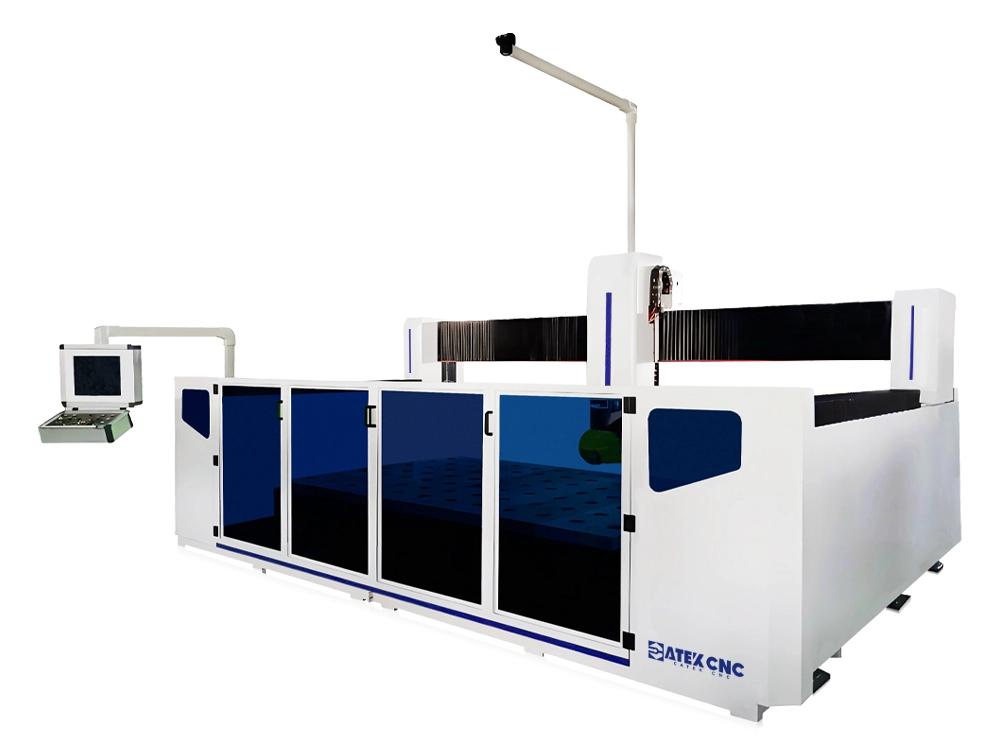

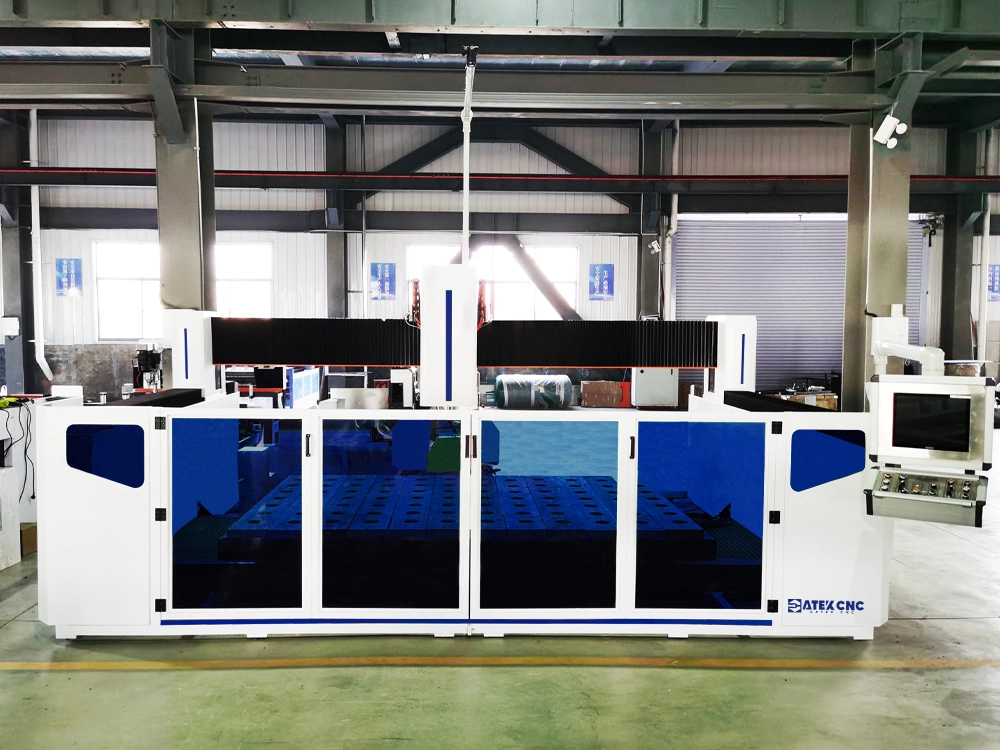

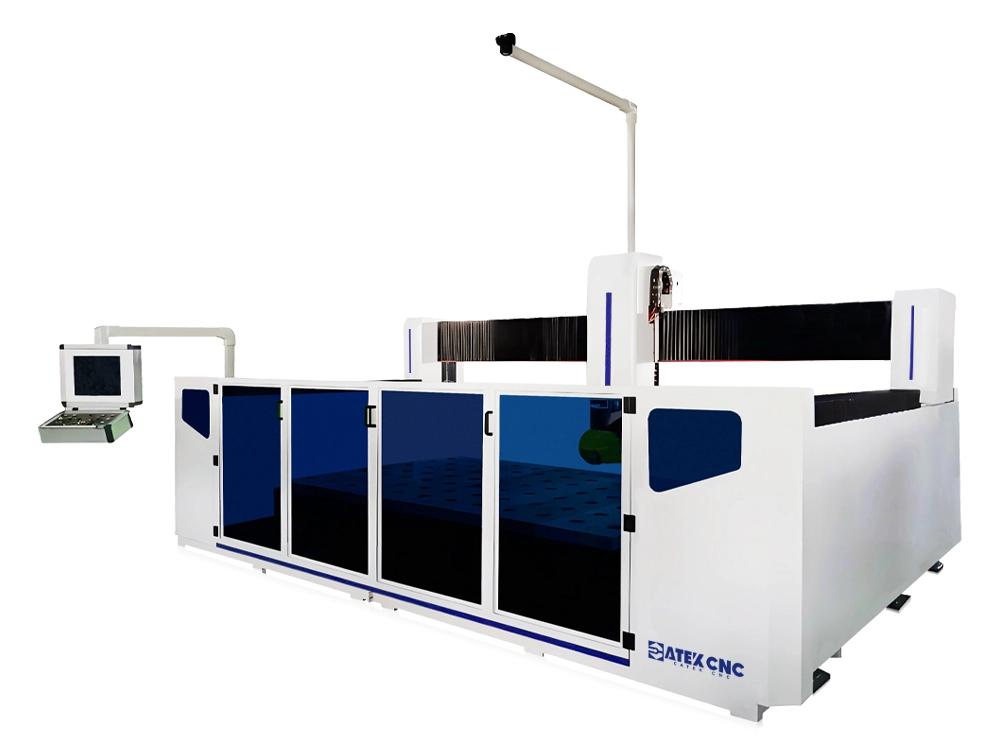

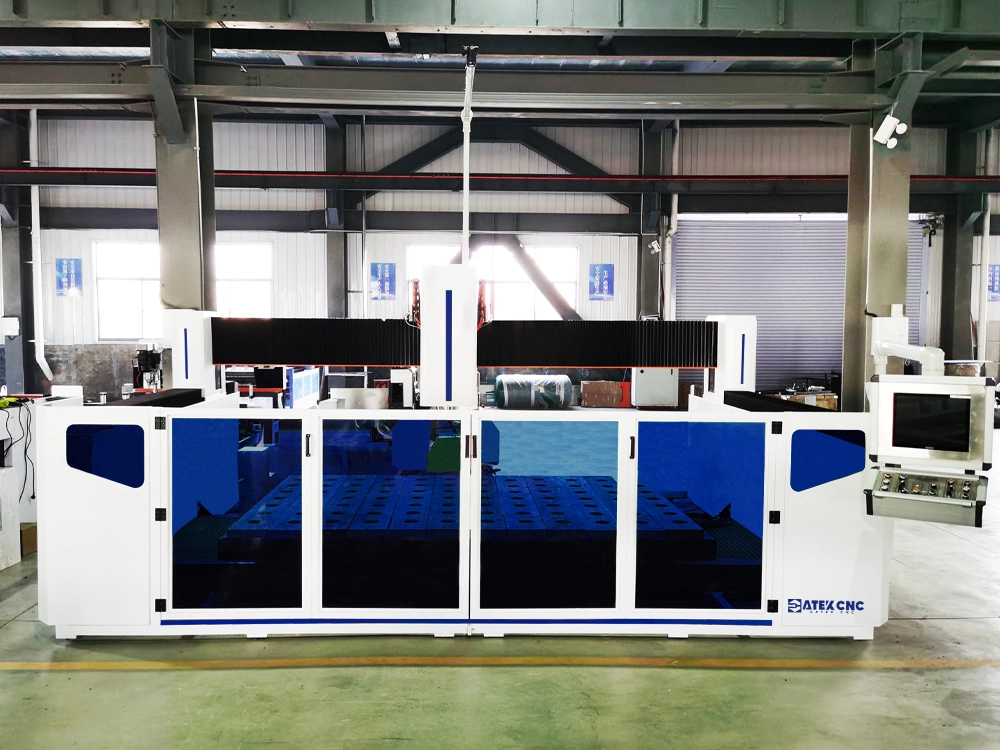

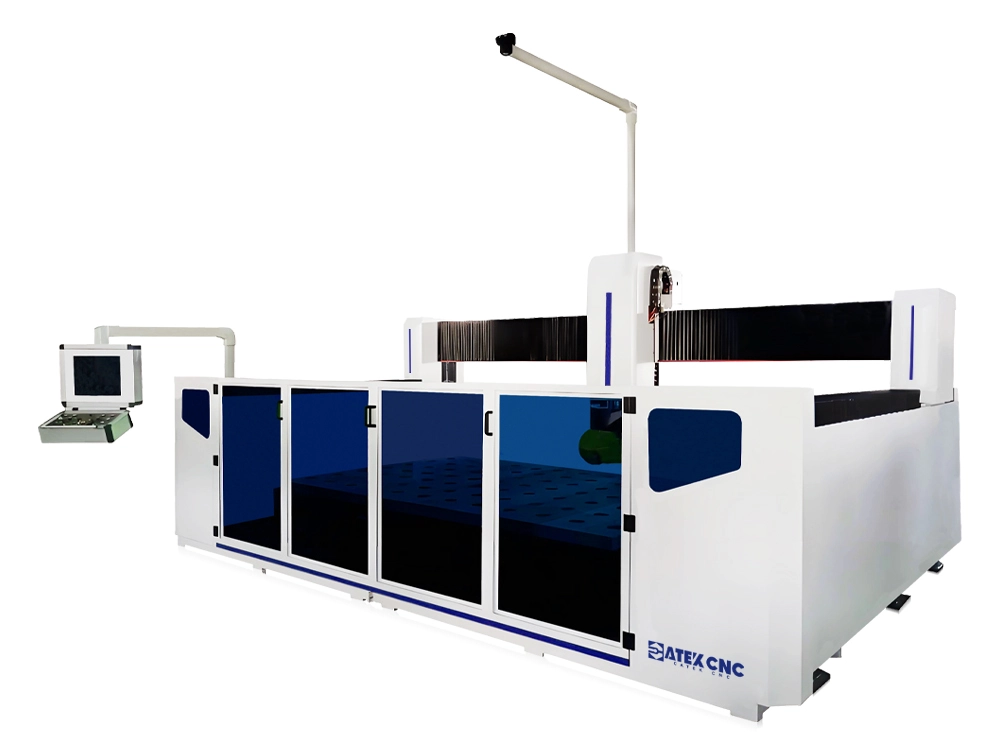

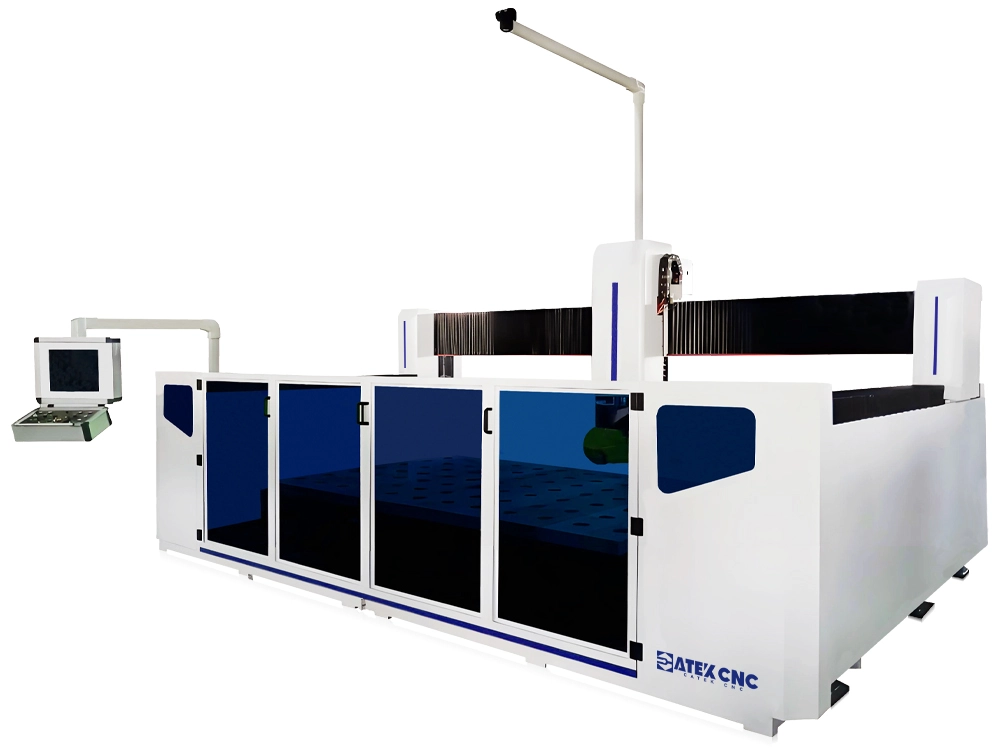

Five-Axis Stone Cutting Bridge Machine for Kitchen and Bathroom Countertop Manufacturing

Five-Axis CNC Stone Bridge Saw for Cutting Marble and Granite

[Function Description]

The five-axis stone cutting bridge machine is a highly efficient and versatile large-scale stone processing machine, widely used in the stone industry for cutting, carving, drilling, milling, edging, and chamfering. Compared to ordinary three-axis stone routers, it adds two additional rotary axes. Through the coordinated work of three linear axes and two rotary axes, it can achieve efficient processing of complex surfaces. It supports various types of stone, including marble, granite, artificial stone, etc., and can adjust processing parameters according to different needs. It is widely used in stone countertops, cabinet panels, profile carving, and other fields.

The five-axis stone cutting bridge saw uses an intelligent CNC system, which is interacted with through a touch screen, making operation very simple. It integrates functions such as cross-cutting, longitudinal cutting, 45-degree angle cutting, circular, oval, and special-shaped layout processing. The five-axis linkage function allows the tool to move and rotate freely in three-dimensional space, enabling precise processing of complex curved decorative stones. Equipped with a camera vision system, using a wide-angle lens, it can capture the entire countertop image in one shot, making the operation intuitive. It can accurately position the stone and quickly complete the processing, saving time wasted on manual positioning.

The five-axis stone cutting bridge machine can complete multiple processes of a product in one go, avoiding the costs and losses caused by multiple handlings (especially for stone that are bulky and heavy), while also reducing the time for positioning and calibration, effectively improving production efficiency. In addition, the high processing accuracy and automation of the five-axis bridge cutting saw also reduce material waste, further lowering production costs.

How Does a Five-Axis Stone Cutting Machine Perform Stone Cutting Tasks?

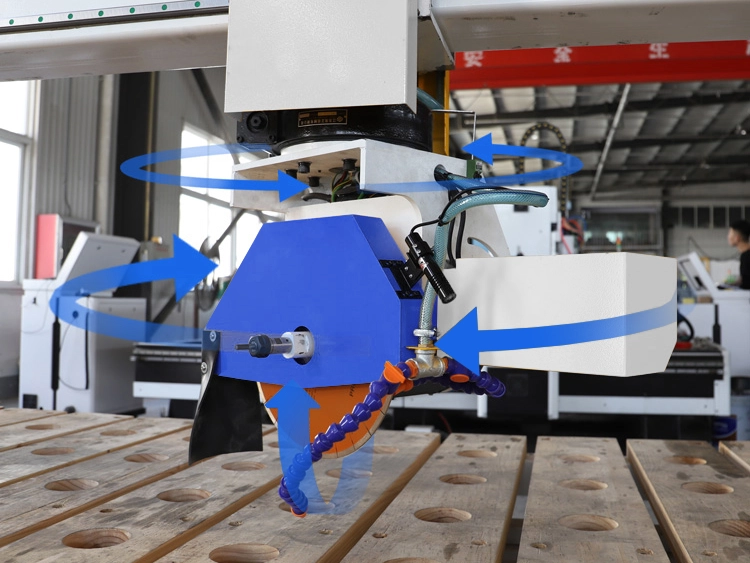

The core of the five-axis stone bridge cutter lies in its five-axis linkage technology and intelligent control system. This system drives the coordinated movement of three linear axes (X, Y, Z) and two rotational axes (A, C) to achieve multi-directional cutting and processing of stone. The three linear axes controlling the longitudinal horizontal movement of the beam (X), the lateral horizontal movement of the Z-axis transverse slide (Y), and the vertical movement of the cutting tool (Z). The two rotational axes are located at the junction of the cutting tool and the Z-axis transverse slide. One allows for a 360° horizontal rotation, used to change the cutting direction of the saw blade; the other enables the vertically downward saw blade to tilt at a certain angle (up to approximately 90°), used for vertical tilt cutting of the stone. This linkage processing method enables the machine to perform complex spatial surface processing, such as cutting, chamfering, grooving, drilling, and other operations on special-shaped stones. Automated control, one-click photo layout, and automatic optimization of processing paths effectively reduce manual intervention, lower the demand for specialized personnel, and enhance production efficiency.

Advantages of Heavy-Duty Five-Axis Stone Cutting Bridge Saw

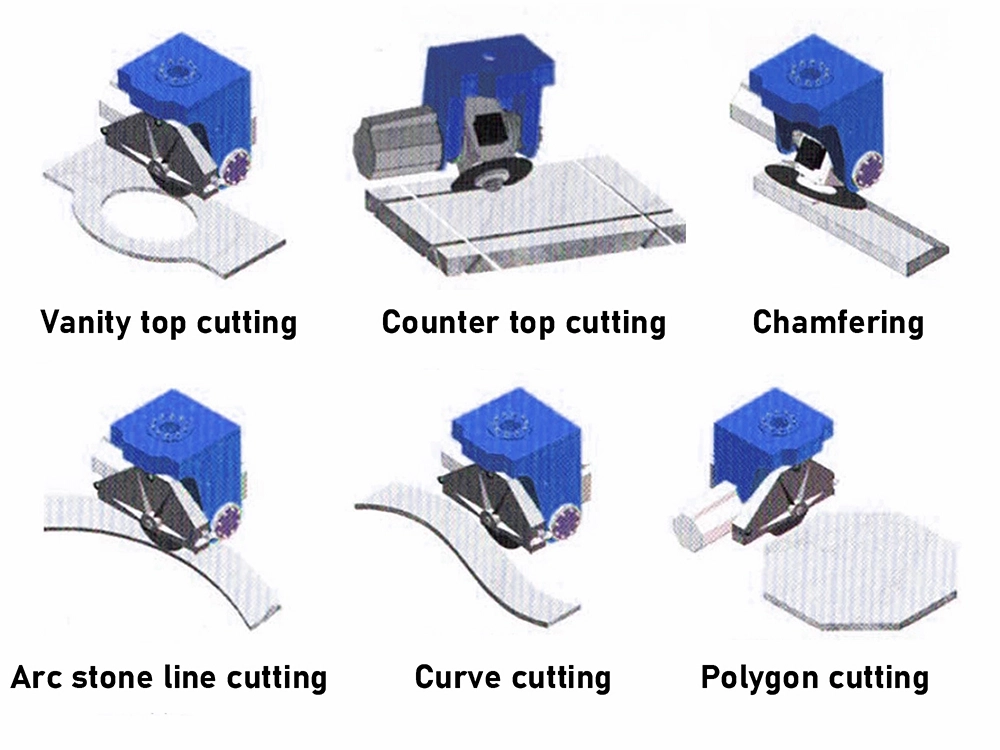

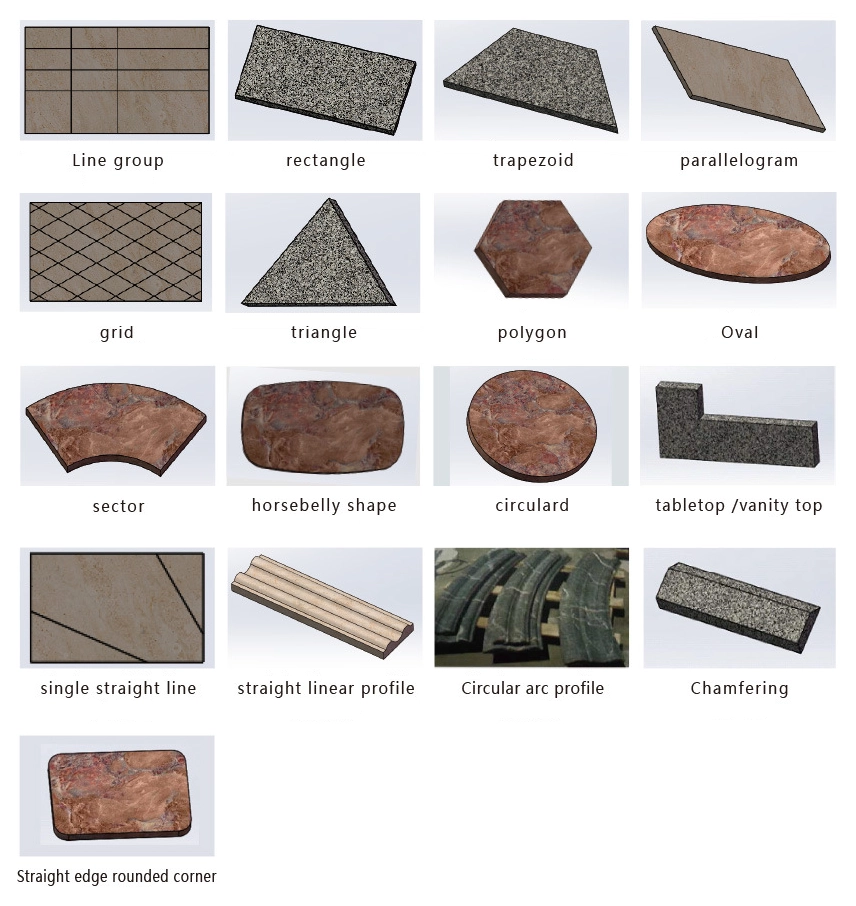

- The cutting head can rotate horizontally at any angle, enabling the processing and cutting of polygons, sectors, circles, ellipses, horse belly edges, grids, flowerpot holes, profiles, and more.

- The cutting head can tilt from 0° to 90° for chamfer cutting. The worktable can tilt up to 85° for easy loading and unloading of slabs.

- Equipped with four suction cups, the machine features a suction cup slab-moving function, capable of moving slabs up to 360KG. It can operate with single or double suction cups, making slab movement more convenient.

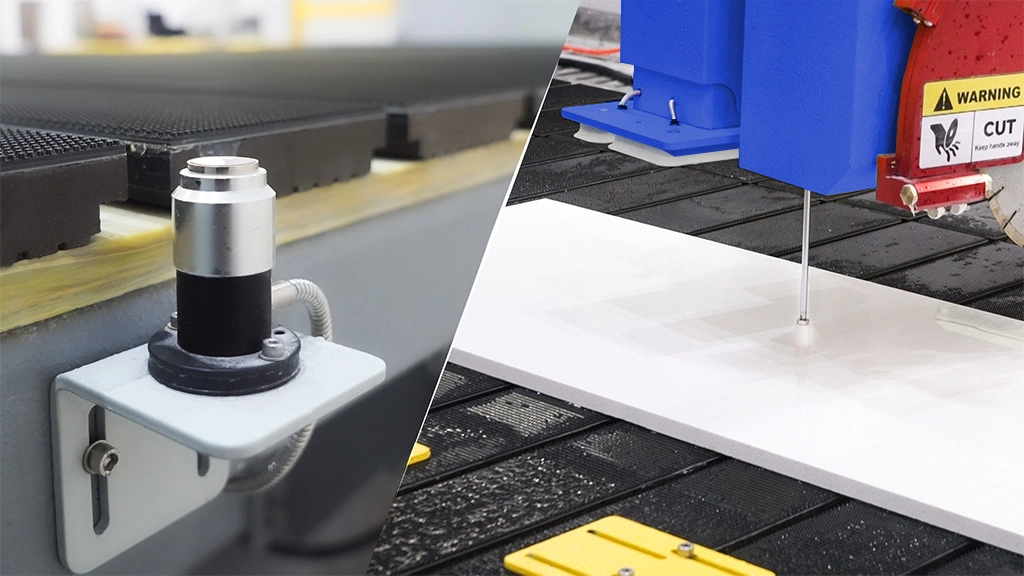

- It includes automatic stone thickness measurement and tool diameter measurement functions, allowing automatic measurement of the saw blade diameter to monitor wear and tear in real-time, eliminating the inaccuracies of manual measurements.

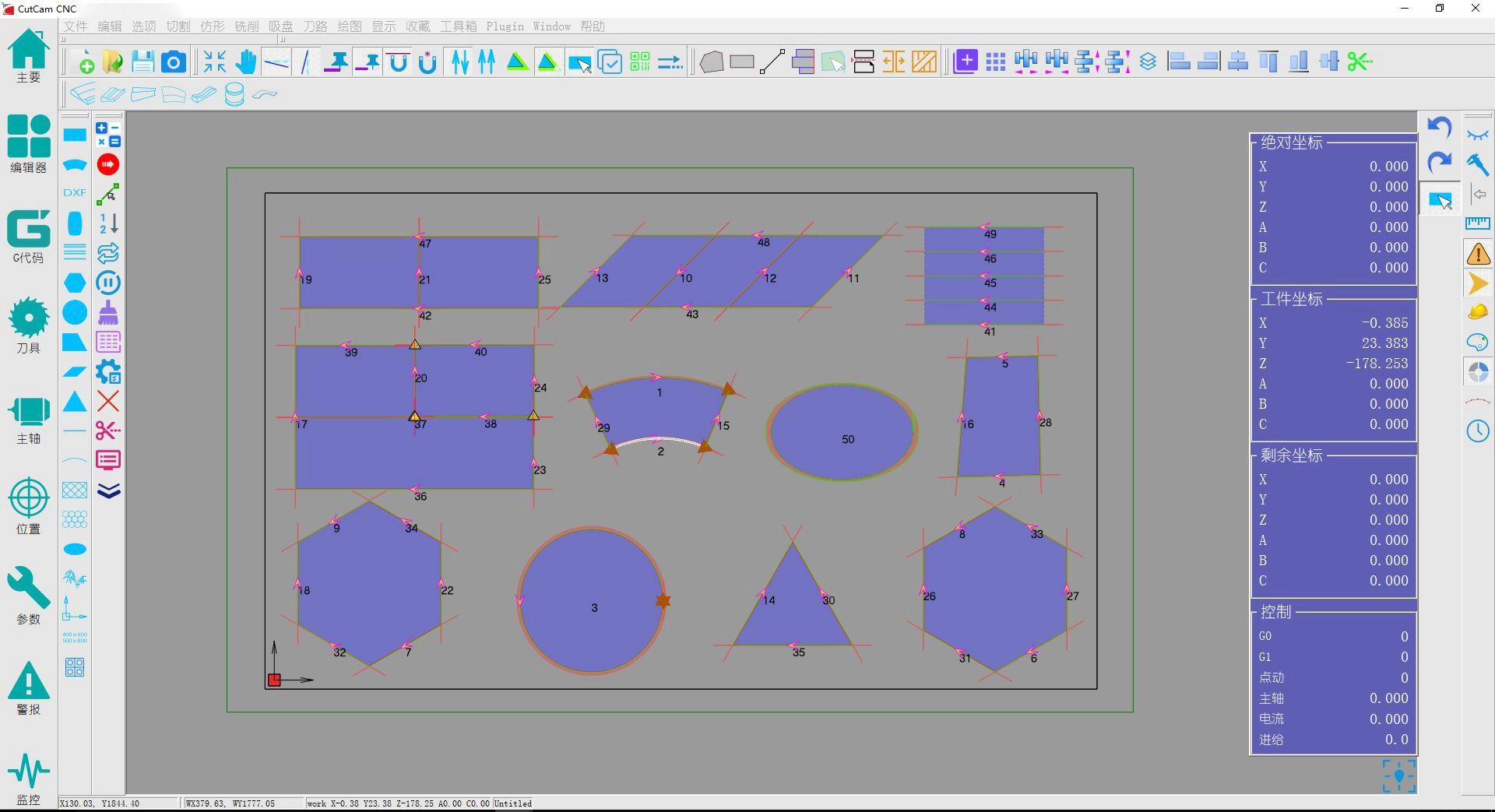

- Utilizing an intelligent CNC system, the accompanying CAD/CAM plugin enables direct graphic input into the five-axis system, simplifying operations and supporting one-click import of DXF files.

- The Y-axis employs a high-power dual-drive form, facilitating easy adjustments and ensuring smoother machine operation. Precision-critical connecting parts of the transmission system use seamless connections to guarantee operational accuracy and stability.

- Equipped with a wide-angle camera, it can automatically take photos to measure dimensions. It supports dividing material defect areas through photos, automatically avoiding these areas during processing layout.

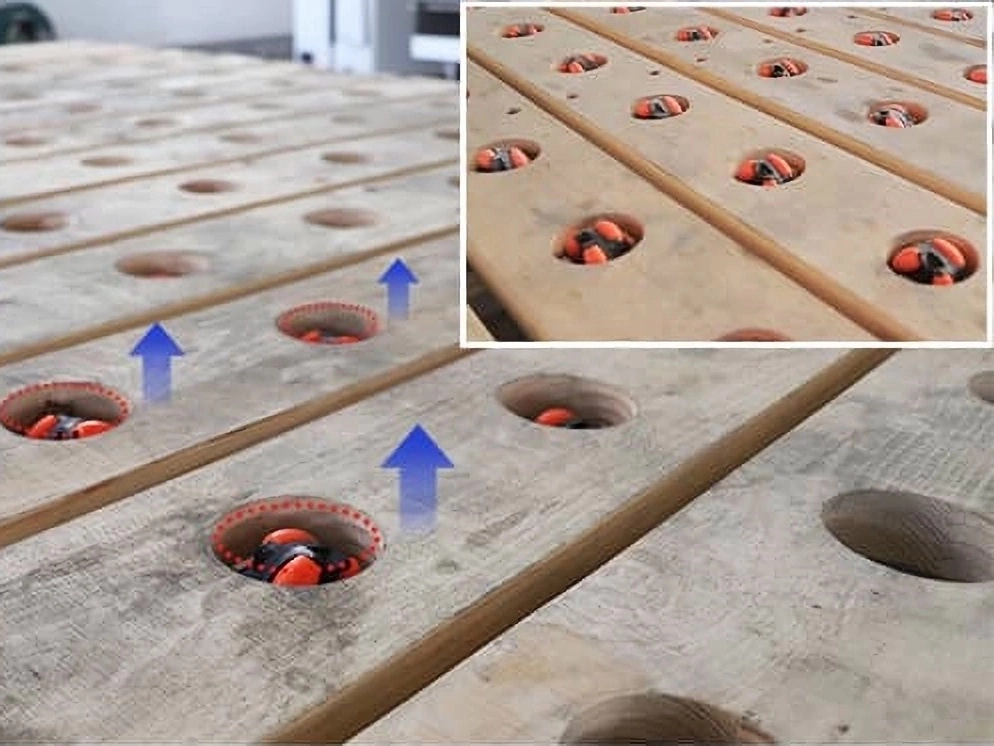

- After processing is completed, pneumatic rollers automatically lift, and the worktable flips over, facilitating the unloading of processed materials.

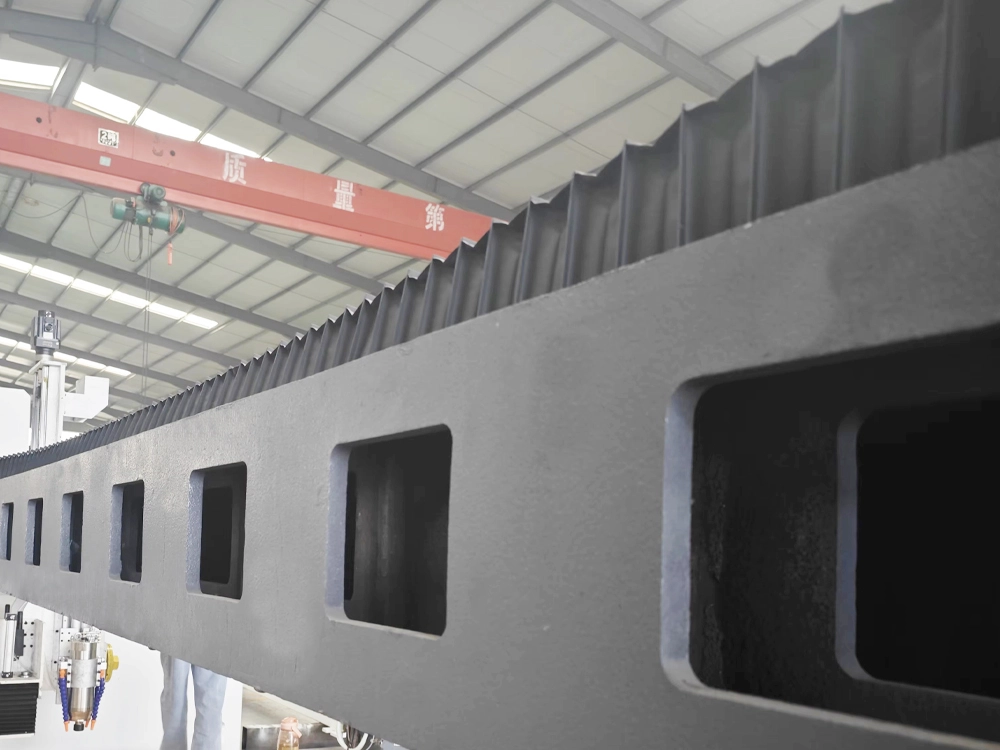

- The machine uses an integrally cast beam, thickened and reinforced for stability, durability, and resistance to deformation, ensuring long-term processing accuracy.

- It comes with pneumatic tabletop pressing rods for easy slab fixation, preventing material waste caused by slab displacement during processing.

Features of the Five-Axis Stone Cutting Bridge Saw

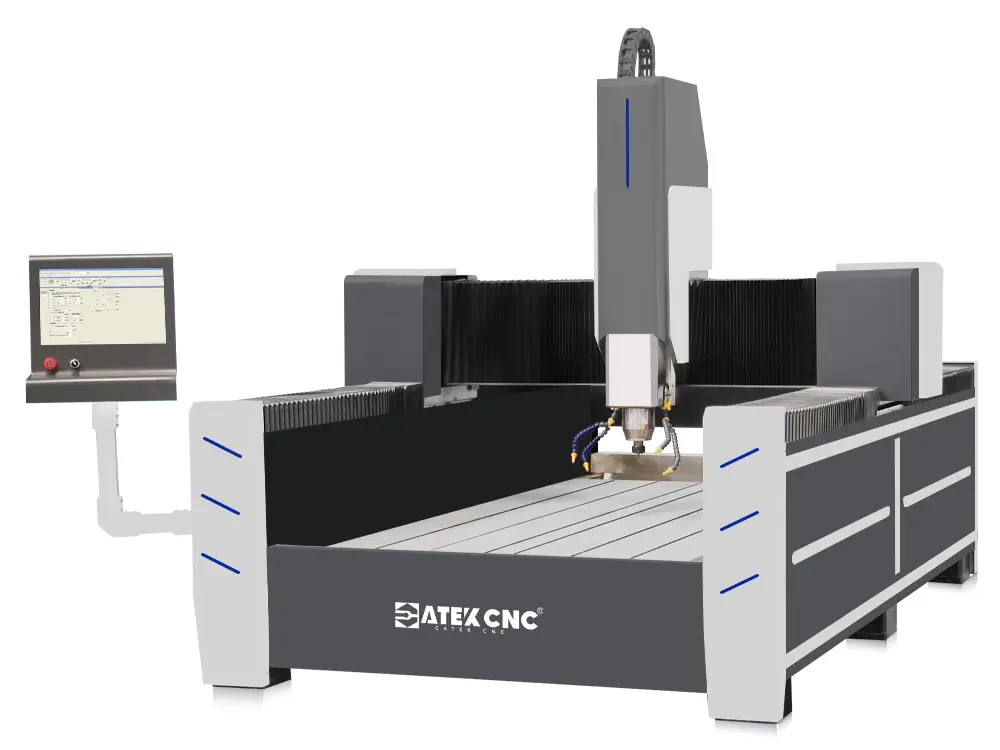

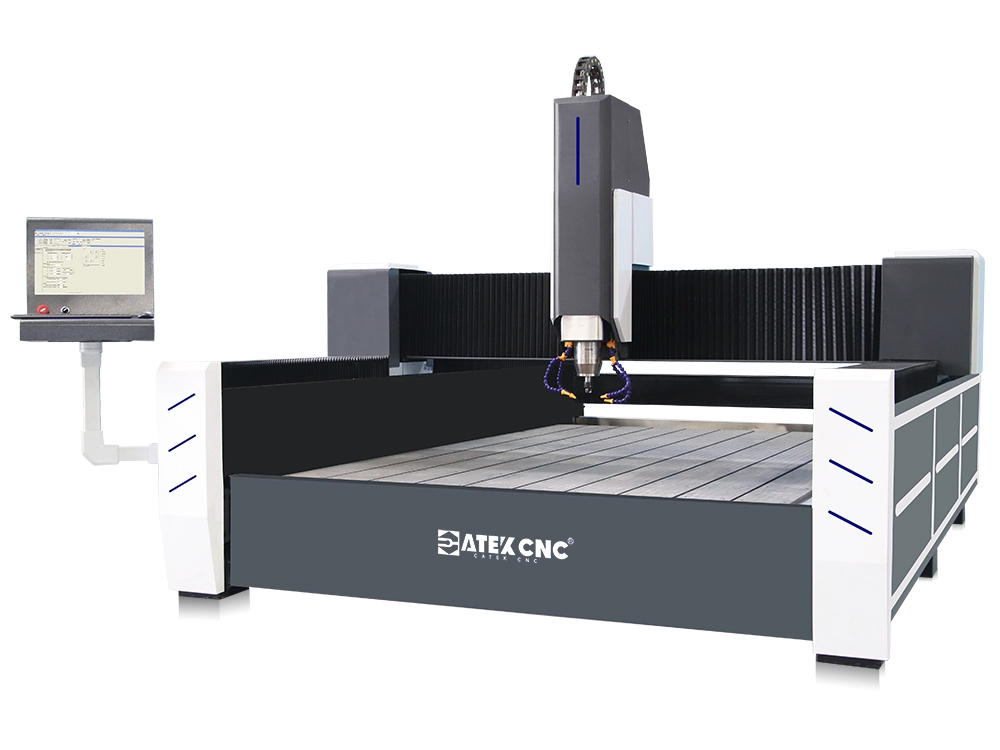

- Bridge structure

The five-axis stone cutting bridge machine adopts a bridge structure, which provides higher rigidity and stability to the machine, thereby ensuring processing accuracy. The bridge structure consists of a beam and guide rails, driven by high-power motors to enable the cutting head to move forward, backward, left, and right, while reducing the impact of load on the equipment.

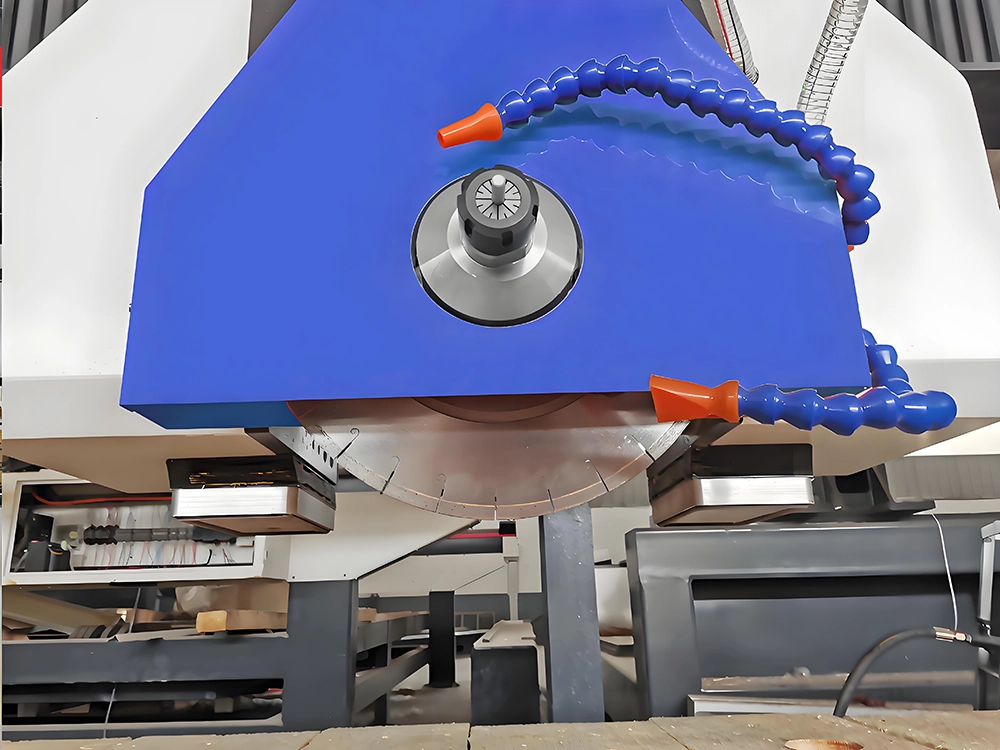

- Saw blade and cutting head

The cutting saw blade uses a diamond saw blade, which can efficiently cut various stone materials. The saw blade diameter ranges from 350-500mm, equipped with a 5.5KW high-speed water-cooled spindle that can hold various tools, suitable for materials such as marble, granite, and artificial stone.

- Space-saving

The five-axis bridge cutting saw has a compact structure and a small footprint, making it suitable for various processing environments.

- Comprehensive functions

It offers a wide range of functions, including automatic slab cutting, four-sided chamfering, chamfering on any edge, surface grooving (wire drawing), grid cutting, stove cutouts, basin holes cutting. and polygons, trapezoids, diamonds, sectors, outer circular edges, elliptical edges, horse belly edges, profile copying, round holes, elliptical holes, arc profile copying, drilling, edge grinding, and engraving.

Details of Five-Axis Bridge Saw for Cutting Stone

- The cutting head with and milling tools

Equipped with two rotating axes, this allows the machine to process stone from all angles and also allows the saw blade and milling tool to be switched by rotation.

- Vacuum suction cups

Vacuum suction cups can efficiently absorb and carry large stone slabs. The suction cups can achieve precise control to prevent the stone from falling off or being damaged.

- Workbench

The hydraulic workbench can be tilted left and right to facilitate the loading and unloading of panels. Its surface is covered with a padding made of multiple parallel wooden strips to prevent damage to the saw blade from contact with the workbench. The workbench is equipped with numerous rollers for easy dragging of panels on the surface. These universal wheels can be raised and lowered, extending beyond the padded surface when needed.

- Automatic tool setting probes and touch probes

The automatic tool setting device can detect the position of the tool tip, so that the system can make corresponding compensation, and can also monitor the wear of the tool. The touch probe can automatically measure the shape or thickness of the stone.

- CCD vision system

One-click photo taking and automatic layout make it more convenient to use.

- Beam

Large span cast beams provide high stability and rigidity.

- Control panel

Touch panel, easy and intuitive operation.

- Control software

The system is highly user-friendly, supports multiple languages, can directly recognize CAD, and does not require complex programs to design CNC paths. Free training is provided.

Technical Parameters of CNC Bridge Cutting Saw for Cutting Marble, Granite and Quartz Stone

| Model | CK-2032-S5 |

|---|---|

| XYZ Axis Travel | 3500-2450-300mm |

| C Axis Travel | ±361° |

| A Axis Travel | -1°-91° |

| Clampable Saw Blade Diameter | 350-500mm |

| Main Motor Power | 8.5KW |

| Main Motor Rated Speed | 3000rpm |

| Main Motor Maximum Speed | 6000rpm |

| XY Axis Maximum Moving Speed | 30000mm |

| Z Axis Maximum Moving Speed | 6000mm/min |

| Main Motor Torque | 58.9N·m |

| C Axis Rotation Speed | 17.3r/min |

| A Axis Rotation Speed | 20.66r/min |

| Number Of Suction Cups | 4 |

| Maximum Suction Weight | 360kg |

| Spindle Power | 5.5KW |

| Spindle Chuck | ER25 |

| Worktable Size | 3200*2000mm(3500*2100) |

| Dimensions | 5700*3400*3100mm |

| Weight | 4200kg |

What Products Can the Five-Axis CNC Stone Cutting Machine Be Used to Process?

It is primarily used for cutting special-shaped edges of building stones such as ceramic tiles, marble, artificial stone, granite, cement products, quartz stone, and sintered stone. It can process items including cabinet countertops, kitchen countertops, washbasin countertops, bathroom countertops, table tops, as well as be used for producing patterns, Roman columns, flower pots, and other products.

- Processable material

The machine can process various stone products such as marble, granite, ceramic foam , sintered stone, ceramic tile, artificial stone, etc.

- Process Examples

The machine can cut the plate at any angle and shape: transverse cutting, longitudinal cutting, arc cutting, elliptical cutting and circular cutting.

Maintenance Methods for Five-Axis CNC Stone Cutting Saw

- Lubrication and Hydraulic Oil Management

Regularly check the oil seal and oil level at the rack seat on both ends of the bed, ensuring the oil level remains moderate.

Lubricate the circular guide rail lifting system and oil pump, adding lubricating oil as needed, and perform lubrication each time the machine is used.

- Maintenance of the Tilting Work Platform

After each use of the tilting worktable, lubricate the tilting center shaft, tilting cylinder support, and the lubrication points of the worktable rotary gear transmission device.

When the work platform is not in operation, it should be raised to prevent rust from rendering it unusable.

- Saw Blade Replacement and Maintenance

Use diamond saw blades to ensure longevity. Ensure the saw blade is adequately cooled to avoid damage caused by overheating.

- Cleaning and Maintenance

Regularly clean the internal dust of the equipment to ensure a clean operating environment.

Clean the machine's work platform and motion axes after each use.

Periodically calibrate the infrared sensors and automatic measurement devices to maintain machine accuracy.

Packaging and Transportation of CNC Five-Axis Stone Cutting Saw

All standard machines from CATEKCNC are packaged in export-grade plywood crates that have undergone fumigation treatment. If the machine size is too large to fit into a container, we will communicate with you to disassemble the machine for packing or use PE stretch film for packaging and transportation.

| Model | CK-2032-S5 |

|---|---|

| XYZ Axis Travel | 3500-2450-300mm |

| C Axis Travel | ±361° |

| A Axis Travel | -1°-91° |

| Clampable Saw Blade Diameter | 350-500mm |

| Main Motor Power | 8.5KW |

| Main Motor Rated Speed | 3000rpm |

| Main Motor Maximum Speed | 6000rpm |

| XY Axis Maximum Moving Speed | 30000mm |

| Z Axis Maximum Moving Speed | 6000mm/min |

| Main Motor Torque | 58.9N·m |

| C Axis Rotation Speed | 17.3r/min |

| A Axis Rotation Speed | 20.66r/min |

| Number Of Suction Cups | 4 |

| Maximum Suction Weight | 360kg |

| Spindle Power | 5.5KW |

| Spindle Chuck | ER25 |

| Worktable Size | 3200*2000mm(3500*2100) |

| Dimensions | 5700*3400*3100mm |

| Weight | 4200kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.