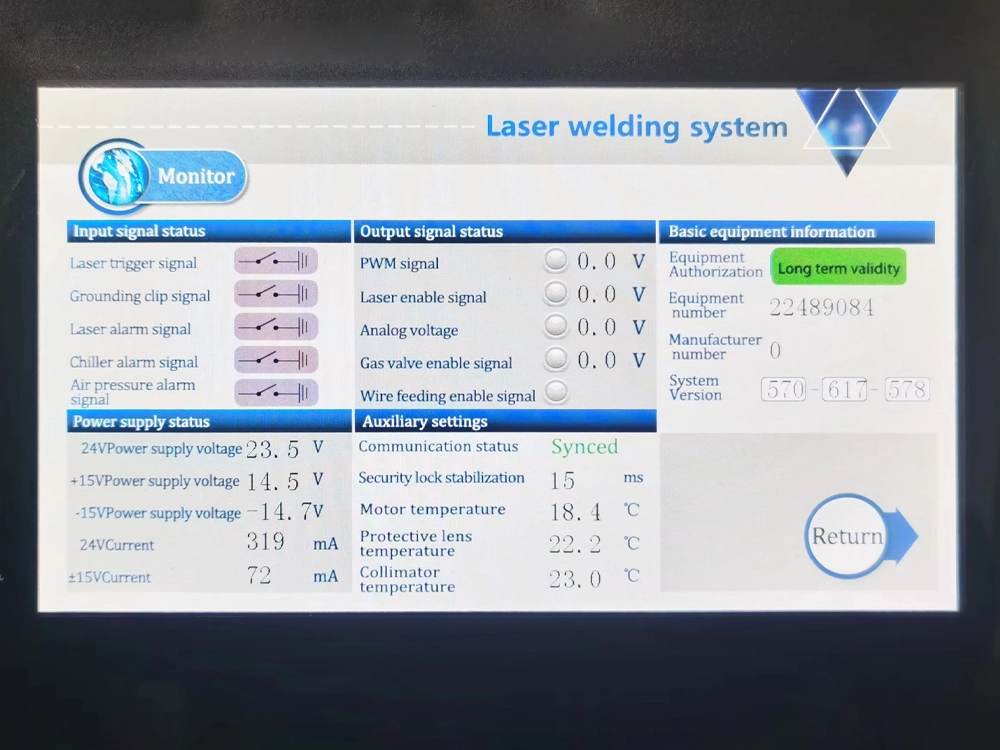

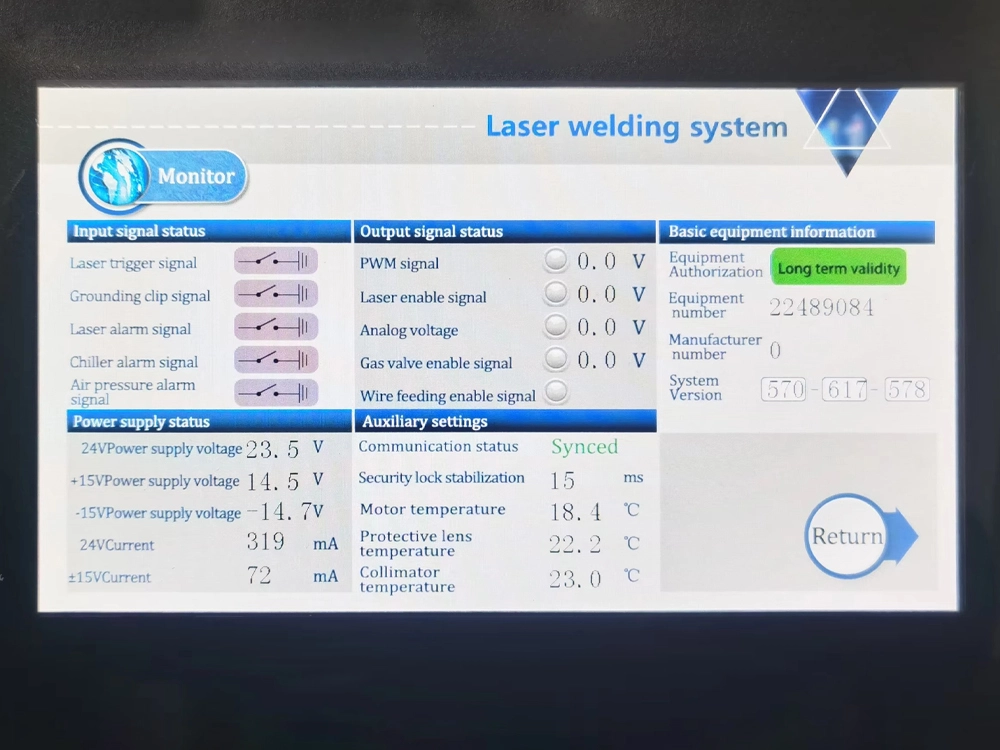

- Control system

Equipped with Relfar control system, supporting customizable settings, parameter storage, and real-time monitoring.

Technical Parameters of 5-In-1 Air-Cooled Laser Welding Machine

| Model | CK-1500-WCH-5 | CK-2000-WCH-5 | CK-3000-WCH-5 |

|---|---|---|---|

| Max. Output Power | 1500W | 2000W | 3000W |

| Stainless/Carbon Steel Welding Thickness | 0.3-4mm | 0.3-5mm | 0.3-7mm |

| Aluminum Welding Thickness | 0.3-2mm | 0.3-3mm | 0.3-5mm |

| Cutting Thickness | 5mm | 6mm | 8mm |

| Loose Rust Cleaning Efficiency | 40㎡/h | 60㎡/h | 80㎡/h |

| Heavy Rust Cleaning Efficiency | 8㎡/h | 10㎡/h | 14㎡/h |

| Indicator Light | Red Light | ||

| Central Wavelength | 1080nm | ||

| Torch Weight | 750g | ||

| Laser Cable Length | 10m (20m optional) | ||

| Cooling Method | Water Cooling | ||

| Max. Air Pressure | 10bar | ||

| Working Mode | Continuous/Pulse | ||

| Working Humidity | ≤70% RH | ||

| Operating Temperature | -20℃ to +50℃ | ||

| Power Supply | 220V 50/60Hz | 380V 50/60Hz | |

| Dimensions (L*W*H) | 950*580*1100mm | 990*600*1120mm | 1100*630*1150mm |

| Weight | 145kg | 158kg | 189kg |

Welding Parameters

| Thickness (mm) | Welding Speed (mm/min) | Welding Width (mm) | Peak Power (W) | Pulse Frequency | Welding Wire | |

|---|---|---|---|---|---|---|

| Carbon Steel | 1 | 300 | 3 | 350 | 2000 | 1 |

| 2 | 300 | 3 | 700 | 2000 | 1.2 | |

| 3 | 300 | 3 | 1100 | 2000 | 1.2 | |

| 4 | 300 | 3 | 1500 | 2000 | 1.6 | |

| 5 | 220 | 3 | 1800 | 2000 | 1.6 | |

| 6 | 220 | 3 | 2200 | 2000 | 1.6 | |

| 8 | 220 | 3 | 3000 | 2000 | 2 | |

| Aluminum | 1 | 300 | 3 | 500 | 2000 | ER5356 1.0 |

| 2 | 300 | 3 | 800 | 2000 | ER53561.2 | |

| 3 | 300 | 3 | 1400 | 2000 | ER5356 1.2 | |

| 4 | 300 | 3 | 1800 | 2000 | ER5356 1.6 | |

| 5 | 220 | 3 | 2000 | 2000 | ER5356 1.6 | |

| Stainless Steel | 0.5 | 300 | 2 | 260 | 2000 | ER304 0.8 |

| 0.8 | 300 | 2 | 300 | 2000 | ER304 0.8 | |

| 1 | 300 | 2 | 350 | 2000 | ER304 1.0 | |

| 2 | 300 | 3 | 700 | 2000 | ER304 1.0 | |

| 3 | 300 | 3 | 1100 | 2000 | ER304 1.2 | |

| 4 | 300 | 3 | 1500 | 2000 | ER304 1.2 | |

| 5 | 220 | 3 | 1800 | 2000 | ER304 1.6 | |

| 6 | 220 | 3 | 2200 | 2000 | ER304 1.6 | |

| 8 | 220 | 3 | 3000 | 2000 | ER304 2.0 |

What Is the Difference Between Single-Oscillation and Dual-Oscillation in Laser Welding Machines?

Single-oscillation system: Equipped with one galvanometer motor, the laser beam can only move in one direction, resulting in relatively simple welding patterns (e.g., sinusoidal). This system is suitable for precision welding of small products.

Dual-oscillation system: Equipped with two galvanometer motors, enabling the laser beam to move simultaneously in two directions. This allows for the creation of complex welding patterns (e.g., circular, square, elliptical, figure-8, ∞-shaped, S-shaped, C-shaped, etc.). Complex weaving patterns effectively enhance the molten pool and reduce welding defects, making the dual-oscillation system more suitable for large-area welding of large workpieces.

What Are the Oscillating Modes of the Dual-Oscillation System?

- Circular oscillating mode: The laser beam oscillates along a circular trajectory during welding, optimizing the distribution of weld penetration and width, suppressing porosity defects, and improving weld quality.

- Sinusoidal oscillating mode: The laser beam oscillates along a sinusoidal trajectory, evenly distributing laser energy, reducing penetration differences, optimizing molten pool flow, and improving weld formation quality.

- Figure-8 oscillating mode: The beam oscillates along a figure-8 trajectory, effectively suppressing porosity defects and enhancing welding results while stabilizing the keyhole to improve overall weld quality.

- Dual-wedge oscillating mode: Achieves a spiral-like weld through a dual-wedge trajectory, suitable for thick-walled pipe welding, flange welding, and other processing needs, offering high repeatability and stability.

- Linear oscillating mode: The beam oscillates along a straight-line trajectory, suitable for simple structural welding requirements.

- S-shaped oscillating mode: The beam oscillates along an S-shaped trajectory, improving heat input distribution and enhancing weld quality.

- Ring-shaped oscillating mode: The beam oscillates along a ring-shaped trajectory, suitable for welding complex structures requiring uniform heating.

- Dot-shaped oscillating mode: The laser beam oscillates in a dot-like trajectory, ideal for precision welding or localized heating.

Why Choose a Dual-Oscillation Laser Welding Machine?

The dual-oscillation laser welding machine can achieve more complex weld weave patterns, balance the torque generated during welding, reduce welding deformation, and improve weld quality. Compared to conventional welding methods, dual-oscillation welding is faster, more efficient, and produces smoother, flatter welds, reducing the need for subsequent grinding. It meets more stringent operational requirements.

Application Scope of the 5-in-1 Water-Cooled Handheld Laser Welding Machine

The 5-in-1 water-cooled handheld laser welding machine is a multifunctional welding device that integrates five functions: welding, cleaning, cutting, weld seam cleaning, and energy storage welding. Below are some common welding application scenarios:

- Metal material welding: Welding of various metal materials such as stainless steel, aluminum alloy, copper, titanium, etc., supporting both similar and dissimilar material welding.

- Battery industry: In energy storage welding mode, it can be used for welding battery casings, battery separators, battery terminals and connecting tabs, busbars, bipolar plates, flow frames, etc.

- Automotive manufacturing: Welding of car body frames and various automotive components, such as engine housings, chassis, doors, windows, etc.

- Home & construction materials: Welding of bathroom hardware, stainless steel products, faucets, tableware, metal furniture, doors and windows, fireproof doors, alloy doors, and metal chair/table frames.

- Aerospace: Welding of aircraft engine parts, high-temperature and high-pressure components, aircraft parts, turbine blades, etc.

- Advertising industry: Welding of metal advertising letters, letter frames, billboard brackets, etc.

- Shipbuilding industry: Welding of yachts, ship hulls, decks, inner walls, propellers, etc.

What to Consider When Purchasing a Laser Welding Machine?

Brand selection

Choosing a reputable brand with reliable after-sales service ensures better machine quality and support. A strong supplier with comprehensive service can provide technical assistance, maintenance, and spare parts supply.

Laser power selection

Laser power is a core parameter of a laser welding machine, directly affecting welding depth, speed, and quality. The appropriate power should be selected based on material thickness and welding requirements:

- For thin metal materials, lower laser power is sufficient.

- For thicker materials or high-speed welding demands, a higher-power machine is recommended.

Budget planning

When selecting a machine, evaluate your budget reasonably. High-end machines offer superior performance but come at a higher cost and may include unnecessary features. At the same time, avoid blindly pursuing low prices. Opting for a cost-effective model (balancing functionality and performance while minimizing costs) is more practical.

Operational costs

Ensure the machine has a user-friendly interface and intuitive operation to reduce operator training time and learning difficulty.

Long-term usage planning

Consider the initial investment, shipping costs, and operational expenses (such as electricity and maintenance). A machine that is easy to maintain with low upkeep costs offers better long-term economic benefits.

Configuration selection

Laser welding machines come with various configurations, including laser welding guns, laser generators, control systems, cooling systems, etc., with significant price differences. If you need guidance in selecting the right configuration, feel free to contact CATEKCNC’s sales specialists. We will provide detailed configuration explanations and professional advice.

| Model | CK-1500-WCH-5 | CK-2000-WCH-5 | CK-3000-WCH-5 |

|---|---|---|---|

| Max. Output Power | 1500W | 2000W | 3000W |

| Stainless/Carbon Steel Welding Thickness | 0.3-4mm | 0.3-5mm | 0.3-7mm |

| Aluminum Welding Thickness | 0.3-2mm | 0.3-3mm | 0.3-5mm |

| Cutting Thickness | 5mm | 6mm | 8mm |

| Loose Rust Cleaning Efficiency | 40㎡/h | 60㎡/h | 80㎡/h |

| Heavy Rust Cleaning Efficiency | 8㎡/h | 10㎡/h | 14㎡/h |

| Indicator Light | Red Light | ||

| Central Wavelength | 1080nm | ||

| Torch Weight | 750g | ||

| Laser Cable Length | 10m (20m optional) | ||

| Cooling Method | Water Cooling | ||

| Max. Air Pressure | 10bar | ||

| Working Mode | Continuous/Pulse | ||

| Working Humidity | ≤70% RH | ||

| Operating Temperature | -20℃ to +50℃ | ||

| Power Supply | 220V 50/60Hz | 380V 50/60Hz | |

| Dimensions (L*W*H) | 950*580*1100mm | 990*600*1120mm | 1100*630*1150mm |

| Weight | 145kg | 158kg | 189kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.