Small Linear ATC CNC Router Machine for Advertising Signage

Small Linear ATC CNC Router with Vacuum Adsorption

[Function Description]

The mini CNC router equipped with an automatic tool change device is powerful in function and compact in structure. It has advantages such as small floor space, low power consumption, low noise, easy operation, and automatic operation. Designed specifically for small enterprises and enthusiasts with in-depth knowledge of CNC, it is very suitable for small-scale production workshops to process small workpieces within 2*3 feet.

Equipped with a 600*900mm vacuum adsorption worktable, a 5.5KW water-cooled automatic tool change spindle, and a linear tool magazine capable of holding 6 tools, this automatic tool change system can automatically change tools according to processing requirements during the machine's operation and processing. This allows the workpiece to complete all processing procedures with only one-time clamping, effectively improving production efficiency while minimizing manual intervention to the greatest extent.

The small ATC CNC router can perform precision processing such as cutting, engraving, drilling, and grooving on various materials including wood, plastic, and metal. With the addition of the automatic tool change system, the average tool change time can be reduced to less than 5 seconds. Moreover, it effectively avoids errors caused by manual tool changes, improves the processing accuracy of workpieces and the repetitive positioning accuracy after tool changes, and increases the comprehensive processing efficiency by more than 50%.

Advantages of the Mini 2x3ft CNC Router with Automatic Tool Changer and Vacuum Adsorption

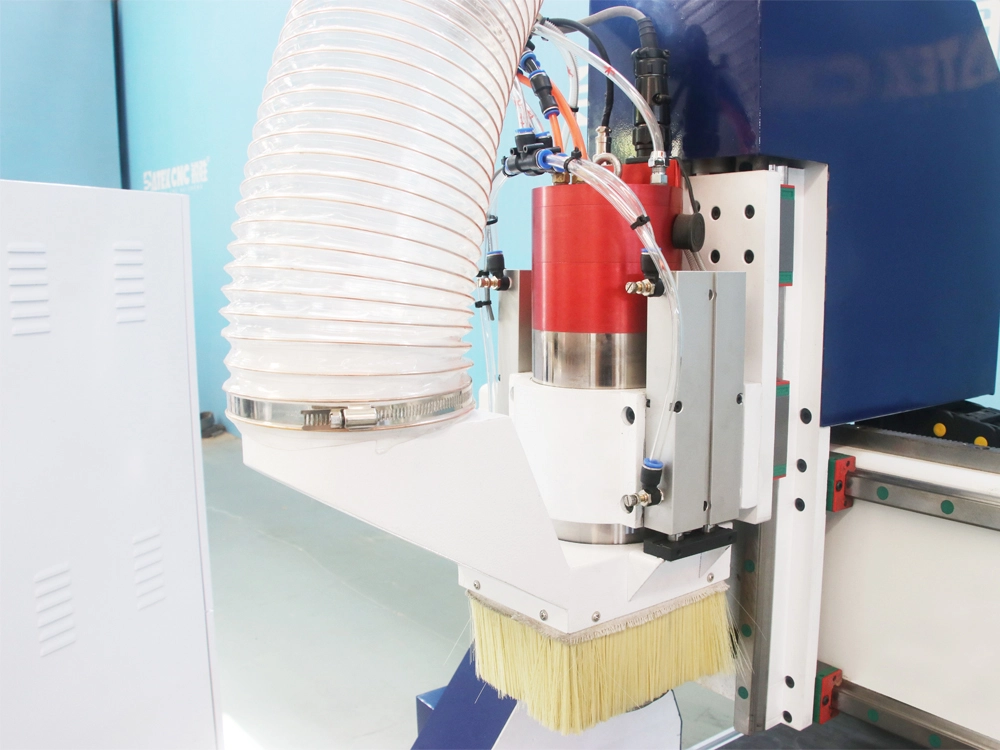

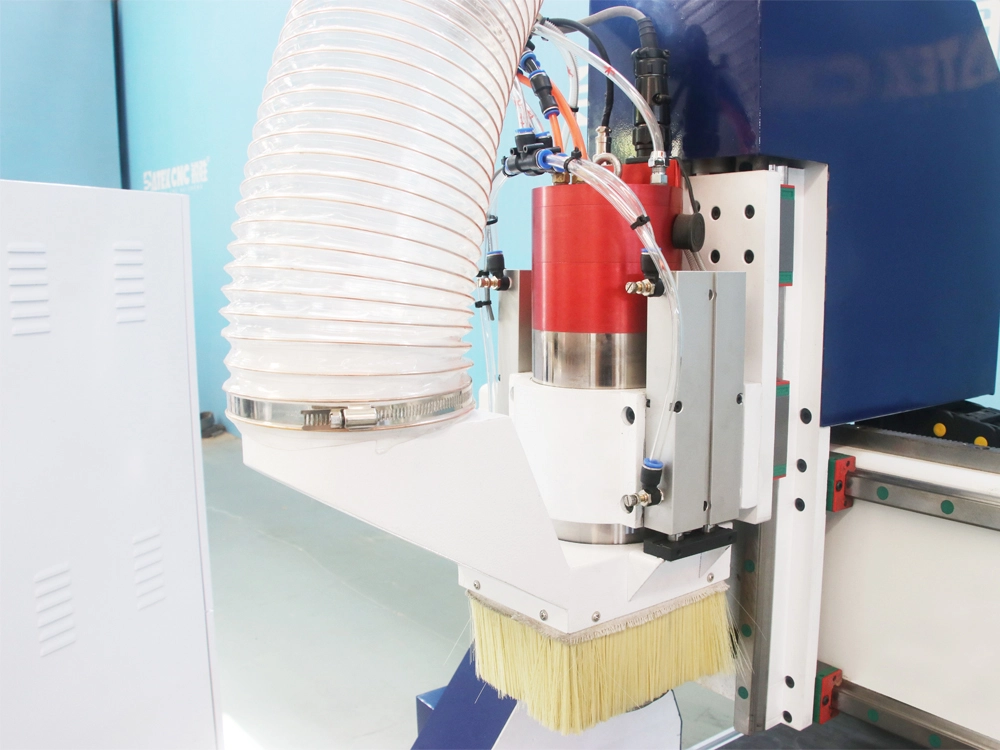

- Equipped with a 5.5KW high-speed water-cooled variable-frequency spindle, featuring a stable spindle speed of 24,000 RPM. Water cooling ensures better heat dissipation and smoother operation.

- The integrated bed is welded from thickened steel pipes and undergoes aging treatment. The guideway and rack mounting surfaces are machined using a five-axis gantry milling machine, ensuring higher machine accuracy and more precise positioning.

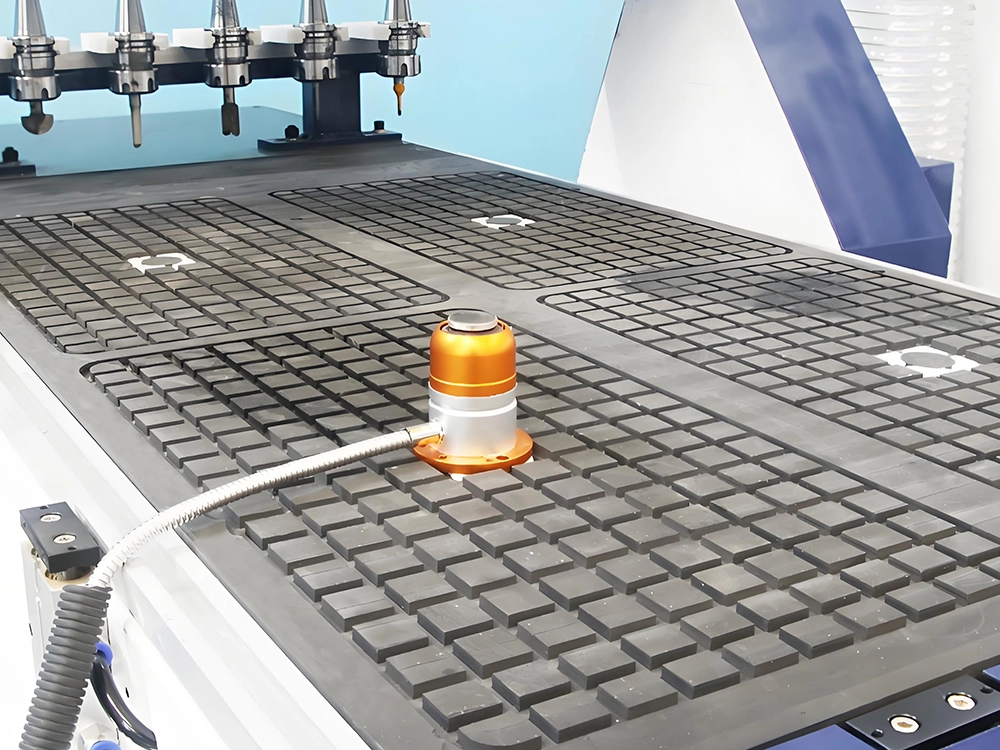

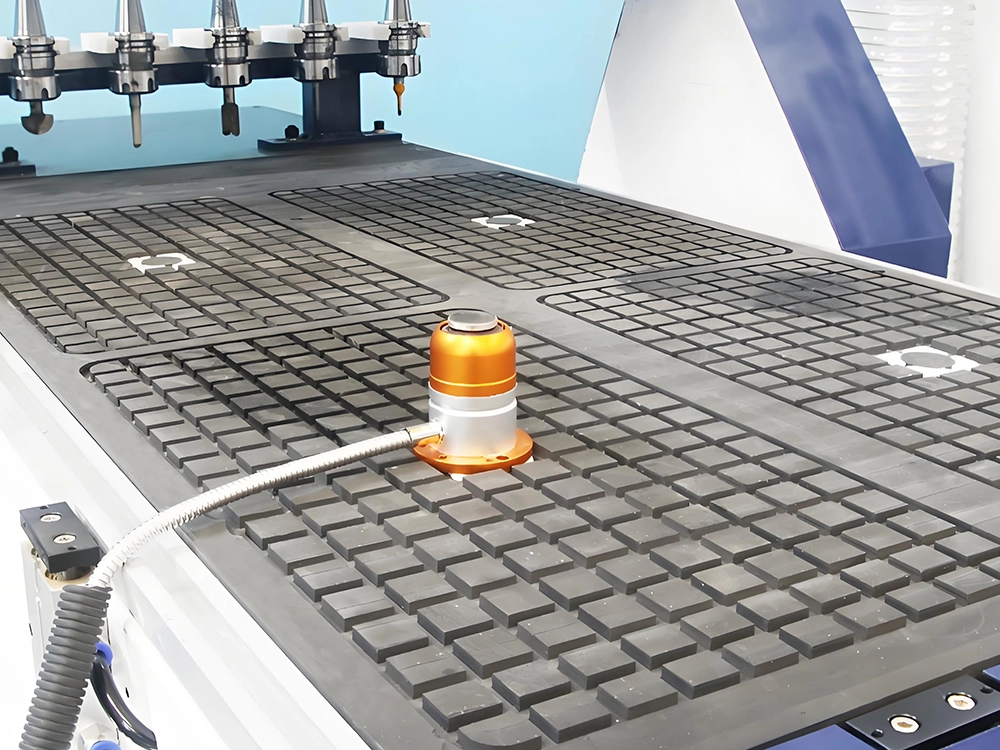

- The 600x900mm vacuum adsorption table is divided into 4 zones, each with an independent control switch. Users can freely control the activation and deactivation of the table zones based on the sheet size, making operation more convenient.

- Fitted with 2+2 positioning cylinders for batch processing. Same-sized sheets can be quickly positioned using these cylinders, simplifying sheet loading and alignment.

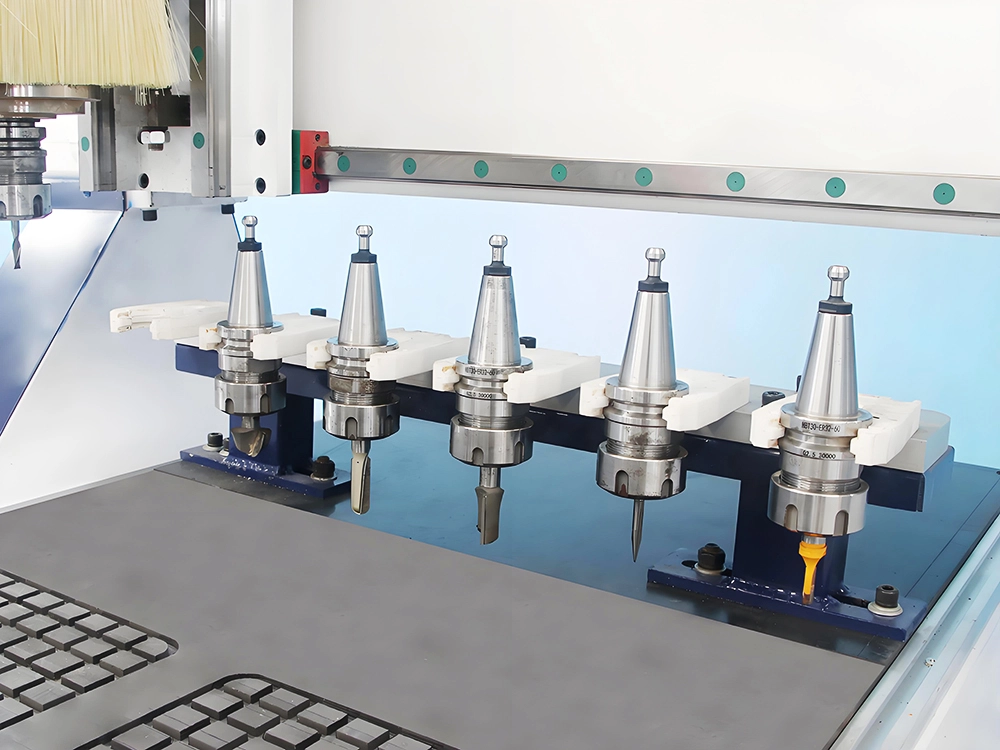

- Utilizes NBT30 tool holders and ER32 collets, with a maximum clamping shank diameter of 20mm. This offers broad compatibility and supports various types of tools.

- Features a 6-tool linear automatic tool change system, which automatically switches tools during operation based on machining requirements. This eliminates manual tool changes, reduces labor, and improves efficiency.

- Includes a 3KW dual-canister bag-type dust collector with an air volume of 3,150 m³/h. The four dust bags have a larger capacity, reducing the frequency of bag cleaning.

- In addition to the vacuum table, aluminum alloy T-slots can be installed on both sides of the worktable. This component secures materials using clamping plates, offering greater flexibility and convenience.

- Linear axes are driven by four sets of CATEKCNC self-developed 750W servo motors. The Z-axis servo motor is equipped with a brake, ensuring higher positioning accuracy and stable operation.

- The XY axes are paired with Japanese Shimpo planetary gear reducers, enabling higher operating speeds, faster braking, and improved positioning accuracy.

- Equipped with HIWIN (Taiwan) 25mm guideways / linear bearings, TBI high-precision ball screws, and high-precision helical racks/gears, ensuring high operational accuracy and fast positioning.

- An electric timed automatic lubrication system automatically lubricates various transmission parts of the machine, significantly extending its service life.

- The LNC (Taiwan) CNC system is user-friendly, even for beginners. Each function has a dedicated button, and the system supports various expansion features with an intuitive interface.

- The spindle uses a high-power Hpmont frequency converter, allowing tool speed adjustment as needed for convenient operation.

- Includes an automatic tool setter. After tool changes, the automatic tool setter can calibrate the tool tip position to zero, eliminating manual calibration and saving time.

- A wireless pulse handwheel controller enables precise movement of the XYZ axes. The handwheel also features a simulation mode for pre-verifying designs and checking machine status, ensuring machining success.

- Controlled via standard G-code, compatible with various CAD/CAM software types.

- Powered by a high-power water-ring vacuum pump, providing stronger negative pressure for more stable board fixation. Air-cooled vacuum pumps or rotary vane vacuum pumps are available as options.

Details of the Mini 2x3ft CNC Router with Automatic Tool Changer and Vacuum Adsorption

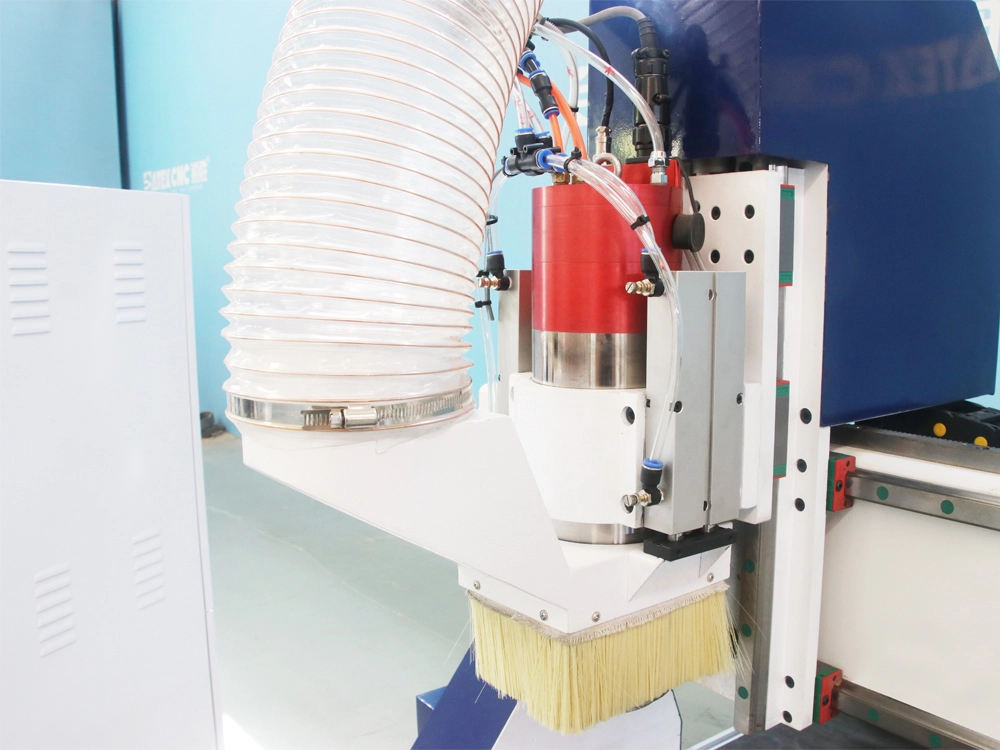

- 5.5kw water-cooled ATC spindle

Utilizes water circulation cooling for superior heat dissipation, ensuring stable operation and enabling 24-hour continuous production.

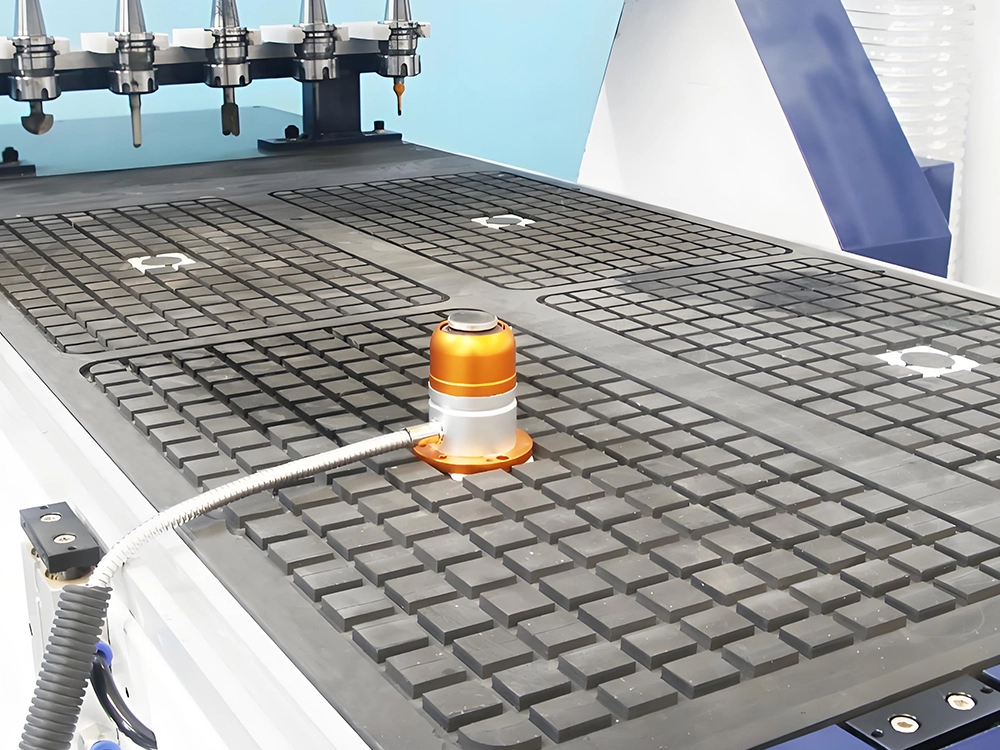

- Vacuum adsorption + T-slot table

Composite worktable design allows rapid material fixation via vacuum suction or traditional clamping plates.

- Linear tool magazine

6-tool capacity magazine compatible with NBT30 tool holders and ER32 collets, accommodating various tool types for flexible machining.

- Automatic tool setter

Automatically measures tool tip position and calibrates zero points after tool changes, eliminating manual intervention and saving setup time.

- Clamping device for separating the tool and the holder

Facilitates rapid tool installation and replacement by specialized holder docking mechanism.

- Wireless pulse handwheel

Enables precise tool calibration and path simulation through intuitive manual control of all linear-axes.

- Automatic lubrication system

Programmed lubrication intervals ensure consistent maintenance of transmission components, preventing potential downtime from manual lubrication delays.

- Taiwan LNC control system

User-friendly interface with multi-language support simplifies operation. Requires minimal training, allowing operators to work efficiently without specialized technical expertise.

Technical Parameters of Mini 2x3ft CNC Router with Automatic Tool Changer and Vacuum Adsorption

| Model | CK-6090-T |

|---|---|

| XYZ Working Travel | 600*900*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beam |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | 5.5 KW high-power water-cooled ATC spindle |

| Spindle Speed | 0–24,000 rpm |

| Tool Holder Type | NBT30 ER32, max. shank diameter Φ20 mm |

| Driving Mechanism | 4× CATEKCNC self-developed 750W pure servo motors (Z-axis with brake motor) |

| Reducer | Japanese Shimpo planetary gear reducers |

| Tool Magazine | 6 linear tool magazine |

| Tool Setting | Automatic tool setter |

| Table | Vacuum adsorption + aluminum alloy T-slot table |

| Vacuum Pump | 5.5 KW water-ring vacuum pump |

| Transmission Mechanism | XY-axis: high-precision ground helical gears; Z-axis: high-precision TBI ball screw |

| Guideway | Taiwan HIWIN high-precision 25mm square linear rails / 25mm flange sliders |

| Equipment Cable | High-flexibility pure copper anti-bending cables + high-strength cable drag chains |

| Dust Extraction | 3KW dual-bag dust collector |

| Control System | Taiwan LNC dedicated cutting control system + wireless pulse handwheel |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC 380V/220V, 50/60 Hz |

| Compatible Software | ArtCam, Type3, CAD, JDPaint, Mastercam, PowerMill, etc. |

| Engraving Instruction | Standard G code |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max.Working Speed | 15,000mm/min |

| Max.Rapid Speed | 35,000mm/min |

| Weight | 700kg |

| Dimensions | 1500*1200*1500mm |

Application of the Mini Linear ATC CNC Router with Vacuum Adsorption

Applicable Materials:

- Wood boards & other boards: Solid wood, MDF, particle board, plywood, plasterboard, multi-layer board, etc.

- Plastics & composites: PVC, acrylic, PVC foam board, PTFE board, aluminum composite panel, etc.

- Engineering materials: ABS, PP, PE, epoxy resin, carbon fiber, artificial stone, PCB, acrylic glass, KT board, etc.

- Metals: Aluminum, copper, etc.

Applicable Industries:

- Wooden crafts: Carved patterns, hollow decorations, wooden artifacts, ornaments, custom badges, etc.

- Advertising products: Acrylic letter cutting, two-color plate engraving, nameplates, department signs, road signs, wooden/plastic/acrylic signs, etc.

- Molds & metal products: Aluminum/copper plates, wood molds, hot stamping molds, printing plates, seals, chocolate/candy/biscuit molds.

- Special material processing: Carbon fiber, resin, epoxy board engraving, PCB circuit boards, etc.

How to Maintain a Mini CNC Router with Automatic Tool Changer?

Timely and proper maintenance ensures that your small CNC router remains in optimal operating condition. Regular upkeep effectively reduces machine downtime, minimizes malfunctions, and guarantees machining accuracy.

- Regular Cleaning

After each use, remove dust, debris, and residual materials from the CNC router.

Use compressed air to clean transmission components, preventing blockages that may affect machining precision.

Regularly check whether guideways, ball screws, and linear bearings have sufficient lubricant. If surfaces are dry, replenish with appropriate lubricating oil.

Periodically clean dust and debris inside the control cabinet. After powering off, open the cabinet and use compressed air to blow away dust. Check for loose wiring and clean dust from cooling fans.

Regularly inspect spindle coolant water to ensure it is clean and free of impurities. Replace the coolant periodically.

In cold weather, add antifreeze to prevent freezing. Verify that the water ring pump functions properly and that water tubes are not bent.

- Tool Changer Inspection

Regularly check whether the ATC system operates correctly and functions normally.

Clean tool holders and their internal taper holes periodically to ensure they are free of dust and oil residue.

Keep the tool magazine and tool racks clean and securely fixed to prevent errors during tool changes.

- Replacing Worn Tools

Frequently inspect tools and replace those that are severely worn or damaged.

Sharp tools improve cutting quality and reduce material waste.

| Model | CK-6090-T |

|---|---|

| XYZ Working Travel | 600*900*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, reinforced steel beam |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | 5.5 KW high-power water-cooled ATC spindle |

| Spindle Speed | 0–24,000 rpm |

| Tool Holder Type | NBT30 ER32, max. shank diameter Φ20 mm |

| Driving Mechanism | 4× CATEKCNC self-developed 750W pure servo motors (Z-axis with brake motor) |

| Reducer | Japanese Shimpo planetary gear reducers |

| Tool Magazine | 6 linear tool magazine |

| Tool Setting | Automatic tool setter |

| Table | Vacuum adsorption + aluminum alloy T-slot table |

| Vacuum Pump | 5.5 KW water-ring vacuum pump |

| Transmission Mechanism | XY-axis: high-precision ground helical gears; Z-axis: high-precision TBI ball screw |

| Guideway | Taiwan HIWIN high-precision 25mm square linear rails / 25mm flange sliders |

| Equipment Cable | High-flexibility pure copper anti-bending cables + high-strength cable drag chains |

| Dust Extraction | 3KW dual-bag dust collector |

| Control System | Taiwan LNC dedicated cutting control system + wireless pulse handwheel |

| Lubrication System | Centralized electric oil-lubrication system |

| Operating Voltage | AC 380V/220V, 50/60 Hz |

| Compatible Software | ArtCam, Type3, CAD, JDPaint, Mastercam, PowerMill, etc. |

| Engraving Instruction | Standard G code |

| Security System | Photoelectric over-travel limit protection on three linear axes |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Max.Working Speed | 15,000mm/min |

| Max.Rapid Speed | 35,000mm/min |

| Weight | 700kg |

| Dimensions | 1500*1200*1500mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.