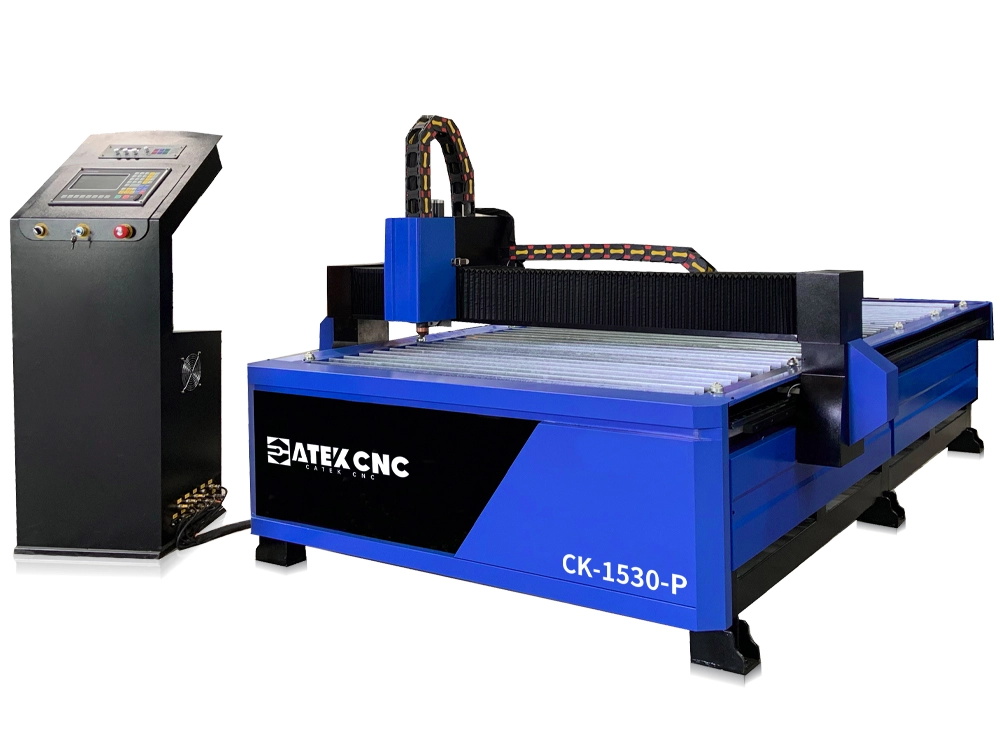

Cheap 4'x8' CNC Plasma Cutter for All Types of Sheet Metal

Cheap 4x8ft CNC Plasma Metal Plate Cutting Machine

[Function Description]

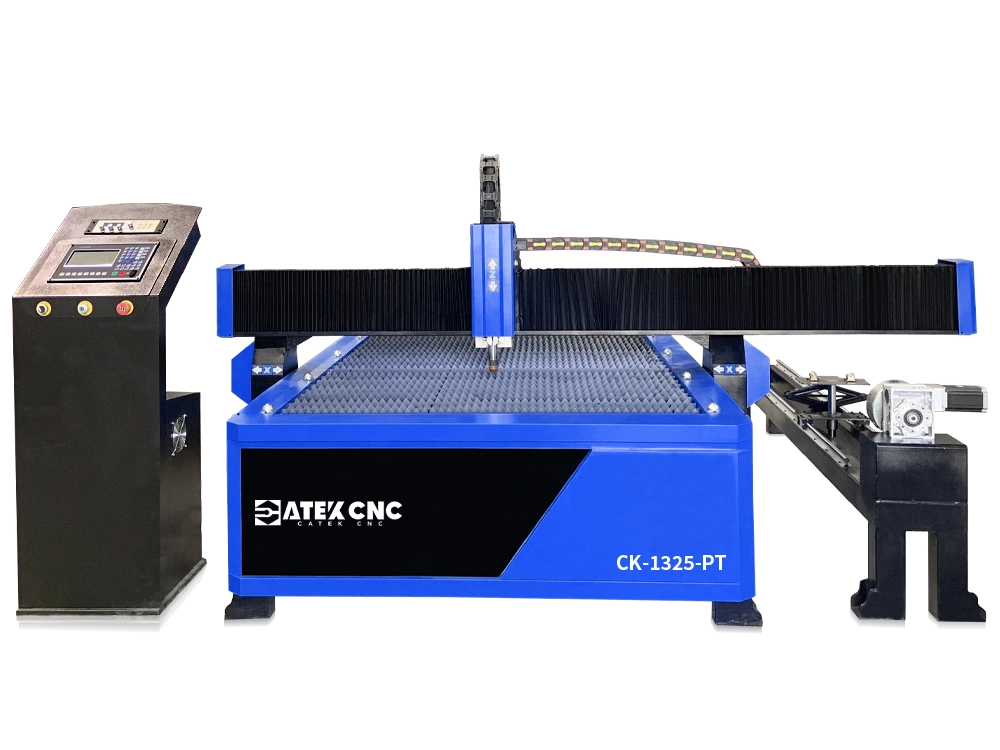

The CNC plasma cutting machine is an automatic cutting machine with a CNC control system and a plasma cutting system. Compared with the traditional handheld plasma cutting machine, it has an additional working platform and a CNC system, which can automatically cut various shapes. It is equipped with a 4*8-foot large-format processing platform, which can place a whole sheet of metal at a time, optimize the processing path through automatic nesting software, nest layout, and fully automatic cutting processing.

In production and processing, CNC plasma cutting machines expand the possibilities of processing. By using automatic nesting software to optimize the processing path, it is possible to minimize waste during the processing process and maximize material utilization. Moreover, it has high cutting accuracy and more precise processing, and can be used to process various non-ferrous and ferrous metals, such as iron, steel, carbon steel, stainless steel, copper, aluminum, etc. CNC plasma cutting machines are inexpensive, low-cost, fully functional and widely used, so they are widely loved and praised by users.

Compared with the laser cutting machine, the CNC plasma cutting machine is very cheap and is more suitable for home studios, small production workshops, and metal industry workers who are just starting a business. It is your first choice for starting a business in the metal cutting and processing industry!

What Is a CNC Plasma Cutting Machine and How Does It Work?

A CNC plasma cutting machine is primarily composed of a CNC system, drive system, plasma cutting torch, plasma arc generator, worktable, transmission system, nesting software, and other components, making it a precision cutting device.

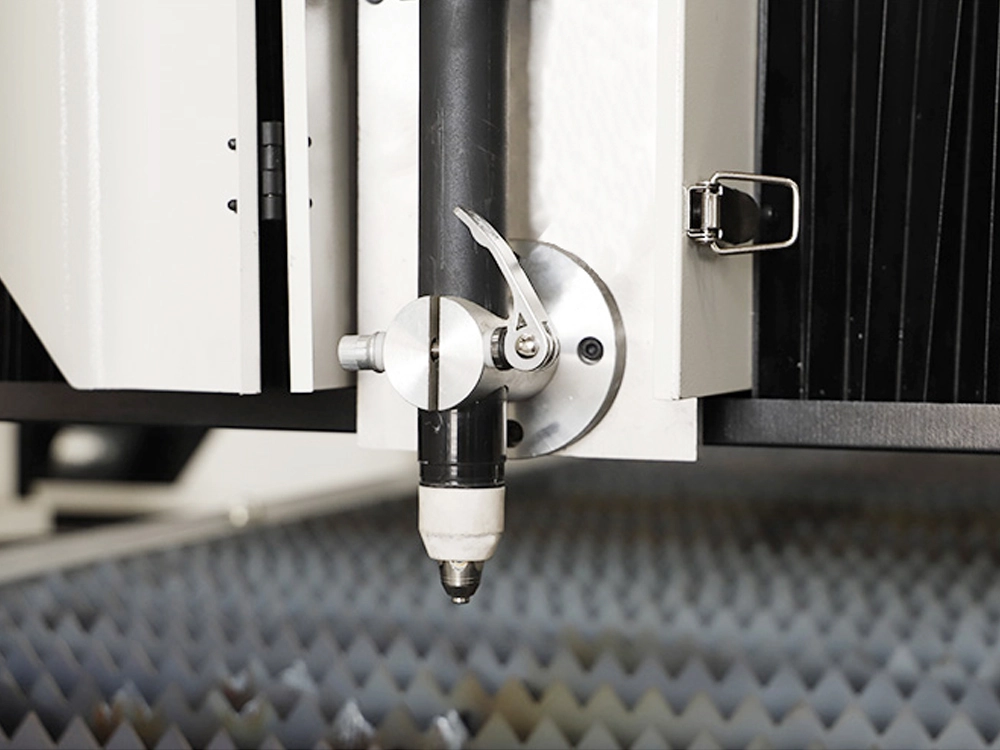

The CNC system controls the movement trajectory of the torch, releasing high-speed airflow at the nozzle. Simultaneously, an ignition arc is generated between the electrode and the nozzle inside the torch, ionizing the gas to form plasma. Plasma has excellent conductivity, creating a current path between the electrode and the workpiece, thereby generating a high-temperature, high-energy-density plasma arc. The high-temperature plasma arc can instantly melt metal, and the airflow blows away the molten slag at the cutting edge, enabling the cutting of various metals. Using specialized software to complete CNC programming, the CNC system automatically controls the entire processing process based on pre-set program instructions, accurately cutting metal sheets into various complex shapes.

Advantages of CNC Plasma Cutting Machine

- High-quality plasma cutting torch, precision-machined via CNC for high concentricity. Multi-faceted heat dissipation design ensures better cooling performance, with dedicated high-conductivity copper rods.

- STARFIRE flame plasma cutting system, supporting multiple languages and featuring simple operation. Equipped with industrial-grade ARM chips, it is suitable for various working environments.

- Plasma-specific tooth-type slats workbench with high levelness, capable of accommodating raw materials of any size for automated cutting.

- Huayuan plasma power supply, with 100% duty cycle (at 40°C), suitable for heavy industry and ultra-heavy-duty operations. Optionally available with Hypertherm plasma power supply.

- Equipped with a high-power exhaust fan, automatically removing smoke generated during processing for more environmentally friendly use.

- Taiwan HIWIN linear square guides/linear bearings, ensuring fast operation speed and higher positioning accuracy.

- Automatic nesting software optimizes cutting paths based on sheet size and processing parts, improving material utilization and reducing waste.

- Central lubrication system, which automatically lubricates the machine's transmission parts by regularly adding lubricating oil through the lubrication system.

Details of CNC Plasma Cutting Machines Suitable for Cutting Various Metals

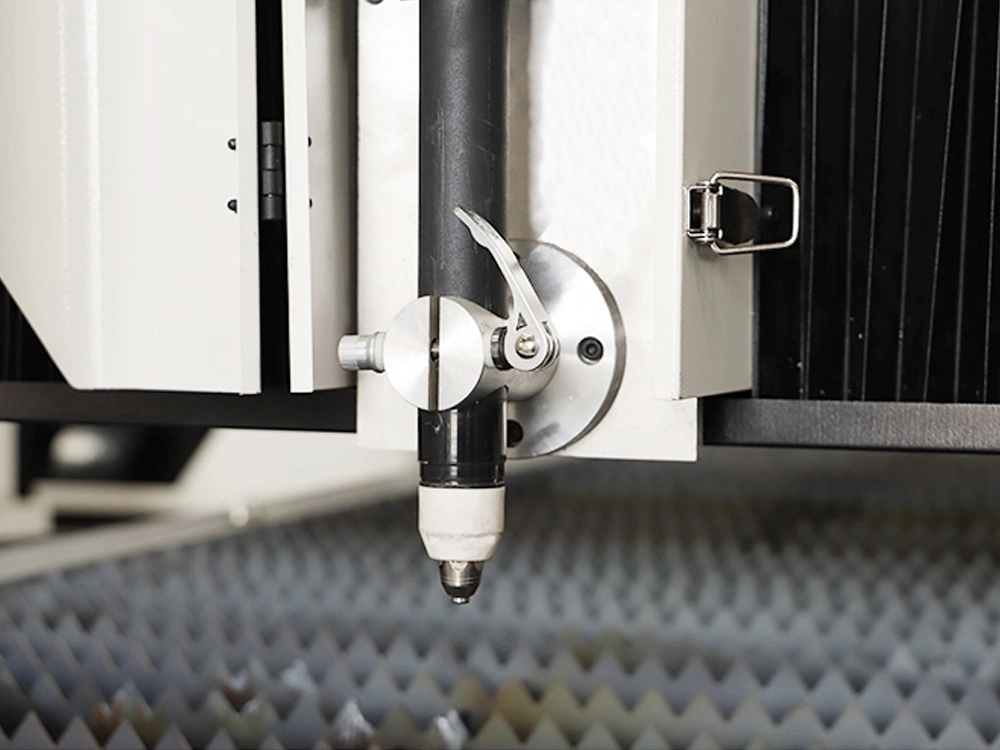

- High power plasma cutting torch

CNC plasma cutting torch with fast perforation and cutting of metal materials.

- Tooth-type slats workbench

Distributed tooth-type slats workbench with good thermal conductivity and without easy to stick.

- Transfer roller

The workbench is equipped with multiple loading rollers to facilitate loading of the plates.

- Plasma source

American Hypertherm/China Huayuan high-quality high-frequency plasma source.

- Control system

Starfire control system Support cutting process settings break point positioning and other advanced functions.

Technical Parameters of 4x8 CNC Plasma Cutter

| Model | CK-1325-P |

| Work Area | 1300mm*2500mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1100kg |

| Dimensions | 3330*2060*1580mm |

What Can the 4*8 CNC Plasma Metal Cutting Machine Be Used For?

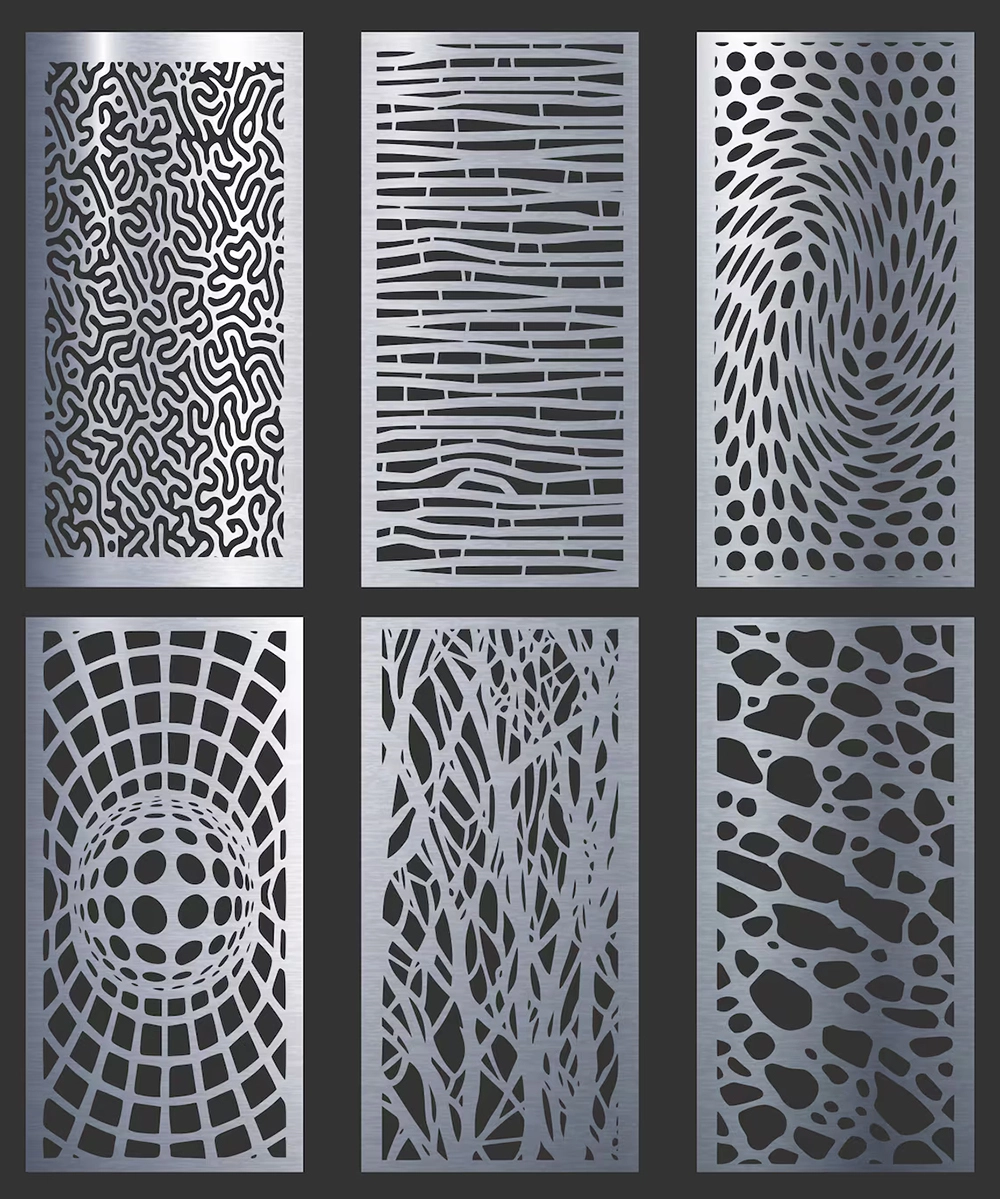

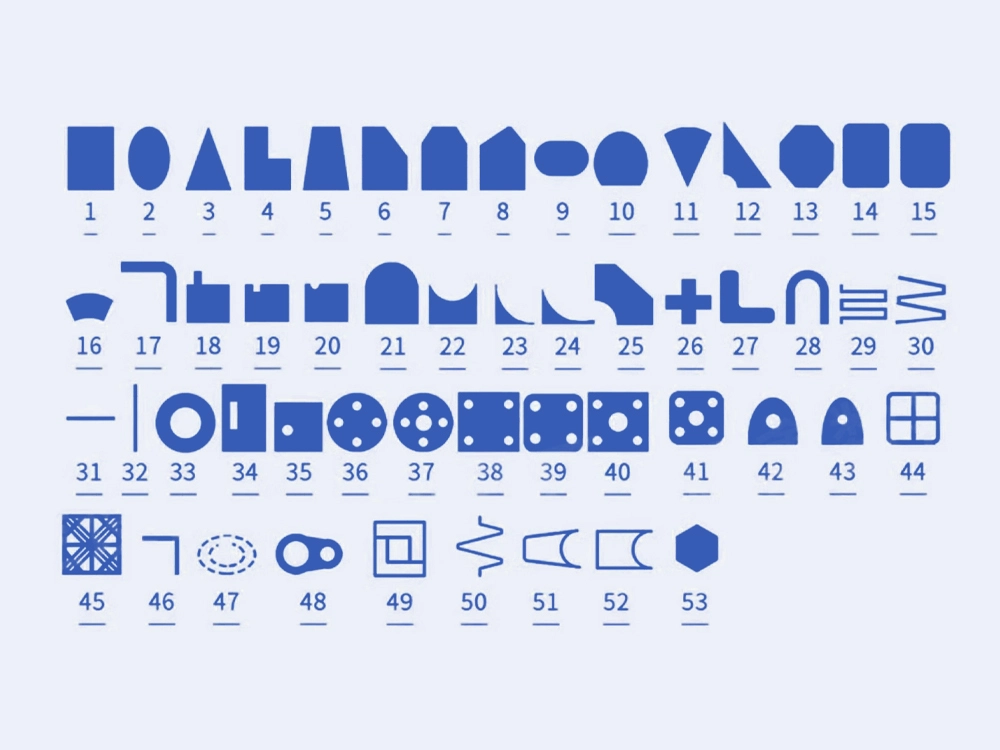

The 4*8ft CNC plasma cutting machine has a wide range of uses and processable materials, and is suitable for all types of metal cutting, hole cutting, grooving, etc.

Applicable Materials

Carbon steel (low carbon steel, medium carbon steel), stainless steel, aluminum, aluminum alloy, copper, copper alloy, brass, bronze, copper, low alloy steel, wear-resistant steel, galvanized sheet, titanium, titanium alloy, nickel alloy, magnesium alloy, gray cast iron and other metal plates.

Applicable Products

Building steel structures, mechanical parts, metal stair handrails, metal brackets, metal connecting plates, roof gutters, curtain wall metal frames, fireproof board brackets, bridge guardrails, street lamp bases, signal tower components, gear blanks, flanges, bearing seat plates, sprockets, aluminum alloy wheel blanks, stainless steel screens, hollow pattern partitions, metal signboards, wrought iron gates, guardrail carvings, wall art reliefs, furniture metal frames (tables, chairs, shelves), lamp shape brackets, stainless steel countertops, range hood ducts, oven liner, shelf layers, forklift accessories, pallet metal frames, etc.

The Following Are the Processable Products of 4x8 CNC Plasma Cutter

| Model | CK-1325-P |

|---|---|

| Work Area | 1300mm*2500mm |

| Power | 63A/120A/160A/200A/300A/400A |

| Gas | Oxygen |

| Application | Metal fabrications |

| Guideway | Taiwan Hiwin square guide rail + X Y rack and Z ball screw |

| Relay Accessories | Schneider |

| Torch Height Controller | Standard high sensitivity arc voltage device |

| Driving System | Leadshine motor and driver |

| Control System | Starfire control system |

| Lubrication System | Electric lubricating oil pot |

| Operating Voltage | 220V/380V 50/60Hz |

| Nesting Software | FASTCAM |

| File Output Mode | USB interface |

| Instruction Format | G code |

| Repeat Positioning Accuracy | ±0.05mm |

| Process Precision | ±0.35mm |

| Maximum Pocessing Speed | 12000mm/min |

| Weight | 1100kg |

| Dimensions | 3330*2060*1580mm |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.