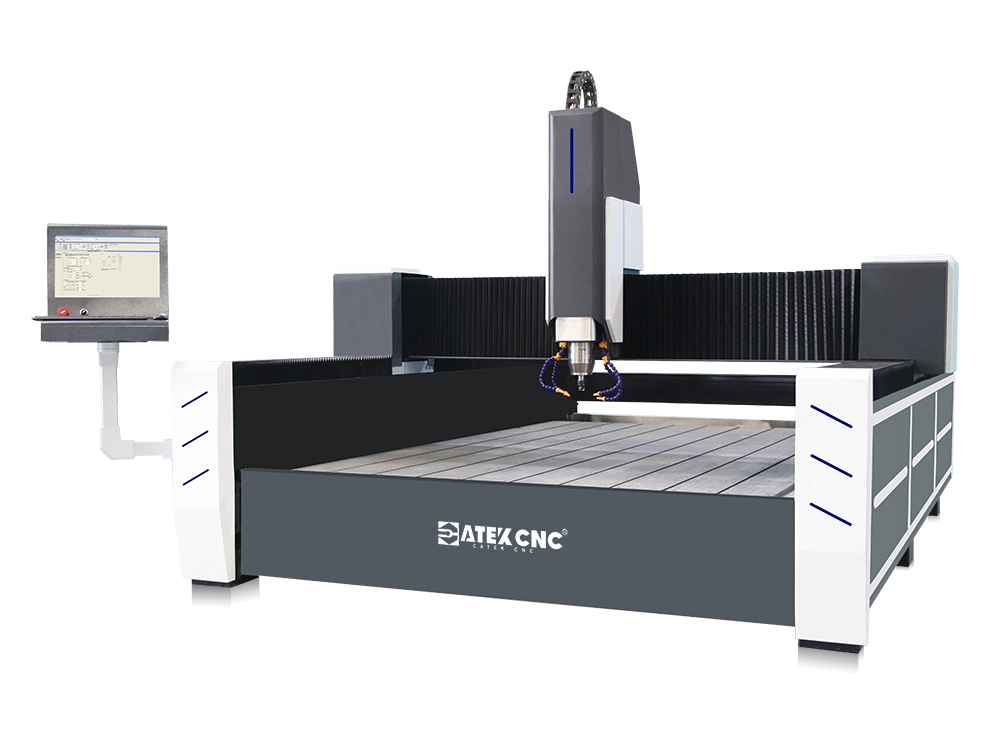

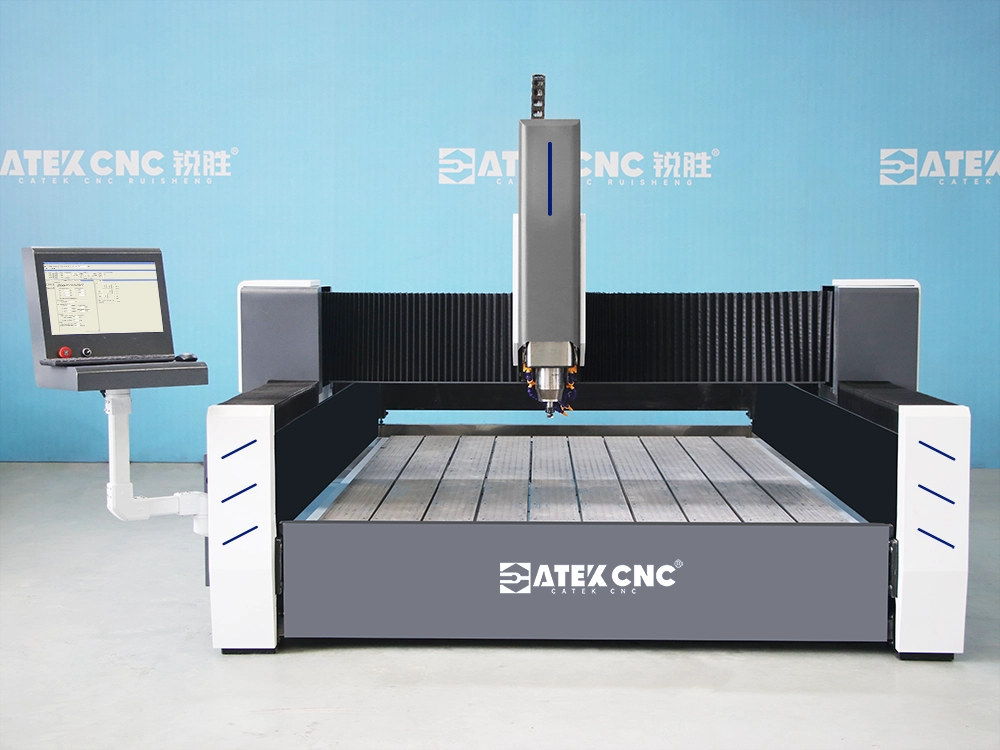

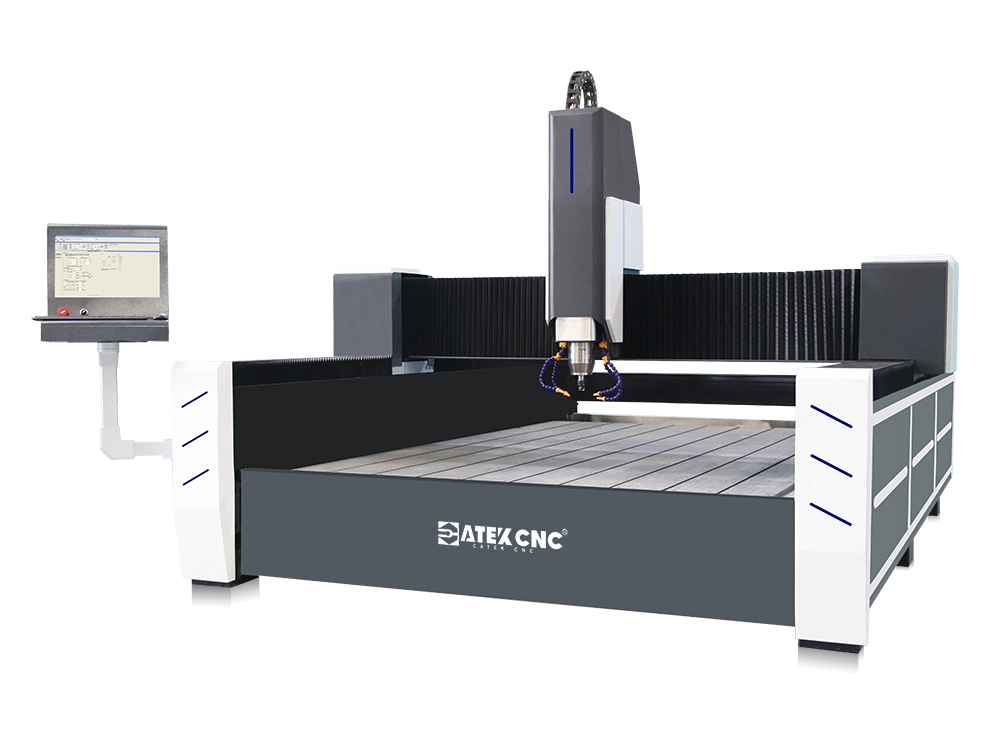

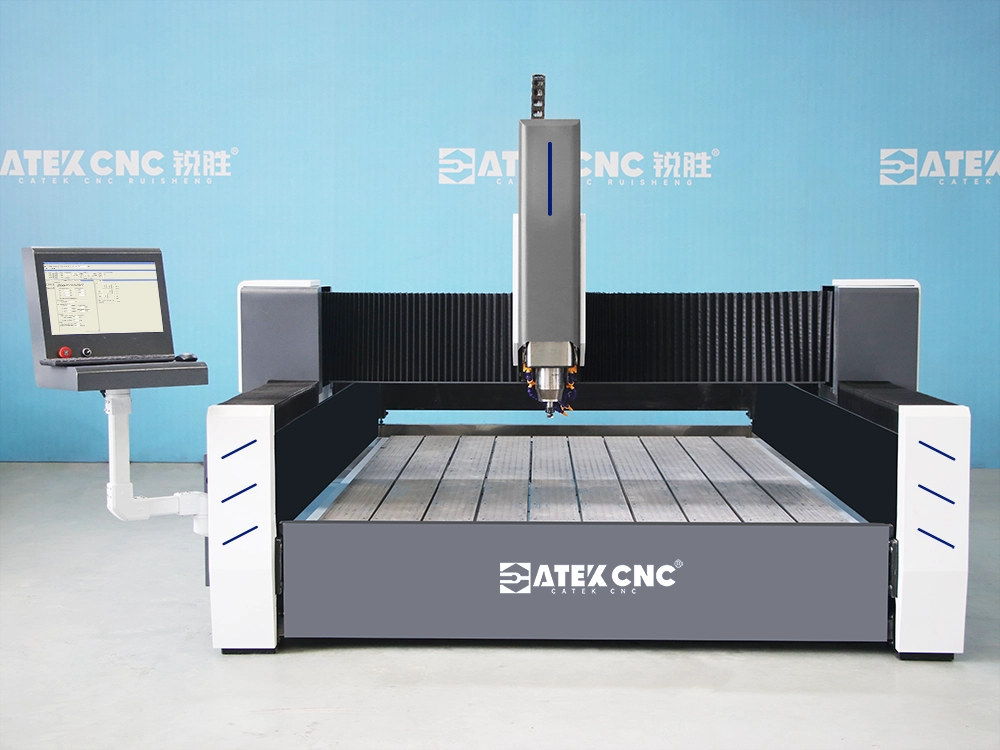

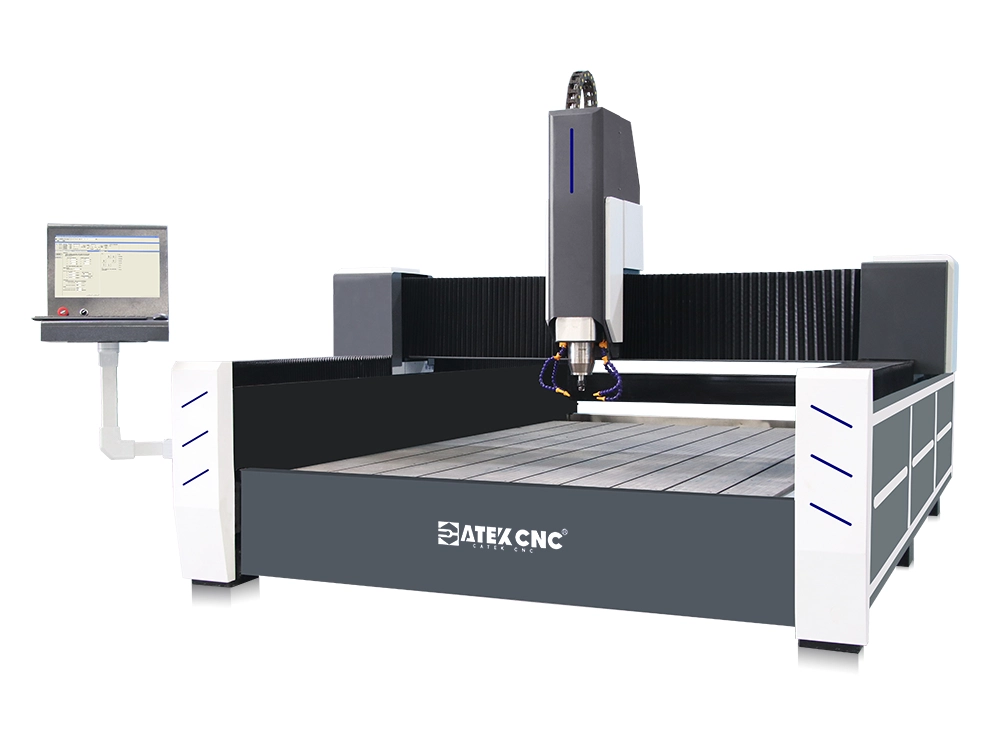

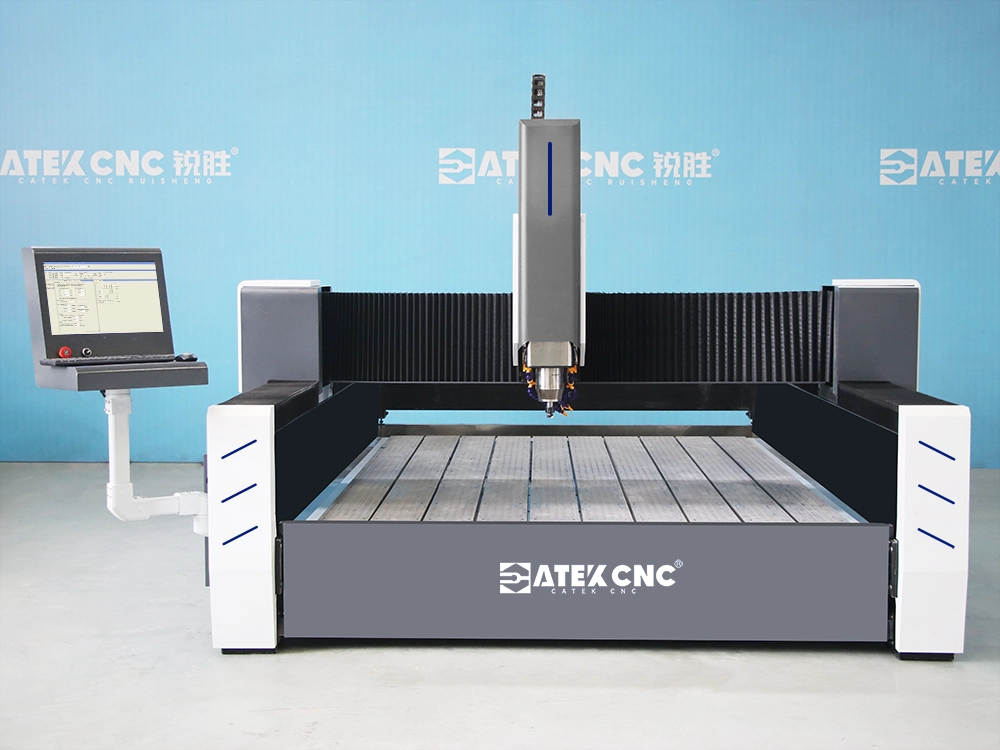

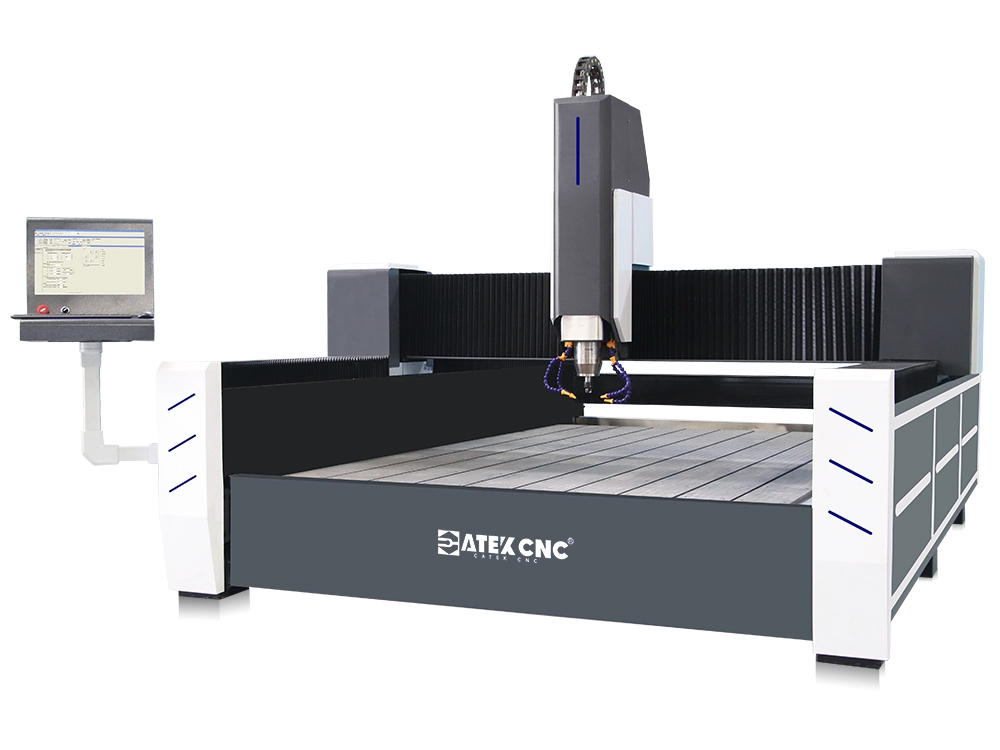

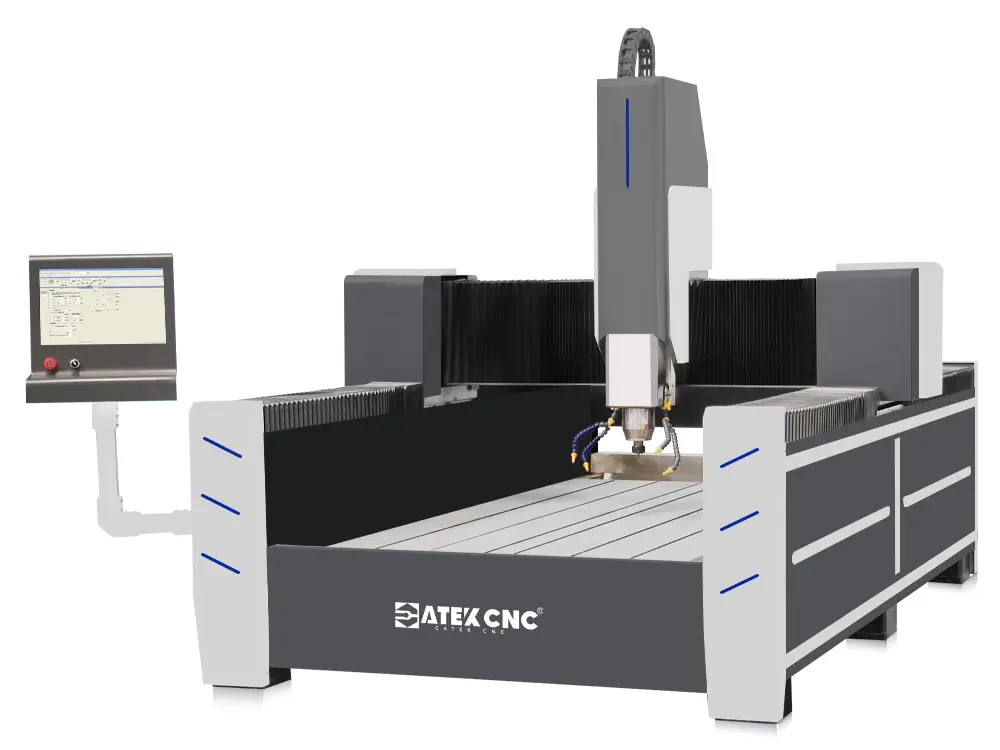

Large-Format CNC Stone Router for Stone Carving on Sale

Affordable 7*10ft CNC Stone Router Machine

[Function Description]

The CK-2030-S is an industrial-grade large-format stone processing machine, equipped with a spacious working table of 2000×3000mm. Its heavy-duty sunk-style bed frame is fabricated by welding thickened steel tubes. Combined with a high-precision transmission system and a 5.5kW high-speed water-cooled variable-frequency spindle, this CNC router is capable of processing a wide range of materials including marble, granite, wood, aluminum and copper.

Boasting high cost-effectiveness, excellent stability and broad applicability, the CK-2030-S CNC stone router not only elevates the automation level of stone processing, but also enables the creation of intricate patterns and fine carvings that are difficult to achieve with traditional manual techniques. As a pivotal piece of equipment for the transformation of the stone processing industry towards intelligence and high efficiency, it caters to the diverse processing needs of both small and medium-sized workshops as well as large enterprises, helping them generate greater economic benefits.

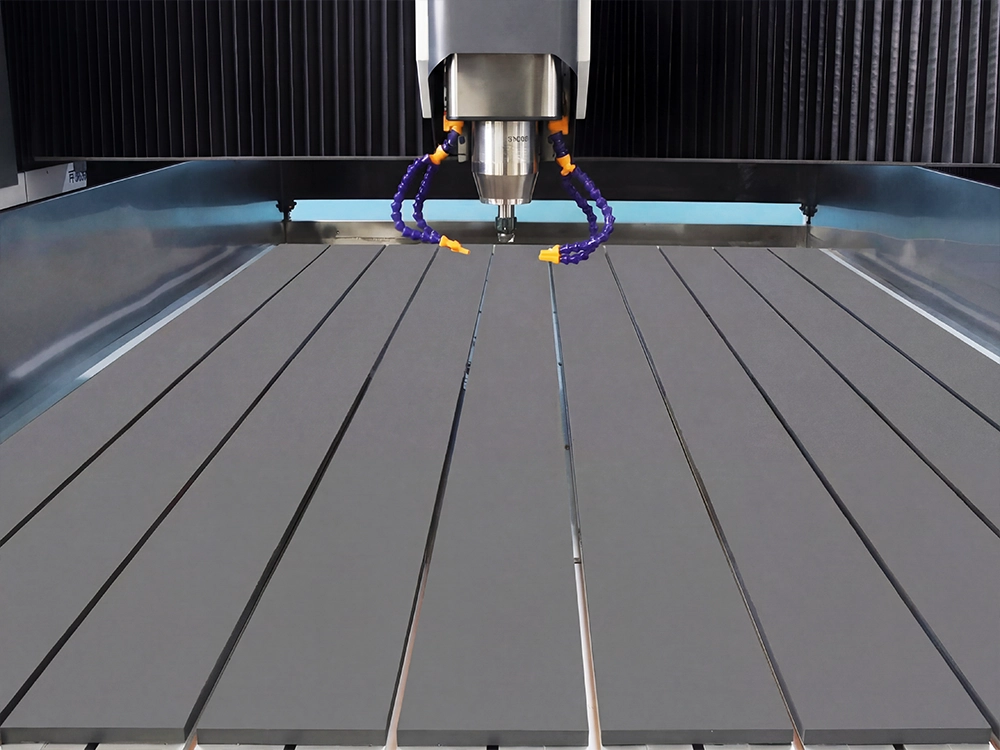

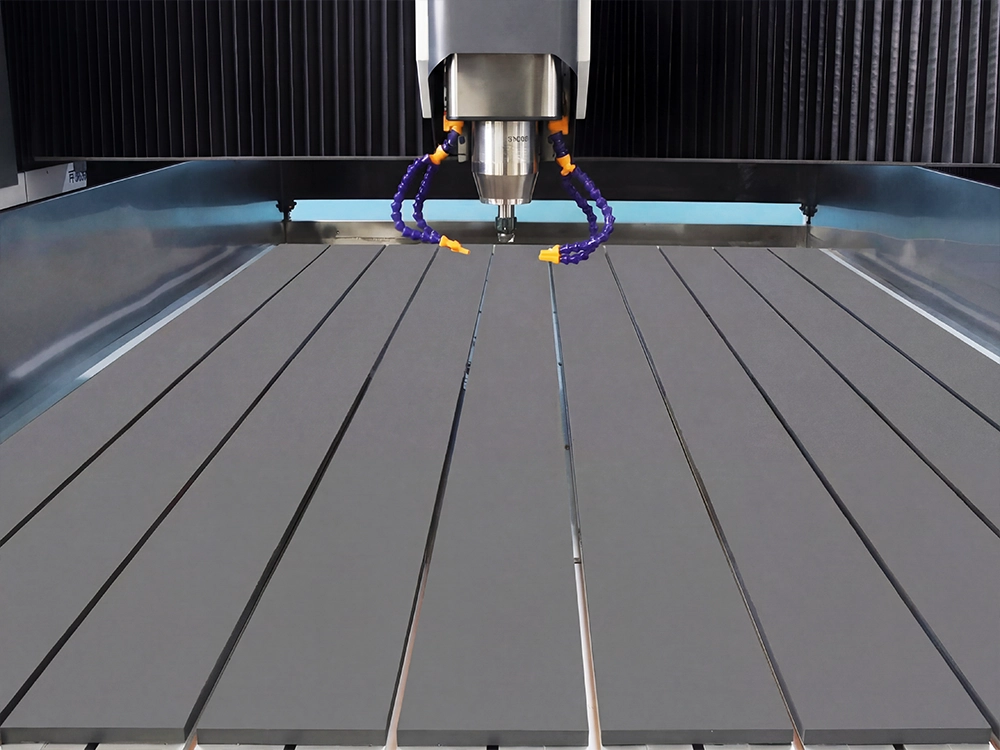

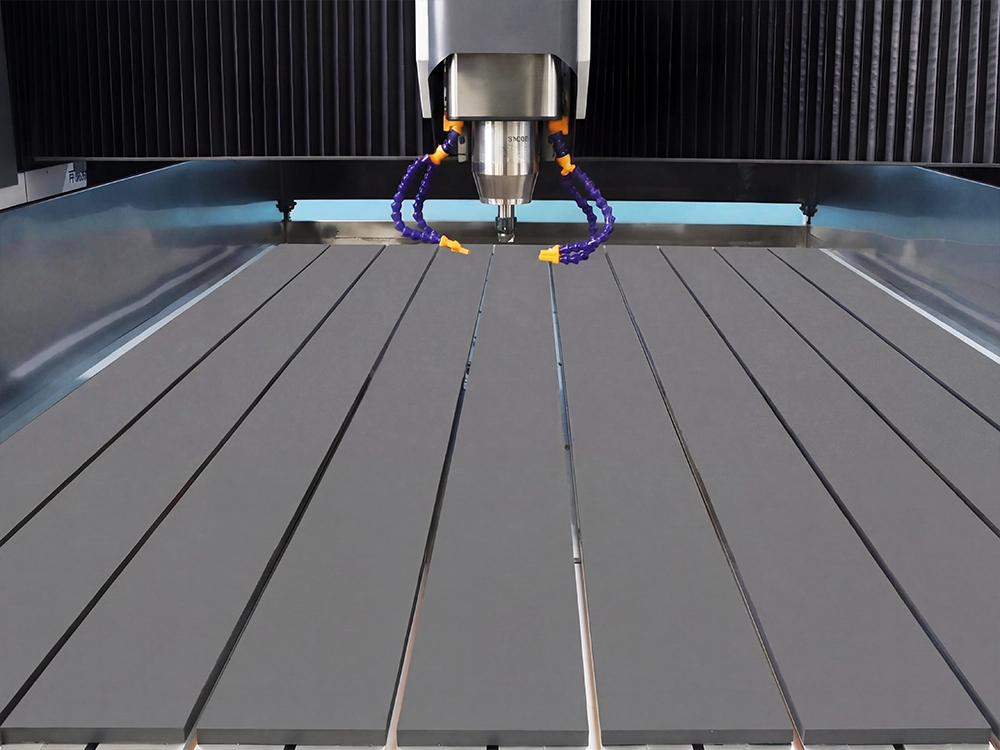

This CNC stone router is fitted with an integrated cooling and protective worktable specially designed for processing hard materials such as stone and metal, adopting a sunk-style one-piece welded stainless steel structure. The cooling system integrates tool cooling and machining dust suppression functions. During operation, multi-directional water channels continuously cool down the high-speed rotating tools, preventing tool blunting, chipping and other issues caused by overheating. This not only extends tool service life, but also effectively suppresses dust and debris generated during processing. The flowing water promptly washes away machining dust and debris, significantly reducing dust emission, improving the working environment and lowering the health risks of dust inhalation for operators.

The stainless steel water tank worktable features a T-slot structure for convenient workpiece clamping. The cooling water is recyclable with a recycling rate of over 90%, allowing for easy maintenance and helping to reduce operational costs.

Advantages of the Large CNC Stone Router With a 7×10ft Worktable

Heavy-Duty Sunk-Style Bed Frame and Heavy-Duty Crossbeam

- Bed Frame: A heavy-duty sunk-style bed frame specifically designed for CNC stone routers, featuring higher rigidity and ideal for heavy-duty machining scenarios such as stone and metal processing. The work surface of the bed frame is lower than the machine's reference plane, fabricated by welding thickened steel tubes and subjected to tempering stress relief treatment. Compared with conventional gantry-type bed frames, it boasts advantages like a low center of gravity, strong stability and high load-bearing capacity. The sunk-style bed frame can support larger and heavier workpieces, effectively reducing machining vibration and ensuring machining precision. In addition, it can be paired with a circulating water tank workbench to form a closed machining area, preventing the overflow of coolant and dust. It also reserves a larger Z-axis travel, meeting the processing requirements of three-dimensional carving and thick workpieces, and serves as a key structure for CNC stone routers to achieve high-precision machining.

- Heavy-Duty Crossbeam: Made of thickened heavy-duty square steel and processed by high-temperature tempering, the crossbeam offers higher rigidity, stronger deformation resistance and greater load-bearing capacity compared with those of ordinary CNC routers. It can be stably matched with high-power spindles, effectively resisting torsion and vibration during high-speed movement and machining, and avoiding machining precision errors caused by crossbeam deformation.

Flood Cooling System + T-Slot Worktable

- Flood Cooling System: The flood cooling system can continuously cool the cutting tools during high-speed machining, preventing tool blunting and chipping caused by overheating, and extending tool service life. Meanwhile, it uniformly cools the workpiece surface to reduce thermal deformation during the processing of hard materials, and can also wash away dust and debris generated during machining, avoiding dust pollution and abrasion of transmission systems such as guide rails. The water tank is formed by welding stainless steel plates and treated with anti-leakage and anti-rust processes, when paired with the flood cooling system, it enables the recycling of coolant.

- T-Slot Worktable: The T-slot worktable made of aluminum alloy has T-slots evenly distributed at standard intervals. The tabletop is paved with a rigid PVC plate, and combined with clamp plates and fixtures, it can quickly clamp workpieces of different sizes and shapes. This worktable has a wide range of adaptability: it can stably hold regular workpieces such as large stone slabs and metal plates, firmly fix various special-shaped parts, and support simultaneous clamping of multiple workpieces, which helps improve batch processing efficiency. Its stable clamping structure can effectively resist vibration and impact during high-speed machining, avoiding the decline of machining precision caused by workpiece displacement.

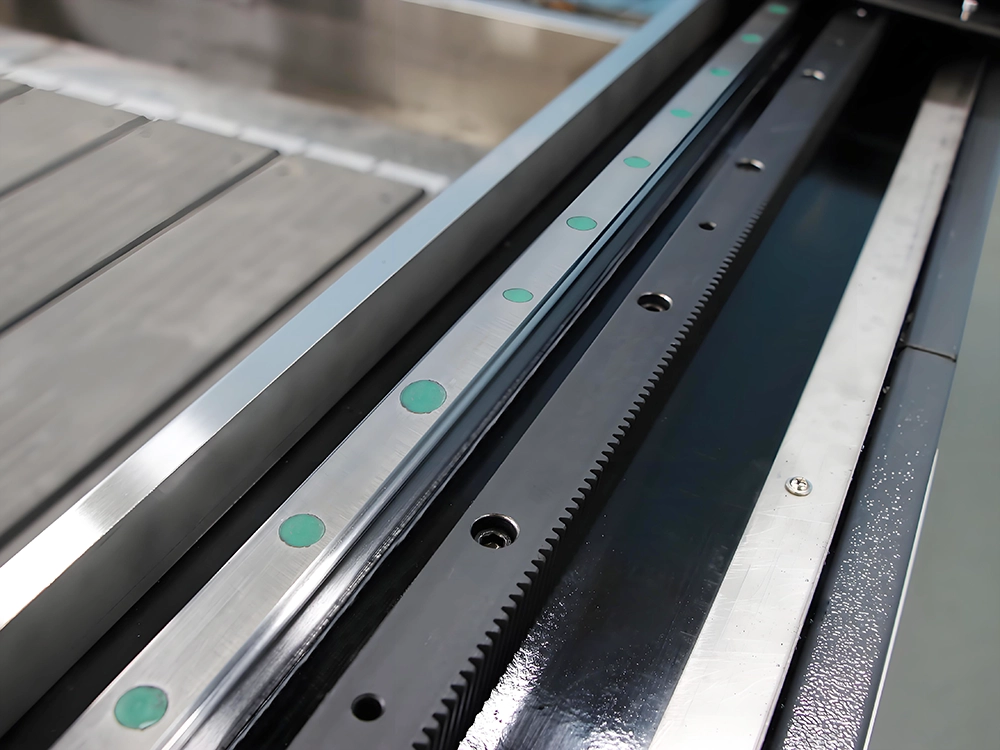

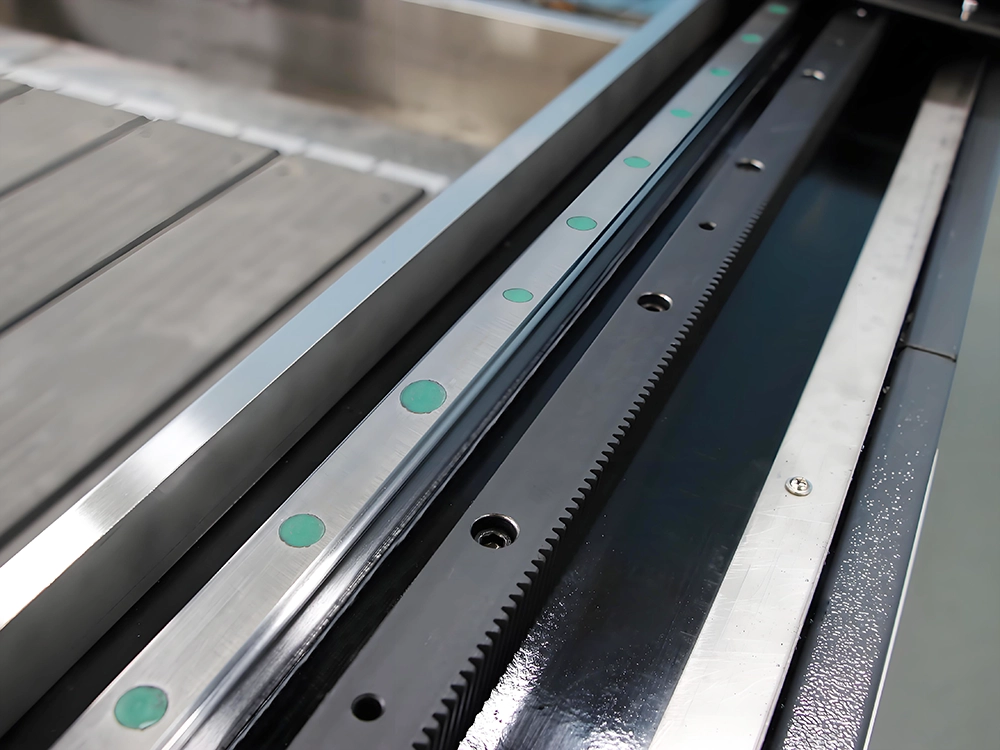

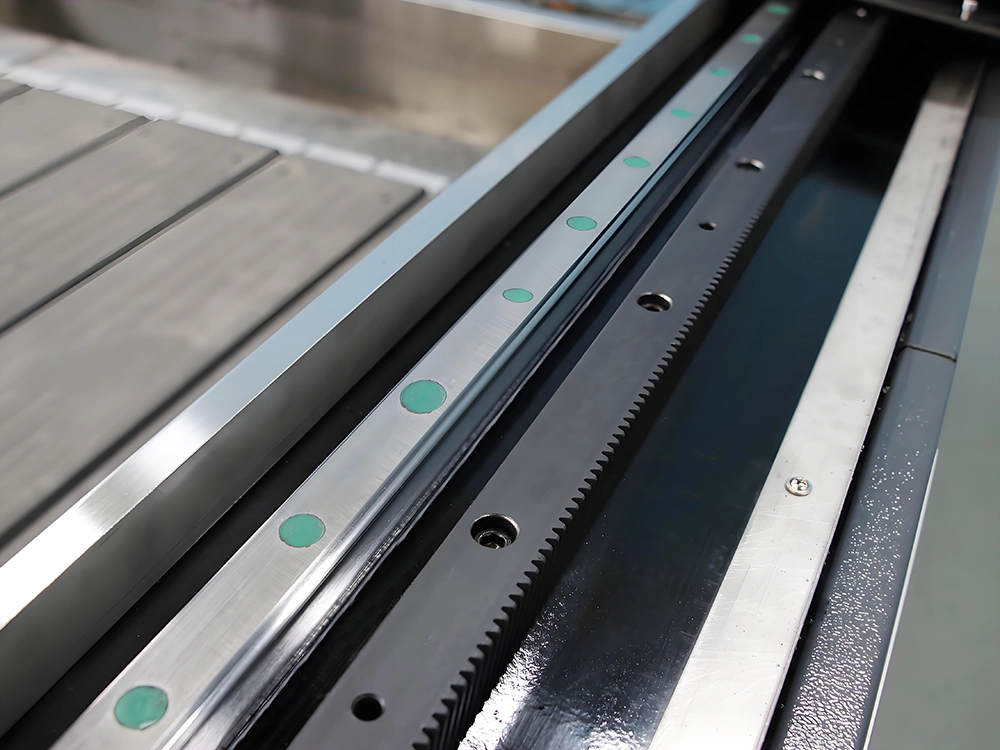

High-Precision XYZ-Axes Transmission System

- Guideways: Adopting a four-row steel ball and four-point contact design, they feature high rigidity, high precision, long service life and strong adaptability. The four-row steel ball layout can bear loads in four directions (up, down, left and right) simultaneously, with a lower friction coefficient than that of conventional sliding guide rails. Equipped with a self-aligning function, they can reduce the installation surface error and effectively ensure the high-speed, stable and long-term reliable operation of the CNC router.

- Racks & Pinions: The X and Y axes adopt high-precision ground helical racks & pinions for transmission, which are treated with high-frequency quenching and boast such advantages as high rigidity, excellent precision, low noise and long service life. After the rack surface is quenched, its wear resistance and deformation resistance are further enhanced. The helical rack & pinion adopts a progressive contact design, which keeps at least two teeth meshed at all times during operation, ensuring smoother transmission. It can also effectively offset partial radial force, suppress vibration during heavy cutting, and is suitable for heavy-load machining conditions.

- Ball Screws: The Z axis adopts TBI ball screws for transmission. Their Gothic arc groove, combined with a preloaded backlash-free design, eliminates axial clearance while maintaining smooth operation, can bear multi-directional loads and suppress vibration during heavy cutting. The rolling friction characteristic of ball screws significantly reduces the driving torque, which is only one-third of that of ordinary sliding screws. Besides, there is no crawling phenomenon at low speeds, and they perform excellently in both high-speed and micro-feed scenarios. In addition, the screws are designed with a sealed dust-proof structure, which helps reduce maintenance costs.

Water-Cooled Spindle and Constant-Temperature Cooling System

- Spindle: The 5.5kW high-speed water-cooled variable-frequency spindle is specially designed for stone processing, featuring heavy-load cutting capability with a maximum speed of 24,000 RPM. Equipped with a 5.5kW Variable Frequency Drive, it delivers high starting torque and excellent machining performance. The spindle is fitted with a fully enclosed water circulation cooling system, whose cooling efficiency is over 40% higher than that of air cooling. Combined with a constant-temperature chiller, it can stably control the operating temperature within 40℃, effectively preventing bearing wear and precision degradation caused by temperature rise. Adopting an ER32 collet, it supports tools with a diameter ranging from 3mm to 20mm, meeting diverse processing requirements.

- Chiller: It is paired with an S&A industrial chiller, which adopts a compressor refrigeration and intelligent temperature control system with a temperature control accuracy of ±1℃. Compared with ordinary circulating water pumps, its cooling efficiency is improved by more than 50%, and it can maintain a constant water temperature, avoiding the impact of spindle thermal expansion and contraction on machining precision. The equipment is equipped with multiple safety functions such as water shortage protection, temperature alarm and flow detection. In case of abnormalities, it can automatically issue an alarm and take protective measures to ensure the stable operation of the spindle and chiller, supporting the long-term continuous operation of the CNC stone router.

High-power Servo Drive System

- Servo Motor: The transmission system adopts a self-developed 1500W servo motor by CATEKCNC, which features high precision, high responsiveness and high torque. Built-in with a high-precision encoder, the motor can provide real-time feedback on its operating status, with a repeat positioning accuracy of ±0.01mm. It effectively addresses the problems of step loss and precision error that may occur with stepping motors during high-speed operation. In addition, the motor has the characteristic of high torque at low speeds, which can easily drive the heavy-duty gantry structure, realize high-speed and precise positioning as well as smooth start-stop, and significantly reduce non-machining time.

- Reducer: It is equipped with a Shimpo planetary gear reducer imported from Japan, which can multiply the output torque of the servo motor, ensure stable driving of the heavy-duty crossbeam, and effectively resist cutting impact during the processing of hard materials such as granite, thereby improving machining quality. Adopting a multi-tooth meshing planetary gear structure, the reducer has a transmission efficiency of over 95%, which can fully meet the processing requirements of high precision and high torque.

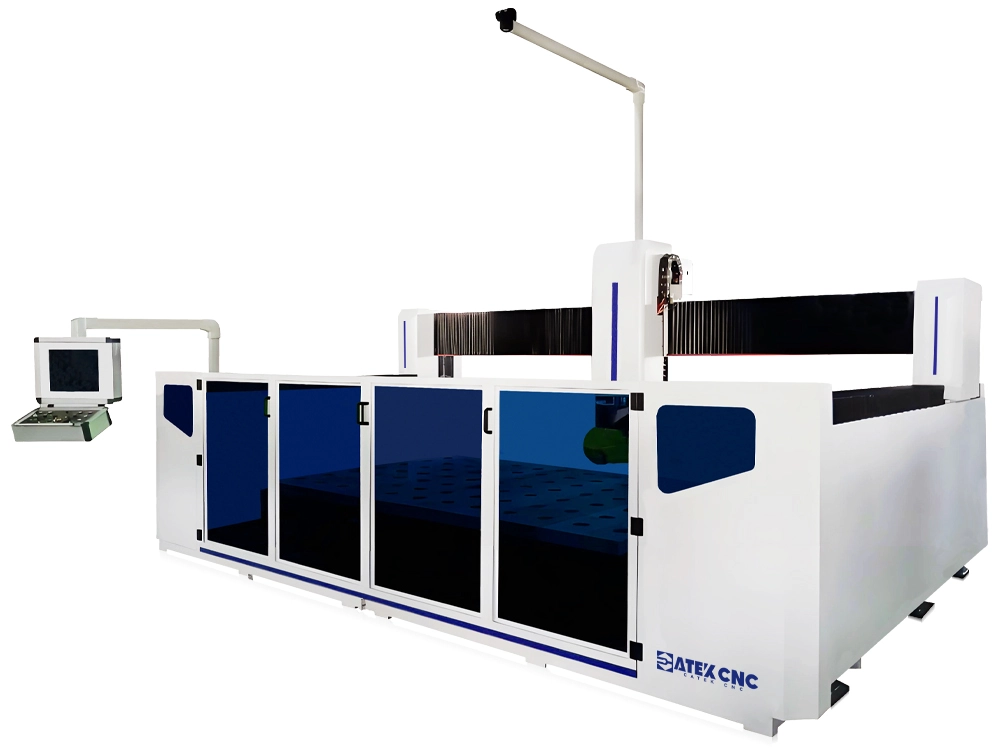

Full Enclosured Protection Assembly

- X & Y Axis Protection: Equipped with a bellows-type full enclosure shield, which is composed of flame-retardant and wear-resistant PVC coated fabric combined with a metal framework. It can flexibly expand and contract with X and Y axes. Its sealed structure can completely prevent stone dust and coolant from entering the transmission areas of the guideways and racks.

- Z-Axis Protection: Adopts a retractable layered sheet metal shield, which is integrally formed by welding and surface-treated with plastic spraying for rust prevention. Featuring high rigidity and impact resistance, it can withstand the splash and impact of stone debris. The shield expands and contracts synchronously with the lifting of the Z-axis, providing full coverage for the ball screws and guideways.

The three-axis full enclosure protection system works synergistically to prevent coolant from infiltrating the transmission components, avoid precision degradation caused by corrosion and contamination, and extend the service life of the CNC stone router.

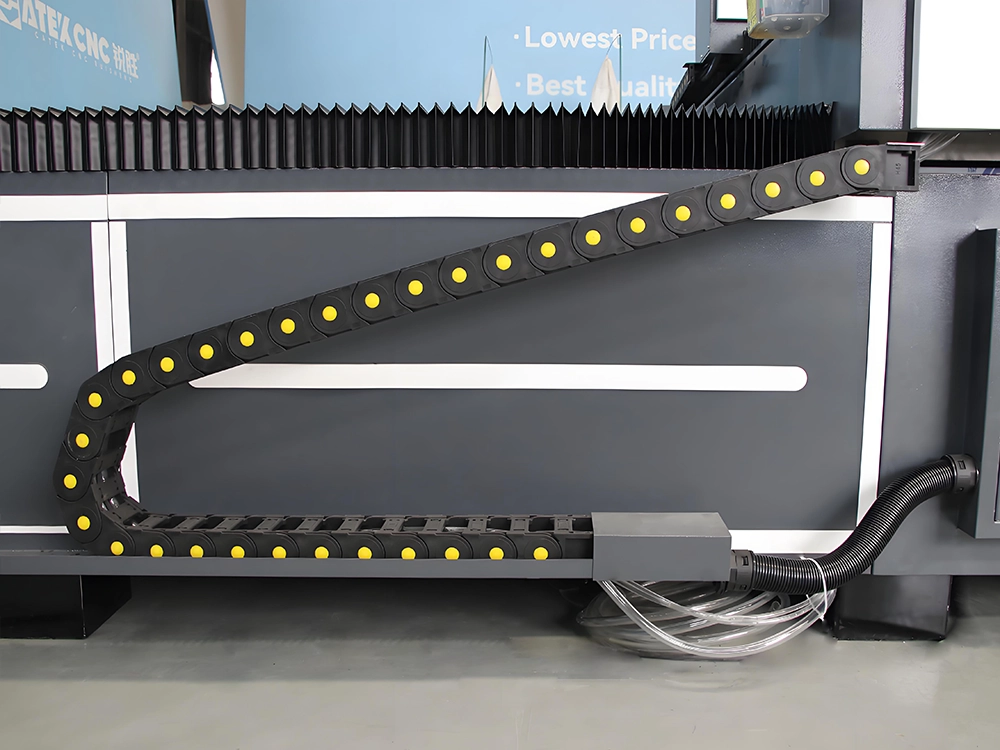

Quality Auxiliary System

- Automatic Lubrication System: The automatic lubrication system supports adjustable oil injection time and interval cycles, with a single oil supply accuracy of ±5%, which can meet the requirements of long-term continuous operation of the router. The lubricating oil pot adopts a sealed dust-proof design, which can effectively prevent dust and coolant generated during machining from entering, and maintain stable operation even under harsh working conditions such as humidity and heavy dust. This system can precisely lubricate transmission components including guide rails, sliders and ball screws, reduce friction and wear, and significantly extend the service life of key moving parts.

- High-strength Cable Carrier: The cable carrier features an integrally molded structure made of reinforced nylon, which is designed for accommodating cables, water pipes and other pipelines of the CNC stone router. Its chain links adopt an arc transition design and the side panels are detachable, facilitating cable assembly, disassembly and troubleshooting. By organizing the pipelines in an orderly manner, the cable carrier prevents tangling or wear of the pipelines during the frequent reciprocating movement of the motion axes, and effectively extends their service life.

Intelligent Control System

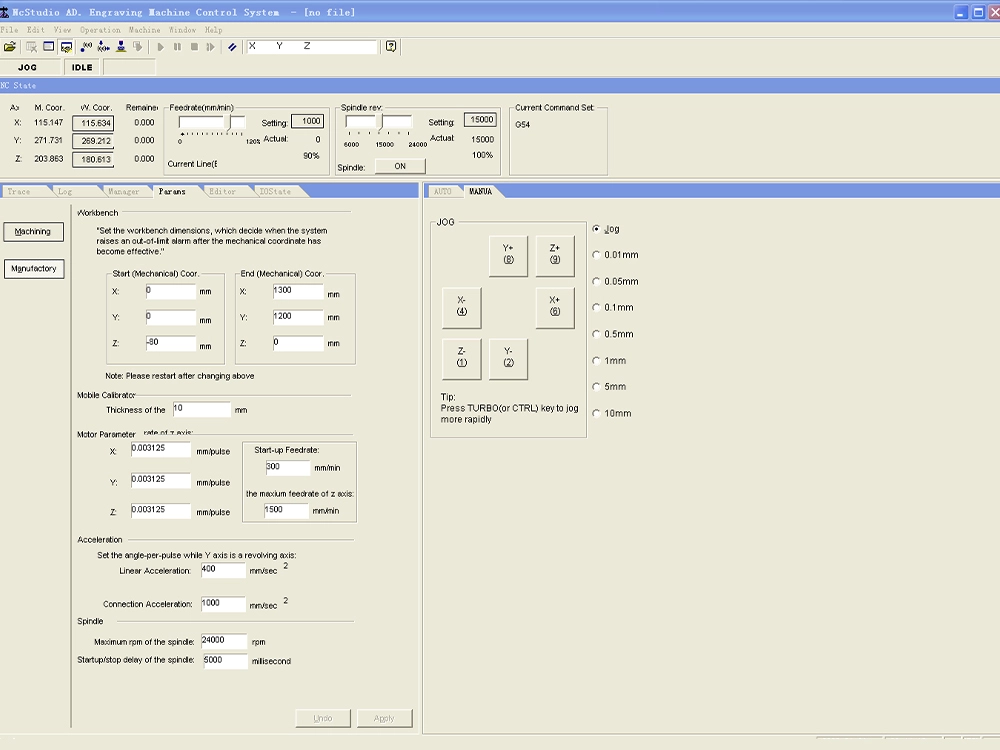

Equipped with the Weihong V5 Control System, which is specially designed for CNC stone routers. This system is used in conjunction with the NCStudio software, supporting multi-axis control and featuring high precision, strong adaptability and high reliability.

With an intuitive and concise interface that supports full English display, it enables easy operation. The system is compatible with various G-code formats and supports advanced functions such as path simulation preview and power-off resumption of carving. It is particularly suitable for high-speed control in heavy-duty stone processing, and can efficiently complete the carving and cutting operations of hard stones such as granite.

Details of the Large CNC Stone Router With a 7×10ft Worktable

- 5.5kW high-speed water-cooled spindle

A water-cooled spindle specially designed for stone processing is adopted, supporting stepless variable-frequency speed regulation from 0 to 24,000 rpm. It delivers stable torque output and can easily achieve deep cutting of hard stones such as granite. The spindle is built with high-speed ceramic bearings, featuring minimal radial runout to ensure stable tool operation.

- Stainless steel circulating water tank + aluminum alloy t-slot worktable

The T-slot worktable, combined with clamp plates and fixtures, enables quick clamping and disassembly of workpieces. It is adaptable to workpieces of various shapes and sizes, offering great flexibility and convenience.

- High-precision guideways + helical racks

High-precision heavy-duty square linear guideways from Taiwan HIWIN and high-precision helical racks from Taiwan YYC are adopted. The system boasts high rigidity, which can effectively resist cutting vibration and multi-directional loads, ensuring stable operation during heavy-load, high-precision and complex machining processes.

- Bellows enclosured shield

The X and Y axes are equipped with retractable full-closure bellows shields, which can effectively prevent machining chips and dust from invading the guide rail and rack areas, keep the transmission system clean, and extend the service life of the CNC stone router.

- Sheet metal enclosure shield

The Z-axis is fitted with a multi-layer retractable sheet metal shield, which can protect against the splash of machining chips and the infiltration of coolant. It prevents corrosion or damage to transmission components, protects the spindle at the same time, and reduces the risk of collision.

- High-strength cable carrier

A cable carrier made of high-strength flame-retardant nylon is adopted, which integrates and accommodates all pipelines of the CNC stone router. It effectively prevents pipeline wear, facilitates troubleshooting, and extends the service life of the pipelines.

- Automatic lubrication system

An independently controlled automatic lubrication system is adopted, with parameters displayed in real time on the digital panel. The lubrication frequency and duration can be preset to realize automatic lubrication, which reduces maintenance costs and avoids equipment failures caused by insufficient lubrication.

- Weihong control system

Equipped with the Weihong control system and matched with NCStudio software, it features an intuitive and easy-to-operate full-English interface, and is compatible with various CAD/CAM software. Users only need to select a pattern to start machining, allowing operators without CNC experience to master the operation quickly.

Technical Parameters of the 7×10ft CNC Stone Router

| Model | CK-2030-S |

|---|---|

| Working Area (XYZ) | 2000*3000*400mm (Customizable processing size available) |

| Bed | 8mm thick steel tube welded heavy-duty bed |

| Cooling Method | S&A circulating water chiller + flood cooling |

| Work Table | Aluminum T-slot table |

| Water Tank | Stainless steel circulating water tank |

| Spindle | 5.5KW high-speed water-cooled variable-frequency spindle (Stone specialized) |

| Spindle Speed | 0–24,000 RPM |

| Inverter | Fuling 5.5KW high-torque inverter |

| Guideways | 30mm HIWIN linear guideways / linear bearings |

| Rack | Taiwan YYC 1.5M rack |

| Z-Axis Ball Screw | Taiwan TBI 2510 ball screw |

| Servo Motor | CATEKCNC dedicated 1500W servo motor / servo drive (Other brands or stepper motors are available) |

| Reducer | Shimpo planetary gear reducer |

| Control Cabinet | Independent anti-interference control cabinet |

| Control System | Weihong multi-function CNC system |

| Voltage | 380V / 3-Phase or 220V / 3-Phase |

| Max. Rapid Traverse Speed | 60,000 mm/min |

| Max. Working Speed | 18,000 mm/min |

| Dimensions | 3900*2900*2200mm |

| Weight | 2700kg |

Application of the 7×10ft CNC Stone Router

Applicable Materials:

Stone: Granite, Marble, Sandstone, Slate, Jade, Artificial Quartz Stone, Artificial Marble, Bluestone, Ceramic, Cement, Crystal, etc.

Wood: MDF, Wood Plank, Plywood, OSB, Bamboo, Aluminum Composite Panel, Honeycomb Panel, etc.

Metals: Aluminum, Copper, Aluminum Alloy, Bronze, Red Copper, Silver, Gold, etc.

Other Materials: Acrylic, PVC, Foam Board (KT Board), Gypsum Board, Epoxy Board, Bakelite, etc.

Applicable Products:

Architectural & Decoration: Tombstones, Stone Railings, Feature Walls, Landscape Stones, Antique-style Stone Carvings, Stone Signage Plates, Jade Ornaments, Stone Doors, Kitchen Countertops, Bathroom Vanity Tops, Relief Feature Walls, Door Trims, Artistic Stone Tablets, Inscribed Stone Monuments, Stone Tables and Benches, etc.

Decorative & Signage: Stone Warning Signs, Acrylic Signs, Acrylic Advertising Letters, MDF Molds, Memorial Plaques, Medals, Aluminum Alloy Trophies, Copper Molds, Aluminum Molds, etc.

Wood Products: Wooden Doors, Wardrobes, Cabinets, MDF Furniture, Antique-style Furniture, Wooden Plaques, Wooden Boxes, Wooden Molds, Wooden Inscribed Tablets, Decorative Wood Panels, etc.

| Model | CK-2030-S |

|---|---|

| Working Area (XYZ) | 2000*3000*400mm (Customizable processing size available) |

| Z-Axis Ball Screw | Taiwan TBI 2510 ball screw |

| Cooling Method | S&A circulating water chiller + flood cooling |

| Work Table | Aluminum T-slot table |

| Water Tank | Stainless steel circulating water tank |

| Spindle | 5.5KW high-speed water-cooled variable-frequency spindle (Stone specialized) |

| Spindle Speed | 0–24,000 RPM |

| Inverter | Fuling 5.5KW high-torque inverter |

| Guideways | 30mm HIWIN linear guideways / linear bearings |

| Rack | Taiwan YYC 1.5M rack |

| Bed | 8mm thick steel tube welded heavy-duty bed |

| Servo Motor | CATEKCNC dedicated 1500W servo motor / servo drive (Other brands or stepper motors are available) |

| Reducer | Shimpo planetary gear reducer |

| Control Cabinet | Independent anti-interference control cabinet |

| Control System | Weihong multi-function CNC system |

| Voltage | 380V / 3-Phase or 220V / 3-Phase |

| Max. Rapid Traverse Speed | 60,000 mm/min |

| Max. Working Speed | 18,000 mm/min |

| Dimensions | 3900*2900*2200mm |

| Weight | 2700kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.