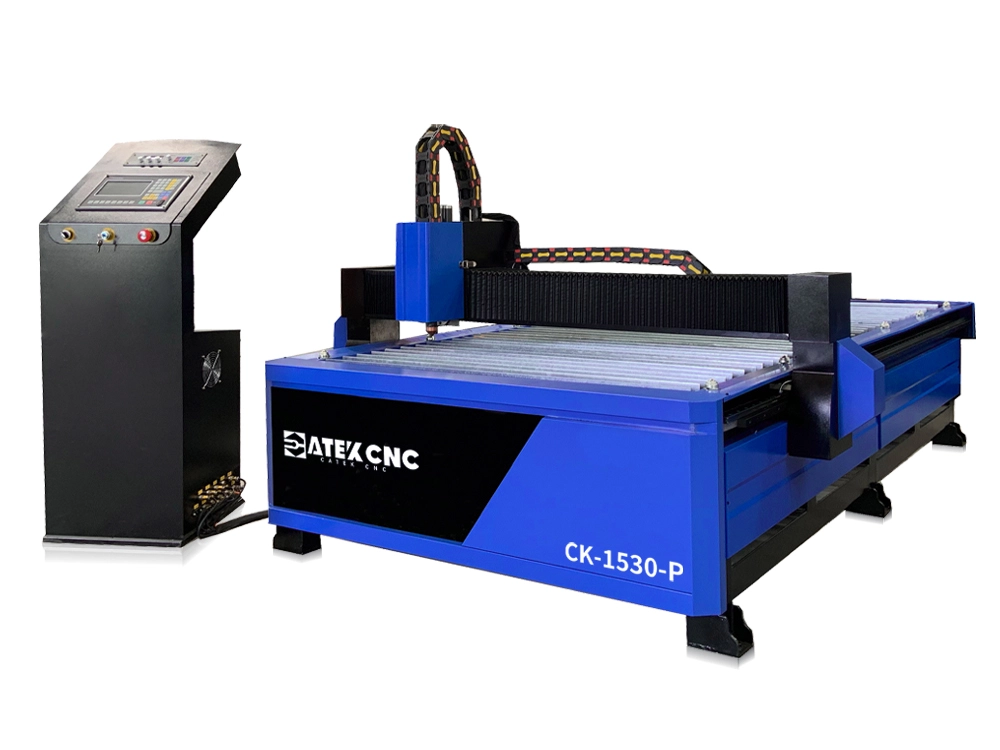

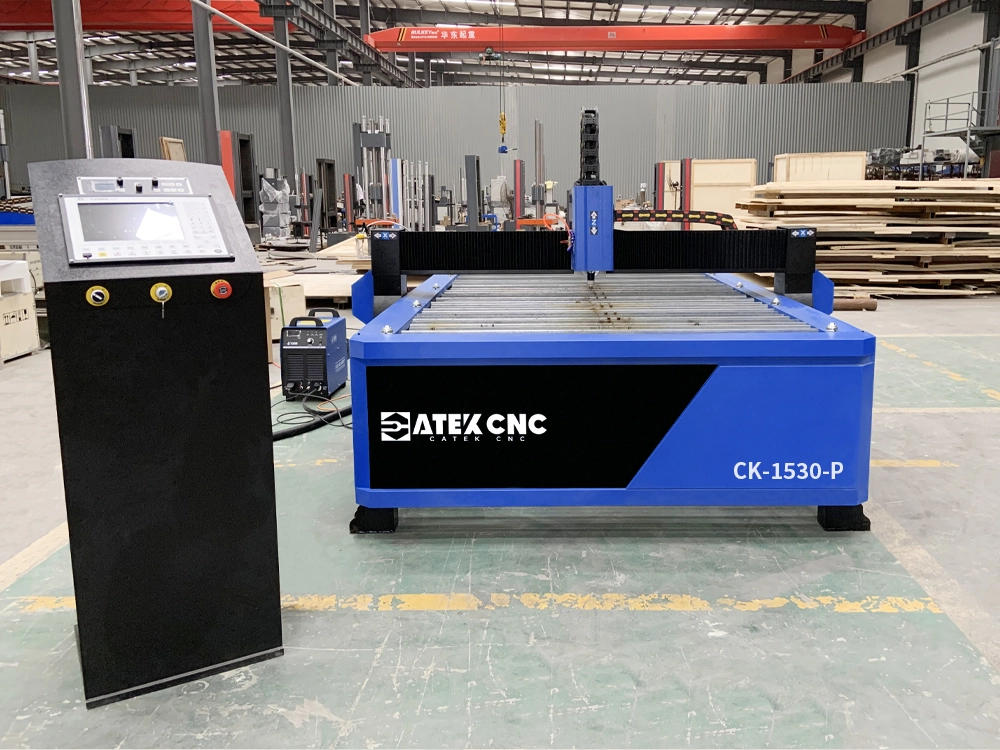

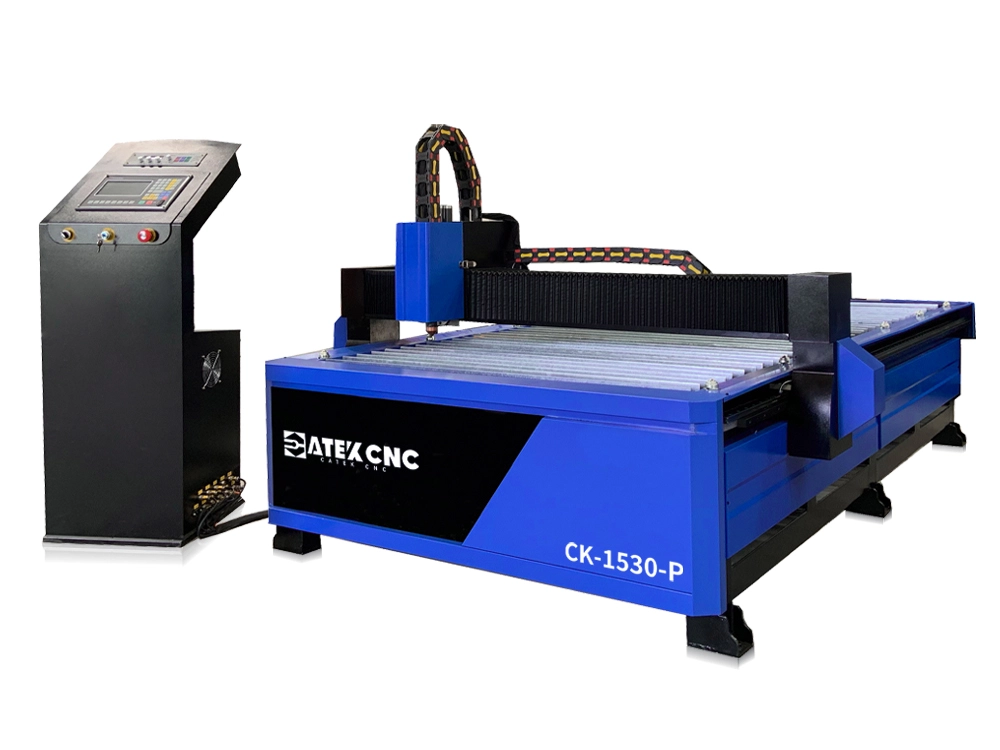

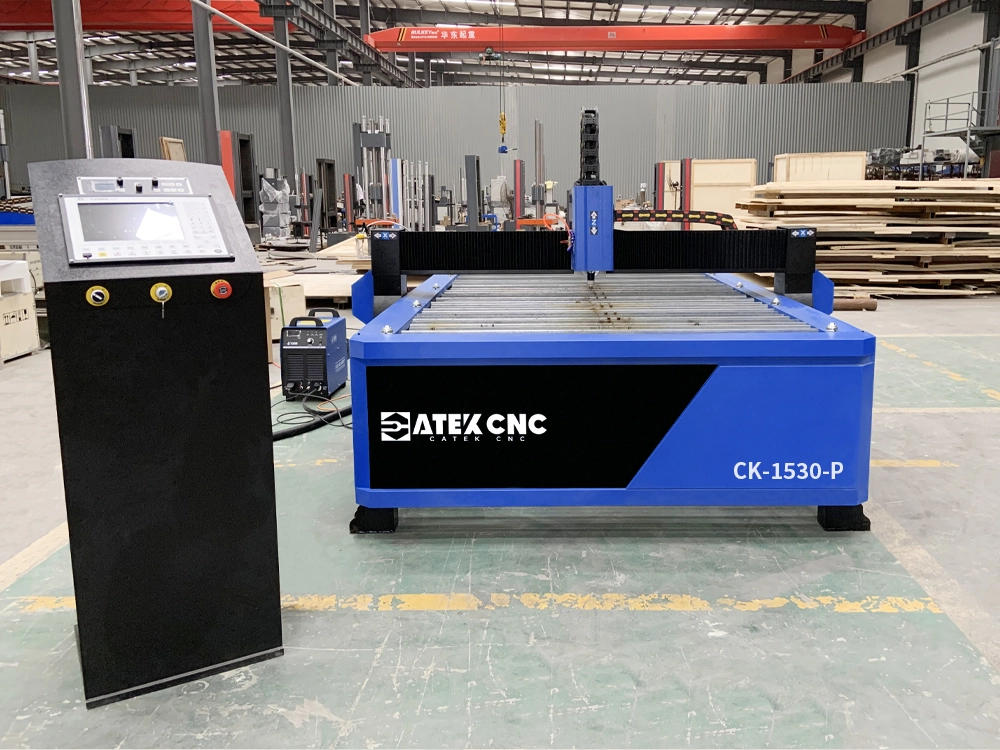

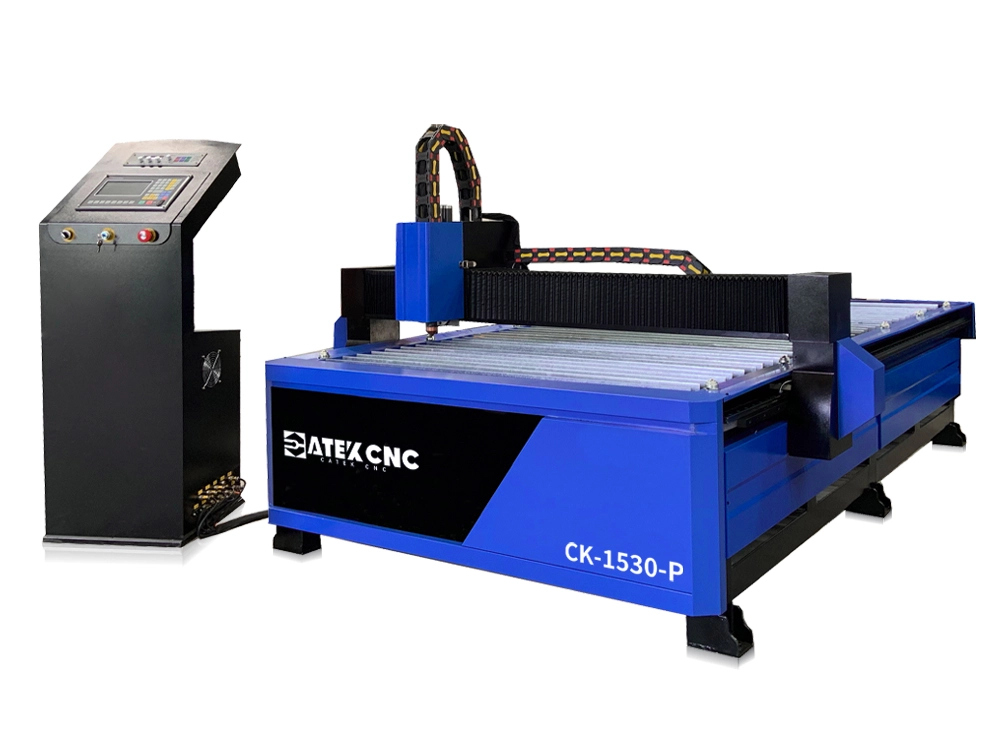

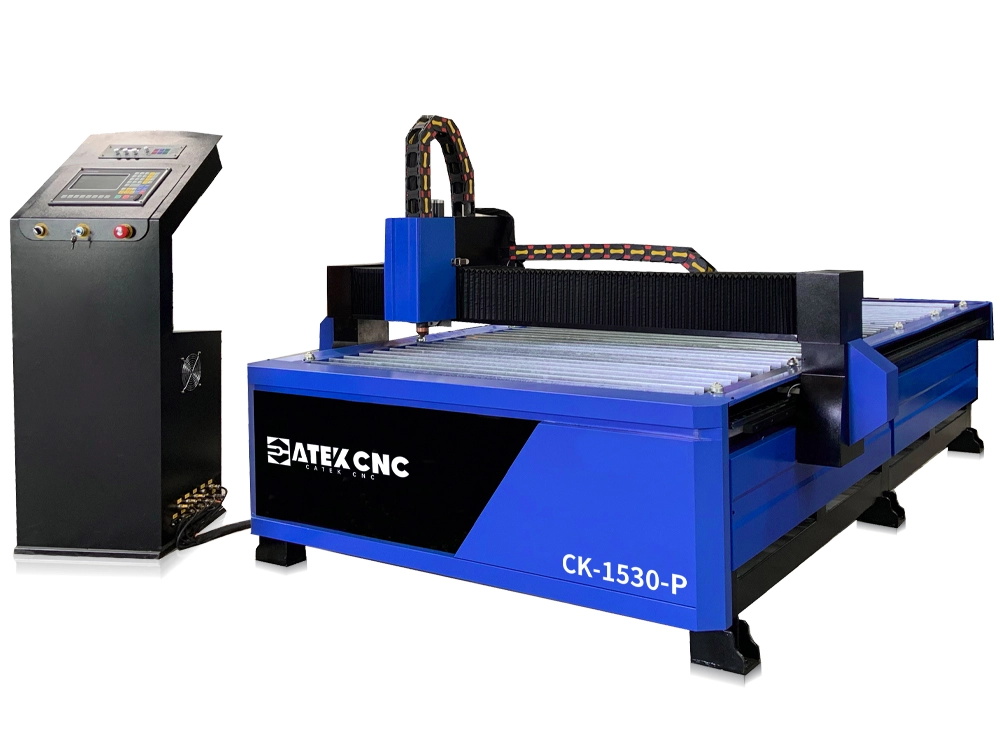

CNC Plasma Cutting Machine for Sale with Large Table

High Precision 5x10ft CNC Plasma Cutter for Metal Plate

[Function Description]

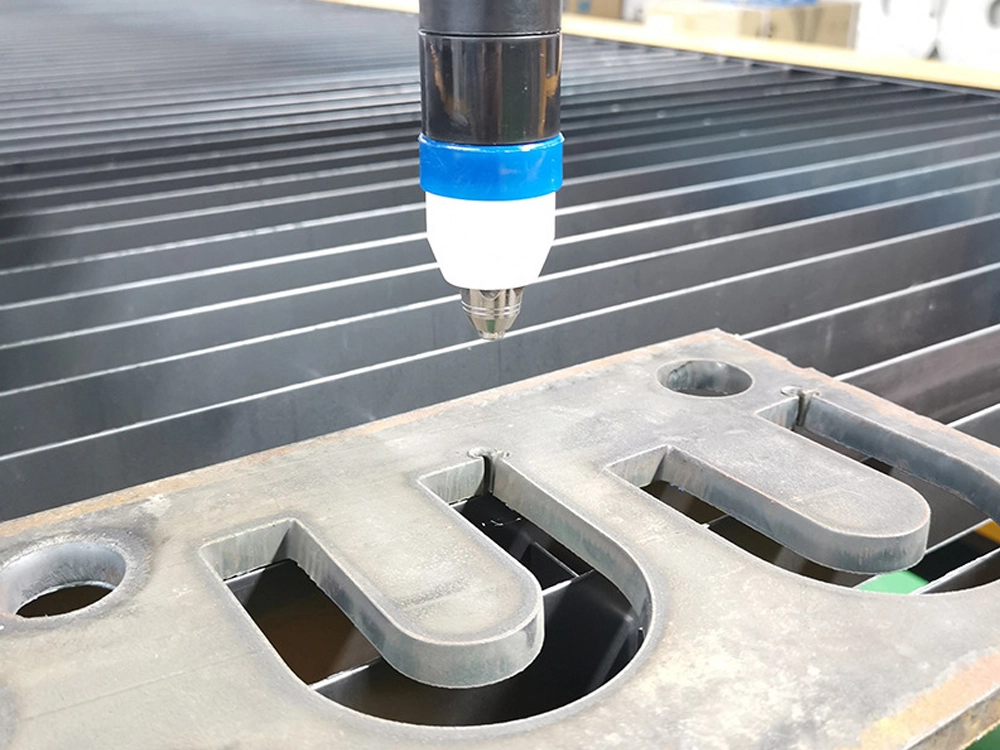

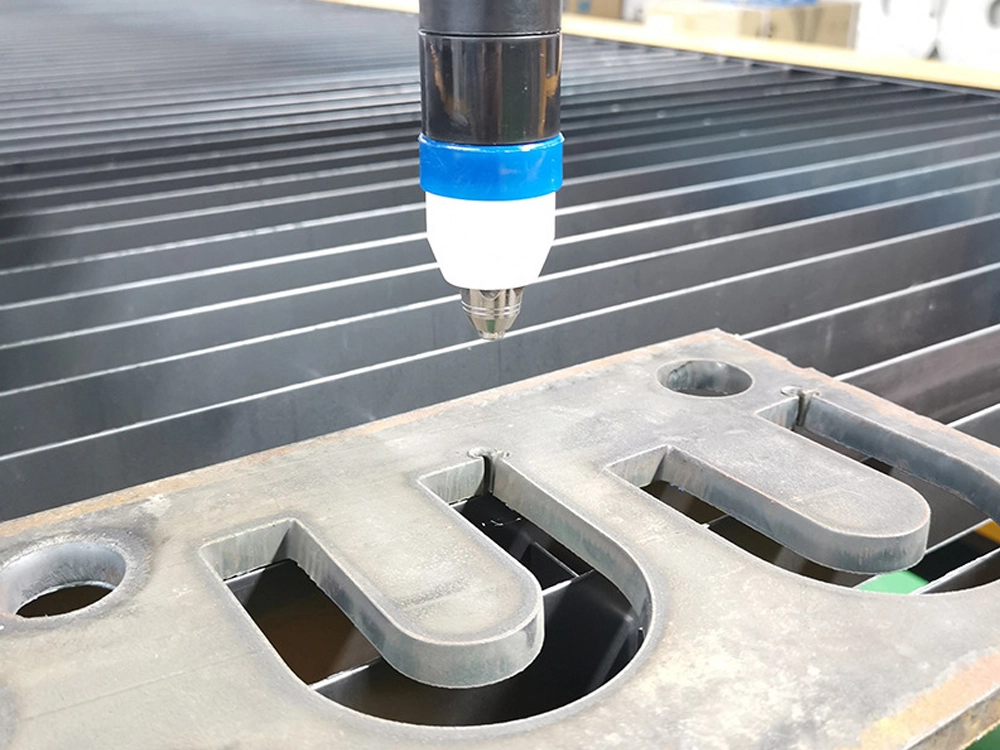

The 1530 CNC plasma cutting machine features a full-size worktable of 1500*3000mm, with a processing speed of over 15,000 mm/min. Compared to traditional flame cutting, it offers faster processing speeds, making it more suitable for batch production. During production, different power plasma power supplies and cutting heads can be selected based on the cutting thickness to meet various industrial needs.

The CNC plasma cutting machine is capable of longitudinal and horizontal straight-line cutting as well as curved cutting such as arcs. The Y-axis is driven by dual motors, and the XYZ axes use high-precision ground helical racks and TBI ball screws, ensuring high-precision processing and fast operation. The CNC system is equipped with automatic arc ignition, providing stable performance and supporting standard G-code path files generated by various software, ensuring broad compatibility. The machine is designed with a lightweight beam and gantry structure, offering low self-weight and small motion inertia, making it more suitable for industrial production.

Additionally, plasma cutting machines are cost-effective, priced at less than a quarter of fiber laser cutting machines. They can cut various types of metal sheets, including stainless steel, aluminum, copper, titanium, and other non-ferrous metals, especially materials that are difficult to process with oxygen cutting. The cutting quality is close to that of laser cutting, while the operational and maintenance costs are lower than those of laser cutting, making them widely popular among users.

Advantages of 5x10-Foot High Performance Plasma Cutter

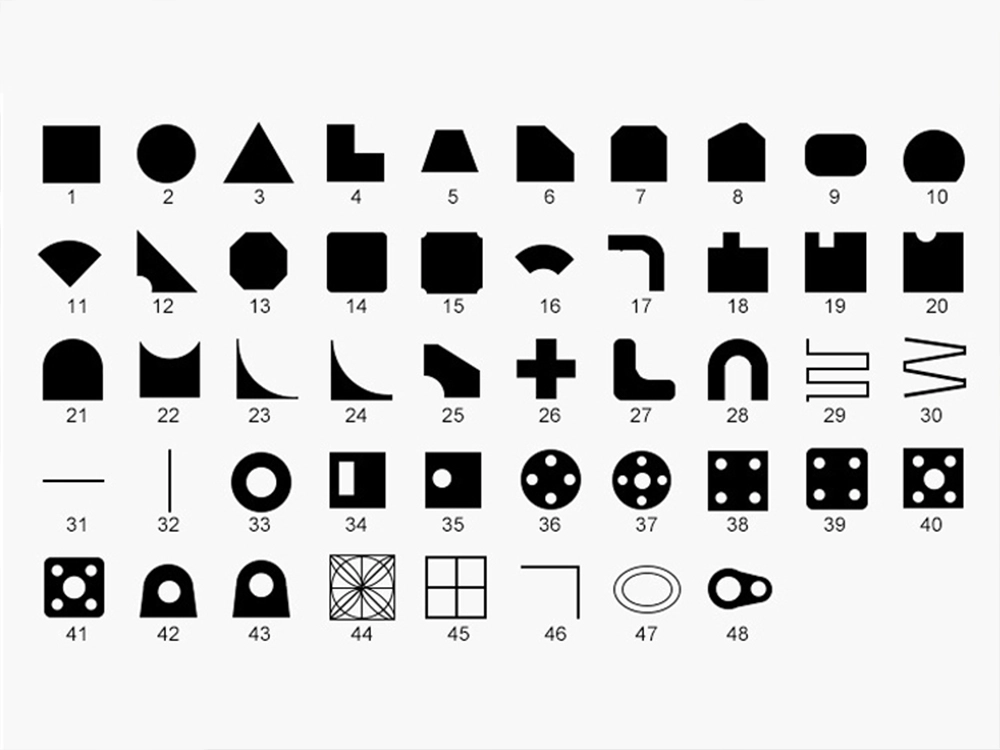

- Using plasma-specific nesting software, simply select the desired cutting pattern in the software, input the corresponding dimensions, and it will automatically generate unfolded drawings, nesting layouts, and cutting program G-code. Import the G-code into the control system via a USB drive for cutting.

- Equipped with a dedicated plasma cutting machine control system, it supports multiple languages, features a user-friendly interface, and is easy to operate. Beginners can perform various operations after minimal training.

- It includes functions such as automatic kerf compensation, retrace processing, and power-off continuation, ensuring uninterrupted operation.

- When cutting curved paths, the machine automatically decelerates at turns, effectively improving cutting quality.

- The CNC system is highly reliable, with self-diagnostic capabilities for fault detection, making operation simpler.

- The nesting software features a unique nesting algorithm, improving material utilization by over 10%, enhancing processing efficiency, and reducing material waste.

- The bed base is constructed with thickened steel tubes, stress-relieved for high strength, precision, and resistance to deformation.

- Taiwan HIWIN square guides ensure high precision, low operating noise, maintenance-free operation, and a long service life.

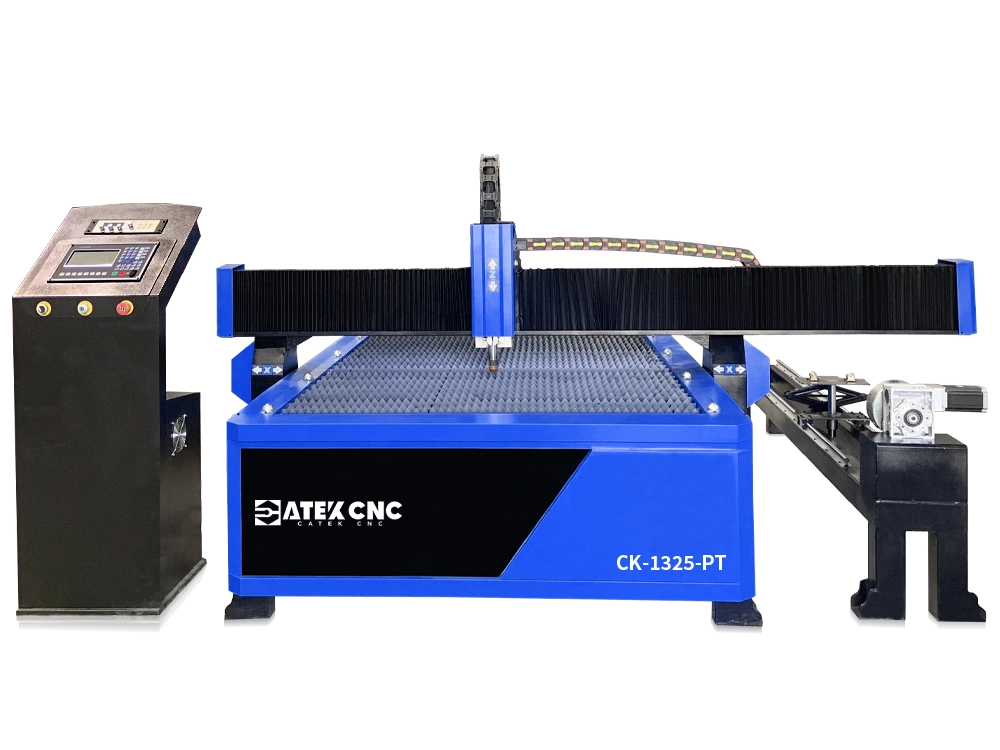

- An optional water tank worktable effectively absorbs smoke and metal dust generated during processing, making it more environmentally friendly.

- Equipped with anti-collision safety limit design, it reduces the risk of operational errors.

Details of 5x10 CNC Plasma Cutter

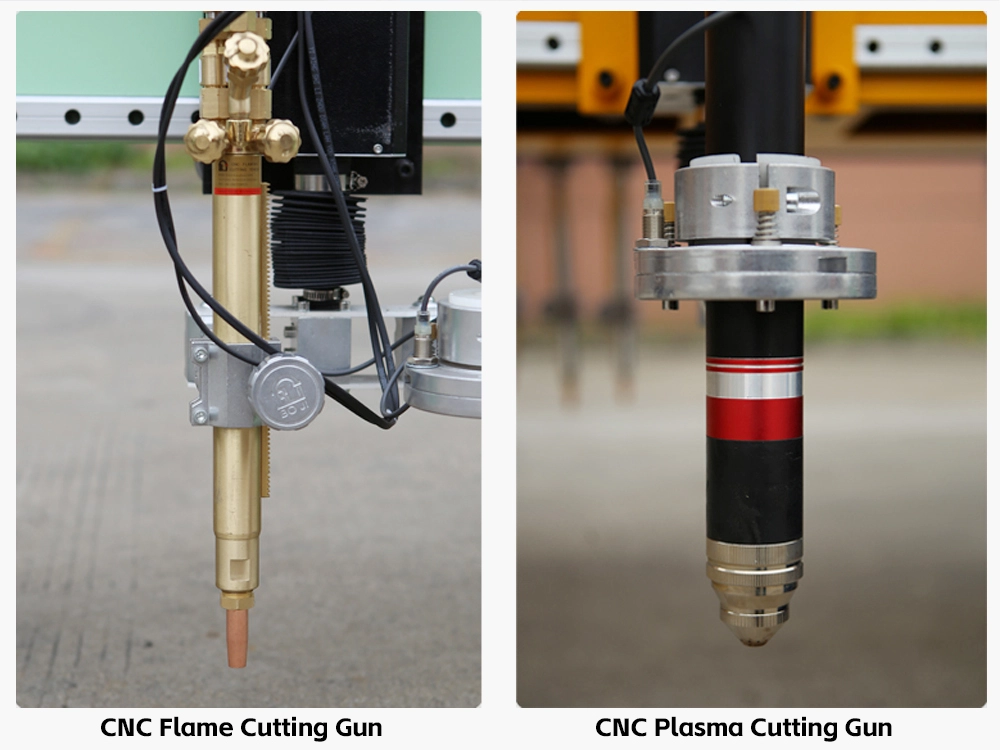

- Can be equipped with two types of cutting guns

-

High power plasma cutting gun + flame cutting gun (freely switchable).

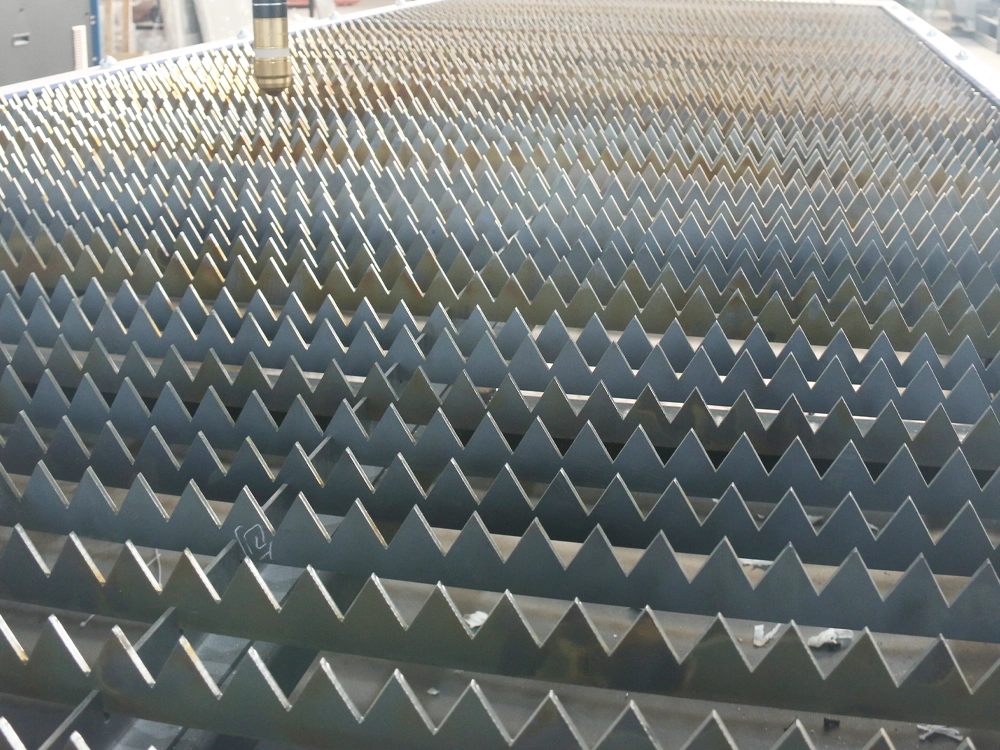

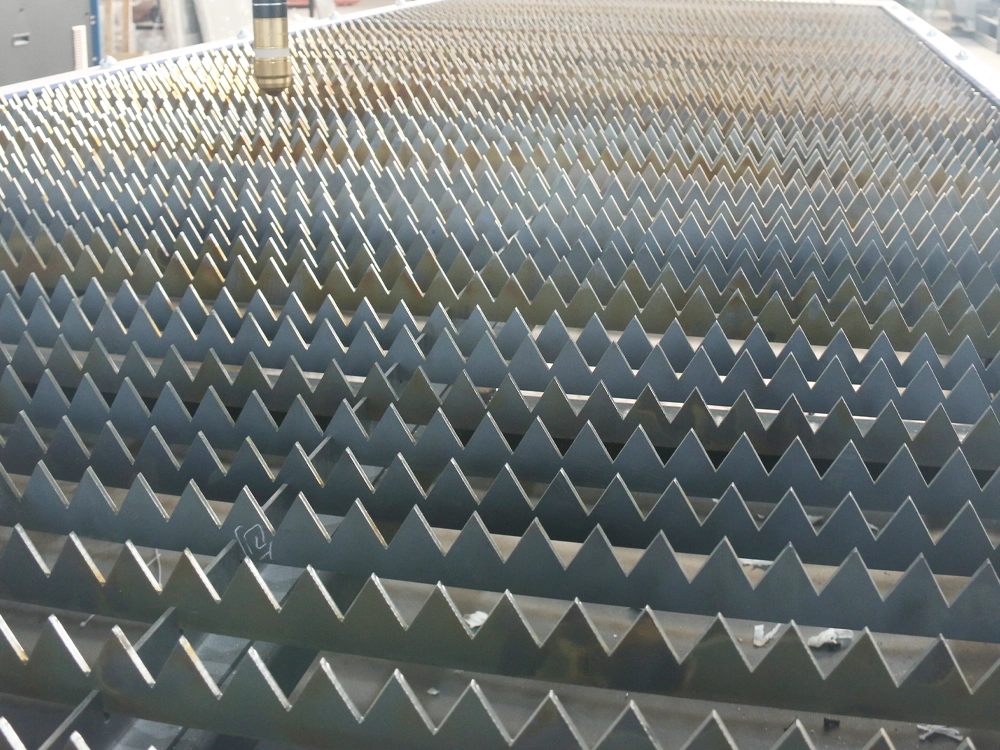

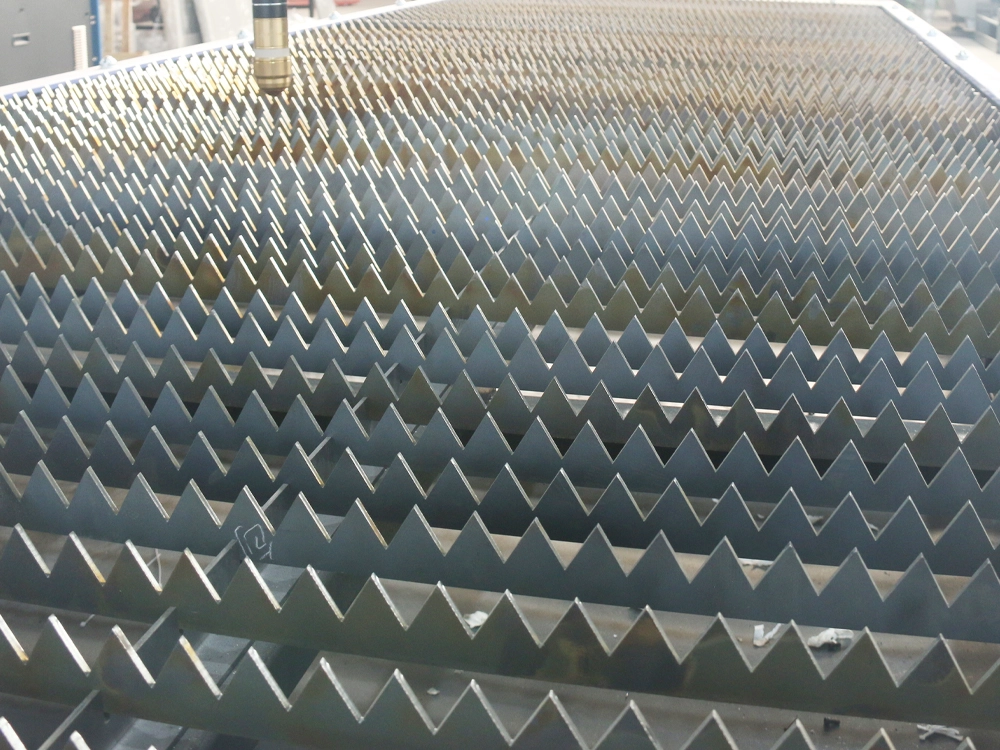

- Tooth-type slats workbench

-

Distributed tooth-type slats workbench with good thermal conductivity and without easy to stick.

- Plasma source

-

Optional plasma source from American Hypertherm or China Huayuan.

- Transmission system

-

High-precision helical rack, Taiwan HIWIN linear square rail.

- Starfire control system

-

Optional Starfire or FL control system.

Technical Parameters of 5x10 CNC Plasma Cutter

| Model | CK-1530-P |

| Work Area | 1500mm*3000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen, fuel gas |

| Cutting Method | Plasma cutting + flame cutting (oxygen + fuel gas) |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1200kg |

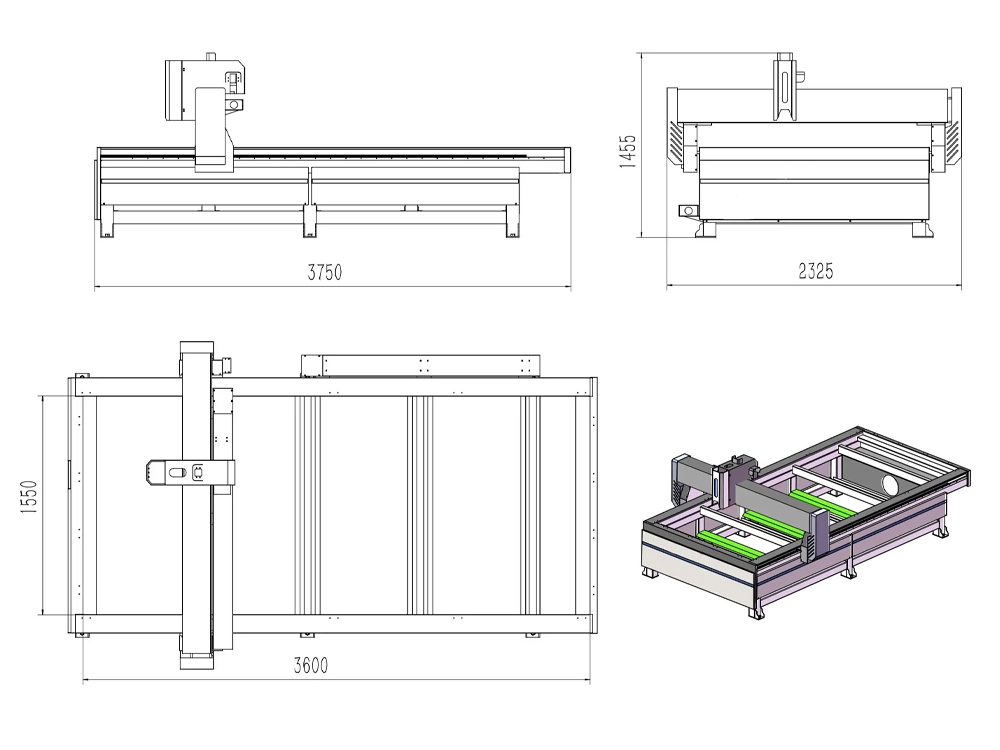

| Dimensions | 3830*2260*1580mm |

Maximum Cutting Thickness of Different Brands of Plasma Power Supplies

| Huayuan | Hypertherm | ||

|---|---|---|---|

| Power | Cuttable thickness(mm) | Power | Cuttable thickness(mm) |

| 63A | 8 | 45A | 8 |

| 100A | 15 | 65A | 10 |

| 120A | 20 | 85A | 12 |

| 160A | 30 | 105A | 18 |

| 200A | 40 | 125A | 25 |

| 300A | 50 | 200A | 30 |

The Use of 1530 CNC Cutter With Flame Cutting and Plasma Cutting Functions

Applicable Materials

Carbon steel (low carbon steel, medium carbon steel), stainless steel (304, 316, etc.), aluminum, aluminum alloy, copper, copper alloy, galvanized sheet, nickel alloy, magnesium alloy, composite metal sheet and other metals.

Applicable Industries

- Automotive Manufacturing: Body sheet metal parts (doors, hoods), chassis structural components, electric vehicle battery frames, truck beams, truck guard plates, car charging pile brackets, train/subway turning connectors, etc.

- Aerospace/Shipbuilding: Hull steel plates, deck structural components, satellite antenna brackets, drone frames, etc.

- Construction and Steel Structures: H-beam cutting, steel structure bracket cutting, steel bridge decks, spiral staircase frames, stainless steel stair railings, wrought iron gate cutting, house steel frames, etc.

- Household and Kitchenware: Stainless steel sinks, grills, metal sculptures, trophy nameplates, musical instrument parts, etc.

The Following Are the Processable Products of 5x10 High Performance Plasma Cutter

Usage Matters

CNC plasma cutting machine is an efficient and precise equipment, widely used in metal processing industry. You can use the machine according to the following steps:

- Pre-Startup Preparation:

-

Inspect the cutting area, remove flammable and explosive materials, and keep away from the jet stream zone.

Check firefighting equipment, such as fire hydrants, fire extinguishers, sandboxes, and other fire suppression facilities.

Ensure all switches and buttons on the control panel are flexible and reliable, and verify that the power supply is properly connected.

- Starting the Equipment:

-

Turn on the power lock on the control panel and press the power button to supply power to the CNC plasma cutting machine.

Confirm that the plasma power supply voltage is stable, the pressure gauge shows 0.4~0.6 MPa, check for no leaks in the compressed air pipeline, and ensure the gas is dry and free of moisture.

Select the cutting mode, choose parameters based on material thickness, import the processing drawing, and automatically generate the cutting path.

Briefly press the torch switch for arc ignition testing, observe if the arc is stable, and then start the processing.

- Precautions During Operation:

-

Operators should wear protective gear such as welding gloves and helmets.

In case of an emergency during cutting, immediately press the red emergency stop button.

Avoid direct contact with the cutting surface, torch tip, or nozzle during the cutting process.

- Daily Maintenance and Care:

-

After each workday, clean dust and metal debris from the cutting machine, especially around the electrode and nozzle areas.

Regularly lubricate the mechanical parts of the cutting machine, such as guides and bearings.

Perform a comprehensive cleaning of the machine weekly, including cleaning the horizontal and vertical guides, drive gears, and racks, and apply lubricating oil.

- Safety Precautions:

-

The CNC plasma cutting machine must be securely grounded, ensuring the power supply's grounding bolt is properly connected to prevent electric shock.

Power must be turned off before replacing any components.

By strictly adhering to the above guidelines, you can effectively ensure the safe operation of the CNC plasma cutting machine and extend its service life.

| Model | CK-1530-P |

|---|---|

| Work Area | 1500mm*3000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1200kg |

| Dimensions | 3830*2260*1580mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.