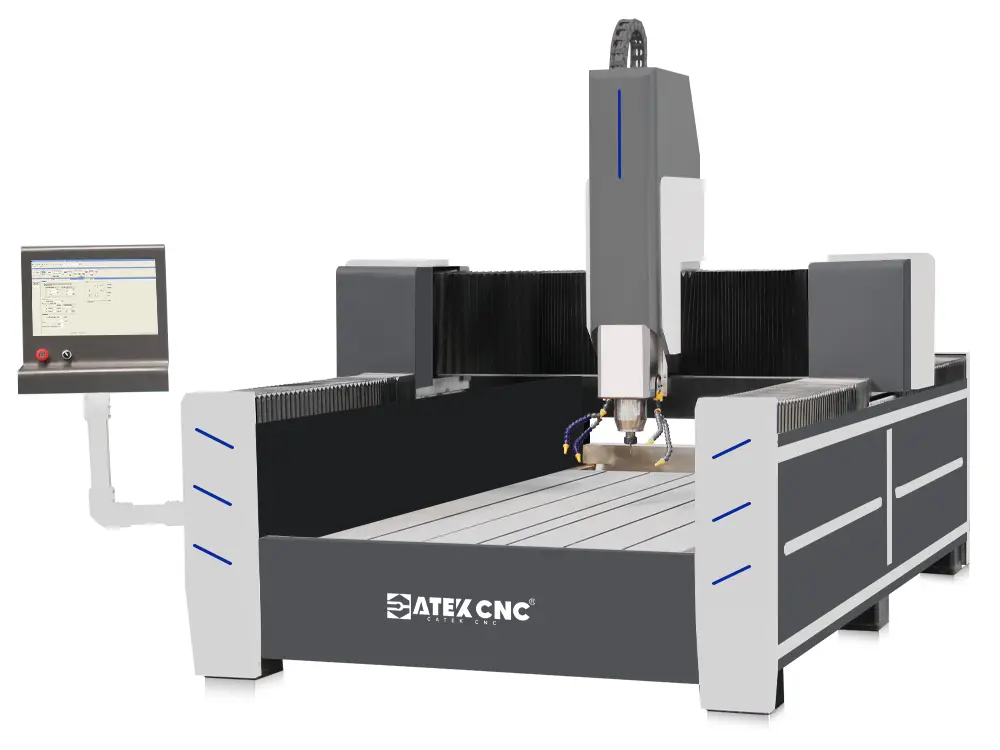

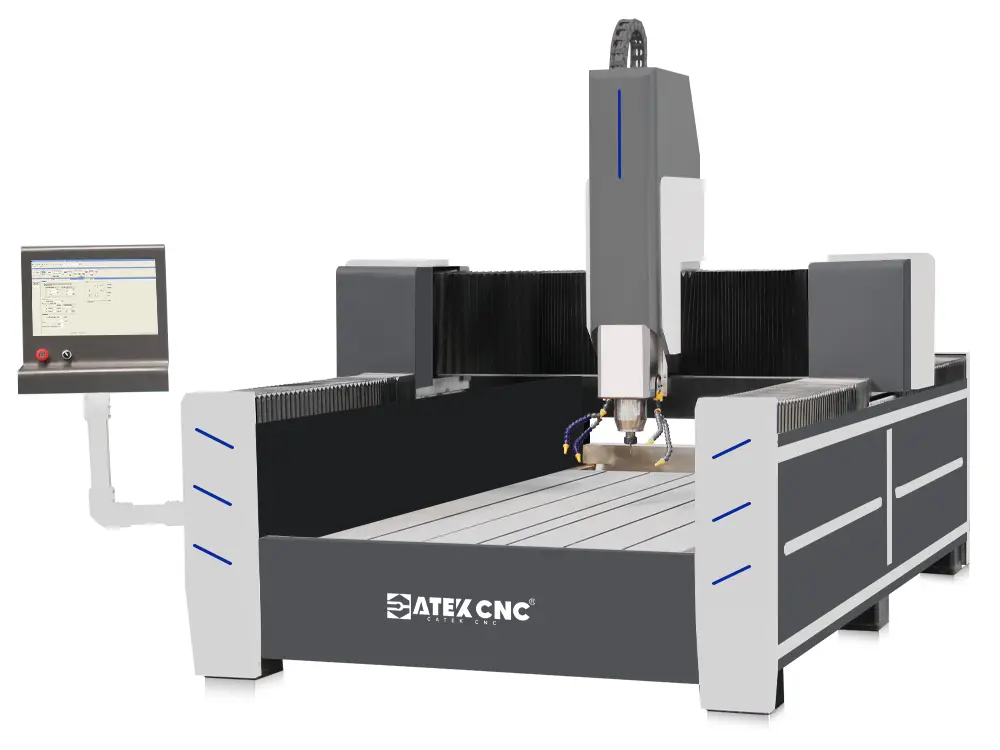

CNC Router Machines for Stone Processing on Sale

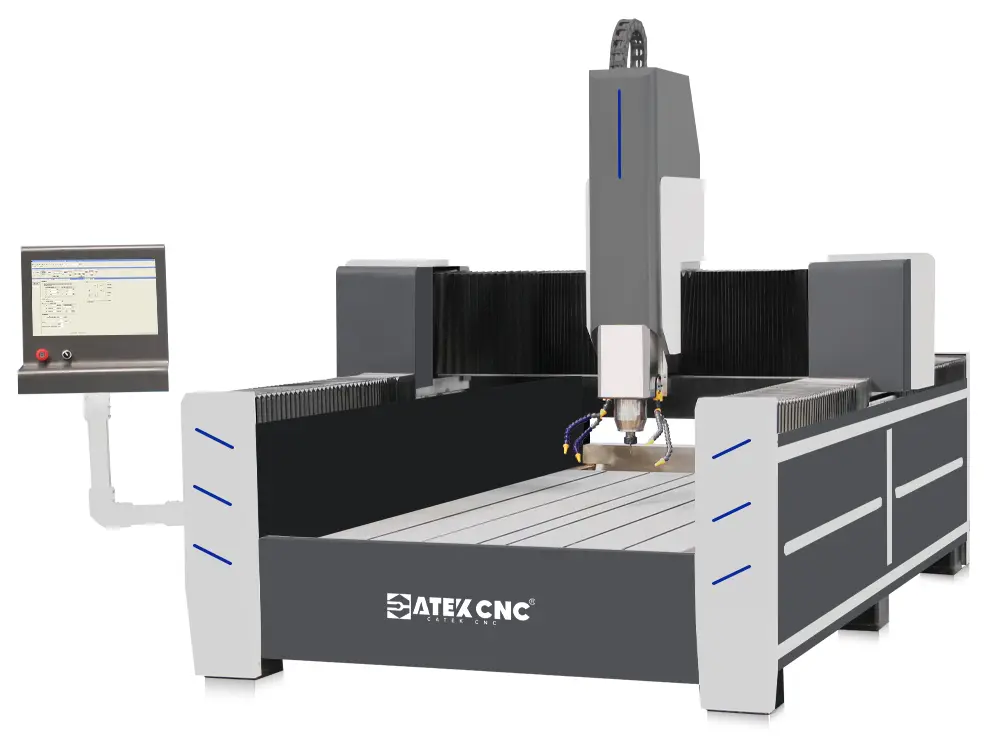

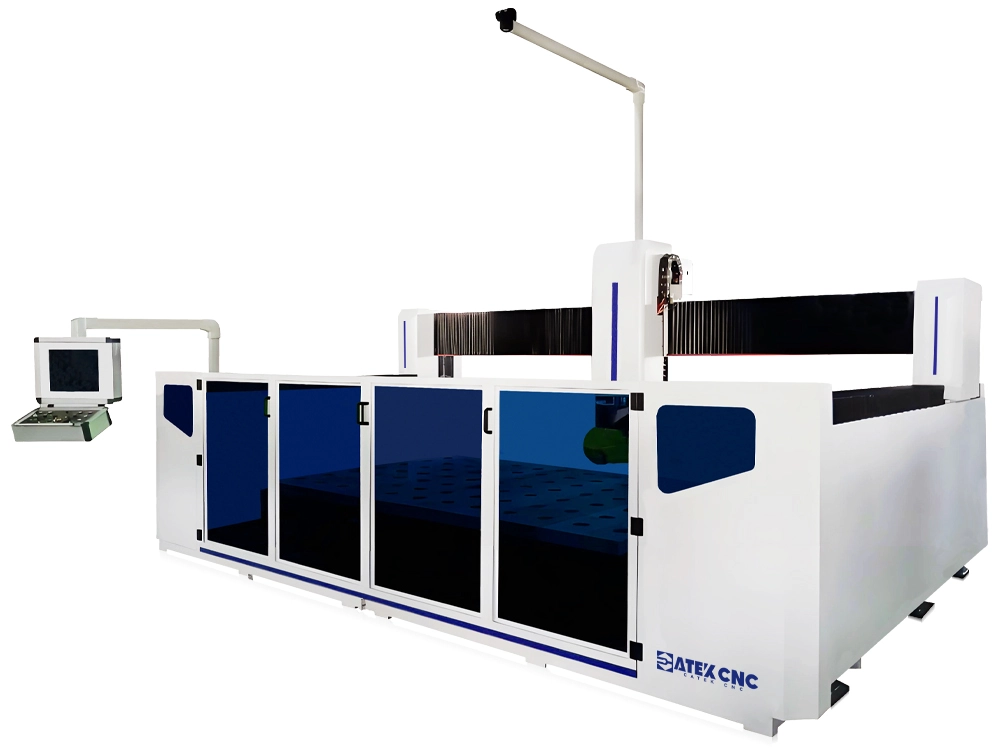

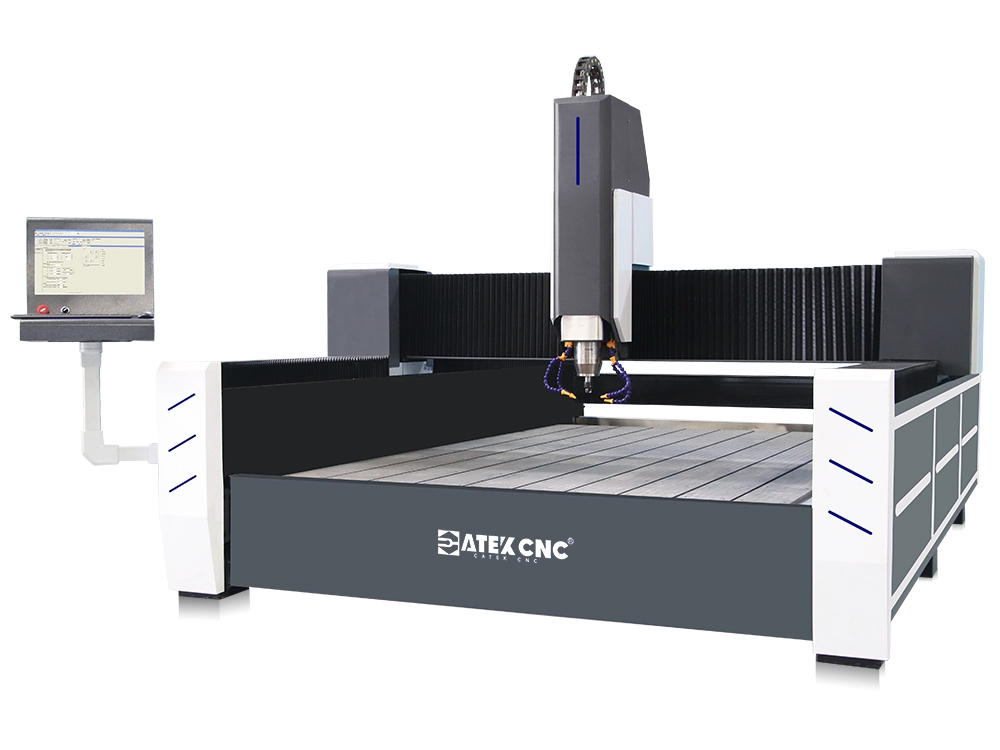

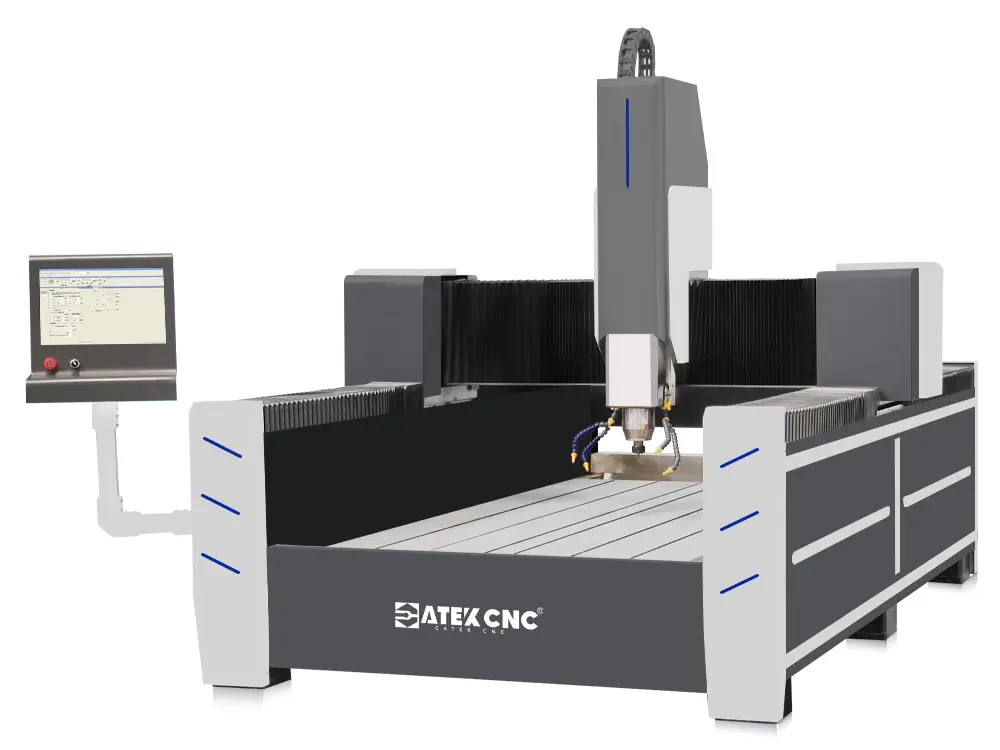

The Most Popular 4*8ft CNC Stone Router Machine

[Function Description]

The 1325 Heavy-Duty CNC Stone Router is a large-scale CNC machine specifically designed for stone processing, suitable for batch and high-precision stone production. With a processing size of 1300×2500mm (4×8 feet), this machine features a high-strength, heavy-duty sunk-style bed structure, and is equipped with a 7.5KW high-power high-speed water-cooled variable-frequency spindle, a high-precision transmission system, and a high-torque drive system. It efficiently and accurately performs 3D engraving, 2D carving, cutting, drilling, grooving, and chamfering on materials such as marble, granite, wood, plastic, aluminum, and copper. Thanks to its powerful processing capabilities, high precision, and stable performance, this CNC stone router is widely used in architectural decoration, tombstone production, and craftware processing.

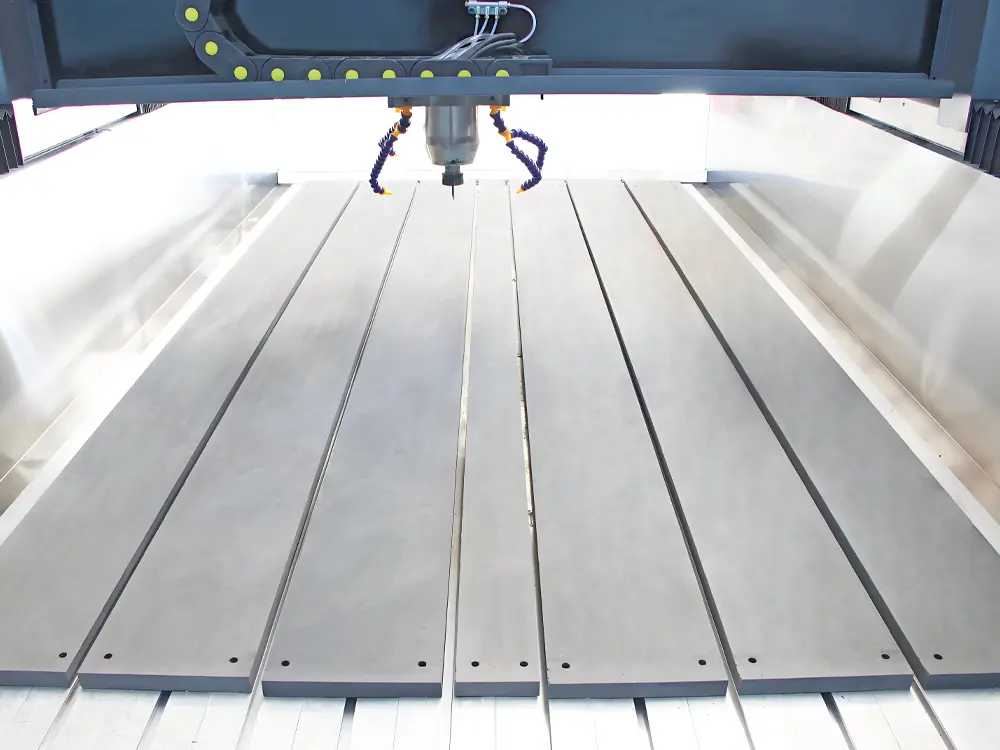

The CNC stone router is equipped with a dual cooling system—spindle water-cooling and flood-cooling—which automatically and efficiently cools both the tool and the spindle via a circulating water system during operation. The worktable is fitted with a stainless steel circulating water tank, seamlessly welded to the bed and equipped with anti-overflow edges to effectively prevent coolant from seeping into the machine interior. This design protects transmission components such as guides and racks from corrosion, thereby reducing the risk of failure. The tank features a large-capacity deep-basin design that holds significant amounts of coolant and stone slurry, minimizing splashing during processing and providing uniform cooling to the bottom of the stone to prevent cracking due to localized overheating. T-slots integrated into the water tank allow flexible clamping of stone materials of various sizes using pressing plates, preventing workpiece displacement caused by water flow or tool impact and ensuring stable processing. This cooling system not only cooling the tool and stone but also flushing away stone dust generated during machining. This reduces tool wear caused by chip accumulation, extends tool life, and improves surface finish quality.

The CNC stone router is reasonably priced and versatile, capable of meeting diverse engraving, cutting, drilling, and grooving needs for various metallic and non-metallic materials. With advantages such as high precision, high efficiency, excellent durability, and wide applicability, it effectively helps users reduce production costs while improving product quality and productivity.

Features of the Most Popular 4x8 Feet CNC Stone Router

1. Heavy-Duty Sunk Bed and Reinforced Gantry

- Bed: Constructed from thickened steel tubes integrally welded, then stress-relieved through high-temperature tempering and vibration aging. The robust structure increases rigidity by over 50% compared to standard CNC routers. Precision machining via a large gantry mill ensures high surface flatness, providing an accurate base for guides and screws, thereby enhancing positioning and repeatability. The sunk design lowers the center of gravity, effectively dampening vibrations during operation. The lower working height also facilitates easier loading/unloading of large stone slabs and improves machining stability.

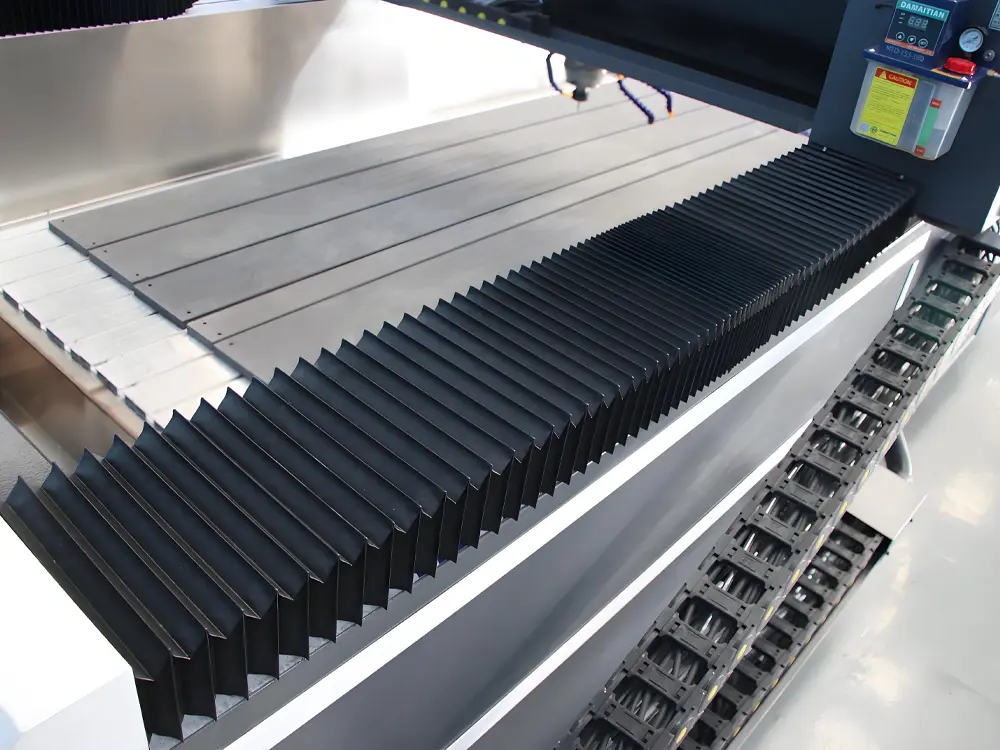

- Gantry: Fabricated from a single thick-walled rectangular steel tube, offering more than 60% greater rigidity than standard models to suppress high-frequency vibrations. The mounting surfaces for rails and racks are precision milled and ground, ensuring a flat base for X-axis linear guides and the rack. A fully enclosed bellows cover on the gantry protects these components from stone dust and coolant.

2. Stainless Steel Circulating Water Tank & Aluminum T-Slot Table

- Water Tank: Made from seamlessly welded stainless steel with a smooth, crevice-free surface that resists scale and dust buildup, simplifying cleaning. Integrated with a circulating pump, it provides continuous coolant flow to the tool and workpiece. The flood cooling system rapidly removes cutting heat, keeping tool temperatures safe and preventing annealing, which extends tool life. The circulating water also carries away stone slurry, preventing accumulation on the tool, workpiece, or table, thereby reducing dust and improving the working environment.

- T-Slot Table: Machined from high-strength aluminum and mounted inside the water tank, it features a thickened, hard PVC surface. The T-slots allow versatile horizontal, vertical, and angled clamping of workpieces in various sizes and shapes, significantly reducing setup time and boosting efficiency.

3. High-Precision Drive System

- Linear Guideway: Utilize HIWIN 30mm square linear guides from Taiwan with double-row, four-column ball sliders. Each slider supports over 420kN, meeting the high-impact, heavy-load demands of stone routing. The integrally machined mounting surfaces ensure minimal perpendicularity error for synchronized guidance and drive accuracy.

- Ball Screw: The Z-axis employs a TBI high-precision ball screw, known for excellent wear and impact resistance, ensuring smooth motion even at low speeds. It is equipped with a fully enclosed cover metal protective cover to effectively prevent stone powder and coolant corrosion, extending its service life.

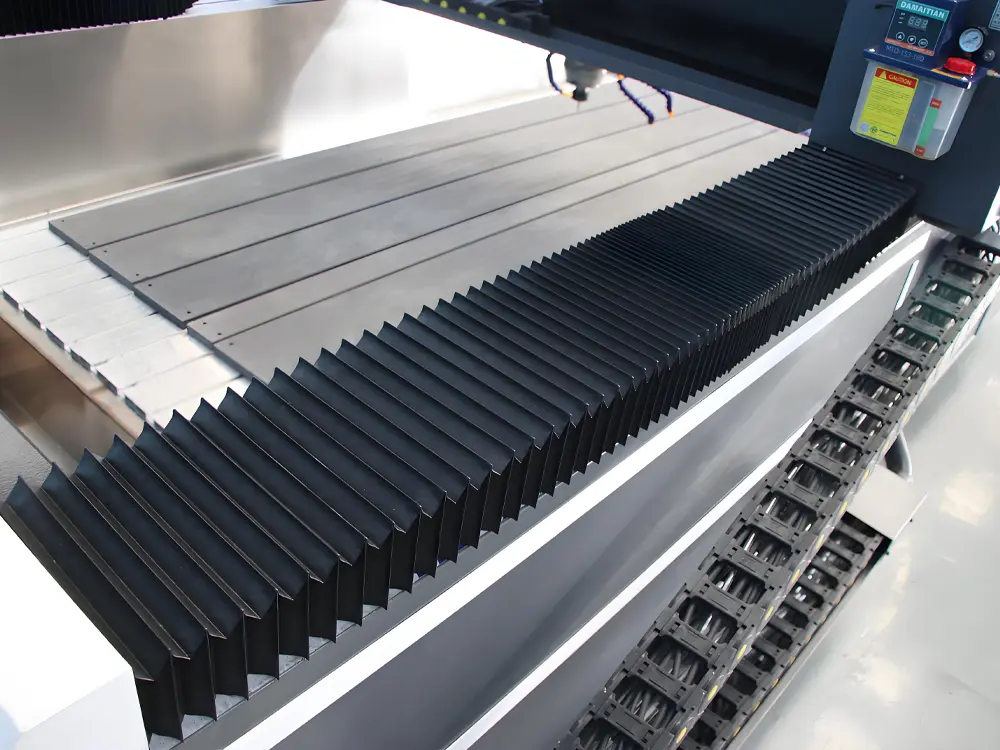

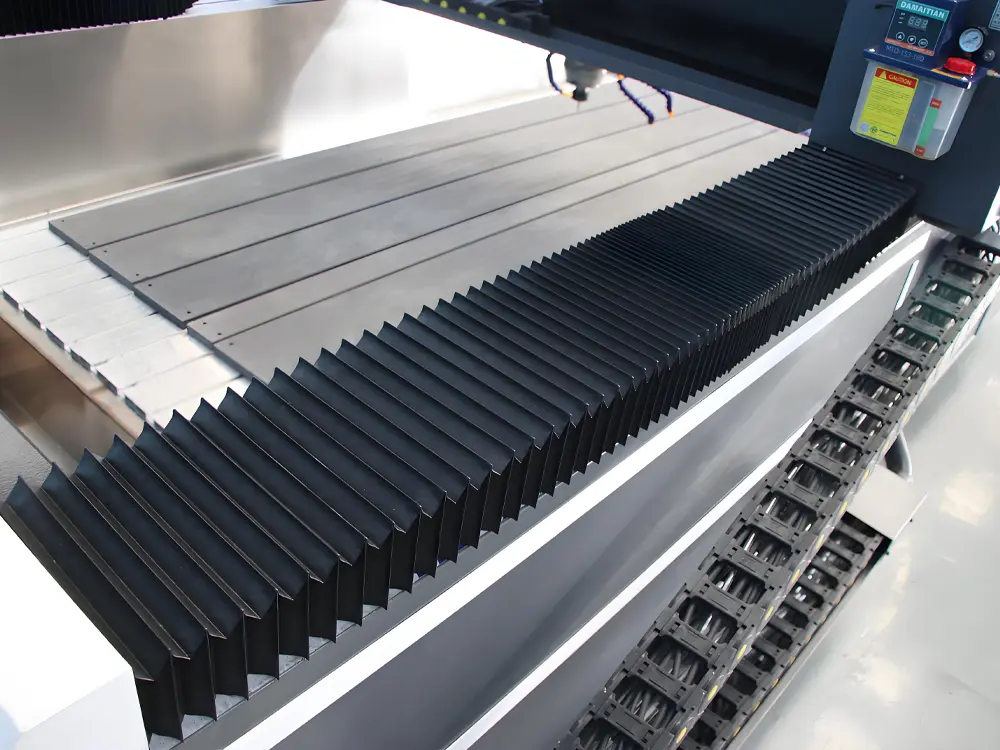

- Rack: Abrasive-grade high-strength helical racks are selected, undergoing integral quenching and tempering as well as induction hardening for the tooth surfaces. Boasting high tooth surface hardness, combined rigidity and toughness, they effectively resist impacts during stone processing. Both X-axis and Y-axis racks are equipped with fully enclosed accordion bellows, which isolate coolant erosion and extend service life.

4. High-Torque Servo Drive System

- Servo Motors: Four 1300W Yaskawa servo motors drive the XYZ axes. The servo system dynamically corrects errors by monitoring speed and position in real-time, ensuring motion path accuracy—ideal for detailed work like small text and relief carving. The Y-axis uses dual motors and intelligent synchronization for symmetrical drive, eliminating load imbalance and accuracy loss common in single-drive systems. This enhances stability, increases load capacity by over 50%, and improves machining accuracy and machine longevity.

- Reducers: Planetary gear reducers on the X and Y axes increase servo motor output torque while improving transmission accuracy and stability. They enhance the machine's resistance to wear and shock from sudden cutting forces.

5. High-Speed Water-Cooled Spindle & Constant-Temperature Chiller

- Spindle: Features a 7.5kW high-speed water-cooled variable-frequency spindle designed for stone, delivering ample torque even at lower speeds. Its dual cooling circuits maintain temperature below 40°C, preventing heat damage. Dual seals provide excellent protection against dust, debris, and coolant ingress.

- Chiller: An S&A constant-temperature recirculating chiller maintains coolant temperature within ±1°C. Customizable temperature settings adapt to different materials and cutting intensities. A water level sensor triggers low-water alarms. Stable cooling prevents spindle thermal growth, ensuring consistent machining accuracy.

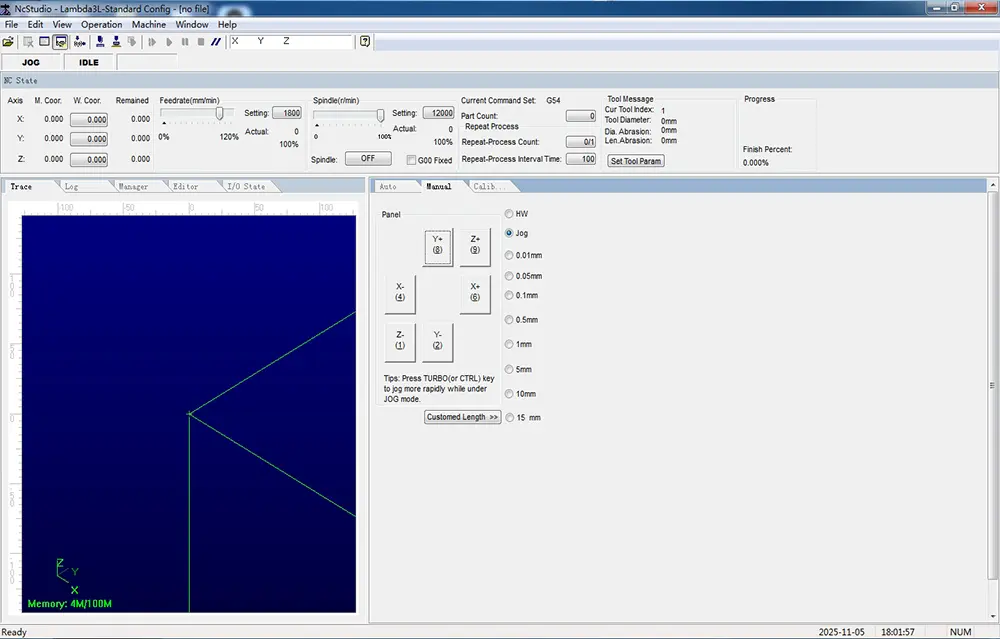

6. High-Precision Control System

Equipped with a Weihong NCStudio 3-axis control system, designed for user-friendly operation, it features an intuitive interface, easy operation, and supports switching between Chinese and English. It is compatible with various CAD/CAM software and includes advanced features like power-off resume, breakpoint processing, and toolpath simulation. Capable of 3D carving with a depth control accuracy of ±0.01mm, it meets the high standards for precision, efficiency, and stability in stone processing.

Details of the Most Popular 4x8 Feet CNC Stone Router

- 7.5KW high-speed water-cooled spindle

Equipped with a 7.5kW high-speed water-cooled variable-frequency spindle specifically designed for stone processing. It reaches a maximum speed of 24,000 RPM, delivers stable torque output, and offers strong impact resistance. Maintains constant torque even when engraving hard materials like stone, ensuring stable and reliable processing quality.

- Aluminum T-slot table

Utilizes a high-strength aluminum T-slot table with a surface covered by thickened hard PVC panels. Used in combination with clamping plates, it allows flexible and secure fixing of workpieces of various materials and sizes, making operation simple and efficient.

- Yaskawa servo drive system

Incorporates four 1300W Yaskawa servo motors. The Y-axis utilizes a dual-motor symmetrical synchronous drive configuration, offering high load-bearing capacity, fast response, and precise positioning to ensure efficient and stable processing.

- Transmission system

Employs HIWIN 30mm linear guideways and linear bearings, paired with precision-ground helical racks, enabling high-speed smooth operation and accurate positioning.

- Fully enclosed spindle sheet metal cover

The Z-axis is outfitted with a fully enclosed sheet metal cover, providing comprehensive protection for the spindle against coolant and processing waste, ensuring reliable operation of the transmission system.

- Fully enclosed bellows cover

Both the X and Y axes are equipped with fully enclosed bellows covers, effectively preventing chips, stone dust, and coolant from entering the transmission system, significantly extending the machine's service life.

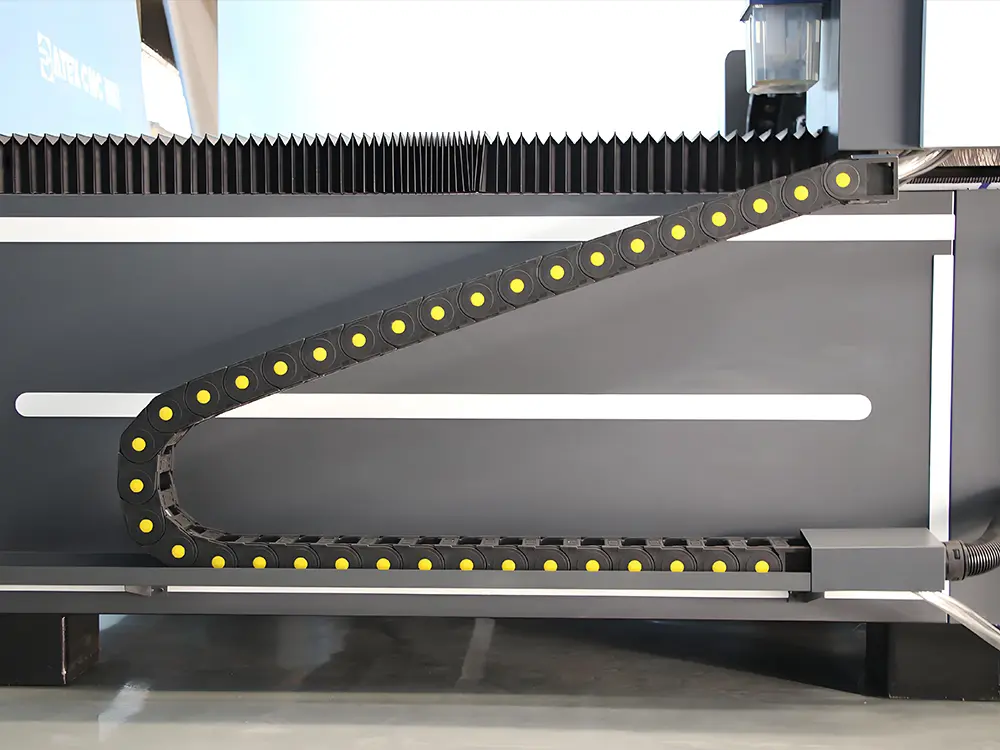

- Reinforced cable carrier

All connecting cables are integrated within a reinforced protective cable carrier, effectively preventing cable damage and ensuring neat and safe wiring layout.

- Automatic lubrication system

Includes a fully automatic electric oil lubricator that allows customizable lubrication timing and frequency, streamlining equipment maintenance and making upkeep more convenient.

- Weihong NCStudio control system

Features a Weihong NCStudio 3-axis CNC system with an intuitive interface and user-friendly operation, enabling quick mastery even for complete beginners. Supports NC, TAP, and TXT file formats, provides precise machining accuracy control, and ensures a smooth user experience.

Technical Parameters of the Most Popular 4x8 Feet CNC Stone Router

| Model | CK-1325-S |

|---|---|

| Working Area (XYZ) | 1300*2500*400mm (Customizable processing size available) |

| Bed | 8mm thick steel tube welded heavy-duty bed |

| Cooling Method | S&A circulating water chiller + flood cooling |

| Work Table | Aluminum T-slot table |

| Water Tank | Stainless steel circulating water tank |

| Spindle | 7.5KW high-speed water-cooled variable-frequency spindle (Stone specialized) |

| Spindle Speed | 0–24,000 RPM |

| Inverter | Fuling 7.5KW high-torque inverter |

| Guideways | 30mm HIWIN linear guideways / linear bearings |

| Rack | Taiwan YYC 1.5M rack |

| Z-Axis Ball Screw | Taiwan TBI 2510 ball screw |

| Servo Motor | Yaskawa 1300W servo motor / servo drive (Other brands or stepper motors are available) |

| Reducer | Shimpo planetary gear reducer |

| Control Cabinet | Independent anti-interference control cabinet |

| Control System | Weihong multi-function CNC system |

| Voltage | 380V / 3-Phase or 220V / 3-Phase |

| Max. Rapid Traverse Speed | 60,000 mm/min |

| Max. Working Speed | 18,000 mm/min |

| Dimensions | 3200*2200*1950mm |

| Weight | 2100kg |

Application of the Most Popular 4x8 Feet CNC Stone Router

Applicable Materials:

Stone: Granite, basalt, bluestone, marble, sandstone, jade, artificial granite, crystal, ceramic tiles, fire bricks, and various other types of stone.

Metals: Aluminum, copper, silver, red copper, brass, aluminum alloys, zinc alloys, and other soft metals.

Wood & Panels: Solid wood, MDF, OSB, bamboo plywood, multi-layer board, composite panels, aluminum-plastic panels, aluminum honeycomb panels, and other sheet materials.

Other Materials: PVC, acrylic, carbon fiber, composite materials, resin, rubber, and various non-metallic materials.

Applicable Industries & Products:

Architectural Decoration: Stone curtain walls, Roman column cladding decorations, complex European-style stone carving patterns, feature walls, entrance screens, fireplace mantels, door and window moldings, skirting boards, stone tables and stools, stone archways, tombstones, longevity materials, monuments, jade ornaments, etc.

Decorative & Signage Items: Company logo plates, product labels, door plates, medals, commemorative plaques, aluminum alloy engraving, copper decorative strips, metal curtain wall decorations, metal screens, copper plate paintings, aluminum molds, epoxy molds, etc.

Wood Products: Carved wooden doors, cabinet door panels, screens, antique furniture decorations, wooden carved ornaments, wooden plaques, musical instrument parts, wooden reliefs, 3D wave boards, decorative lines, architectural models, artistic models, etc.

Plastic Products: Acrylic signs, light box panels, 3D letters, display racks, acrylic furniture, plastic molds, electronic product housings, lighting accessories, etc.

| Model | CK-1325-S |

|---|---|

| Working Area (XYZ) | 1300*2500*400mm (Customizable processing size available) |

| Bed | 8mm thick steel tube welded heavy-duty bed |

| Cooling Method | S&A circulating water chiller + flood cooling |

| Work Table | Aluminum T-slot table |

| Water Tank | Stainless steel circulating water tank |

| Spindle | 7.5KW high-speed water-cooled variable-frequency spindle (Stone specialized) |

| Spindle Speed | 0–24,000 RPM |

| Inverter | Fuling 7.5KW high-torque inverter |

| Guideways | 30mm HIWIN linear guideways / linear bearings |

| Rack | Taiwan YYC 1.5M rack |

| Z-Axis Ball Screw | Taiwan TBI 2510 ball screw |

| Servo Motor | Yaskawa 1300W servo motor / servo drive (Other brands or stepper motors are available) |

| Reducer | Shimpo planetary gear reducer |

| Control Cabinet | Independent anti-interference control cabinet |

| Control System | Weihong multi-function CNC system |

| Voltage | 380V / 3-Phase or 220V / 3-Phase |

| Max. Rapid Traverse Speed | 60,000 mm/min |

| Max. Working Speed | 18,000 mm/min |

| Dimensions | 3200*2200*1950mm |

| Weight | 2100kg |

YOU MAY ALSO LIKE

REVIEWS

Let more people know what you share.