Cheap CNC Mini Advertising Sign Making Machine Suitable for Personal Studio

Mini CNC Router Suitable For Small Woodshop and Beginners

[Function Description]

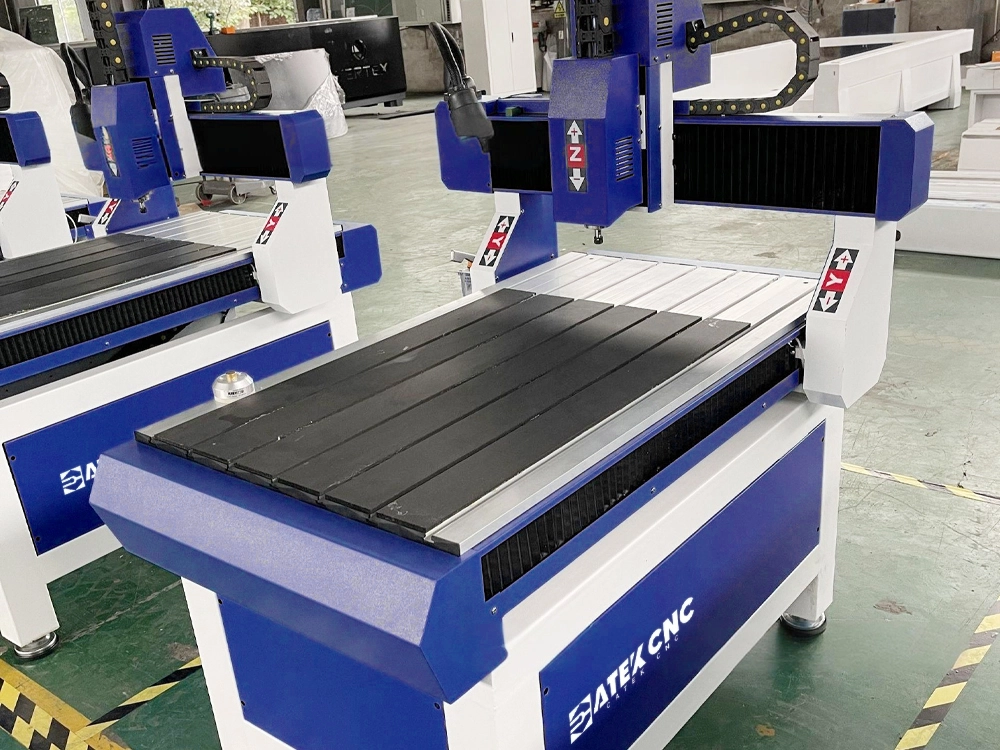

The small mini CNC router is designed for small studios and amateur DIY enthusiasts. It has the advantages of small footprint, low power consumption, low noise, very simple operation and low price. You only need $1,800 to buy the most basic model, which is more suitable for use in small studios. It uses an optimized PC CNC system, is easy to operate, and is compatible with various common CAD/CAM type software. Even CNC beginners can quickly master how to use it. It uses a water-cooled spindle with a fast speed and can work continuously for 24 hours. It can be used to process various small crafts, personalized aluminum metal signs, wooden signs, small decorations, signboards, etc. Compared with manual engraving, it is faster, has higher processing accuracy, and is more exquisite, delicate and fine than manual engraving.

Advantages of Small Mini CNC Wood Router

- The CNC sign engraving machine uses a 2.2kw high-speed water-cooled variable frequency spindle, which can adjust the speed at will, can hold a maximum of 1/2-inch tool handle, is compatible with many tools, and is flexible to use.

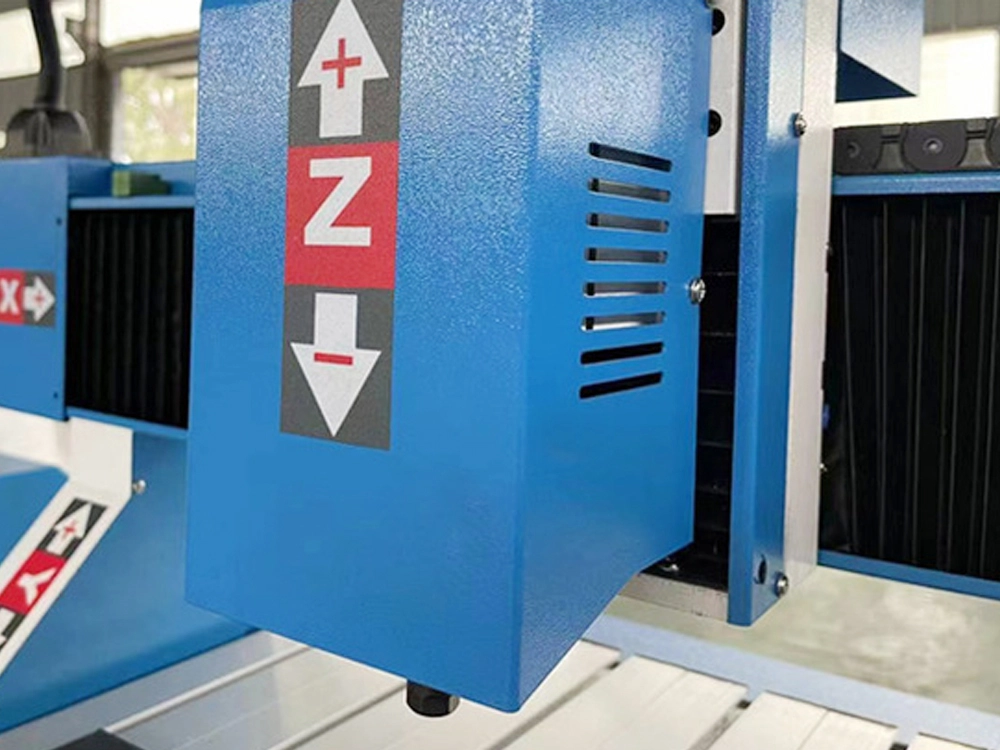

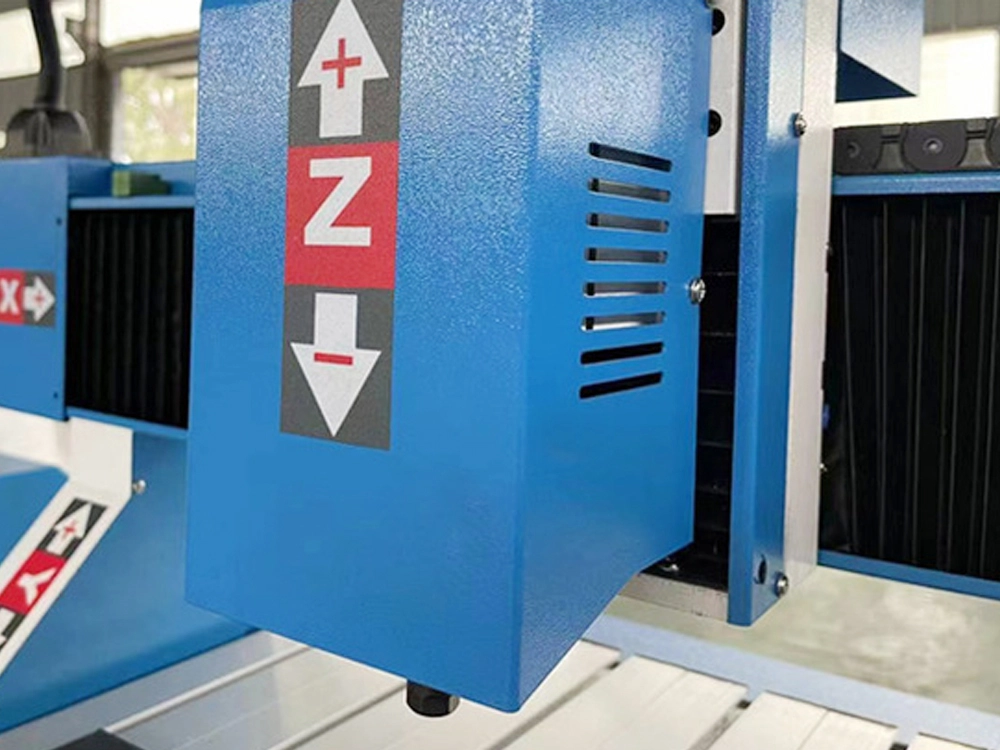

- The three axes of XYZ are all driven by high-precision TBI ball screws, and are used in conjunction with Hiwin guide rails/sliders, with high processing accuracy and precise positioning.

- It uses an integrated bed, a high-strength gantry bracket, and a built-in chassis for the bed, which has a compact structure, saves more space, and runs stably.

- Using a central lubrication system, the machine can be lubricated and maintained by itself according to actual use, which is simple and convenient.

- The small CNC router has good compatibility and supports various CAD/CAM type software, such as artcam, type3, jdpaint, etc.

- The xy axis uses a fully enclosed dust cover to ensure the stability and accuracy of the machine for long-term use and extend its service life.

- The control system is easy to operate and supports power-off/breakpoint continuation, so it can continue to work after an emergency.

- T-slot + hard PVC board workbench, use clamps to fix the workpiece, simple operation and flexible use.

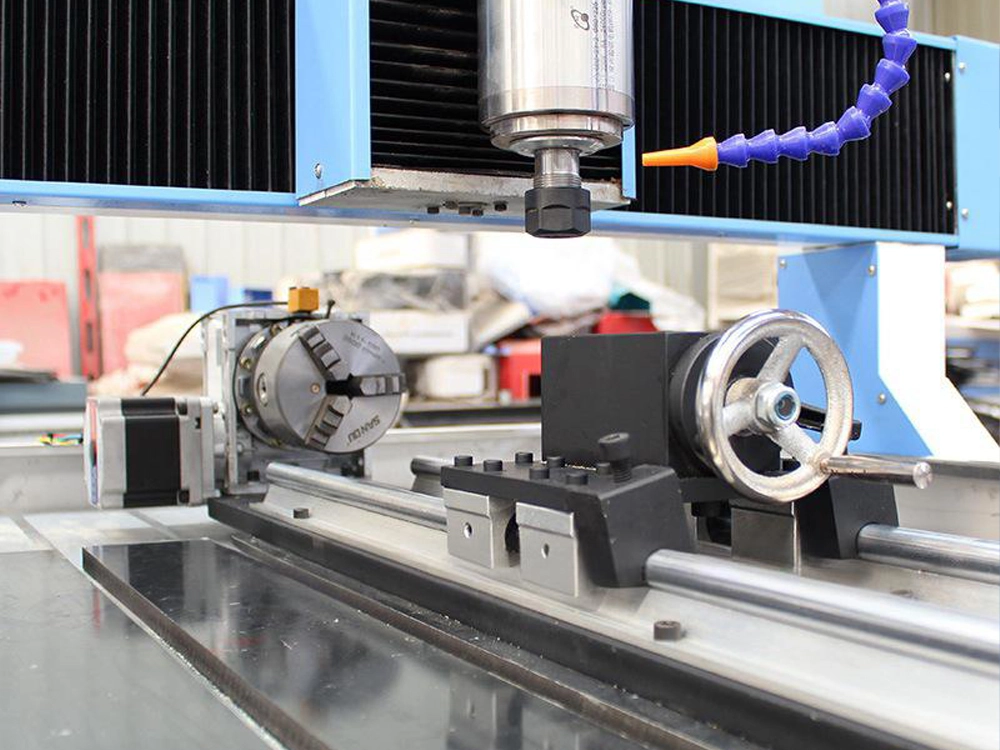

- Optional 3D rotation axis for 3D caving.

Details of Mini CNC Router

- Water-cooled spindle

-

High-speed water-cooled spindle, with a maximum speed of up to 24000r/min, is more suitable for long-term engraving operations.

- Aluminum alloy T-slot workbench

-

More flexible and convenient clamping of small workpieces.

- DSP controller

-

Easy-to-use control handle, supports power-off and resume engraving.

- Spindle protection hood

-

Prevent the spindle from being damaged by collision.

- Optional fourth rotary axis

-

The device can clamp a workpiece and rotate it so as to process multiple faces or surfaces-of-revolution of the workpiece.

- Optional cooling spray system

-

This system cools the tool and flushes away material chips.

Technical Parameters of Small Mini CNC Wood Sculpting Machine

| Model | CK-6090 |

| XYZ Working Travel | 600*900*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, steel beam |

| Bed | The bed by machining center processed (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 2.2KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Stepper motor driver / Yako/Leadshine motor driver |

| Frequency Converter | BEST/Hpmont inverter |

| Table | Aluminum alloy T-slot table |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V/50/60HZ |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Processing Speed | 12000mm/min |

| Weight | 550kg |

| Dimensions | 1300*1100*1350mm |

Optional Accessories for The Mini CNC Router

| Control System | Richauto DSP/Mach3 etc. |

| Spindle | 1.5/2.2/3.5/4.5KW air-cooled/water-cooled spindle |

| Table | Vacuum adsorption table |

| Tool setting method | Automatic tool setting instrument |

| Pressure Roller | Double rod pneumatic pressure roller |

| Motor | Hybrid servo/servo motor |

| 3D Carving | Fourth rotary axis |

| Dust Removal | Double-barrel bag vacuum cleaner |

Application Scope of Small Mini CNC Router

Small mini CNC routers can be used in the advertising industry, toy industry, small commodity industry, small handicraft industry, etc. They can be used to manufacture various products, such as cutting advertising words, wood carving, handicraft carving, crystal word cutting and other small product processing. They are suitable for various small studios or amateur personal enthusiasts. The following are some common applications for you.

- Wooden handicrafts: embossed patterns, hollow decorations, wood flower carvings, cabinet parts, wooden badges, etc.

- Advertising industry supplies: advertising signs, acrylic word cutting, two-color plate carving, badges, department signs, road signs, wooden signs, plastic signs, acrylic signs, etc.

- Molds and metal products: aluminum signs, copper signs, wooden molds, hot stamping molds, printing molds, seals, chocolate molds, candy molds, biscuit molds, etc.

- Products made of other special materials: carbon fiber, resin, epoxy board engraving, PCB circuit boards, etc.

The Following Are the Processable Products of Mini CNC Router

| Model | CK-6090 |

|---|---|

| XYZ Working Travel | 600*900*200mm (customizable according to processing requirements) |

| Gantry | Thickened aged steel gantry, steel beam |

| Bed | Machining center bed processing (heavy duty bed), independent anti-interference control cabinet |

| Spindle | CATEKCNC dedicated 2.2KW high speed water-cooled variable frequency spindle |

| Spindle Speed | 6000-24000r/min |

| Driving Mode | Stepper motor driver / Yako/Leadshine motor driver |

| Frequency Converter | BEST/Hpmont inverter |

| Table | Aluminum alloy T-slot table |

| Transmission Mode | XY axis high-precision ground helical rack drive + Z axis high-precision TBI ball screw drive |

| Guideway | Taiwan Hiwin high precision linear square rail / flange slider |

| Equipment Cable | Pure copper anti-bending high-flexible cable |

| Holdable Tool Shank Diameter | 3.175mm, 4mm, 6mm, 12.7mm, etc., ER20/ER25 |

| Control System | NCStudio V5.4.49 (support resuming carving after power outage) / Richauto DSP / Mach3 |

| Lubrication System | Electric oil injection maintenance system |

| Operating Voltage | AC380V/220V 50/60Hz |

| Compatible Software | Artcam, type3, AutoCAD, CDR, JDpaint, etc. |

| Engraving Instruction | Standard G code, u00, mmg, plt |

| Security System | XYZ three-axis all photoelectric limit |

| Repeat Positioning Accuracy | ±0.02mm |

| Engraving Accuracy | 0.01mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 550kg |

| Dimensions | 1300*1100*1350mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.