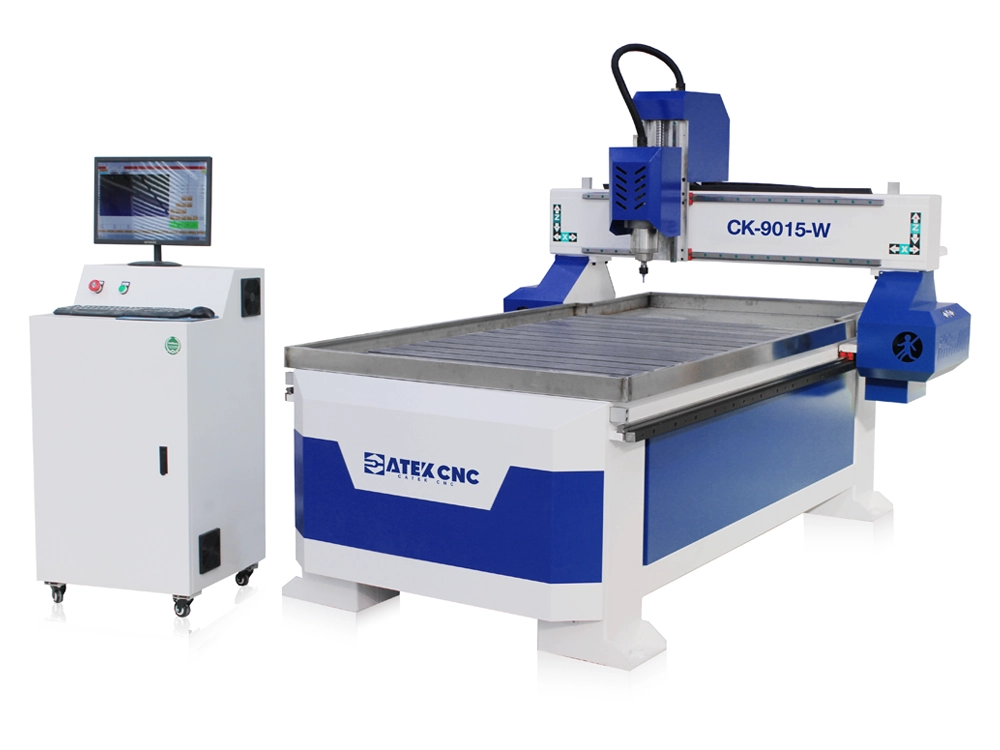

Small CNC Router for Machining Hard Materials

3x5ft Small CNC Router Machine With Flood Cooling

[Function Description]

The CNC router with a flood cooling is a CNC device designed for processing hard materials, such as stone, aluminum, copper and other metal materials. The circulating water cooling system cools the tool, reduces dust, prolongs the tool life and improves the processing effect. The sink can be used to store cooling water, which is sprayed on the tool and material surface through the circulating water spray system to reduce the high temperature generated during processing and prevent the tool from overheating and wear (especially for hard materials such as metal and stone). The water cooling system can also suppress dust during stone processing and protect the working environment.

When processing stone, especially jade and other materials, the circulating water sink is very important. In addition to taking away the dust generated during processing and cooling the tool, the water can also be used to cool the stone to prevent the stone from cracking due to excessive temperature. Cooling water can effectively reduce the friction between the tool and the material, prolong the tool life, and when processing metal, stable temperature control also helps to maintain processing accuracy and avoid thermal deformation of metal materials.

Features of Small CNC Router With Flood Cooling

- The circulating water tank workbench can effectively cool the tool and processing materials, improve precision and reduce material waste.

- Circulating water work can avoid dust generated during processing and protect the working environment.

- Water circulation can effectively extend the life of the tool and avoid the chipping and deformation caused by high temperature of the tool, especially for precious tools, which can effectively save costs.

- Use a circulating submersible pump to circulate cooling water, which can be recycled indefinitely to reduce resource waste.

- When processing hard materials such as metal and stone, you can choose to use circulating water for processing. When processing ordinary materials such as wood and mdf boards, you can choose not to use a circulating water tank. You can freely choose according to the processing scene and use it flexibly.

- It can be used for cutting, engraving, drilling, grooving, milling, etc. of various materials, with complete functions.

- Small CNC routers are small in size, low in power and cheap in price, suitable for various production scenarios.

- Simple operation, equipped with a complete user manual, more than 2,000 processing drawings are given free of charge, you can choose to use them at will, and we also provide engineers to draw drawings free of charge.

Advantages of 9015 Small CNC Router With Sink Workbench

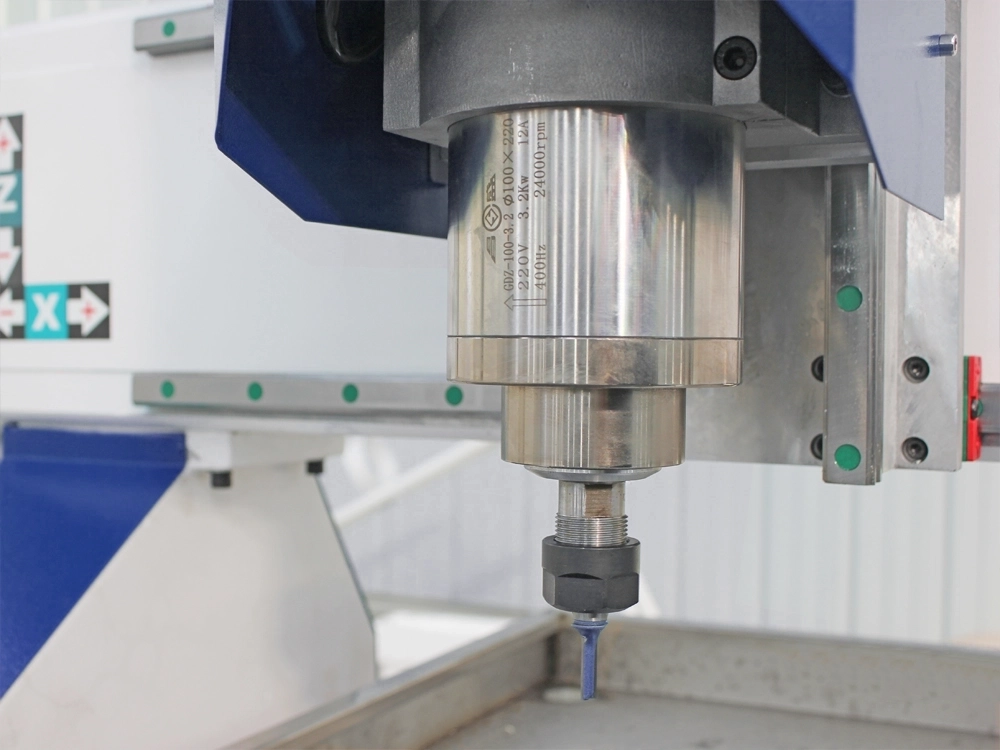

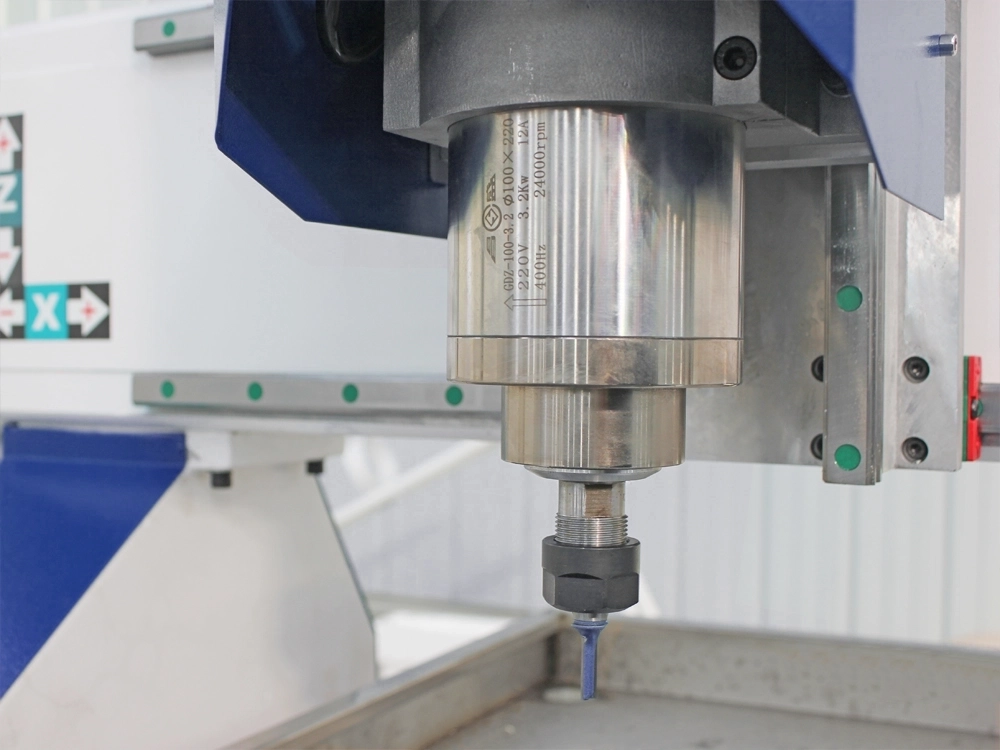

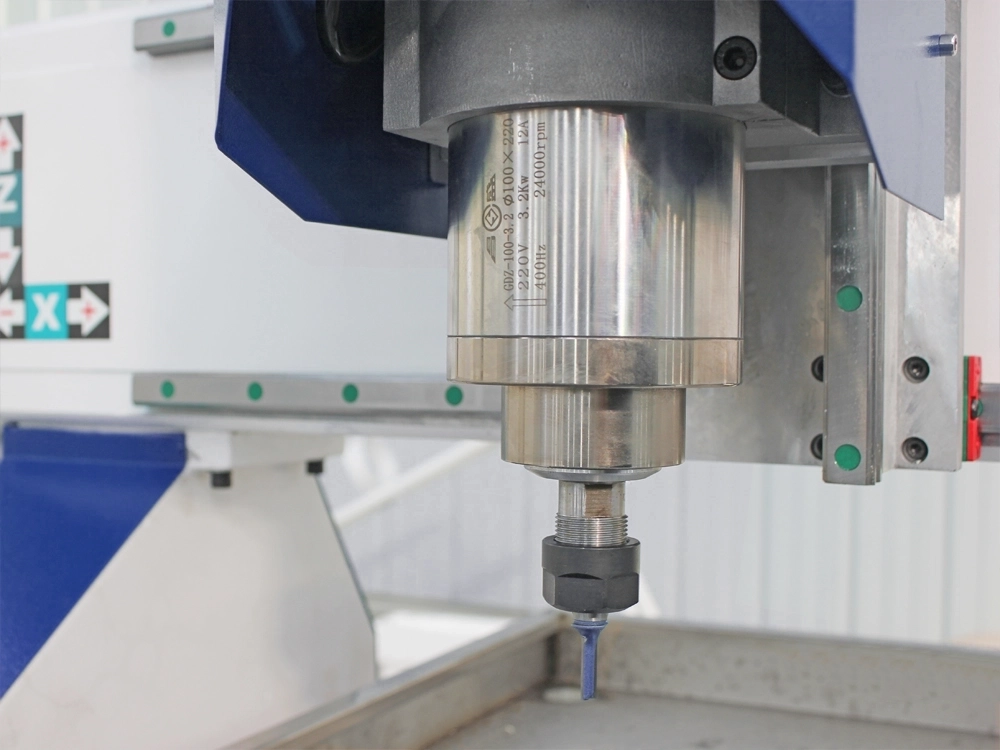

- 3.2KW high-speed water-cooled variable frequency spindle, speed 24000r/m, ER20 tool holder, can clamp 12.7mm inner tool handle, compatible with a wide range of tools.

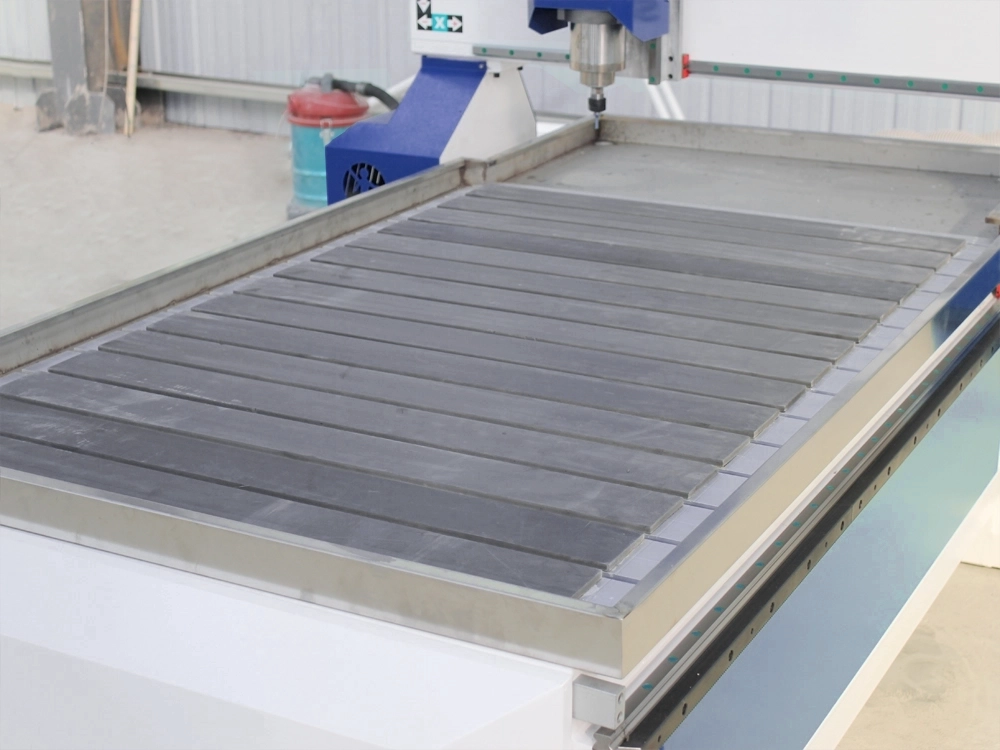

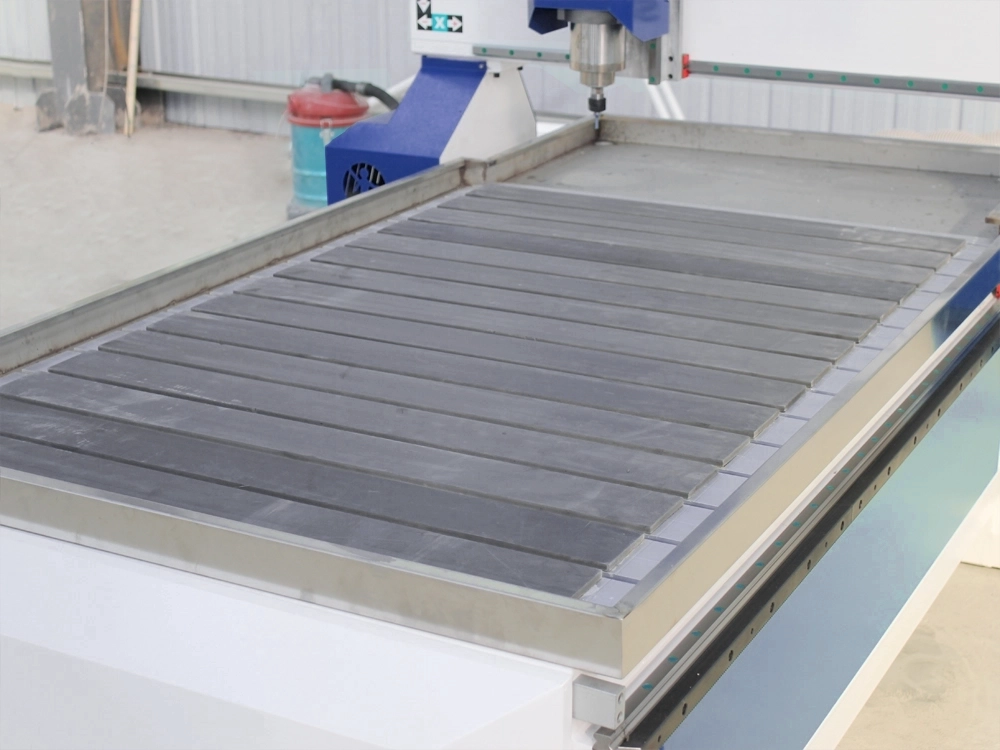

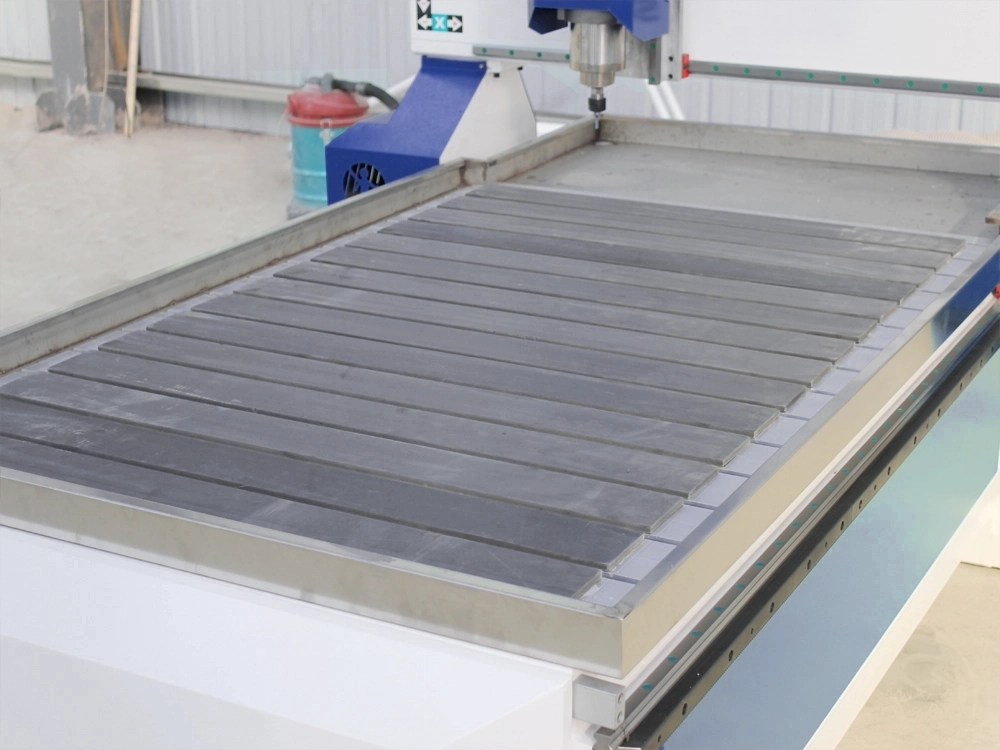

- Aluminum alloy T-slot workbench, can fix materials of various sizes, flexible to use.

- Stainless steel circulating water tank, completely wraps the aluminum alloy workbench, circulating water cooling to cool the tool and workpiece.

- Best inverter, stable speed output, large torque, minimal frequency fluctuation, ensure long-term operation of the machine.

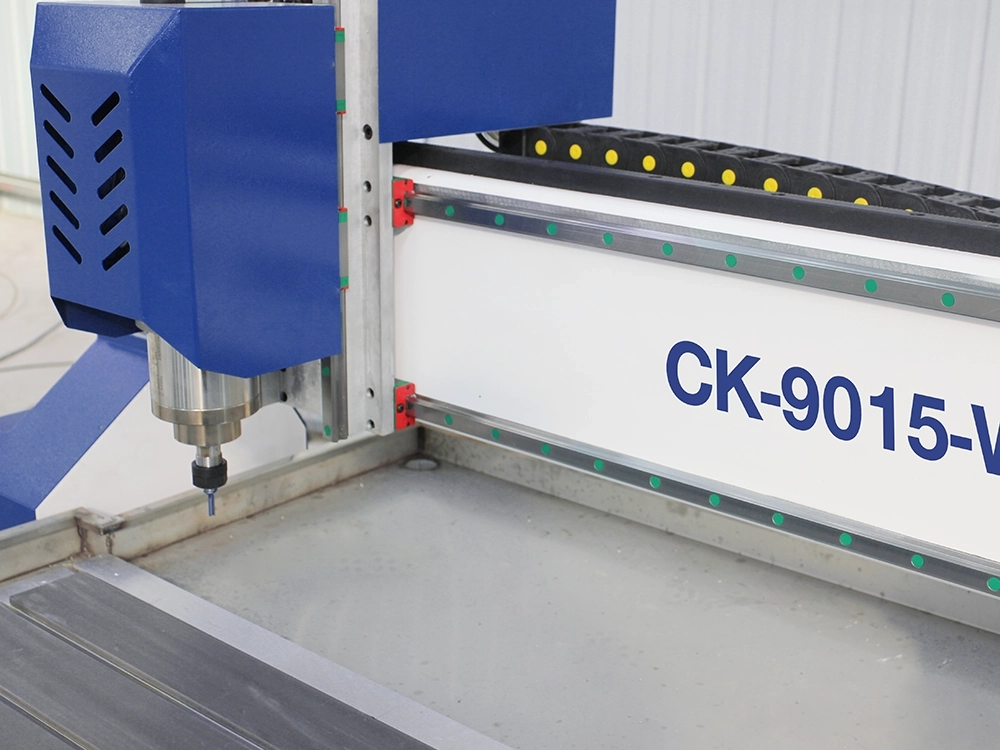

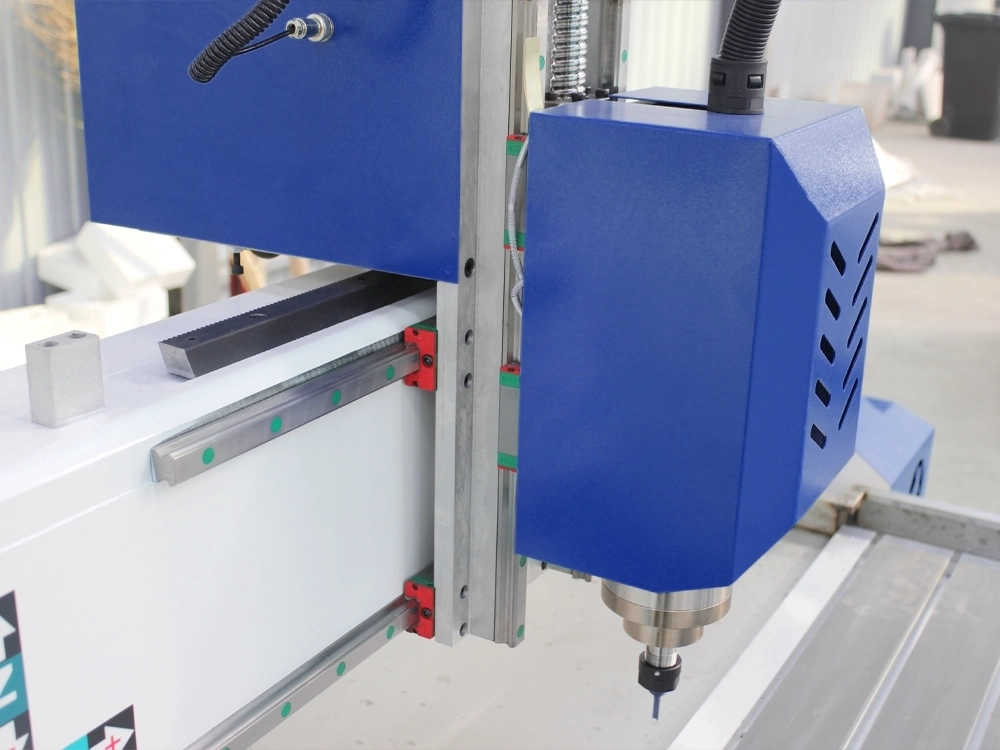

- Taiwan Hiwin linear guide/linear bearing, TBI ball screw, high-precision helical rack/gear, fast transmission speed, high positioning accuracy, suitable for various high-precision processing tasks.

- Leadshine driver/drive motor, precise torque control, running accuracy can be accurate to ±0.02mm.

- Weihong NC Studio v5.4.49 control system, compatible with various cad/cam software, supports G code files such as nc/txt/tap, full English operation interface, easy to use.

- The central lubrication system can set the automatic lubrication interval of the machine according to the actual frequency of use, and automatically lubricate and maintain the machine.

Details of Small CNC Router With Flood Cooling

- 3.2KW high-speed water-cooled spindle

Built-in four ceramic bearings, speed 24000r/m, the speed can be adjusted arbitrarily according to processing requirements.

- Aluminum alloy T-slot workbench

The surface is paved with hard PVC to keep the workbench flat, and it is fixed with a pressure plate, which can flexibly fix materials of various sizes.

- Stainless steel circulating water tank

The whole stainless steel material is used in conjunction with the circulating water pump, and the cooling water circulates continuously to cool the tool and workpiece.

- Best inverter

Stable speed output, small fluctuation, to ensure the normal operation of the spindle.

- Leadshine driver/drive motor

stable torque output, high positioning accuracy, can work continuously for 24 hours.

- Taiwan Hiwin guide rail/linear bearing, helical rack/gear

Low operating noise, high repeat positioning accuracy, to ensure that the workpiece size remains at a high standard.

Technical Parameters of Small CNC Router With Sink Workbench

| Model | CK-9015-W |

|---|---|

| Processing Size | 900*1500*200mm(Processing size can be customized) |

| Gantry | Thickened aged steel gantry, steel beam |

| Bed Base | Machining center bed processing (heavy duty bed) |

| Drive Mode | Stepper motor driver / Leadshine driver |

| Spindle Power | CATEKCNC dedicated 3.2KW high-speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Workbench | Aluminum alloy T-slot tabletop + stainless steel circulating water sink |

| Transmission Mode | The XY axis uses high-precision helical racks, and the Z axis uses Taiwan TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / linear bearing |

| Tool Shank Diameter That Can Be Clamped | 3.175mm,4mm,6mm,8mm,10mm,12.7mm etc. |

| Control System | Weihong NC Studio v5.4.49 (supports power failure/breakpoint resume) |

| Lubrication System | Automatic lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam,type3,CAD,CDR,solidworks,UG,powermill etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt etc. |

| Security System | Photoelectric sensor limiter |

| Repeat Positioning | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Empty Line Speed | 18000mm/min |

| Maximum Processing Speed | 8000mm/min |

| Dimensions | 2100*1500*1550mm |

| Weight | 850kg |

What Products Can Be Processed by a Small CNC Router With a Sink Worktable

Applicable Materials:

Wood, hardwood, cork, mdf board, plastic, pvc, pcb, acrylic, two-color board, bakelite, carbon fiber, epoxy resin, fiberglass, mica board, foam, EVA, pearl cotton, graphite, marble, granite, quartzite, artificial stone, jade, jadeite, aluminum, copper, red copper, aluminum alloy and other materials.

Application Products:

Wood carvings, seals, jade pendants, electrodes, molds, circuit boards, ashtrays, tombstones, bronze seals, badges, corporate logos, signs, electronic components, three-dimensional ornaments, audio housings, badges, architectural models, gift boxes, jewelry boxes and other products.

| Model | CK-9015-W |

|---|---|

| Processing Size | 900*1500*200mm(Processing size can be customized) |

| Gantry | Thickened aged steel gantry, steel beam |

| Bed Base | Machining center bed processing (heavy duty bed) |

| Drive Mode | Stepper motor driver / Leadshine driver |

| Spindle Power | CATEKCNC dedicated 3.2KW high-speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Workbench | Aluminum alloy T-slot tabletop + stainless steel circulating water sink |

| Transmission Mode | The XY axis uses high-precision helical racks, and the Z axis uses Taiwan TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / linear bearing |

| Tool Shank Diameter That Can Be Clamped | 3.175mm,4mm,6mm,8mm,10mm,12.7mm etc. |

| Control System | Weihong NC Studio v5.4.49 (supports power failure/breakpoint resume) |

| Lubrication System | Automatic lubrication and oiling maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam,type3,CAD,CDR,solidworks,UG,powermill etc. |

| Engraving Instructions | Standard G code, u00, mmg, plt etc. |

| Security System | Photoelectric sensor limiter |

| Repeat Positioning | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Empty Line Speed | 18000mm/min |

| Maximum Processing Speed | 8000mm/min |

| Dimensions | 2100*1500*1550mm |

| Weight | 850kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.