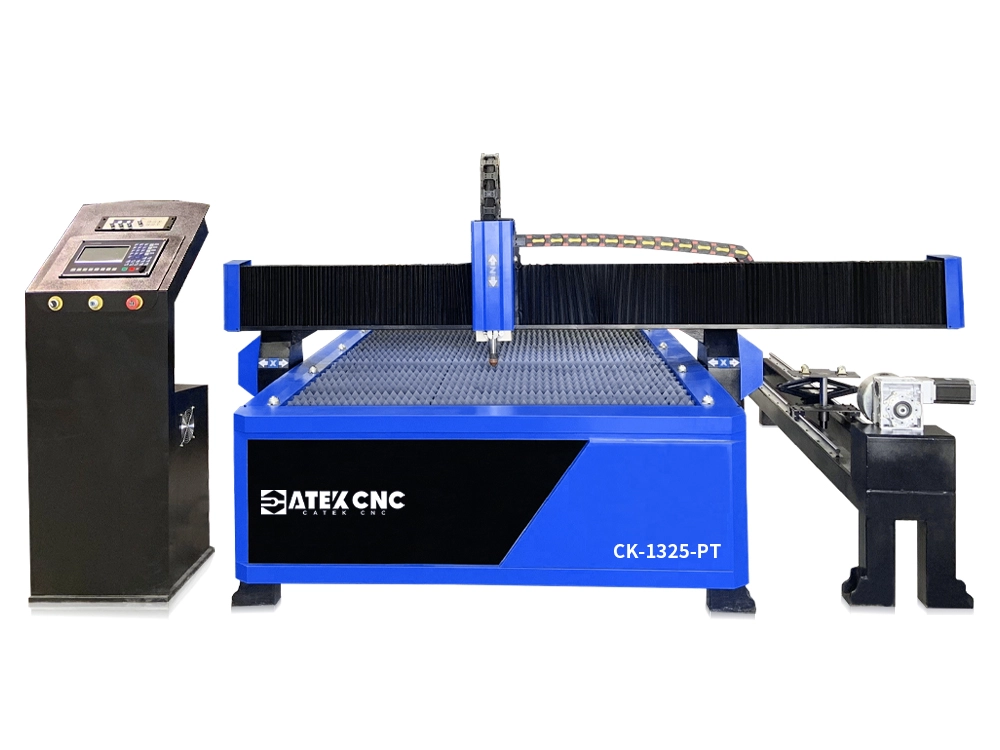

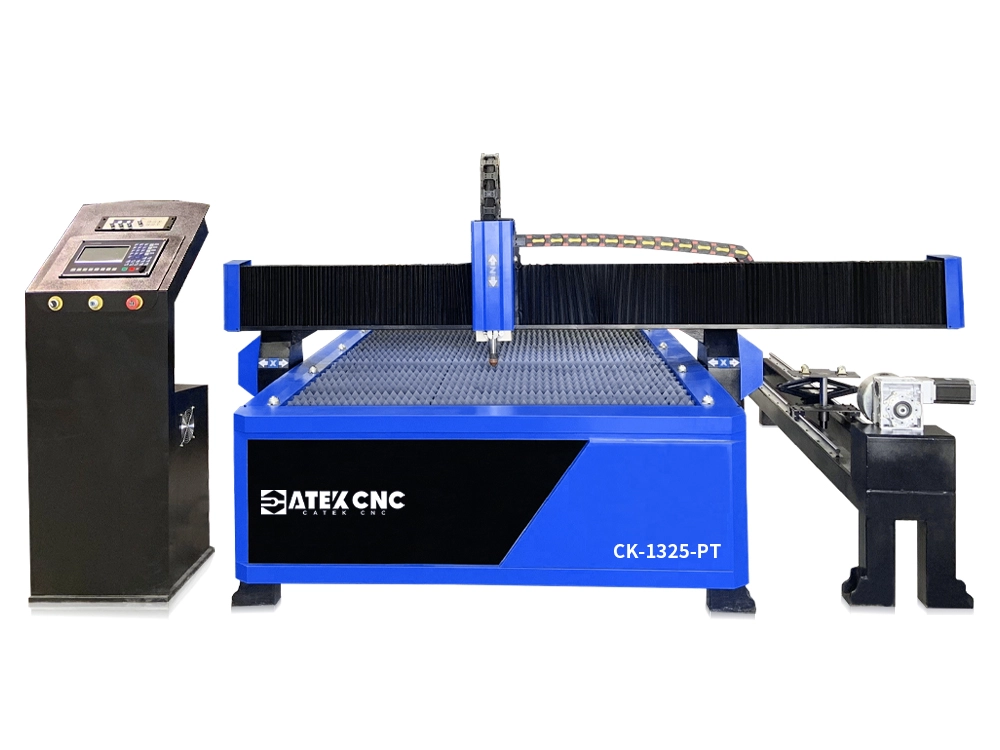

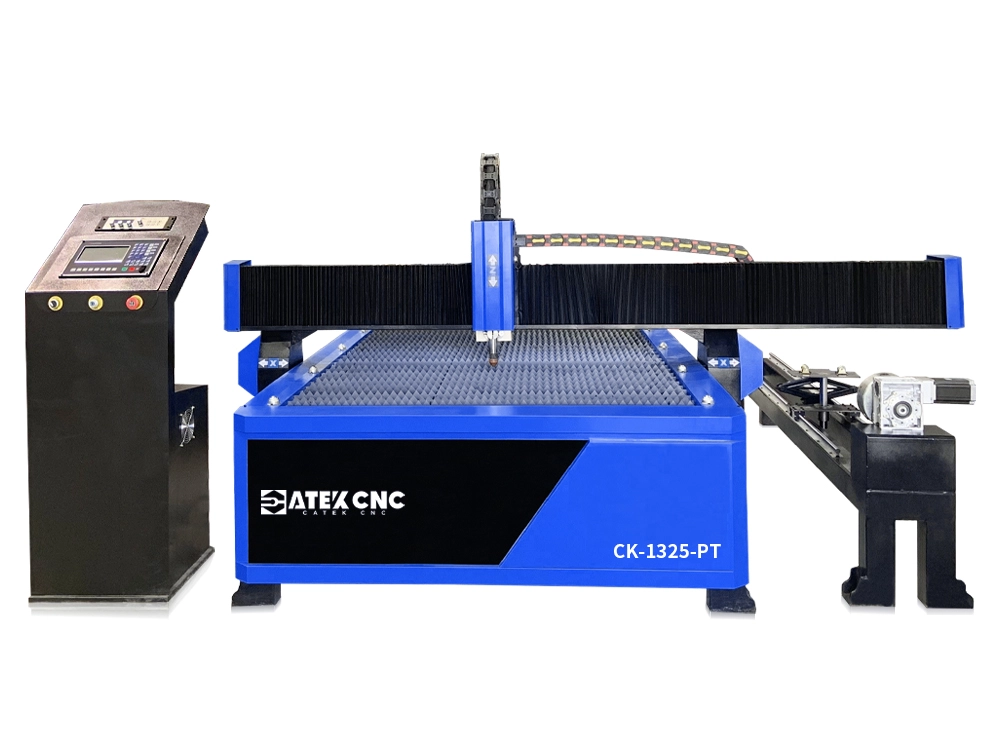

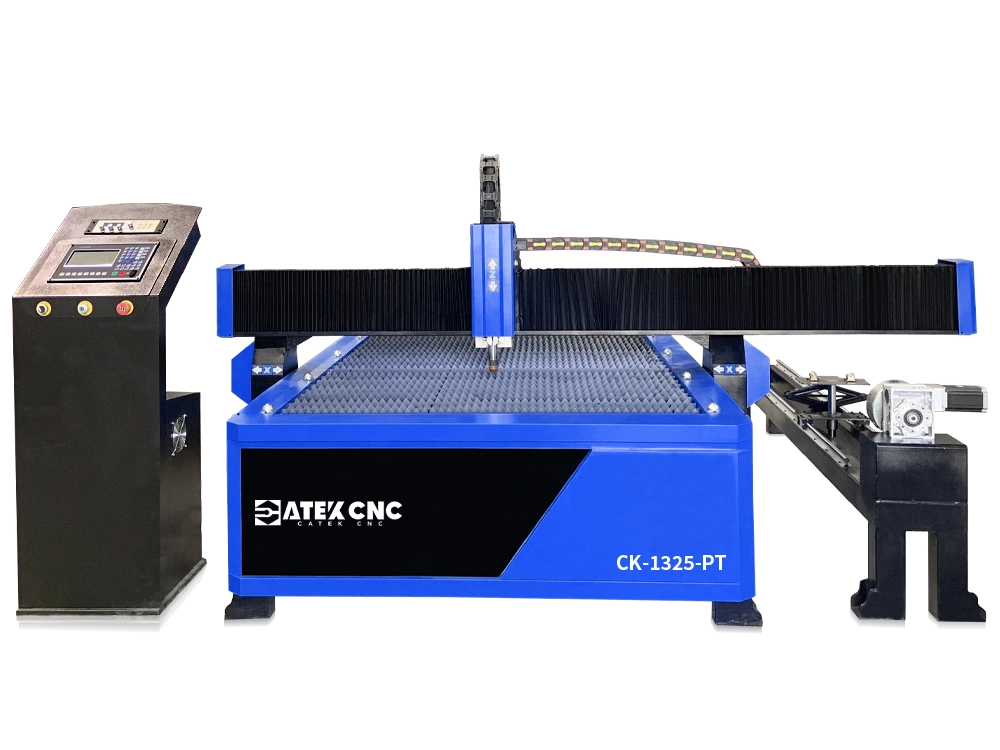

4x8ft CNC Plasma Cutting Machine for Both Metal Sheet and Metal Pipe Cutting

4x8ft CNC Plasma Cutting Machine for Sheet and Pipe

[Function Description]

The 1325 CNC sheet and tube plasma cutting machine is controlled by a CNC system and supports automatic programming and drawing conversion. Building upon the standard plasma sheet cutting machine, it incorporates a rotary cutting device, enabling both sheet cutting and tube cutting through CNC system control. This machine requires only the space of a single device to cut both metal sheets and tubes, reducing investment costs and making it an ideal choice for users with both sheet and tube cutting needs.

The CNC plasma cutting machine offers fast cutting speeds, especially when cutting thin carbon steel sheets, where thermal deformation is almost negligible. The cutting surface has a high finish with almost no heat-affected zone. During processing, parameters such as current, cutting speed, and gas pressure can be freely adjusted based on different materials and thicknesses, providing great flexibility in use.

Advantages of 4x8 CNC Plasma Cutting Machine with Rotary Cutting Device

- The bed base is constructed using high-strength thickened square steel welding, ensuring high stability and strong resistance to deformation.

- The gantry beam and guides are processed by a large German-made five-face gantry milling machine, guaranteeing high precision in the movement of the cutting head.

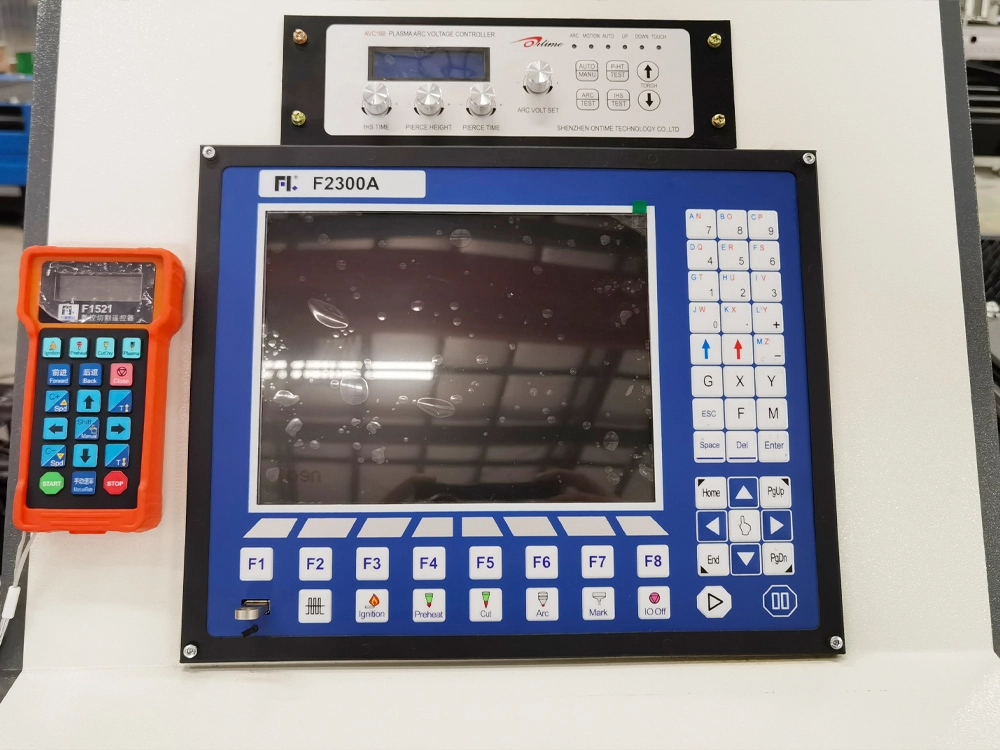

- The industrial-grade CNC system supports graphic import, automatic programming, path optimization, offline programming, and real-time monitoring of processing status.

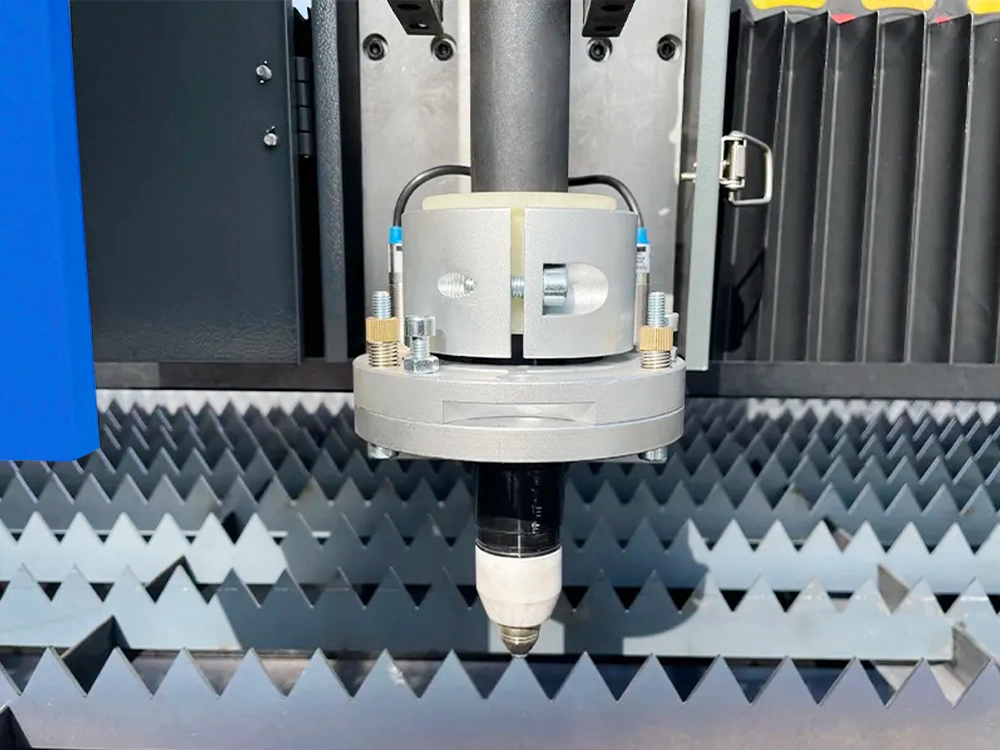

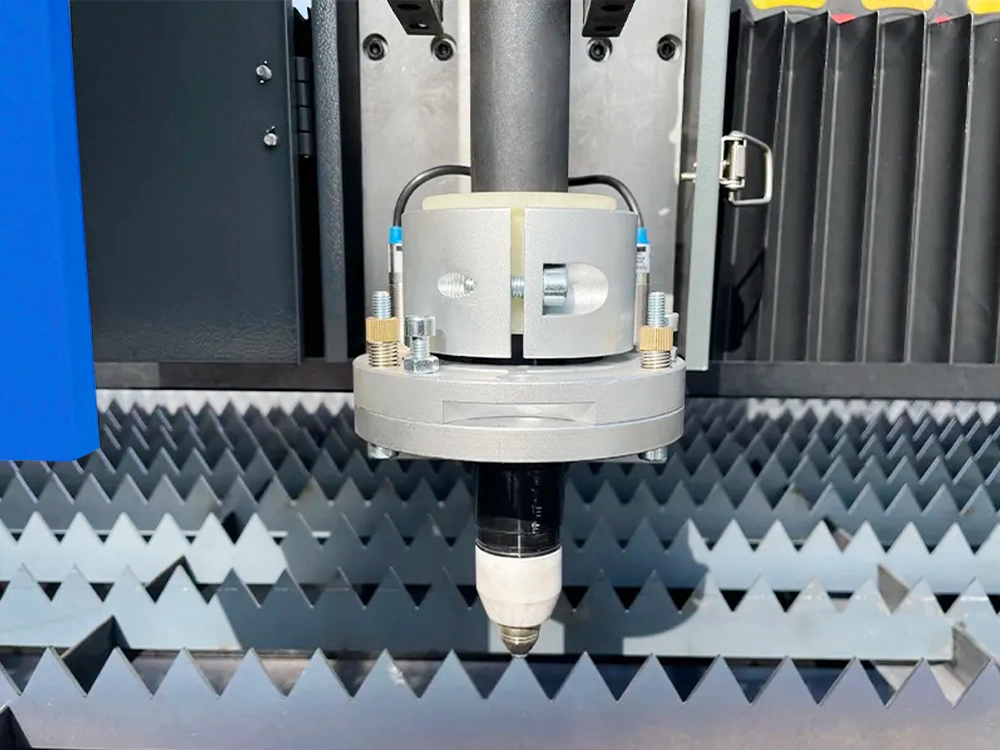

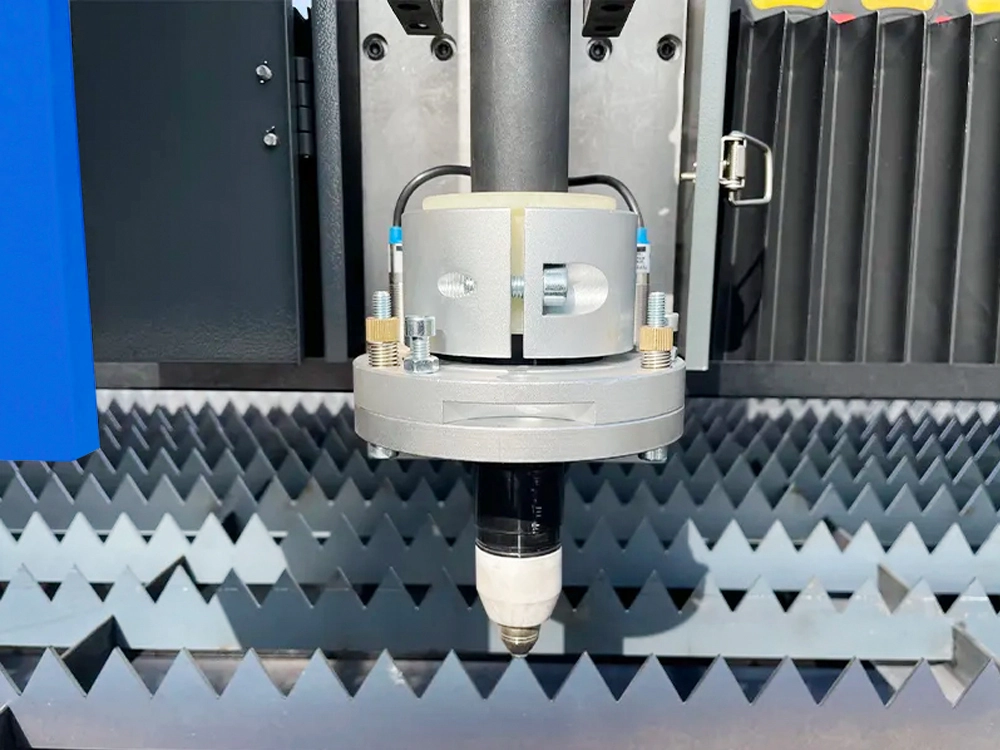

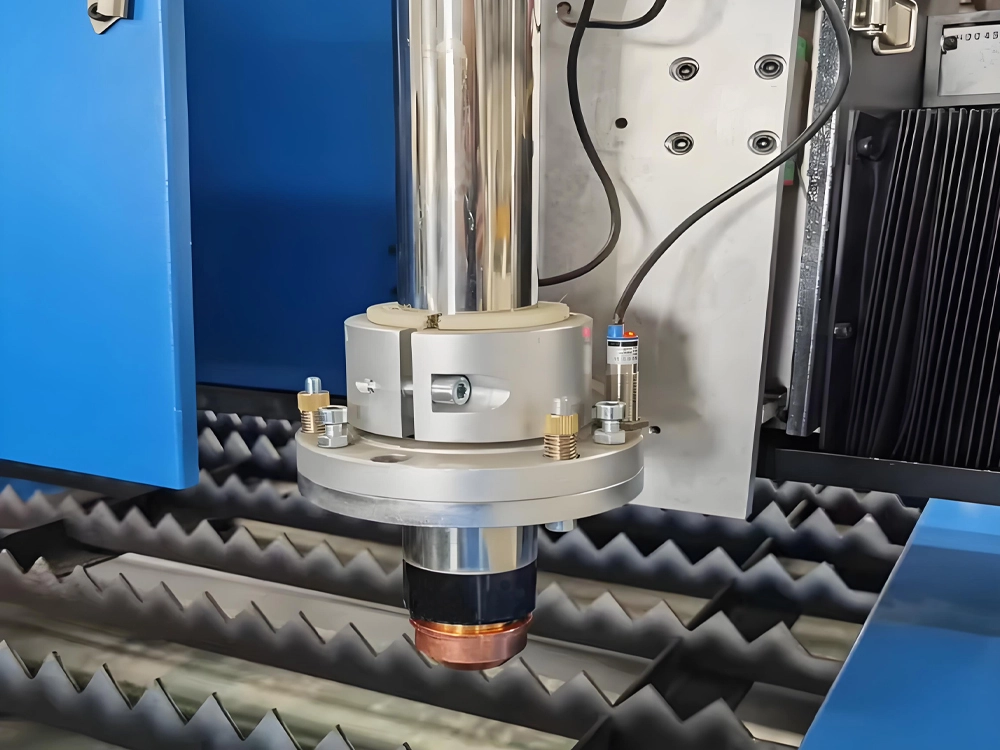

- Equipped with an arc voltage automatic adjustment system, it adjusts the torch height in real time to address issues caused by uneven sheets or thermal deformation.

- Anti-collision devices prevent damage to the torch due to operational errors or workpiece deformation.

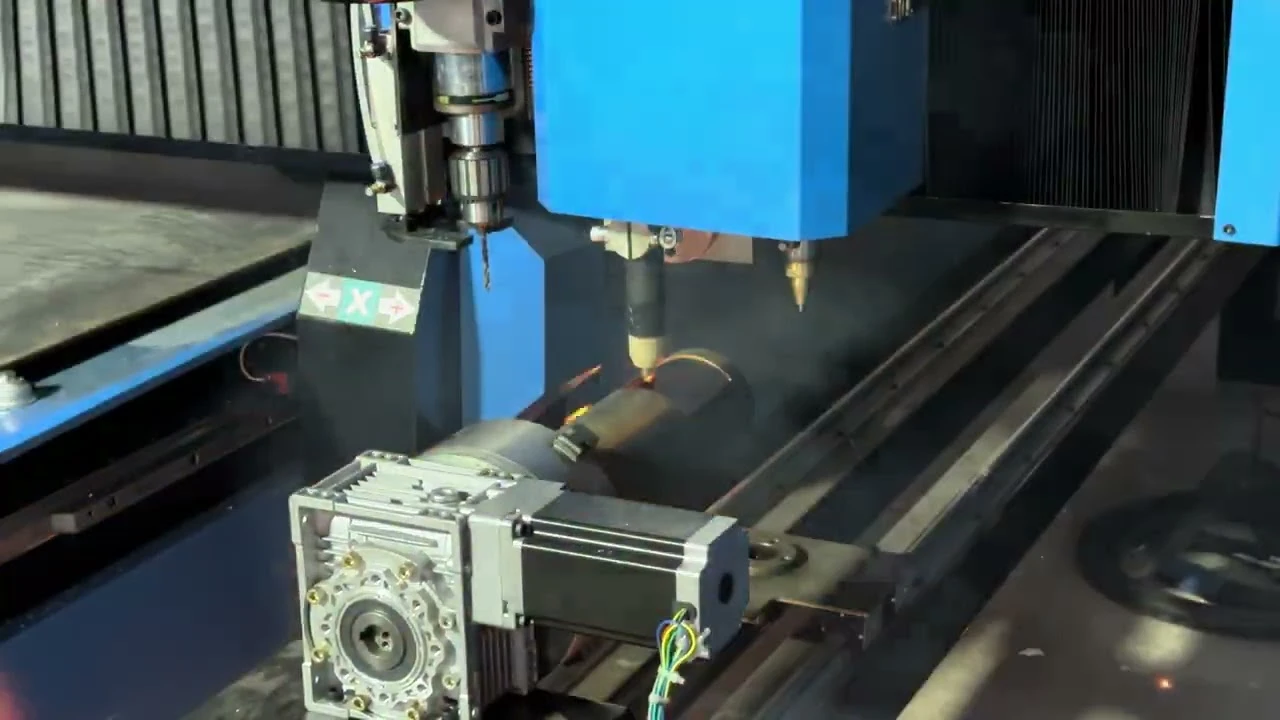

- The chuck clamps the tubes with high rotational accuracy and low inertia, allowing for both forward and reverse clamping.

- By inputting the radius, intersection angle, and cutting speed of the main and branch tubes into the computer, the cutting program is automatically generated. The universal sheet 2D cutting system is simple to operate.

- Taiwan HIWIN high-precision linear guides, TBI ball screws, and gear-rack combined transmission ensure high operational accuracy, low noise, and fast speeds.

- By using different working gases, it can cut various metals that are difficult to cut with oxygen, especially non-ferrous metals.

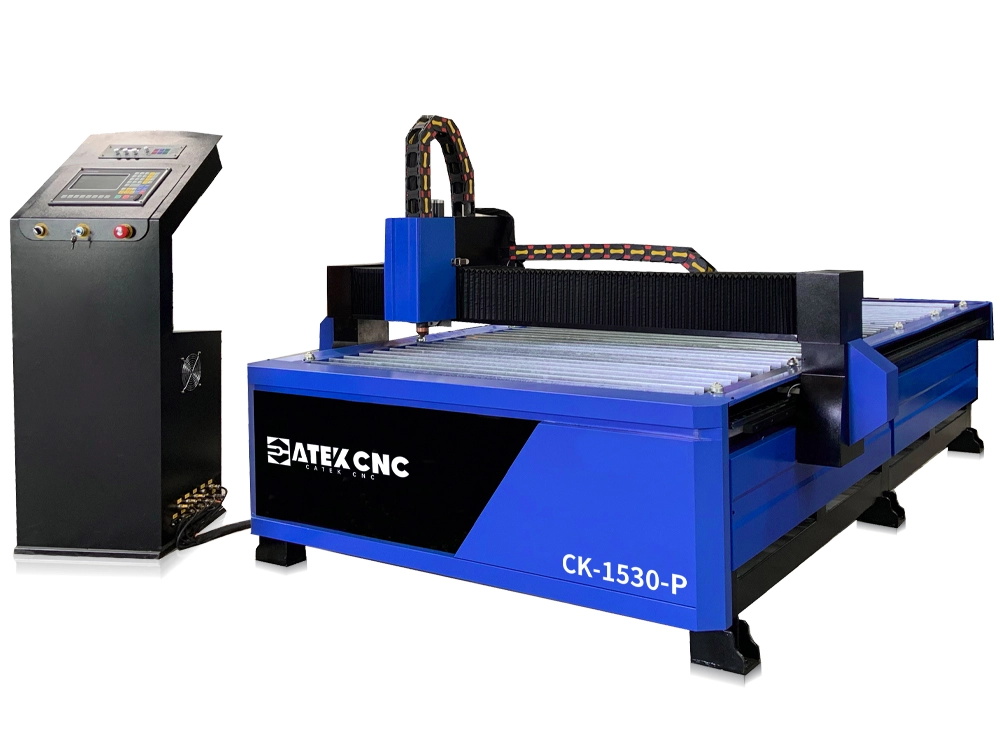

Details of CNC Plasma Cutting Machines Suitable for Metal Plates and Tubes

- CNC Plasma cutting torch

-

CNC plasma cutting torch with fast perforation and cutting of metal materials.

- Plasma power supply

-

Optional plasma source from American Hypertherm or China Huayuan.

- Plasma rotary axis for pipe cutting

-

The indexing chuck on the side of the machine can rotate and cut the pipe.

- Pipe steady rest

-

A manual steady rest that can slide forward and backward and raise and lower to support the pipe.

- Exhaust fan

-

The exhaust fan can remove smoke and odors generated during the processing.

- Drag chains

-

Drag chains are used to organize and protect cables, allowing them to move with the drive system without becoming tangled during processing.

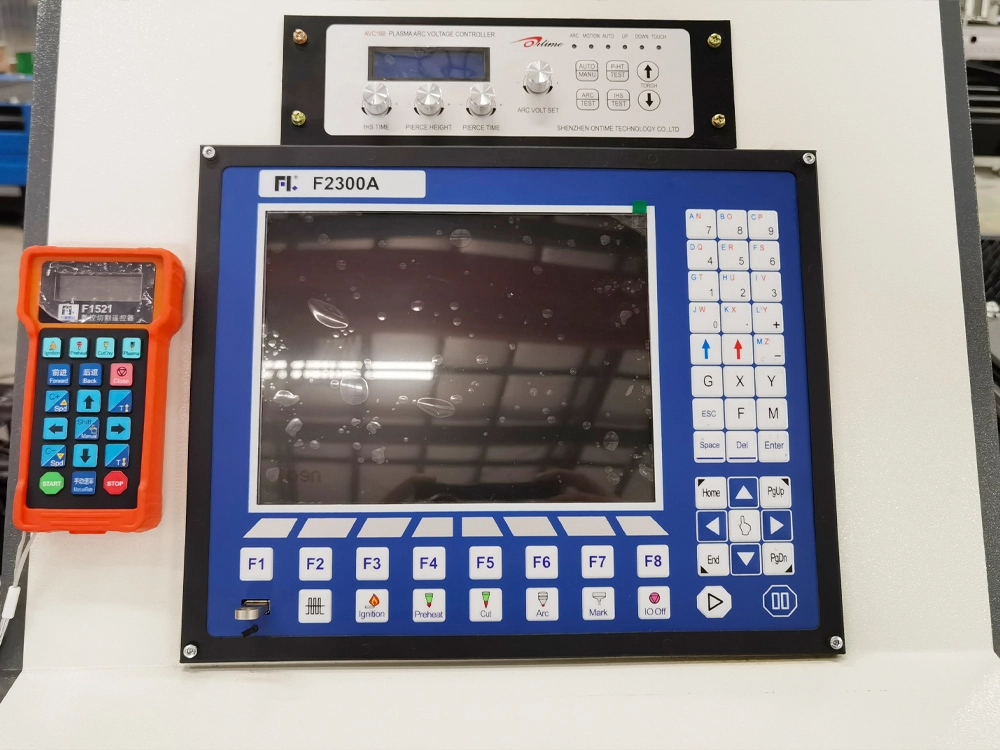

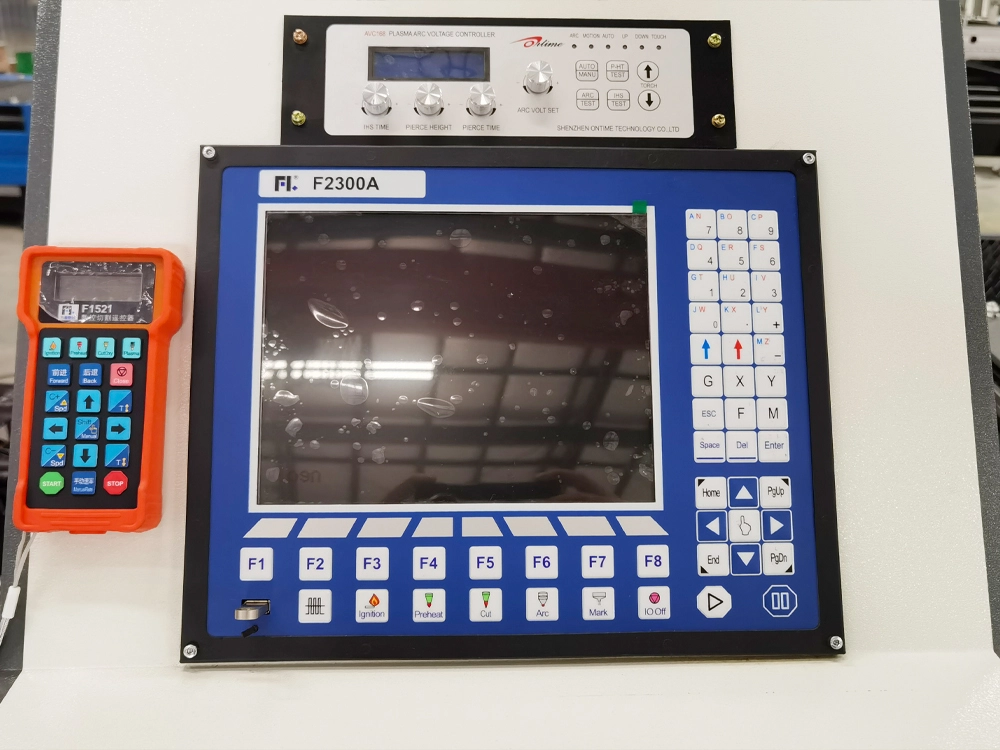

- Control system

-

The control system can be selected from STARFIRE or FL.

Technical Parameters of 4x8 Plasma Cutter For Sheet Metal & Tube

| Model | CK-1325-PT |

| Work Area | 1300mm*2500mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1500kg |

| Dimensions | 3330*2860*1580mm |

The Thickness of Materials That Can Be Cut by Hypertherm Plasma Power Supplies of Different Powers

| Materials/Powers | 45A | 65A | 85A | 105A | 125A | 200A |

|---|---|---|---|---|---|---|

| Carbon Steel | 12mm | 16mm | 18mm | 20mm | 25mm | 32mm |

| Stainless steel | 12mm | 12mm | 16mm | 20mm | 20mm | 25mm |

| Aluminum | 10mm | 12mm | 16mm | 20mm | 25mm | 32mm |

What Products Can the CNC Plasma Tube and Plate Cutting Machine Be Used to Process?

- Cutting materials: carbon steel, stainless steel, aluminum, brass, copper, alloy, galvanized steel, titanium, nickel, aluminum alloy, magnesium alloy and other materials.

- Cutting tube type: round tube, square tube, rectangular tube, oval tube, waist round tube, etc.

- Application industries: automobile manufacturing, shipbuilding, fan manufacturing, kitchen cabinet ventilation and refrigeration, chassis cabinet, pressure vessel, steel structure processing, steel plate cutting and blanking, advertising cutting, sheet metal processing, engineering machinery, agricultural machinery and other machinery, boiler manufacturing, petrochemical equipment, light industrial machinery, aerospace, as well as decoration, large sign manufacturing and other industries.

| Model | CK-1325-PT |

|---|---|

| Work Area | 1300mm*2500mm |

| Rotation Size | Diameter 10-500mm, Length 3000mm-6000mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1500kg |

| Dimensions | 3330*2860*1580mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.